Belt packaging cable and cable packaging assembly thereof

A technology for packaging components and cables, which is applied in the field of packaged cables and their cable packaging components, can solve the problems of complicated operation methods, waste of manpower, and low efficiency, and achieve the goals of saving manpower, quick installation and disassembly, and reduced friction area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

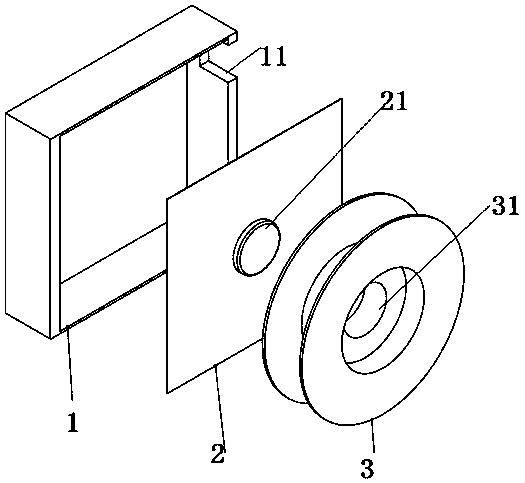

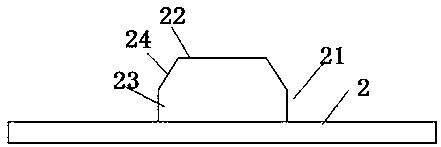

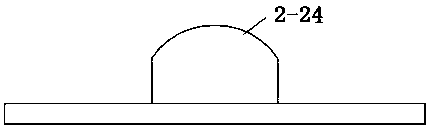

[0036] Embodiment 1 of the packaged cable of the present invention, such as figure 1 As shown, the packaged cable includes a cable and a cable packaging assembly, wherein the cable packaging assembly includes a box body, and a cable reel 3 arranged in the box body. The above-mentioned cables are wound on the cable reel 3 and arranged on the A support for supporting the cable drum 3 inside the box. Wherein, the box body is the support carrier of the whole cable reel 3, and the above-mentioned support member and the cable reel 3 are all arranged in the box body. In this embodiment, the box body includes the bottom wall of the box body. When in use, the cable reel 3 is supported and suspended on the bottom wall of the box body by the supporting member, and the box body is set as a carton 1 whose upper end can be opened and closed. On the one hand, the cart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com