Patents

Literature

46results about How to "Achieve filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

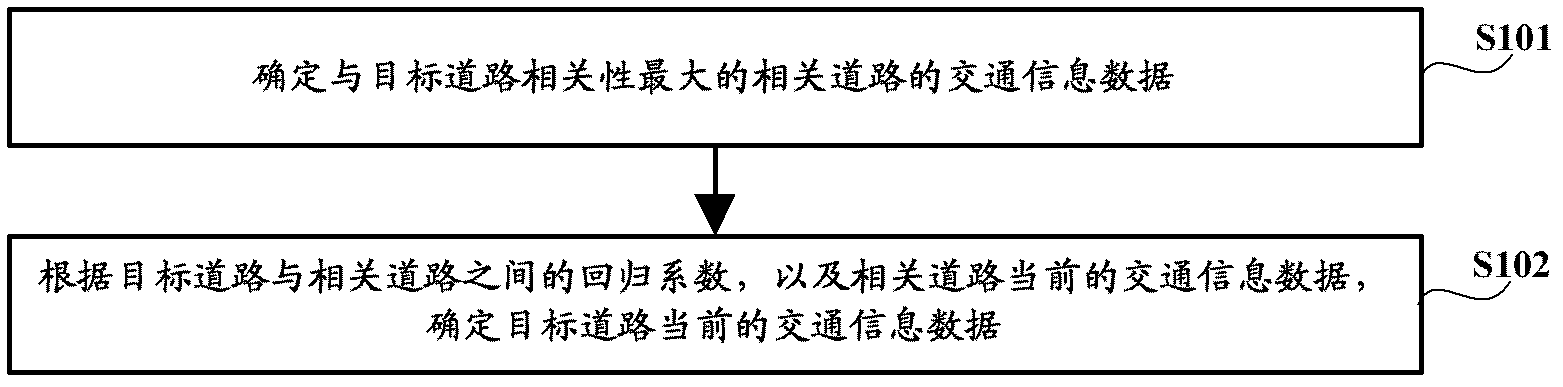

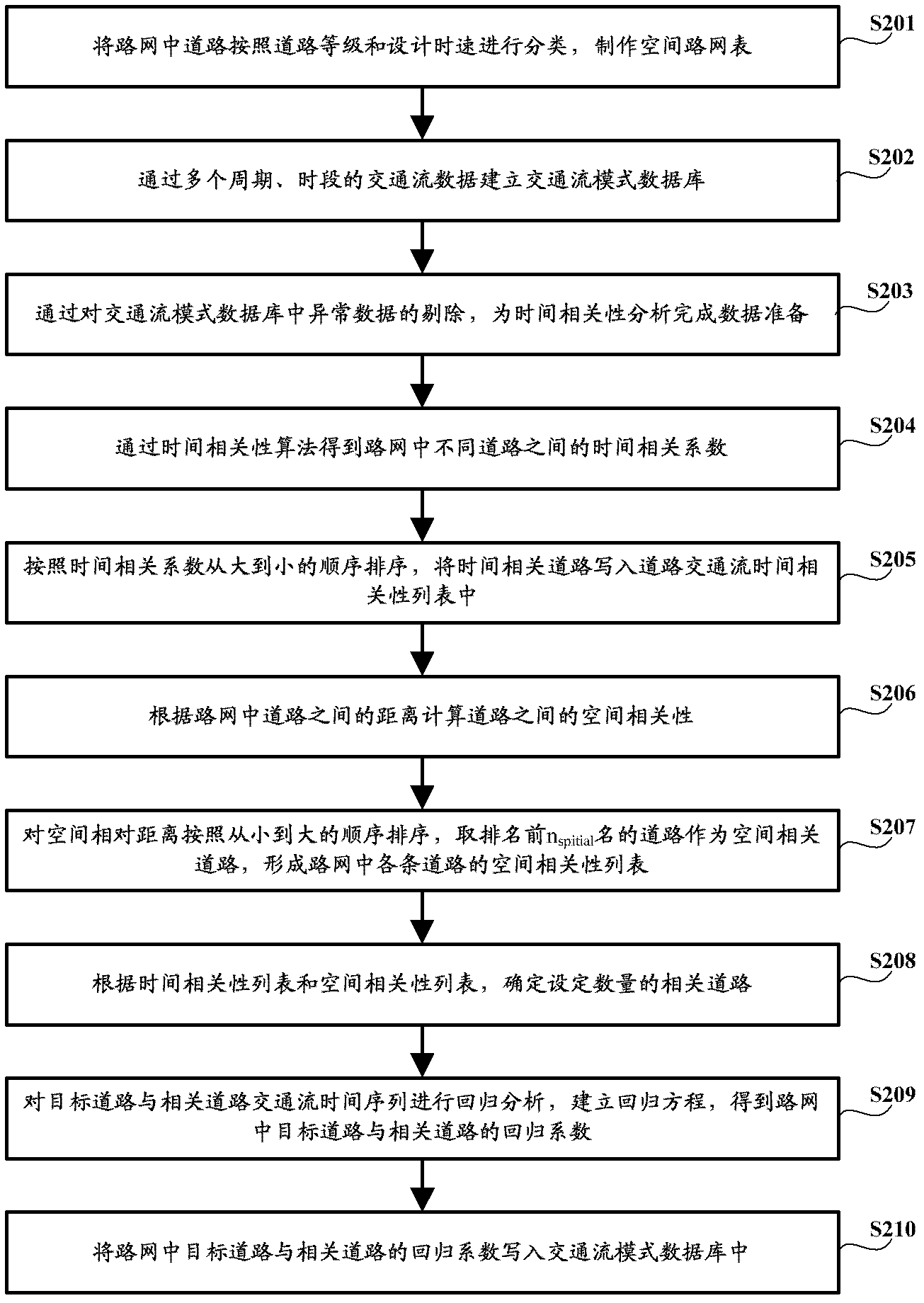

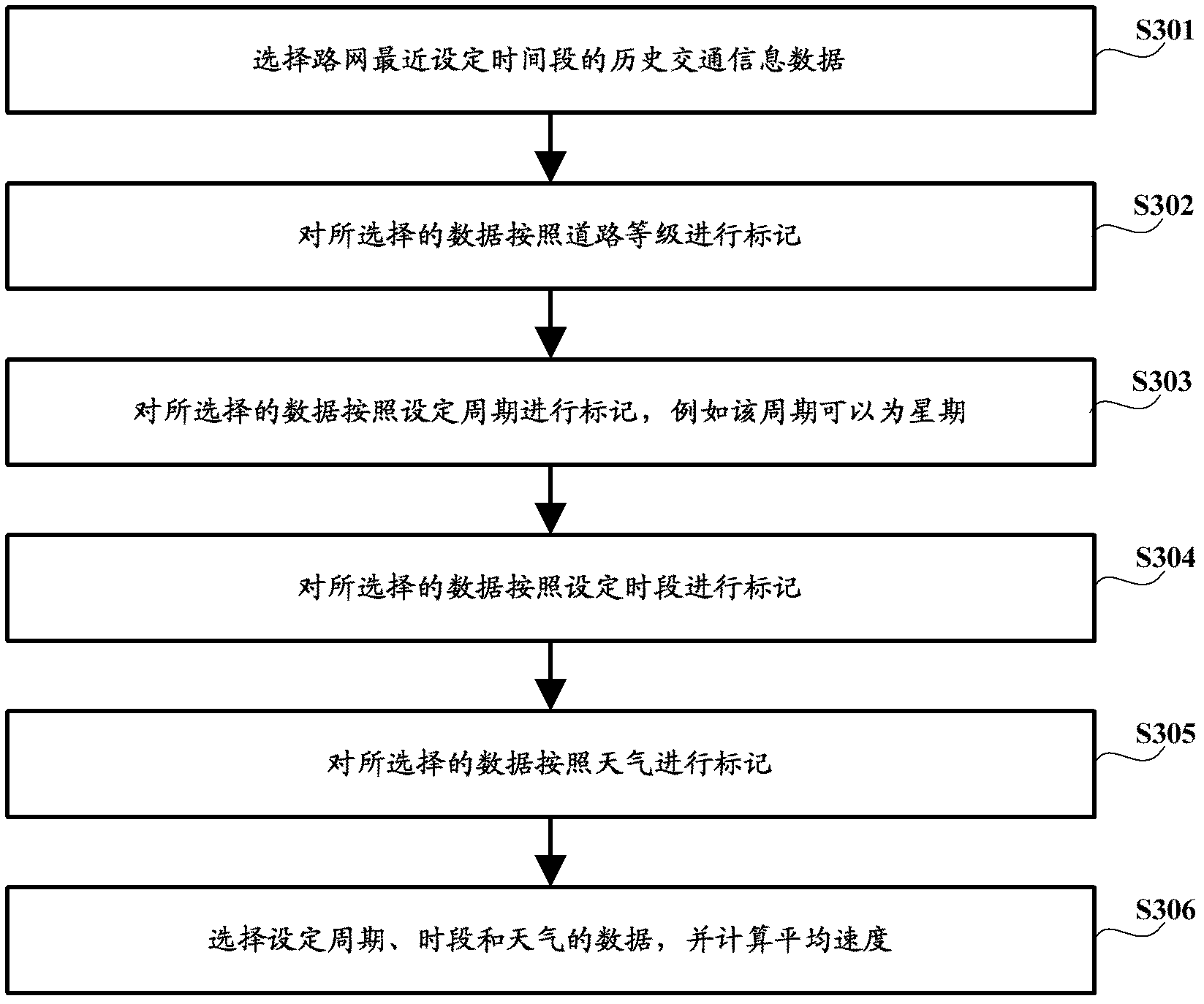

Traffic information data recovery method and device

InactiveCN102622880AImprove integrityImprove accuracyDetection of traffic movementRecovery methodReal-time data

The invention discloses a traffic information data recovery method and a traffic information data recovery device, and relates to a traffic information technology. In the embodiment of the invention, firstly, a related road with large relevancy with a target road is determined and then a regression coefficient is determined according to historical traffic information data of the target road and the related road, so that when real-time data of the target road is missed or is inaccurate, traffic information data of the target road in a current time period can be determined by the traffic information data of the related road with the largest relevancy and the regression coefficient of the target road and the related roads; and the traffic information data of the target road is determined by the mode, so that the filling of real-time traffic flow missing data and the correction of the real-time data can be implemented and the integrity and the accuracy of traffic information publishing are also improved.

