Pad for steam cleaner

A technology of cleaners and pads, which is applied in cleaning equipment, cleaning devices, cleaning machinery, etc., and can solve problems such as hard pushing and pulling, strong adsorption force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

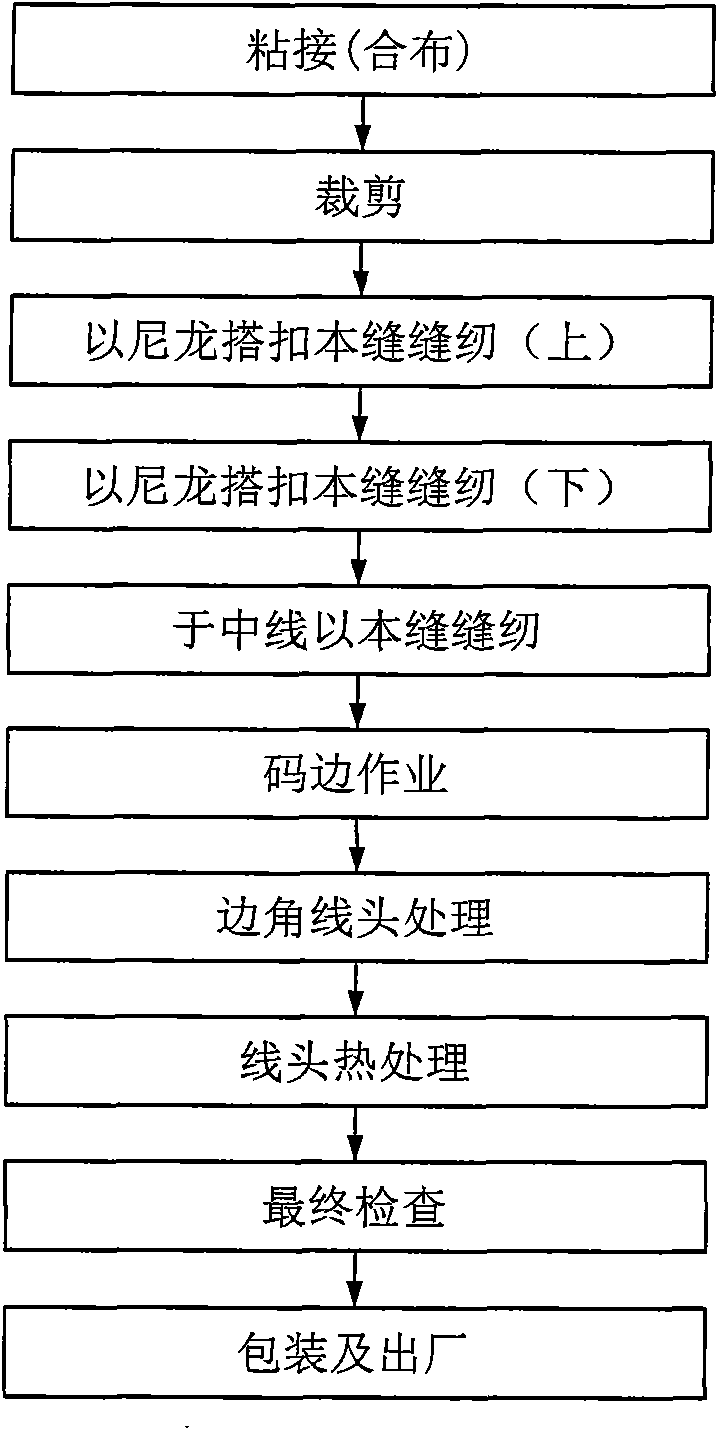

[0016] Embodiments of the present invention are described below with reference to the attached drawings.

