Selectable-seeding-rate double-row side-charging precision rice dibbling feed

A double-row side-filling and seed metering technology, which is applied in the fields of seeder parts, agricultural gas emission reduction, climate sustainability, etc., can solve the problem of increasing the mechanical damage of rice seeds, inconvenient adjustment, and affecting the seeding of the seed meter Cavitation effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

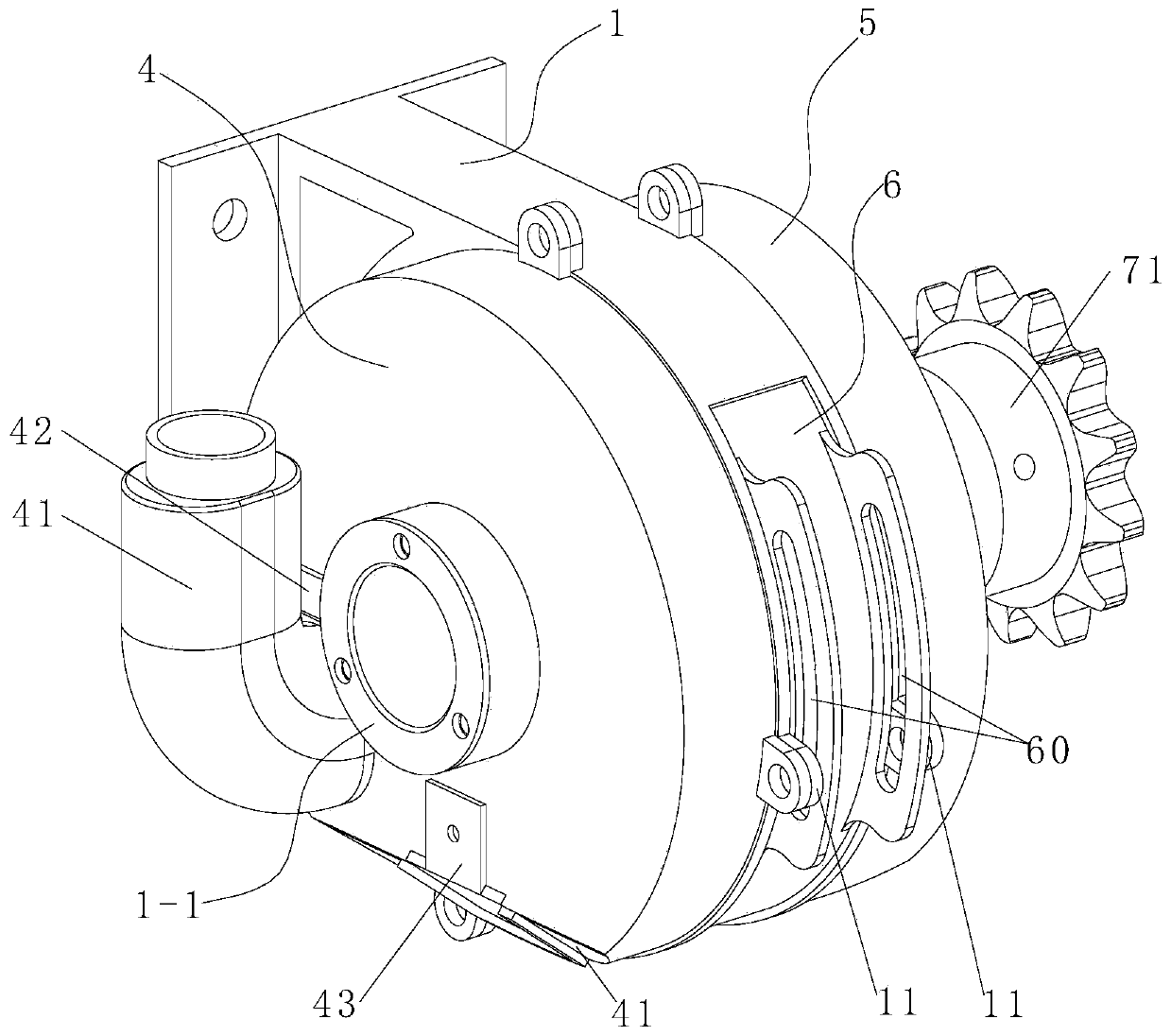

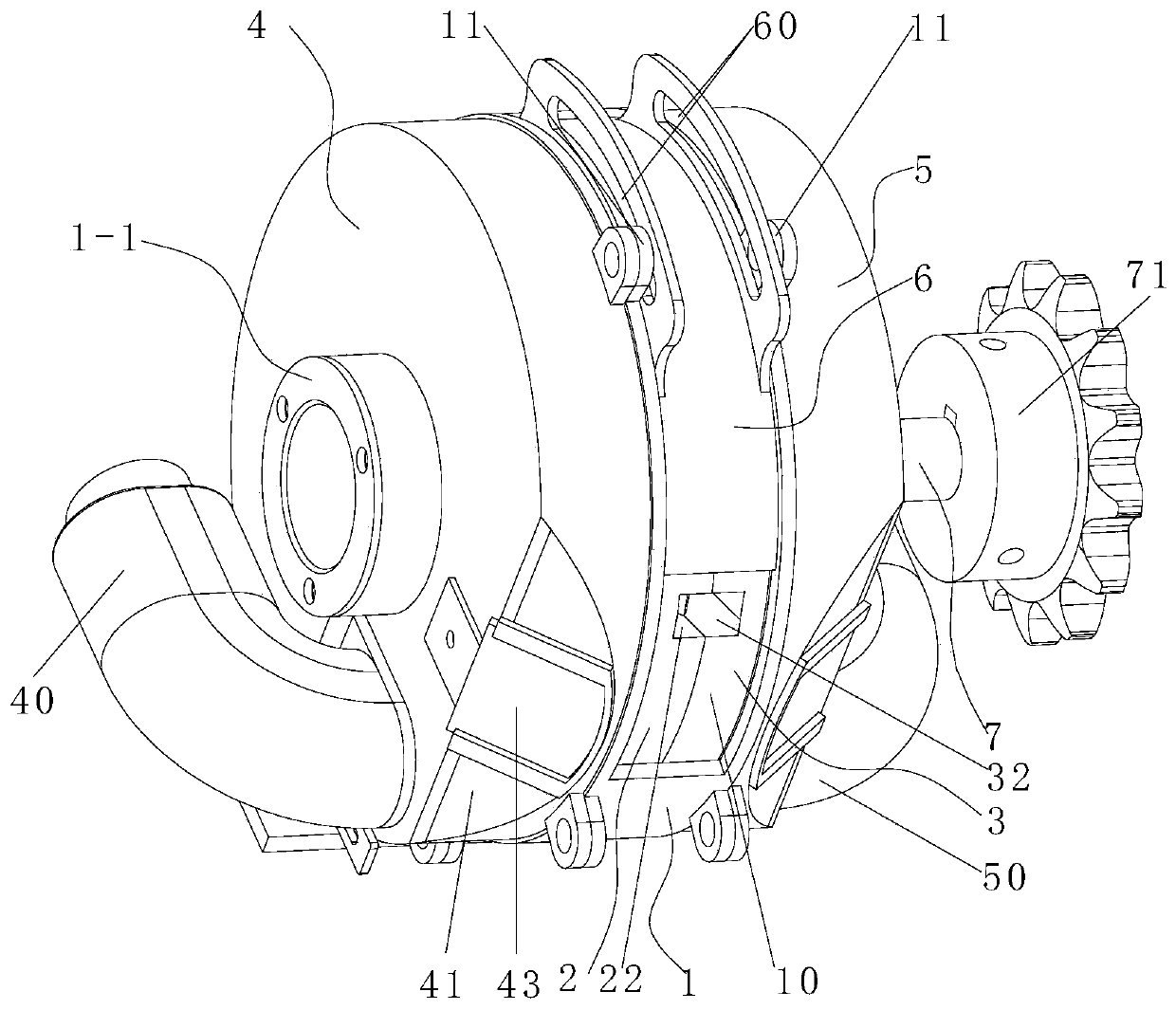

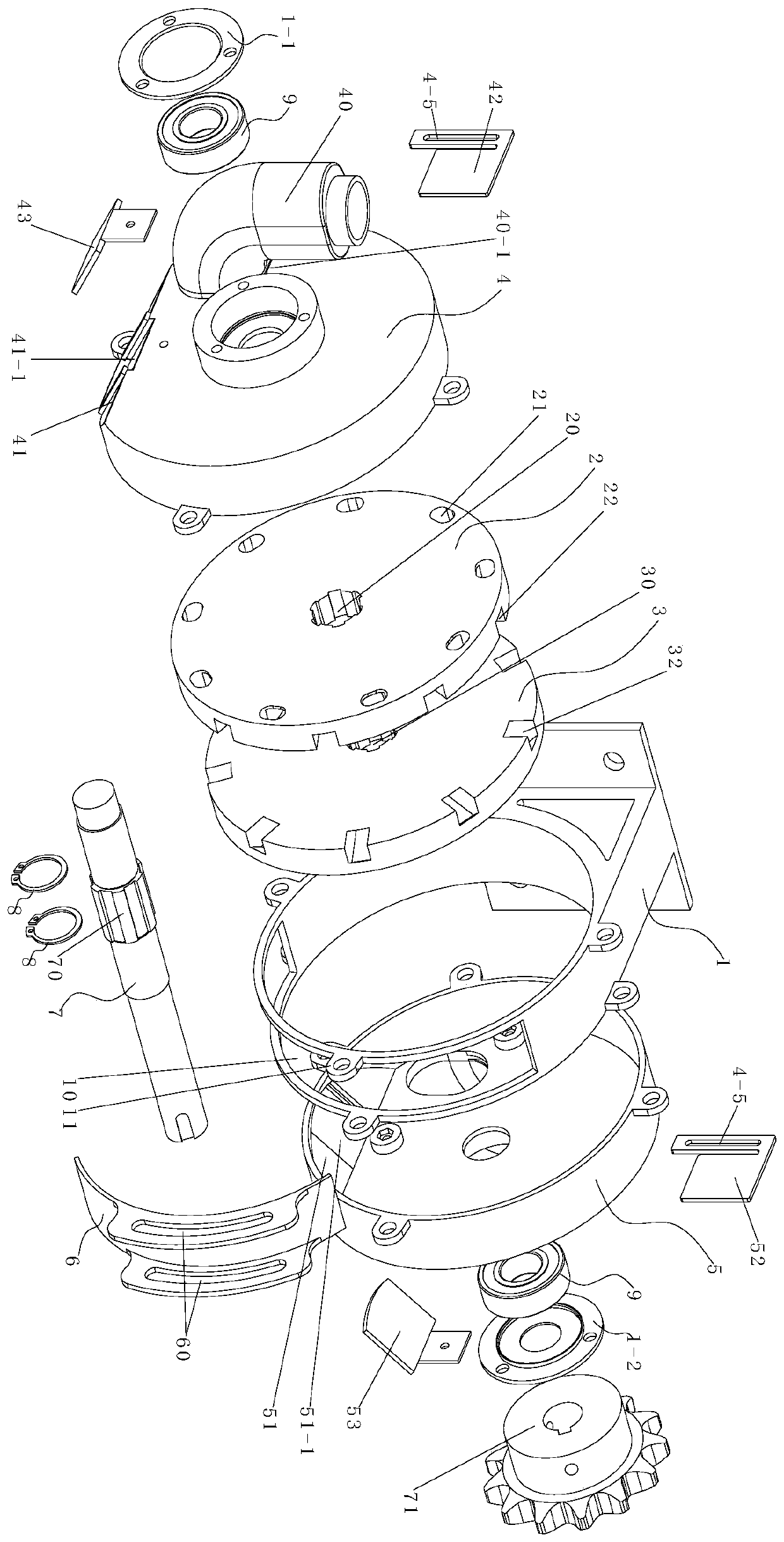

[0062] The present invention adopts the seeding method in which the first seeding disc 2 and the second seeding disc 3 are combined, the first seeding disc 2 and the second seeding disc 3 are respectively connected with the external spline 70, and are axially clamped by the outer card 8 Position limit, the first seed filling chamber cover 4 is tightly connected to one side of the seat shell 1, and the second seed filling chamber cover 5 is tightly connected to the other side of the seat shell 1;