Owner:北京捷易联科技有限公司

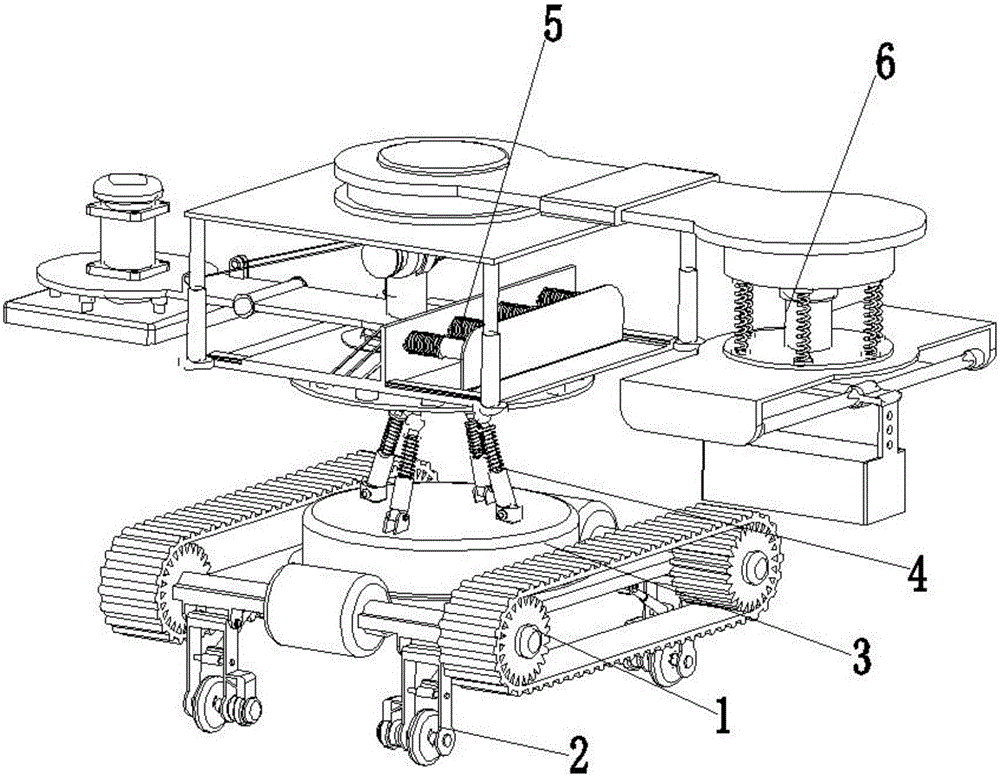

