Hardness unit clamping device universal for multiple test platforms

A clamping device and multi-test technology, which is applied in the direction of testing material hardness, measuring device, strength characteristics, etc., can solve the problems of affecting measurement accuracy, lack of clamping device, unfavorable general technology promotion of hardness testing equipment, etc., to improve operation Scope of application, effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

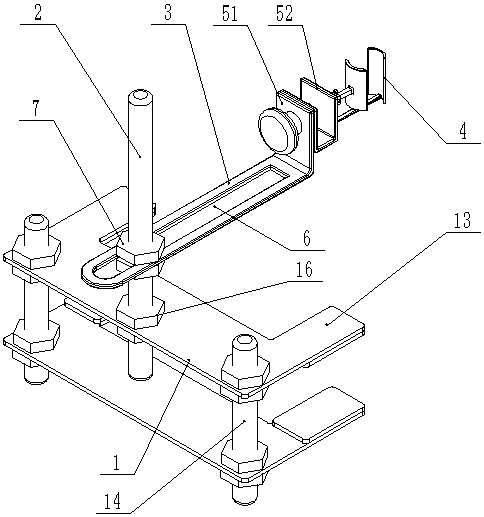

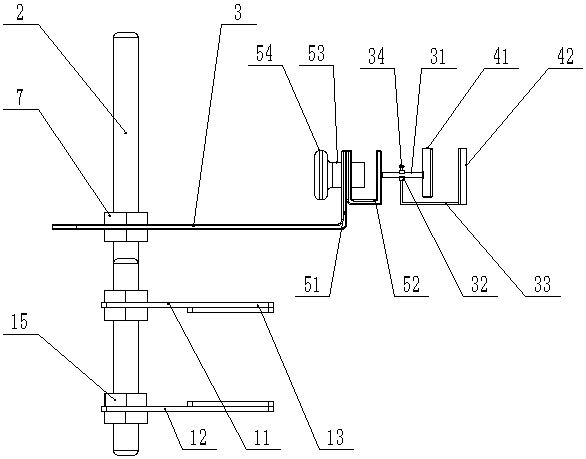

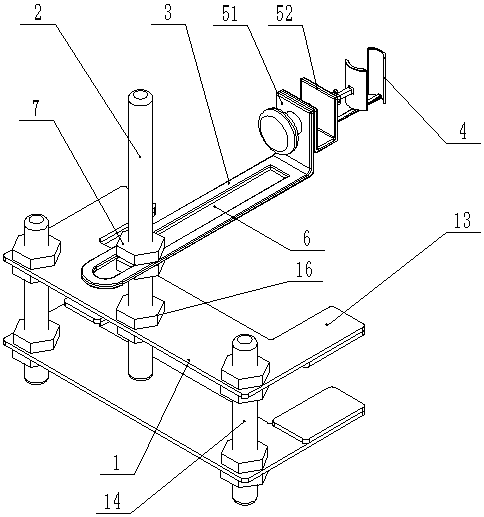

[0030] Such as Figure 1 to Figure 2 As shown, a general-purpose hardness unit clamping device for multiple test platforms of the present invention includes a clamping base 1 and a vertical column 2 arranged vertically on the clamping base. The vertical column 2 is provided with a bracket 3 arranged perpendicular to it. The bracket The end of 3 is provided with hardness standard rod holder 4.

[0031] The hardness standard rod clamping seat 4 includes a fixed half seat 41 and a movable half seat 42 which are relatively arranged. clamping part. Since the movable half-seat 42 can move relative to the fixed half-seat 41, the adaptive clamping of standard rods with different diameters and hardnesses can be realized.

[0032] Wherein the fixed half-seat 41 is fixedly connected with the bracket 3 through the fixed connecting rod 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com