[0063] One end face edge of the first seed row 2 presents a circumference and is evenly provided with a plurality of type holes 21, and the other end face edge of the first seed row 2 presents a circumference and is evenly provided with a plurality of seed outlets 1 22, and the first seed row 2 A plurality of U-shaped bends 23 are evenly arranged in the inner circumference, and one end of the U-shaped bends 23 communicates with the shape hole 21, and the other end communicates with th...

Embodiment 2

[0068]On the basis of Example 1, the rotation speed of the seeding disc and the stability of the seeding are inversely correlated. When the forward speed of the seeder is high, the corresponding seeding frequency is high, and the speed of the seeding part needs to be increased. , on the contrary, if the filling time of the hole is reduced, the number of seeds per hole planting will be uncertain, and the seeding performance will be poor. It is necessary to reduce the speed of the seeding plate for small sowing hybrid rice hole planting. Curve one 23 and the U-shaped curve two 33 in the second seeding tray 3 are installed at an staggered angle, and hybrid rice seeds are added in the first seed-filling cavity cover 4 and the second seed-filling cavity cover 5, and the seeds are sorted , the seeds in the first seed-filling chamber cover 4 enter the U-shaped bend-23 through the hole-21 on the first seed-discharging disc 2, and then discharge from the seed outlet-22; the second seed-...

Embodiment 3

[0070] On the basis of Embodiment 1, the seat shell 1 is provided with an arc-shaped notch 10, and fixed ear seats 11 are arranged symmetrically in the middle of the edge of the arc-shaped notch 10, and the seed protection plate 6 and the inner wall of the seat shell 1 Circumferential sliding connection, the seed guard plate 6 is provided with an arc-shaped groove 60, and the arc-shaped groove 60 is aligned with the fixed ear seat 11, and the fastening bolt passes through the fixed ear seat 11 and the arc-shaped groove 60, and is fixed by a nut Locking realizes the adjustment of the installation angle of the seed protection plate 6, changes the angle of the seed protection area, adjusts the position of the seed, and makes the hole formation of the seed row the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com