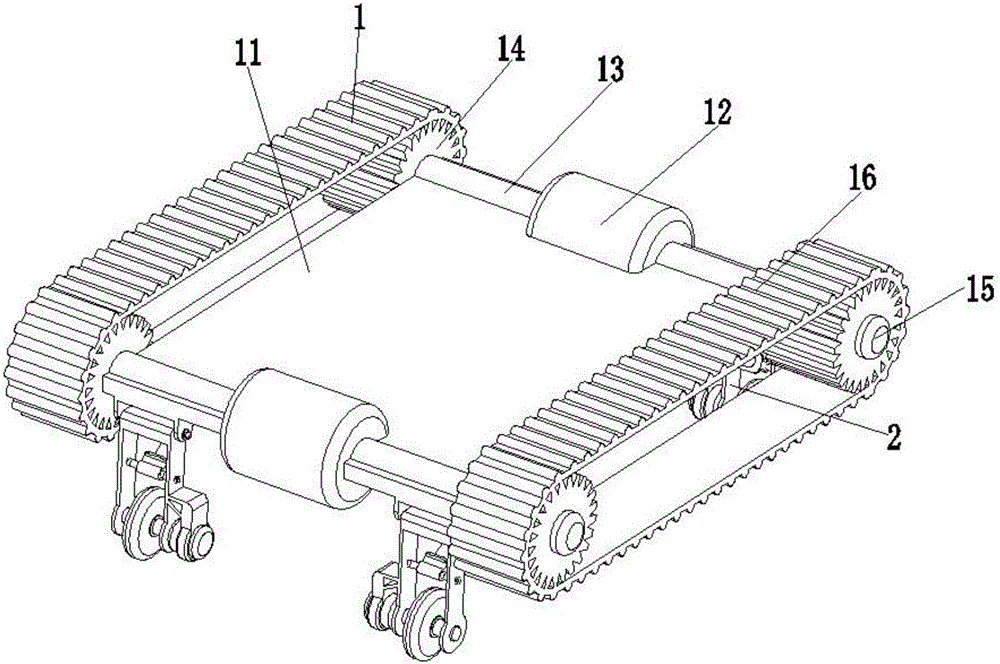

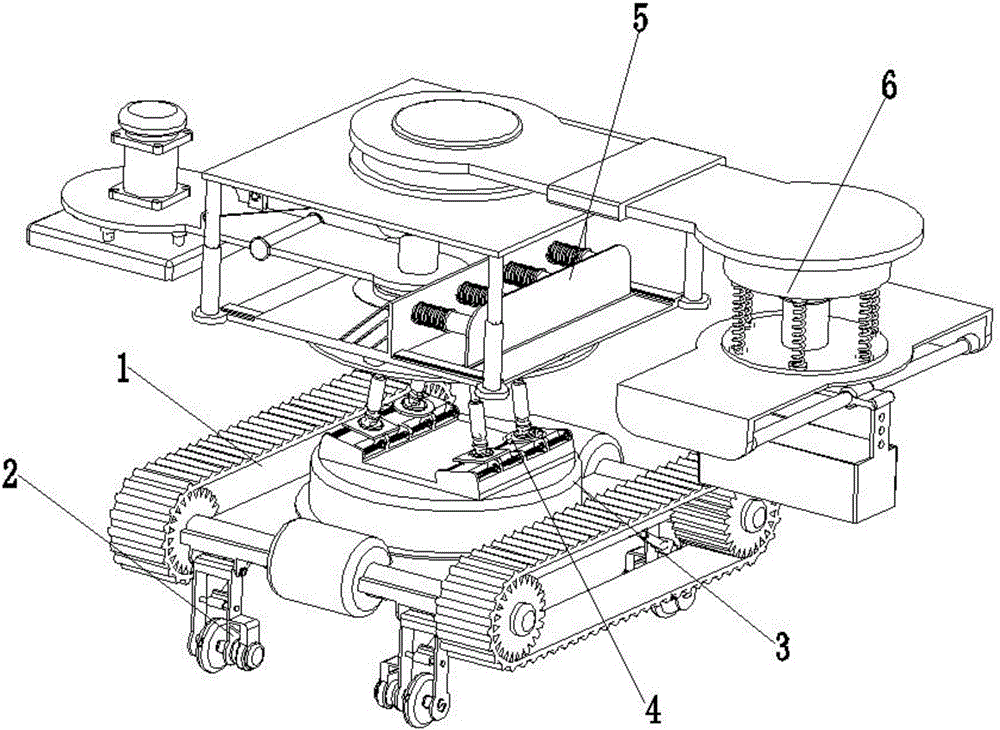

