A rapid verification device for the hardness unit of a comprehensive test bench

A technology of comprehensive testing and verification devices, applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve problems such as unfavorable general technical promotion of hardness testing equipment, failure to cooperate with verification devices, affecting measurement accuracy, etc., and is conducive to general technical promotion. , eliminate errors, and ensure the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

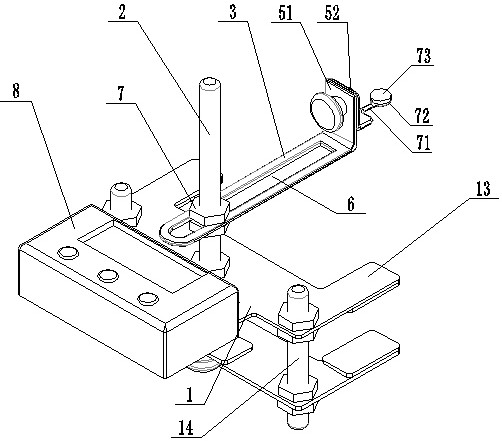

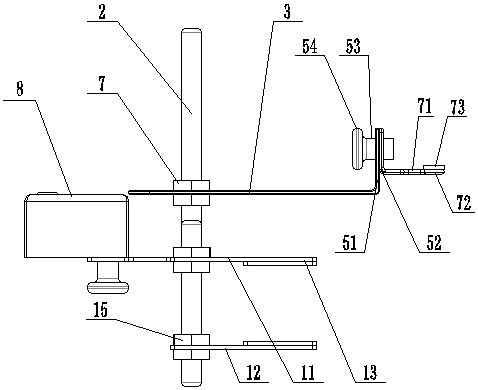

[0031] Such as Figure 1 to Figure 2 As shown, a comprehensive test bench hardness unit rapid verification device of this embodiment includes a clamping base 1 and a column 2 vertically arranged on the clamping base. The column 2 is provided with a bracket 3 vertically arranged thereon. The bracket 3 The end of the sensor is provided with a verification sensor mounting seat. The verification sensor mounting base includes a base body and a sensor installed on the base body, and the central control display 8 of the sensor is installed at the clamping base 1 .

[0032] In this embodiment, the sensor is a load cell 73, so that pressure verification can be realized.

[0033] The seat body includes a support arm 71 extending forward along the direction of the bracket 3, the end of the support arm 71 is provided with a seat ring 72, the load cell 73 is embedded on the seat ring 72, and the sensing surface of the load cell 73 protrudes from the seat ring 72 setting, which is conveni...

Embodiment 2

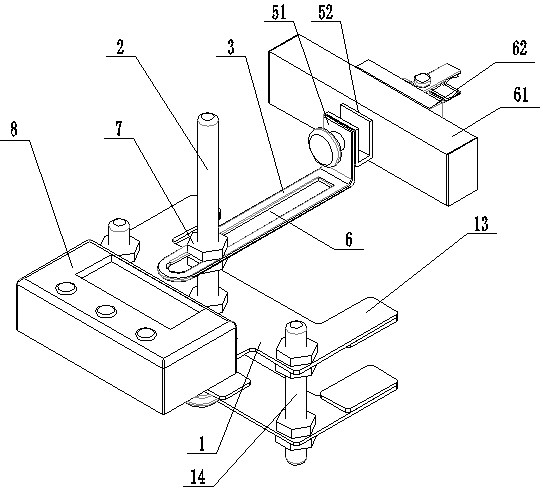

[0042] like Figure 3 to Figure 4 As shown, the difference between this embodiment and the first embodiment is that the sensor is a grating scale sensor 62, and the grating scale sensor 62 is installed on the base body 61, so that the pressure displacement can be verified.

[0043] The sensor can also be an infrared sensor or an image sensor, and its installation refers to the second embodiment, which can cooperate to realize the verification of the pressure application time or pressure displacement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com