Sowing device for thesium chinense planting

A seeding device and a technology for variegata, applied in the field of seeding devices for variegation planting, can solve the problems of troublesome dismantling and replacement installation, inconvenient operation, poor use effect, etc., and achieves convenient adjustment, good use effect, and use range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

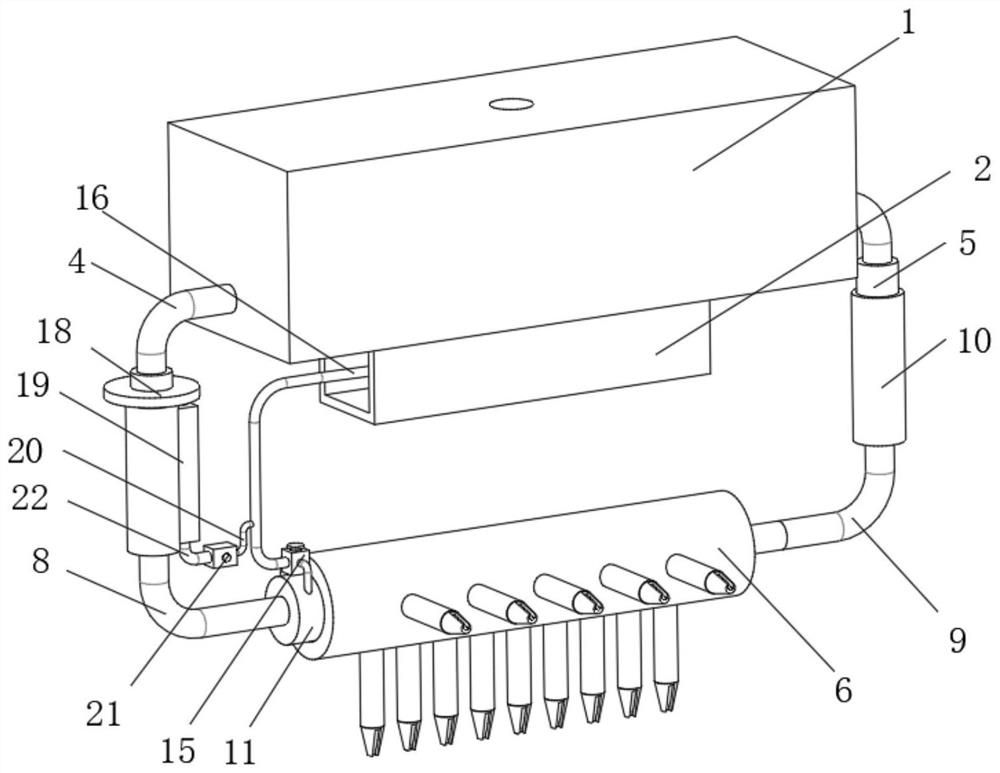

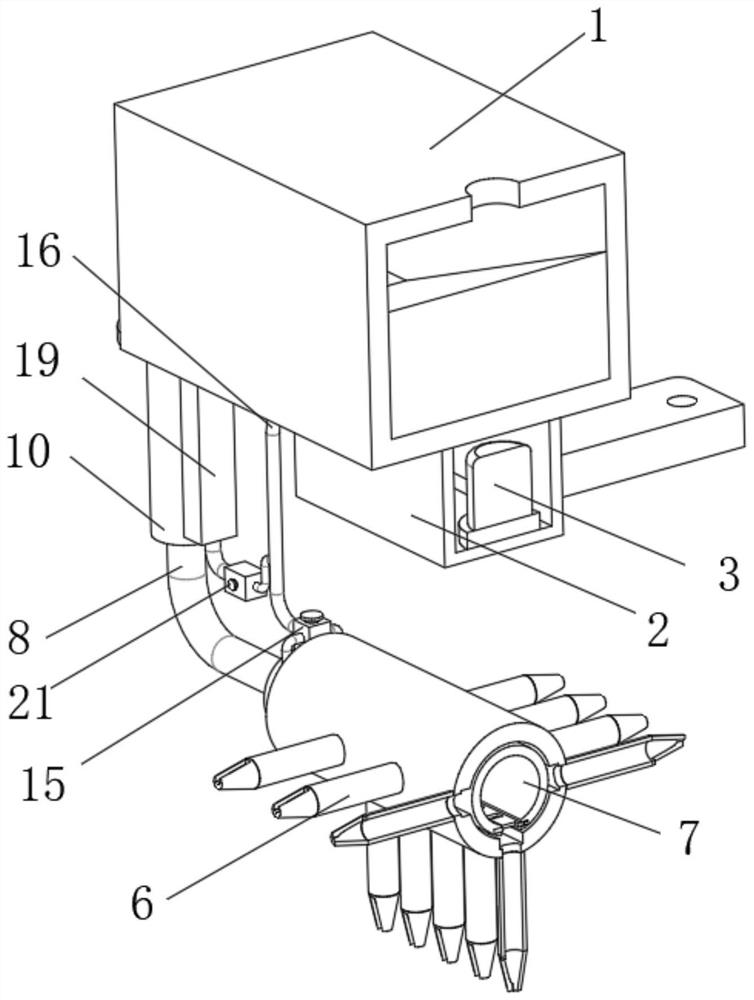

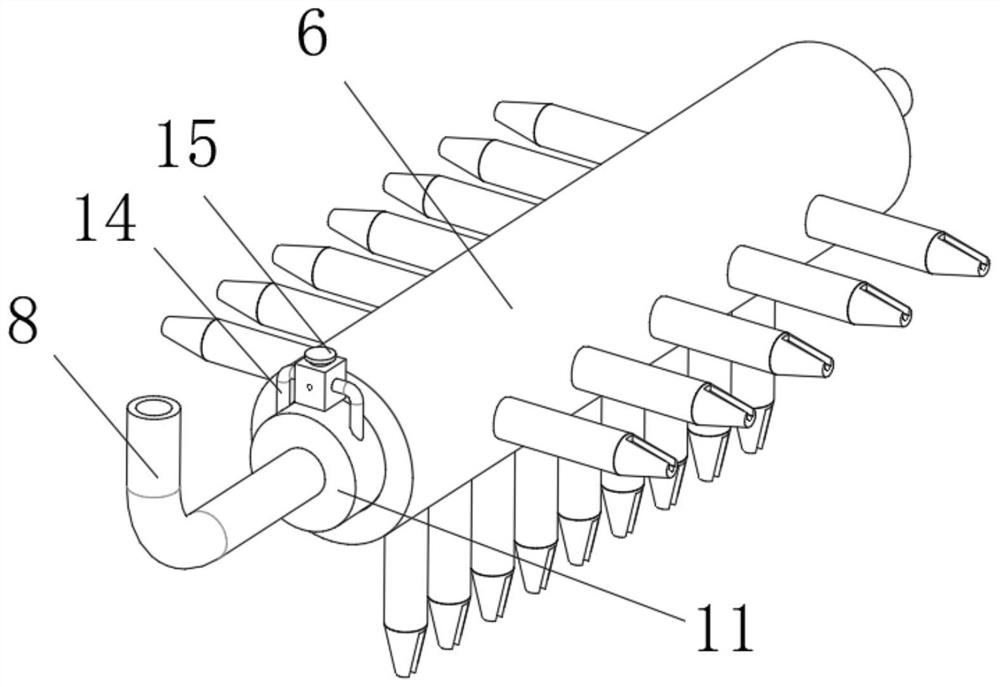

[0042] The first embodiment: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, when the sowing row spacing needs to be changed, the air pump 3 is started, so that the air pump 3 passes the gas into the inside of the adjusting mechanism 15 through the No. The No. 1 hole 152 is communicated, and at the same time, the other end of the curved hole 156 is communicated with the No. 3 pipe 16, so that the gas passes into the communication pipe 14 on one side, and into the sealing sleeve 11 through the communication pipe 14. The gas is fed straight down, and the gas pushes the push plate 13 on one side in the sealing sleeve 11, so that the push plate 13 pushed by the gas drives the casing 12 to rotate, so that the casing 12 drives the seeding cylinder 6 to rotate. The spring 17 rotates to the limit position, the No. 1 seeding tube 62 at the bottom of the seeding cylinder 6 rotates and moves upward, and at the same time, the No. 2 seedi...

no. 2 example