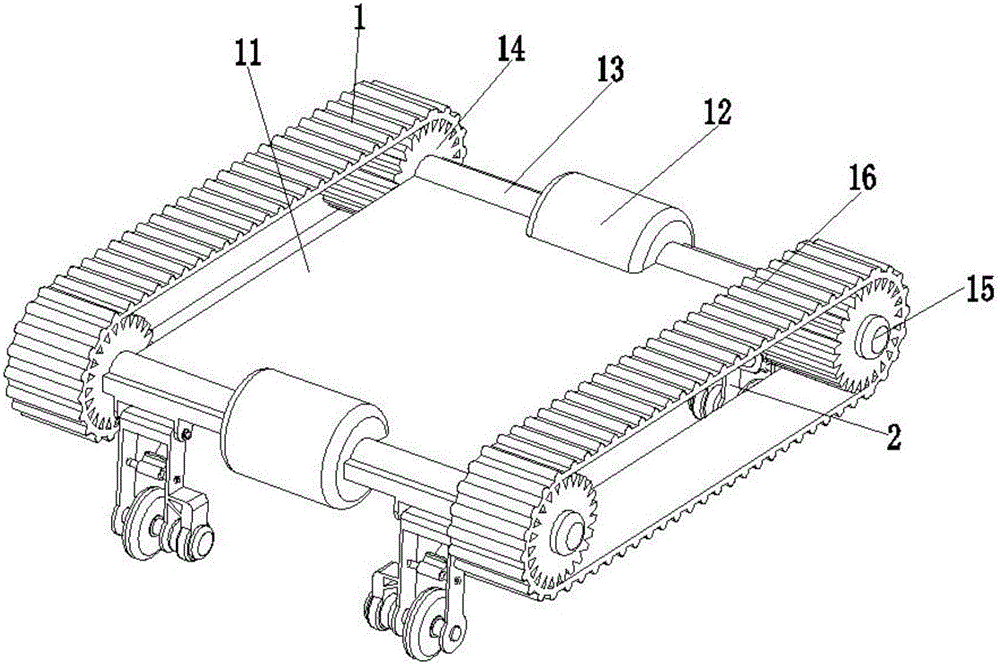

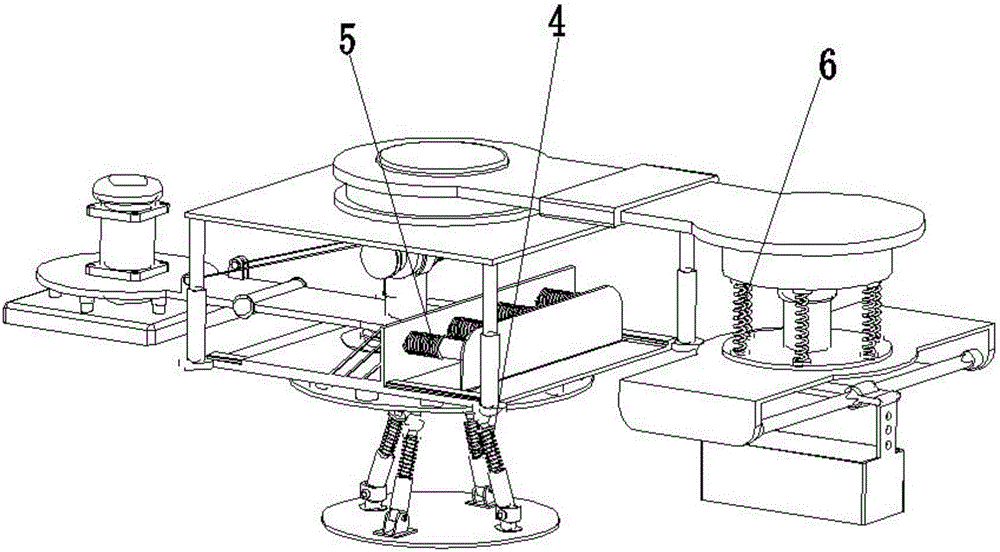

