Cooling equipment for tool with high heat intensity

A high-strength and tool technology, applied in lighting and heating equipment, household heating, heating methods, etc., can solve the problems of inability to increase the wind power of the airflow meter, no setting, and inability to protect the internal components of the airflow meter, so as to avoid malfunctions. Inhalation of dust, safe and convenient use, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

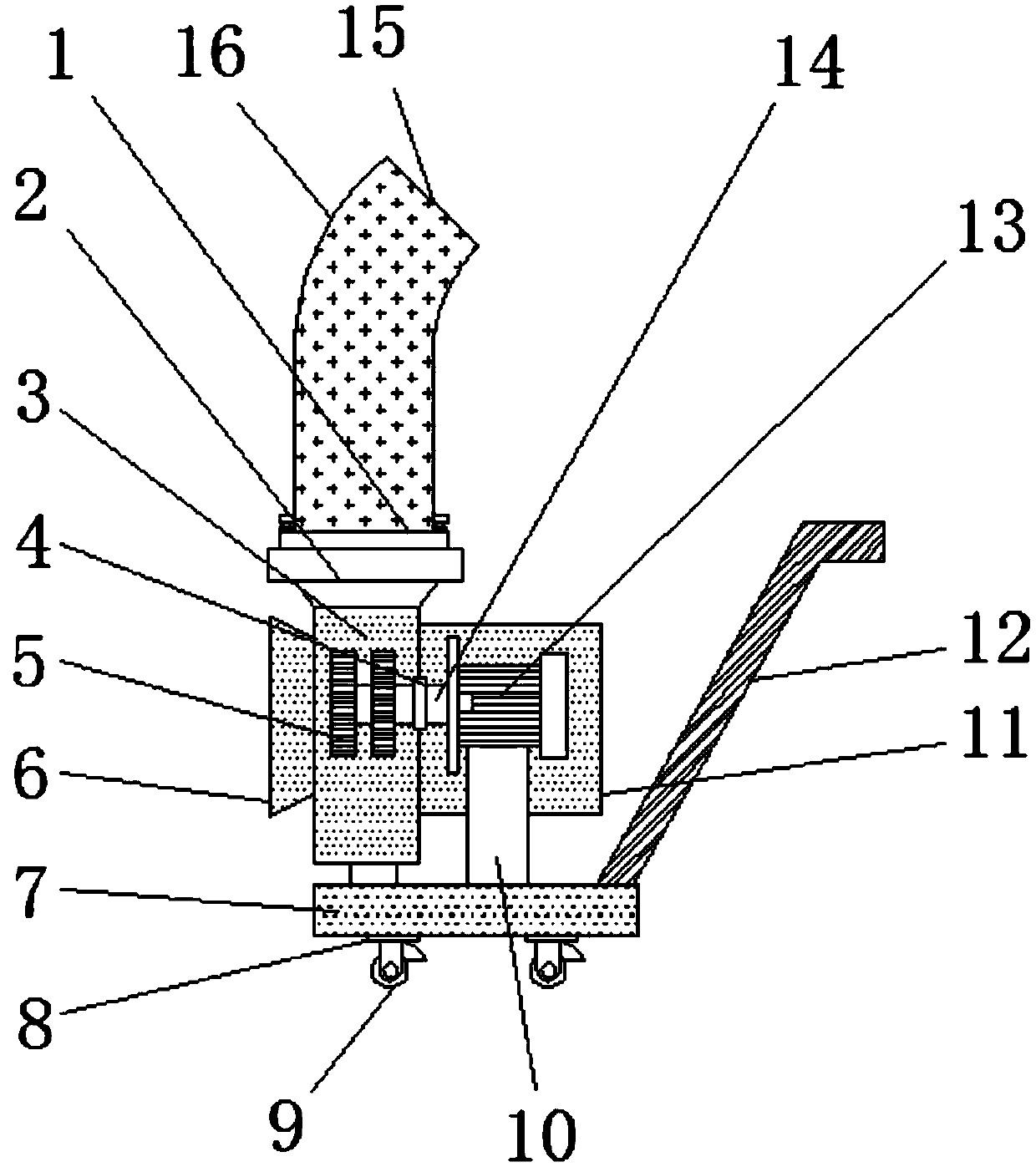

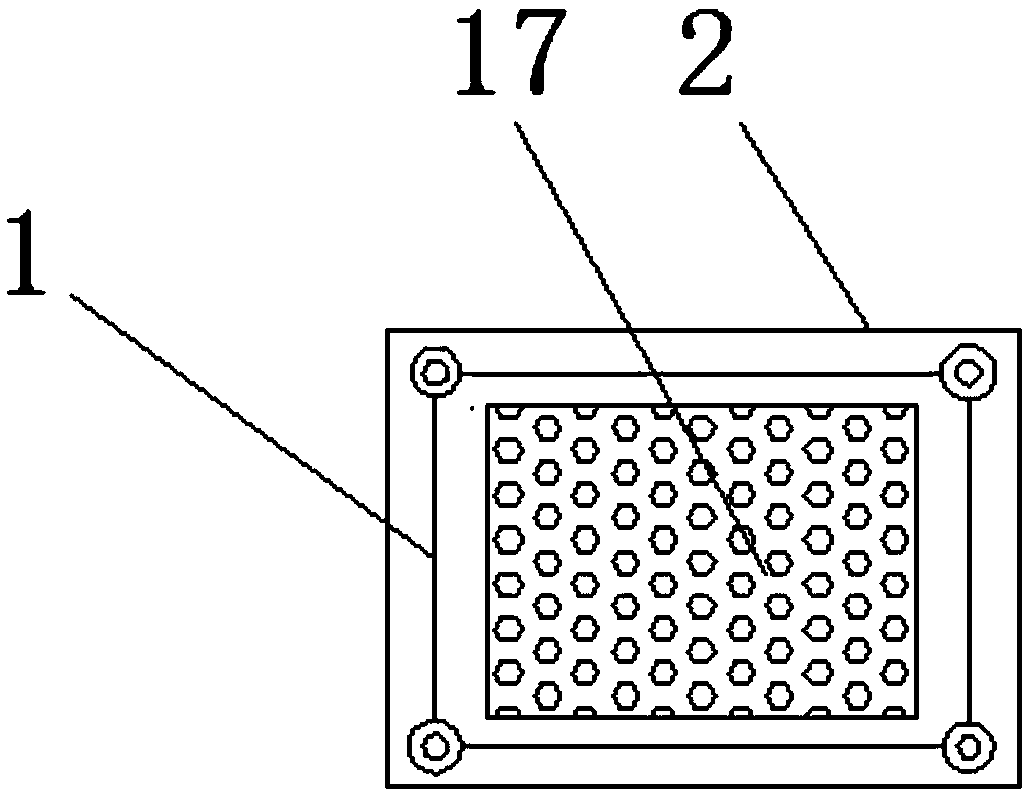

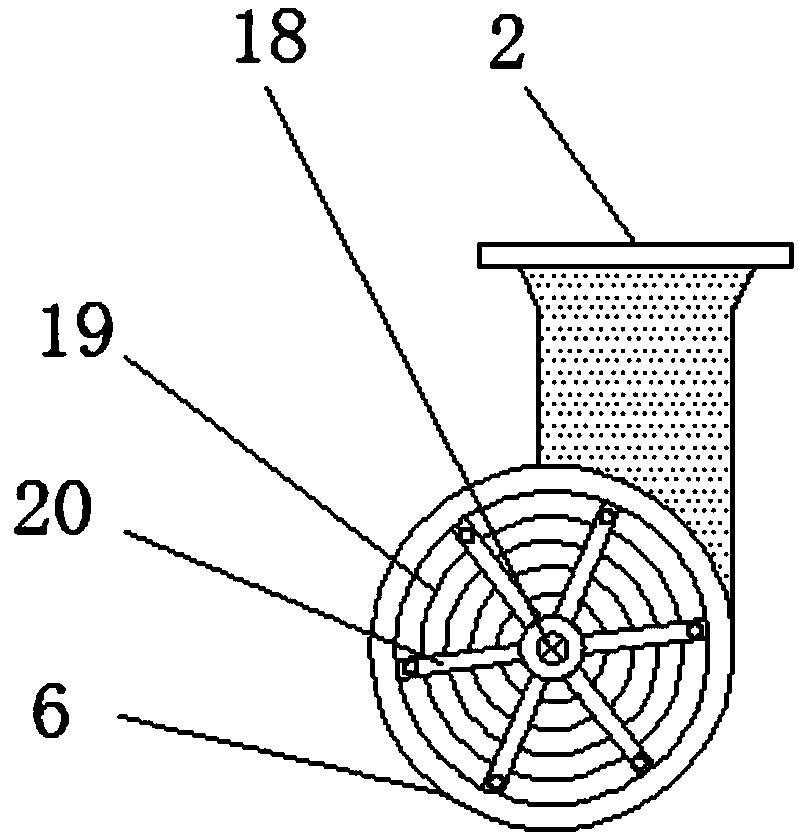

[0020] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a cooling device for a tool with high thermal intensity, including a thin metal plate 1, a primary output terminal 2, an air flow meter 3, a rotary rod 4, a sheet rolling machine 5, an inlet 6, Base 7, Firm Base 8, Ring Omnidirectional Fixer 9, Contact Rod 10, Anti-Travel Film 11, Drive Shaft 12, Energy Consumption Motor 13, Metal Ring Slider 14, Secondary Output 15, Soft Plastic Channel 16, small hole 17, metal crown rotating object 18, thin metal wire braided spacer 19 and firm bar 20, the upper end of base 7 is provided with contact bar 10, and the lower end of base...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap