Electronic equipment patch jig and manufacturing method thereof

A technology of electronic equipment and manufacturing method, which is applied in branch office equipment, telephone communication, electrical components, etc., can solve the problems of glass protection sheet deviation, affect product appearance and performance, and cannot guarantee the lamination accuracy, so as to reduce the lamination error , Guarantee the effect of product appearance and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

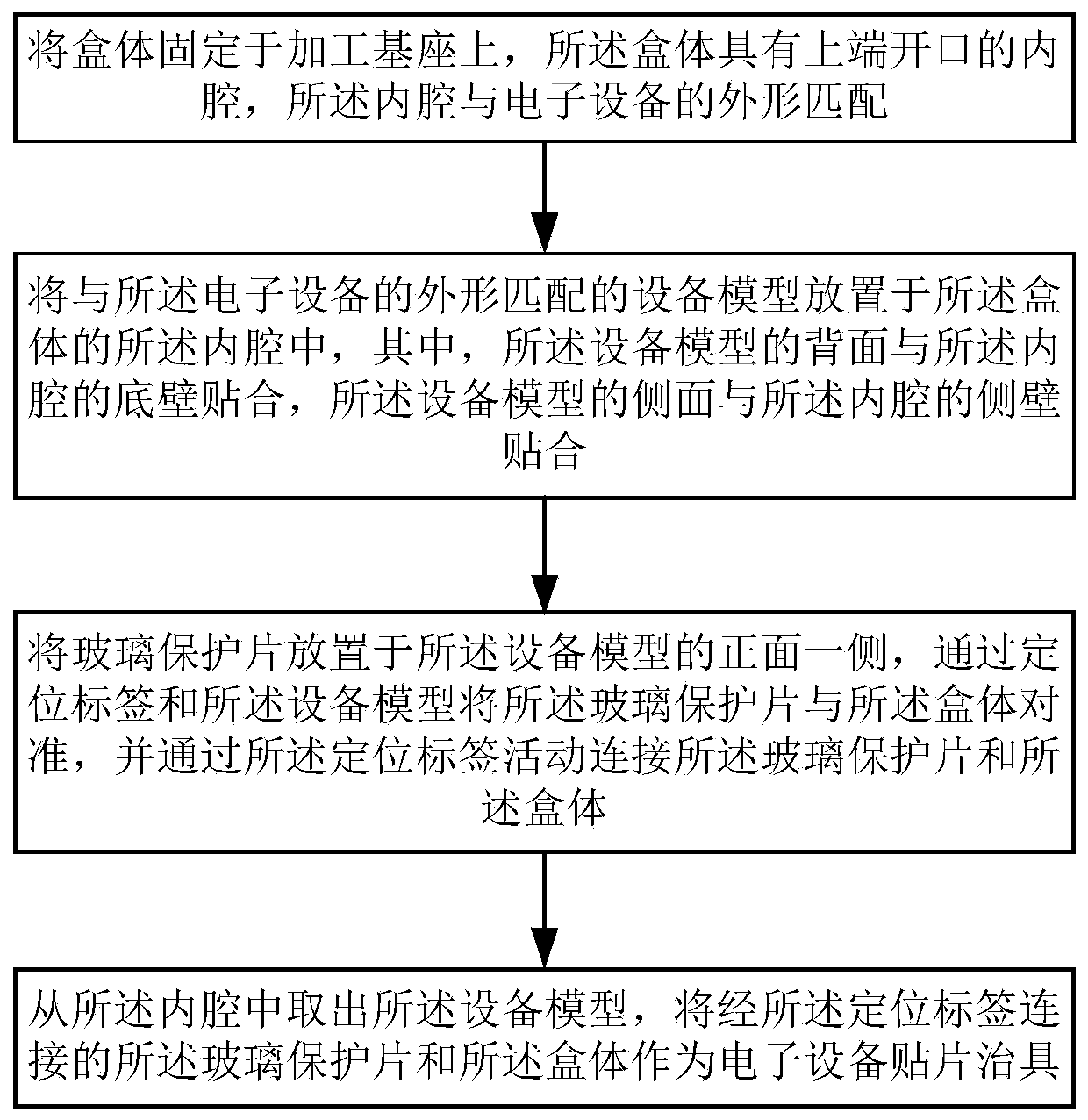

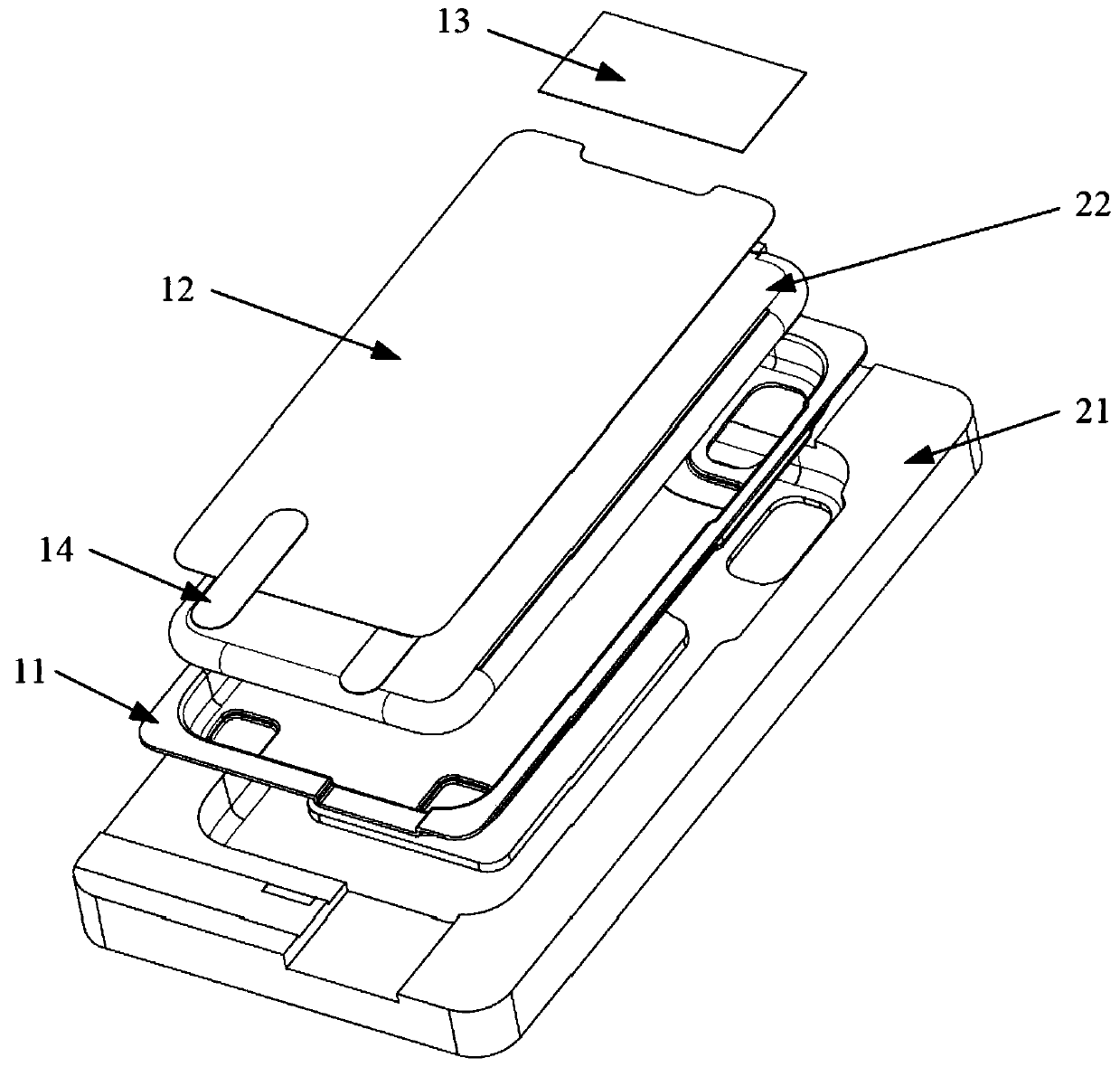

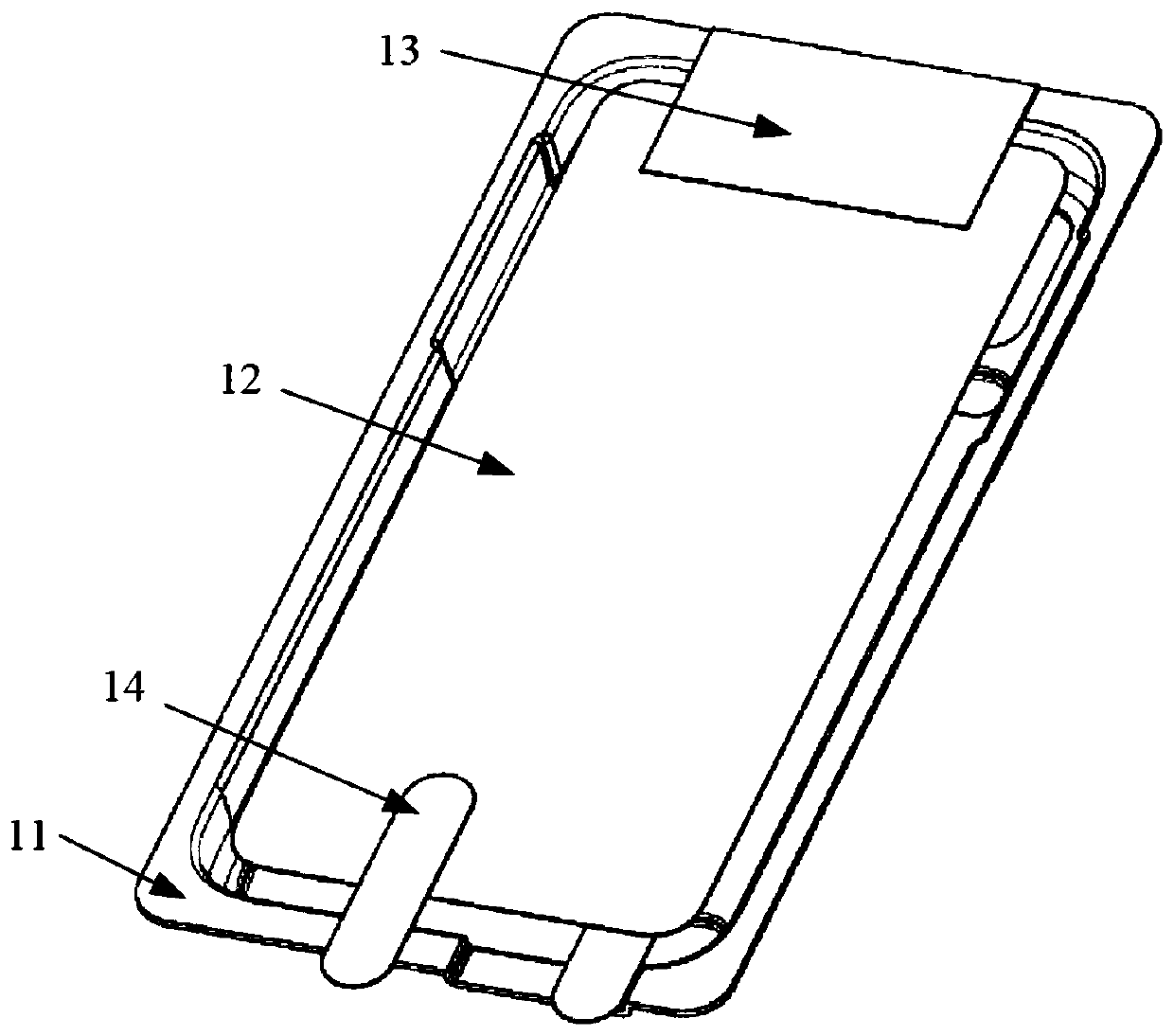

[0017] Such as figure 1 and figure 2 As shown, a method for manufacturing an electronic device patch fixture provided by an embodiment of the present invention includes the following steps:

[0018] The box body 11 is fixed on the processing base 21. The box body 11 has an inner cavity with an open upper end, and the inner cavity matches the shape of the electronic device.

[0019] Specifically, the inner cavity of the box body 11 can be formed by, for example, compression molding, and the inner cavity matches the shape of the electronic device to be mounted. For example, if the electronic device is a mobile phone, and its shape is a rounded rectangle, the inner cavity also is the same rounded rectangle. It shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com