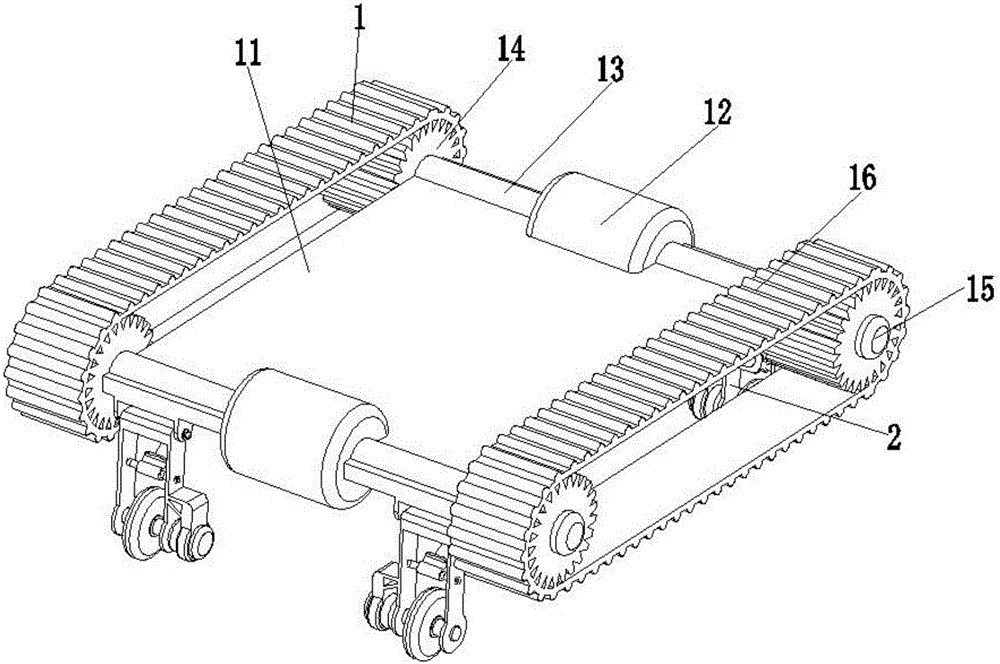

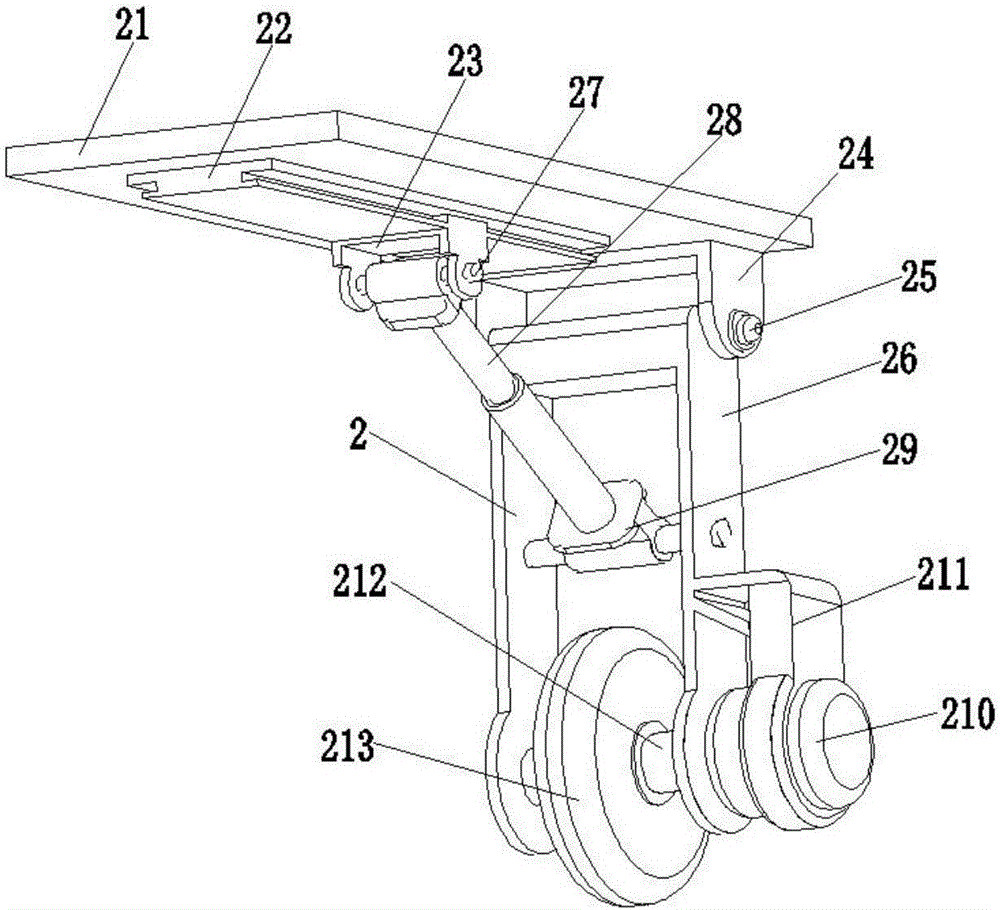

