Bearing roller for rolling mill

A bearing roller and roller technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems affecting the service life of bearings, shortage of fitting surfaces, bearing vibration, etc., to reduce the wear area, reduce wear, The effect of enhancing the usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

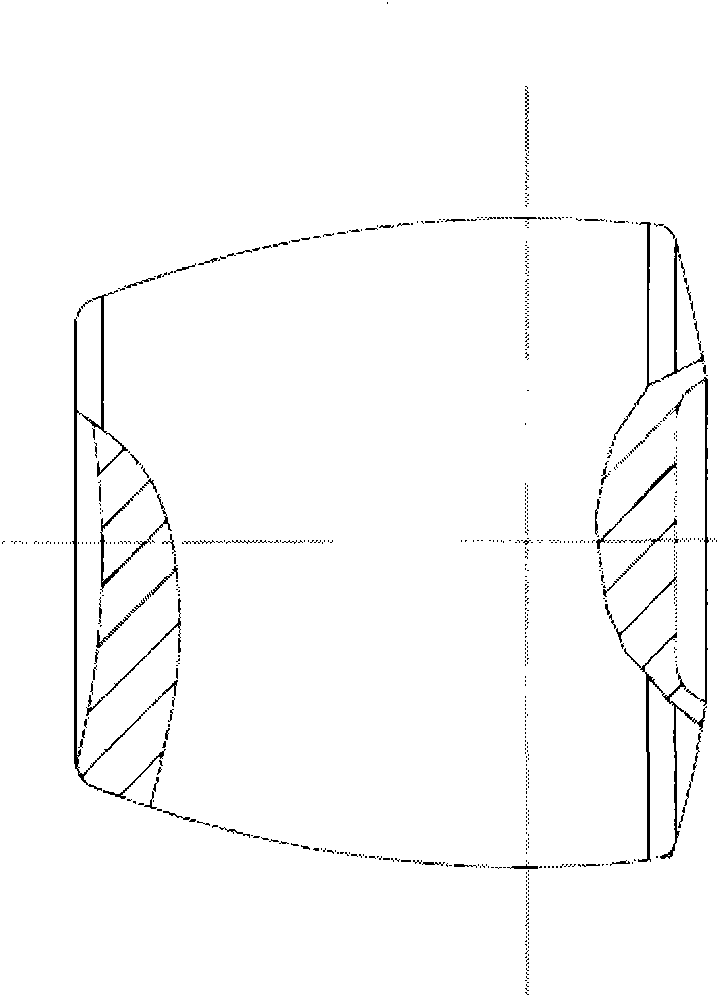

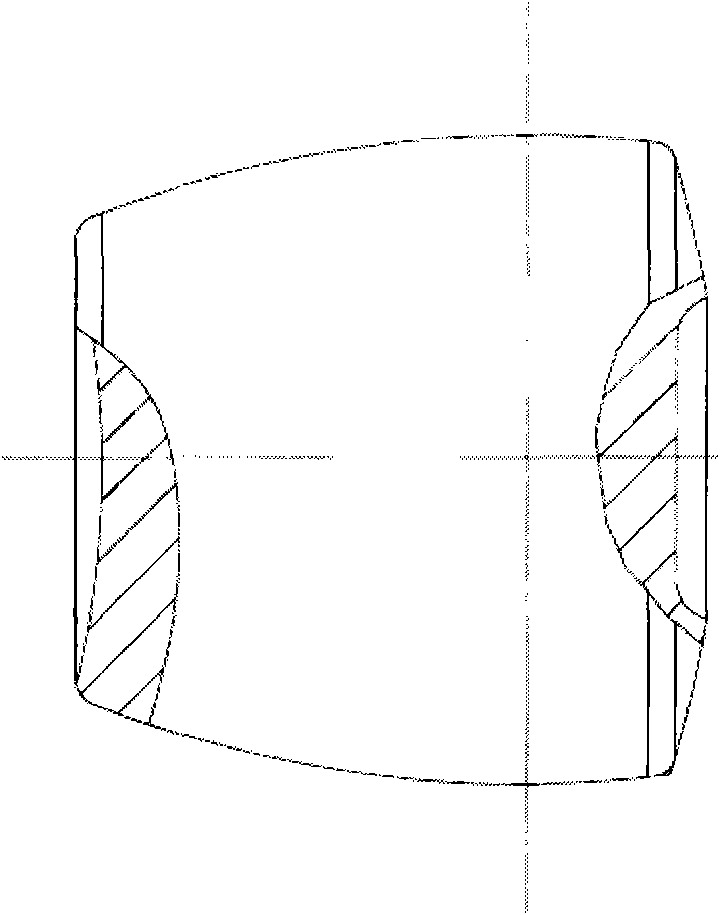

[0008] refer to figure 1 In the bearing roller provided by the present invention, the rolling surface of the roller is a rotary surface structure formed by turning a straight arc around the center line; the straight arc is inclined, so that the two sides of the roller form a large end face with a large cross-sectional area and a large cross-sectional area. Small facets. The bearing of the present invention is mainly used in rolling mills. In the figure, there are rounded corners at the edges of the end surfaces on both sides of the roller. In addition if figure 1 The shaded part on the right side is partially sectioned, the center of the large end surface is provided with a circular flat-bottomed groove, and the groove wall is in the form of a concave arc surface transition. The partial cross-sectional structure of the shaded part on the left side of the figure shows that the small end surface forms a spherical groove from the edge to the center.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com