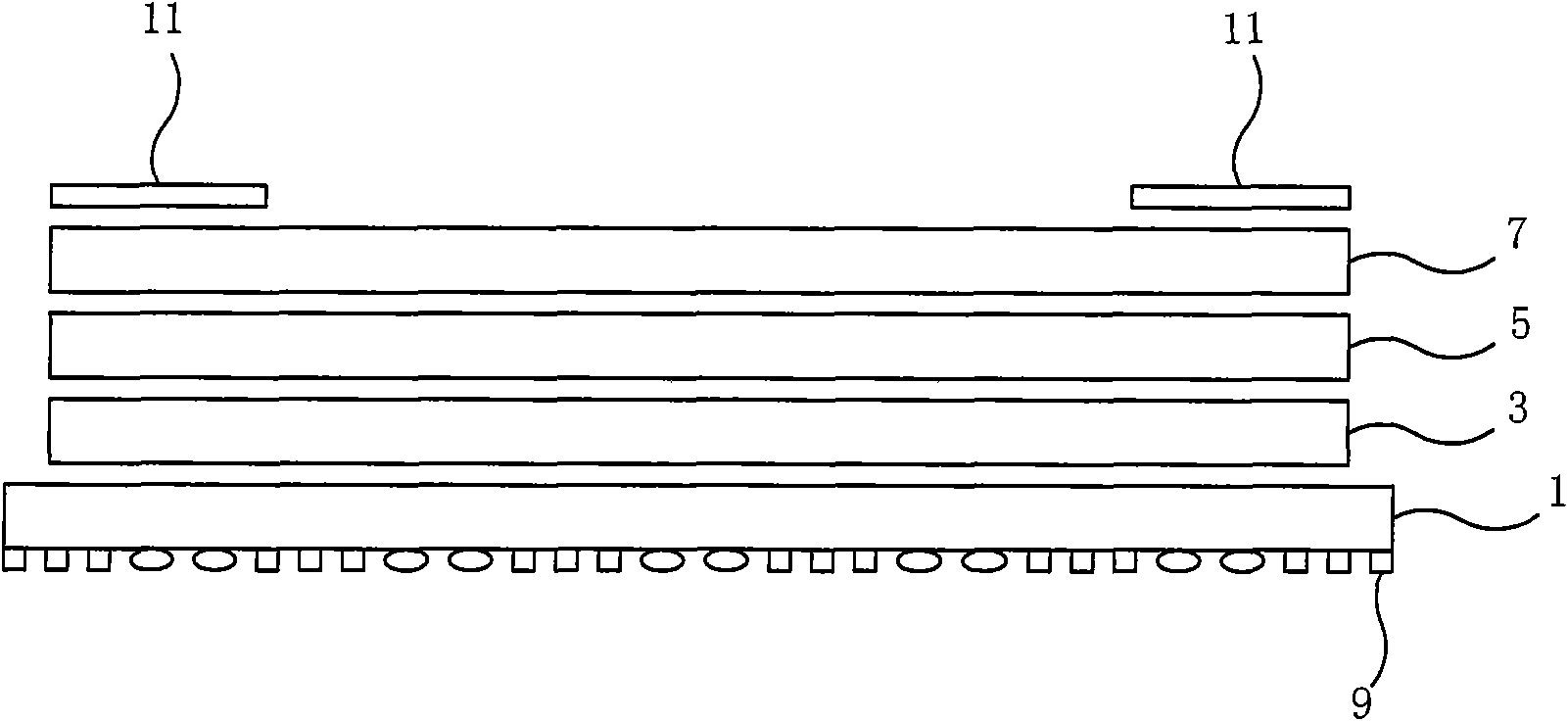

[0017] figure 1 Generally shown is an isolated cross-sectional view of a steam cleaner pad in accordance with an embodiment of the present invention.

[0018] Such as figure 1 As shown, the steam cleaner pad in this embodiment is mainly composed of a four-layer structure of an ultrafine filament layer 1 , a non-woven fabric layer 3 , a pile layer 5 and an ultrafine filament layer 7 .