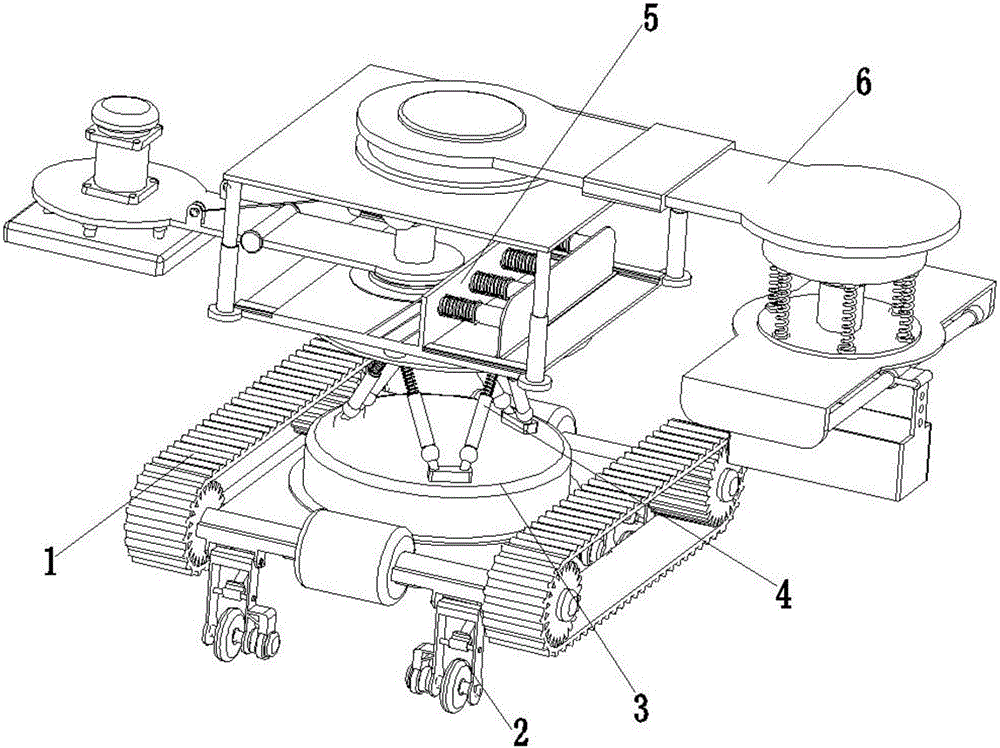

