Road surface crack repairing device

A technology for pavement cracks and grouting, applied in road repair, roads, roads, etc., can solve problems such as difficult to meet repair tasks, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

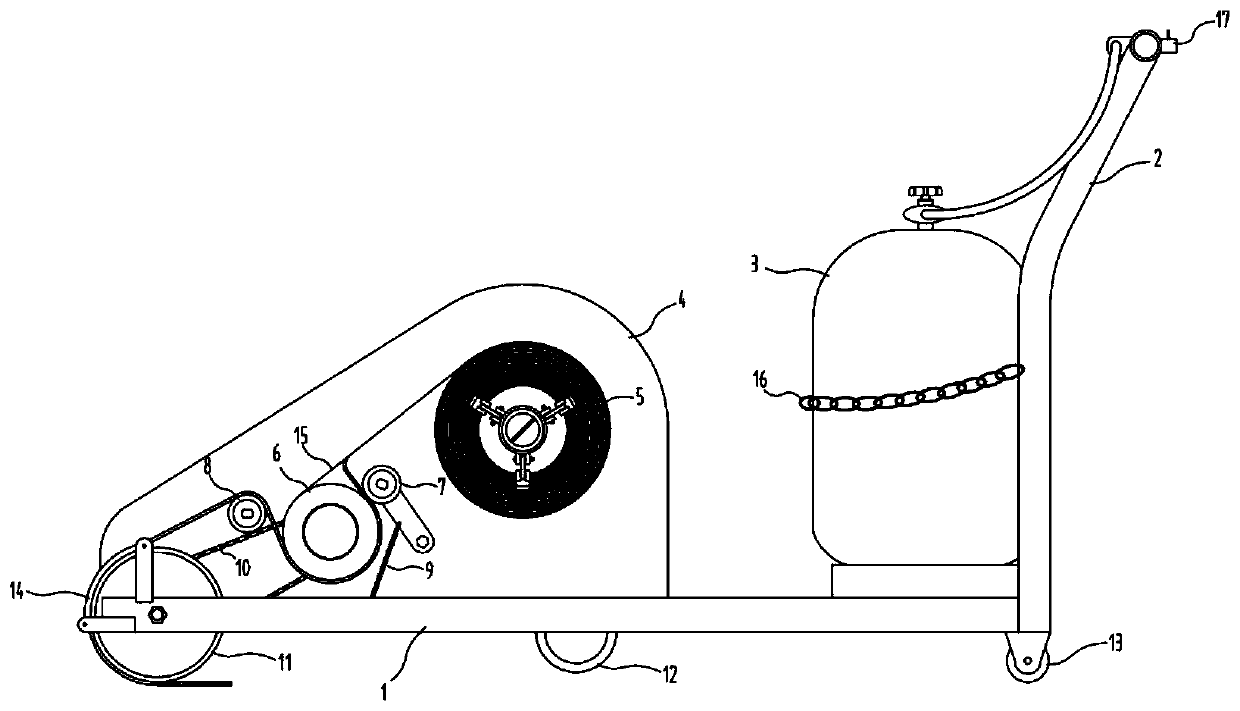

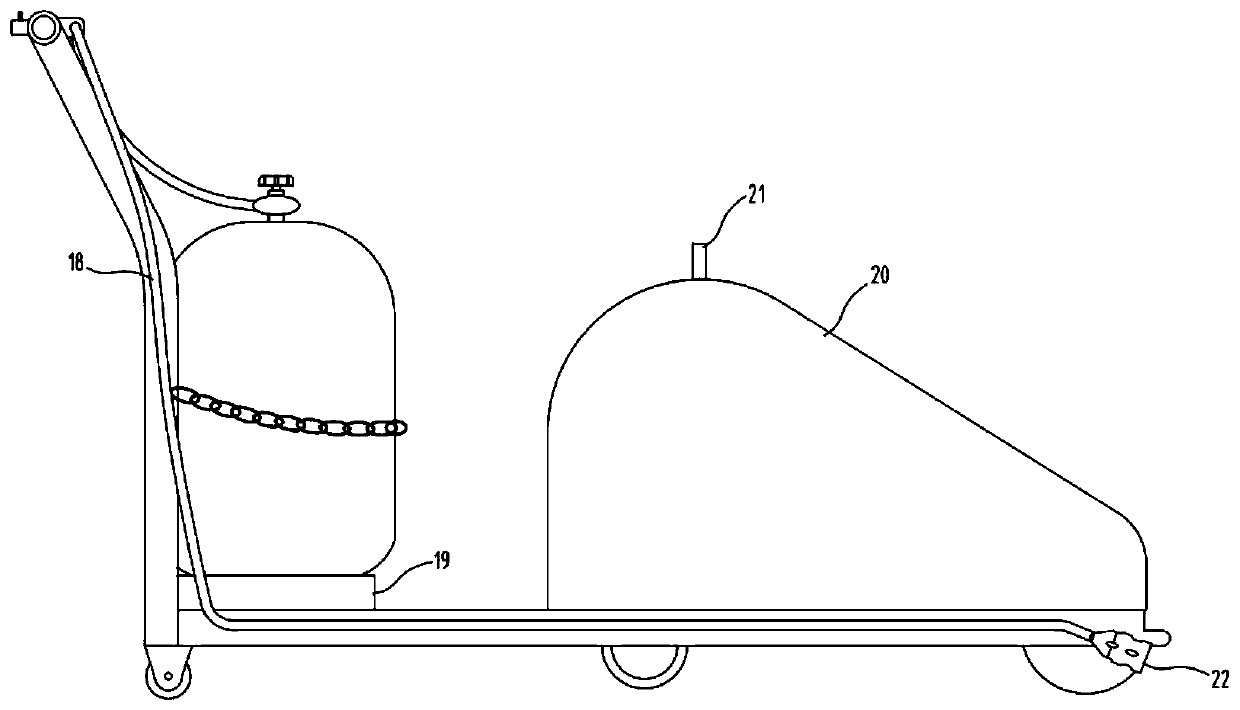

[0020] Below will be combined with the appended in the embodiment of the present invention Figure 1-3 , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

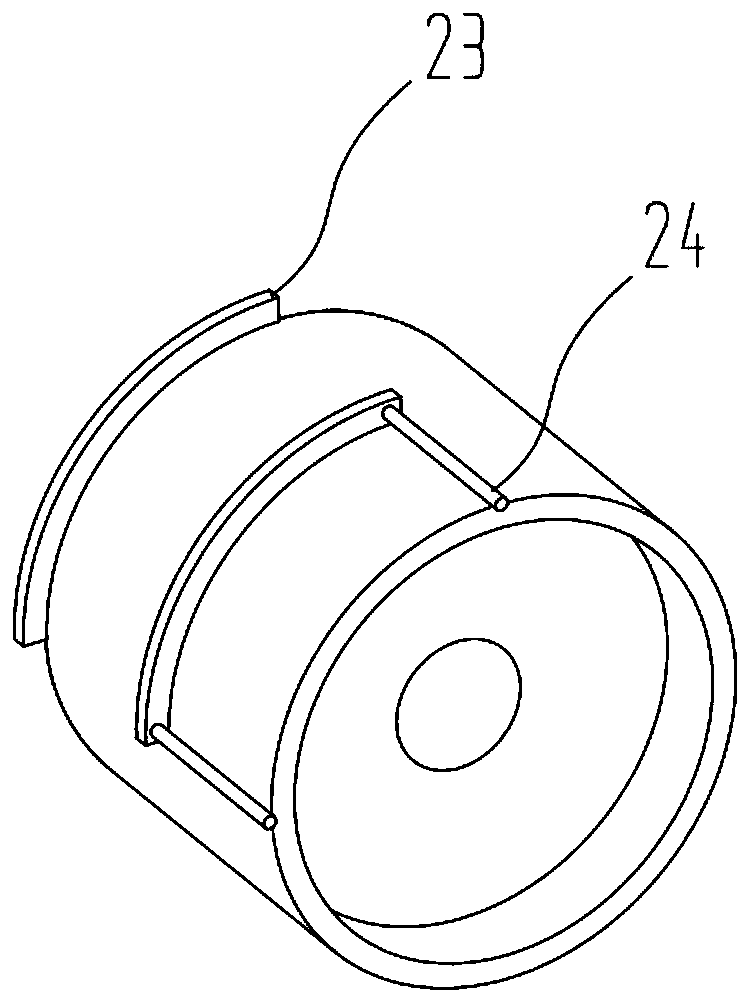

[0021] A device for repairing cracks on the pavement, comprising: joint filling tape 14, bracket, gas cylinder 3, transmission mechanism of joint filling tape 14, and gas delivery pipe 18, the support includes a holding part 2 and an installation part, and the holding part 2 is welded to the installation part On one side, the installation part is composed of an installation plane 4 for installing and repairing the transmission mechanism of the belt and an installation frame 1 for installing the rollers. The installation plane 4 is vertically welded on the side edge of the installation frame 1, and the plane of the installation frame 1 is also welded There is a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com