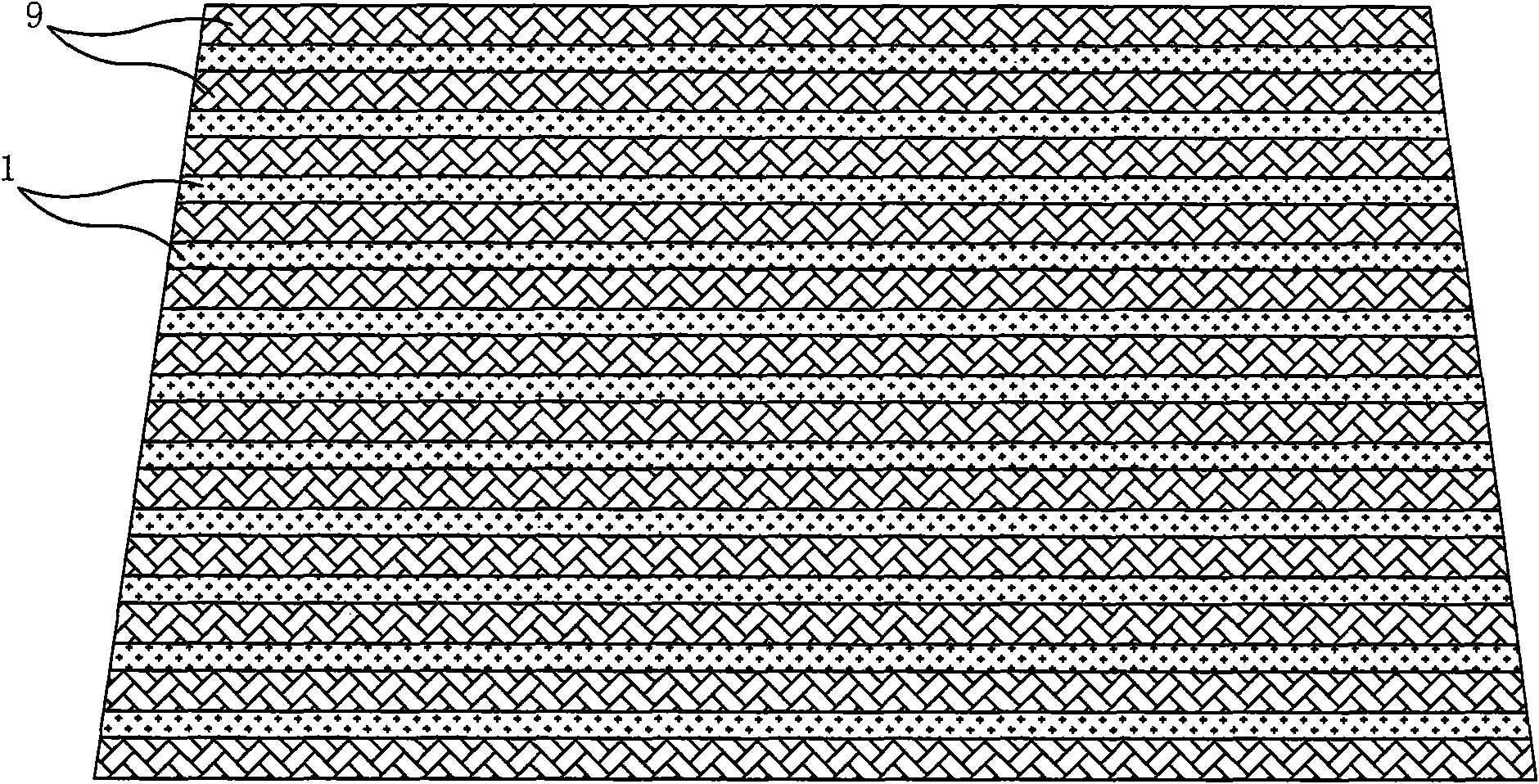

[0019] and, if figure 2 As shown, the bottom surface (i.e. the outermost layer) of the ultra-fine silk layer 1 is sewn with polypropylene (PP) silk 9 which can improve the push-pull effect.

[0020] That is, the cloth bottom surface of the ultrafine filament layer 1 is sewn with polypropylene filaments 9 at intervals. This structure is a combined structure of wiping performance and easy push-pull performance, which can relatively reduce the surface area occupied by the ultrafine filamen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com