[0050] Second embodiment: as figure 1 , figure 2 , Figure 5 , Figure 8 , Figure 9 and Figure 10 As shown, when the seeding density needs to be adjusted during seeding, the electromagnet 29 is activated, so that the electromagnet 29 is energized with magnetism, and the magnetism of the energized electromagnet 29 is opposite to that of the magnetic strip 284. Power-on has opposite magnetism, so that the repulsive force pushes the magnetic strip 284 on the moving mechanism 28 to move, so that the moving mechanism 28 slides between the two sets of slots 26, and the groove 282 of the moving plate 281 moves along the sealing block 27 when moving. , so that the flow cross section of the missing groove 282 is gradually reduced, the amount of seed falling is reduced, and the amount of seeds sown per unit area is reduced under the condition that the planter moves stably, and the control of reducing the seeding density is completed. When it needs to be further reduced, gradually...

no. 3 example

[0055] The third embodiment: as figure 1 , figure 2 , image 3 , Figure 11 , Figure 12 and Figure 13 As shown, when the seeding depth needs to be adjusted, the adjusting rod 155 in the adjusting mechanism 15 is rotated so that the curved hole 156 of the adjusting rod 155 is not communicated with the No. 3 pipe 16, and the sealing rod 214 is rotated outward so that the No. 3 hole 212 is connected to The side pipe 20 is connected, and the air pump 3 is started. As the gas passes into the side pipe 20 through the No. 3 pipe 16, and into the trachea 22 through the No. 3 hole 212, the gas in the trachea 22 enters the lifting mechanism 19. In the inner cavity 192, as the gas passes into the inner cavity 192, the internal air pressure increases and pushes down the fixing plate 191 to move down along the fixing rod 194, thereby causing the fixing tubes 10 on both sides to move down along the sleeve tube 5. Move down, so that the seeding tube 6 moves down, and at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com