Rotary bus battery compartment heat dissipation grille and automatic rain-proof wind-increasing heat dissipation control method

A technology of heat dissipation grille and battery compartment, which is applied in battery/fuel cell control devices, electric vehicles, secondary batteries, etc., can solve the problems of reducing air intake, increasing the probability of rainwater entering the cabin, etc., so as to improve the heat dissipation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present application is further described in conjunction with the following examples.

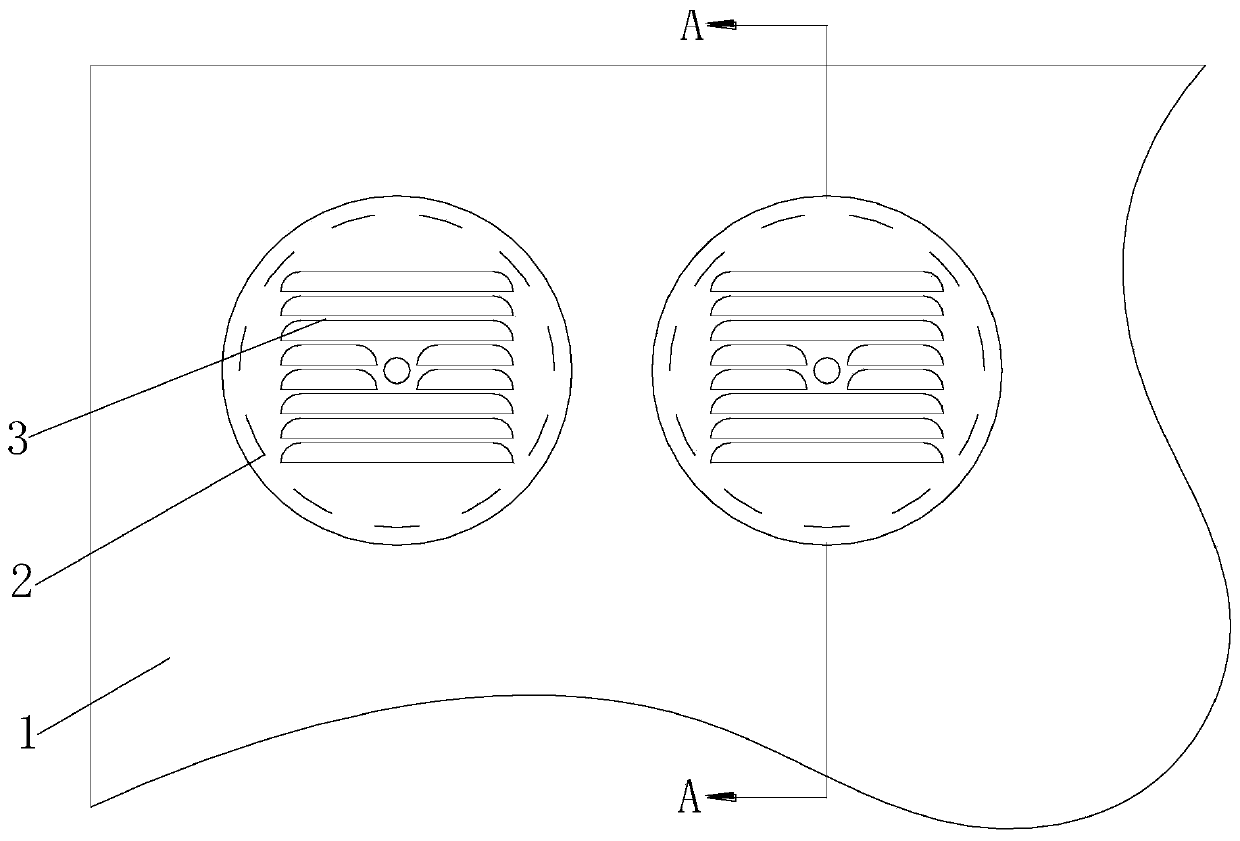

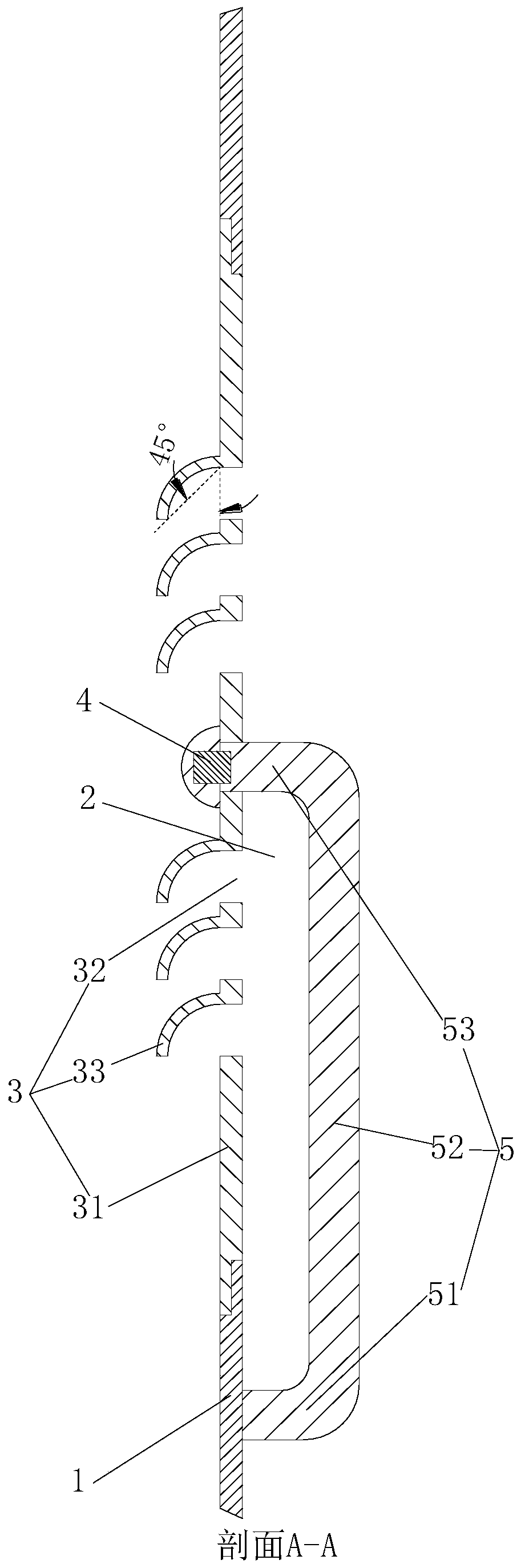

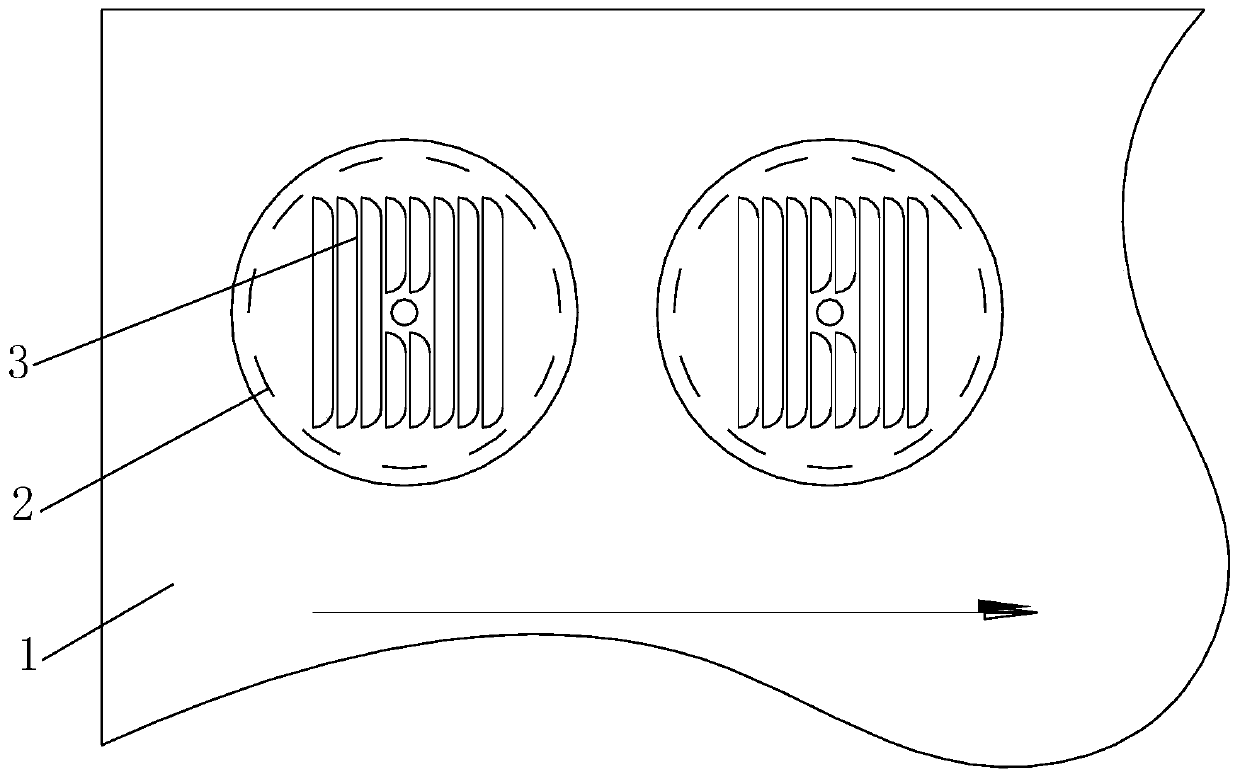

[0038] Such as Figure 1 to Figure 8 , the rotary bus battery compartment cooling grille is mainly used in electric buses, including a battery compartment door 1; the battery compartment has a cooling opening 2; the rotary bus battery compartment cooling grille also includes a grid panel 3 and rotary drive 4. Wherein, the grille panel 3 is cooperatingly arranged in the heat dissipation port 2 and communicated with the heat dissipation port 2, and can rotate 360 degrees horizontally relative to the battery compartment door 1; The center of the grid panel 3 is connected to the grid panel 3 and drives the grid panel 3 to rotate horizontally by 360 degrees relative to the battery compartment door 1 .

[0039] The heat dissipation grille of the battery compartment of the rotary bus connects the rotary drive device 4 with the grille panel 3 by setting the grille panel 3 at the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com