A method for loading and unloading large-capacity power modules

A power module, large-capacity technology, applied in the field of high-voltage power, can solve the problems of safety accidents, large weight and volume, and a lot of time and manpower, and achieve the effect of rapid installation on the shelf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

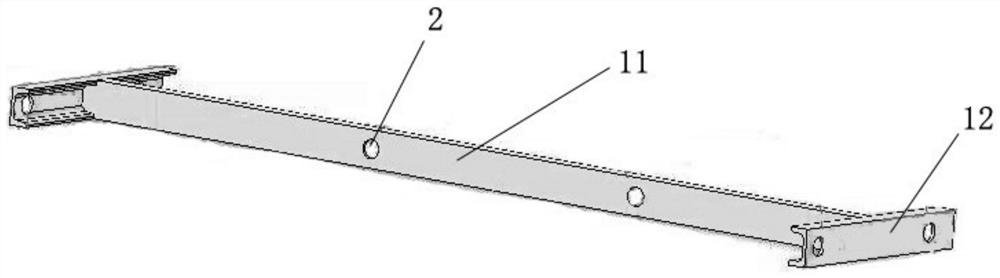

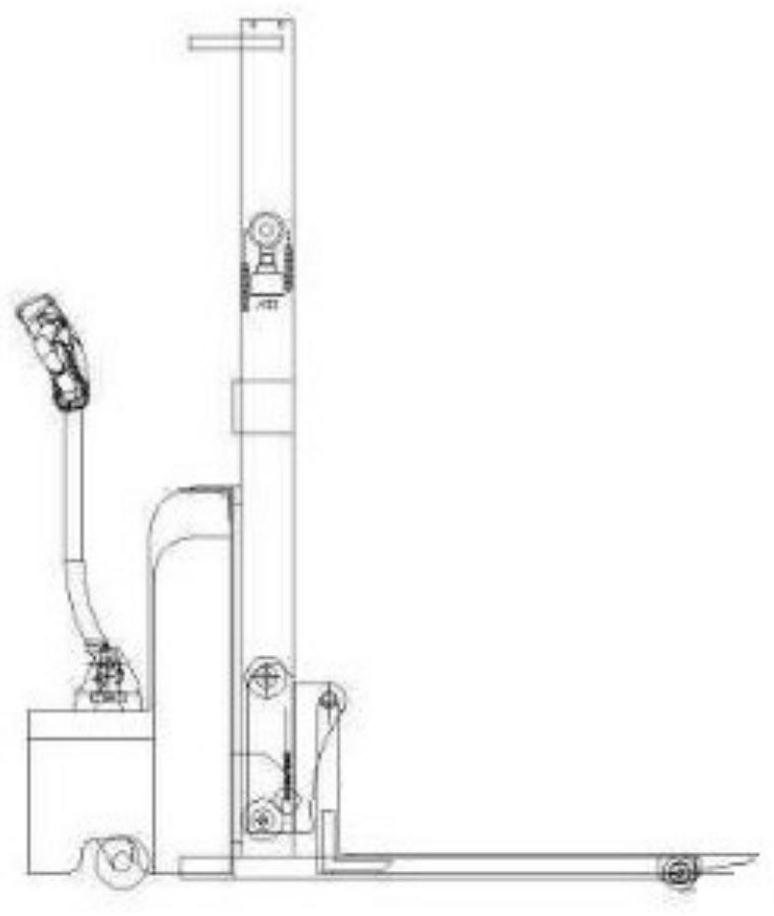

[0027] Such as figure 1 and figure 2 A lifting tool for a large-capacity power module is shown, including a lifting frame, a lifting rope, a U-shaped buckle, a self-locking hook, and a tooling floor; Two channel steels 12 are formed at the two ends of the steel bar 11, and there are two hoisting holes 2 at a certain distance in the middle of the steel bar 11, and a hoisting hole 2 is opened at each of the two ends of the channel steel; the tooling bottom plate is a steel plate 31 with two long sides folded , the length is equal to that of the power module, a plurality of bolt holes 33 are opened on the tooling bottom plate near the folded edge, and a plurality of pulleys 32 are installed according to the distance between the power modules, so that the power module can be slid and embedded in it.

[0028] There are five sets of lifting ropes, U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com