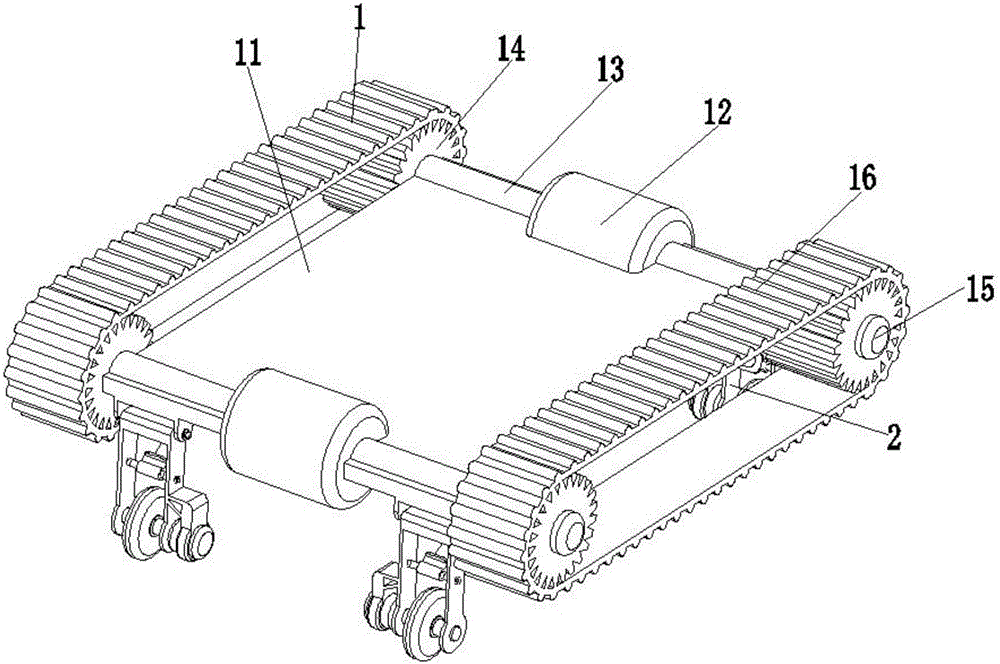

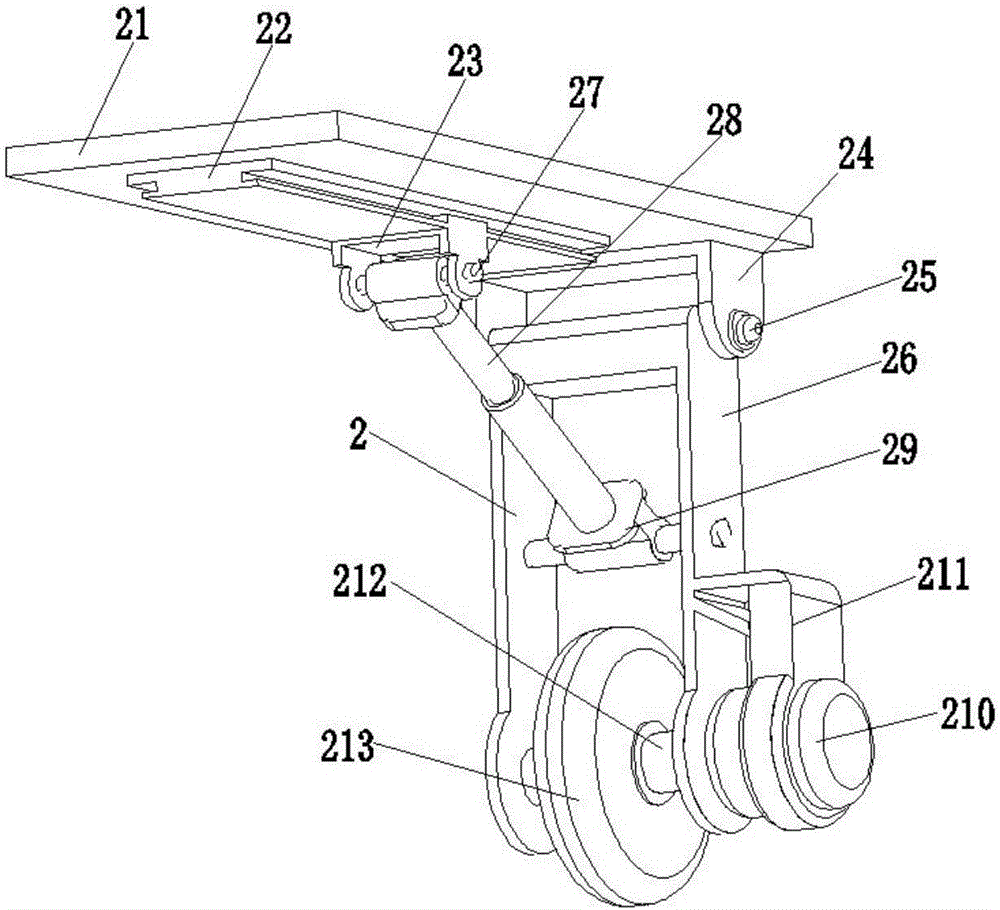

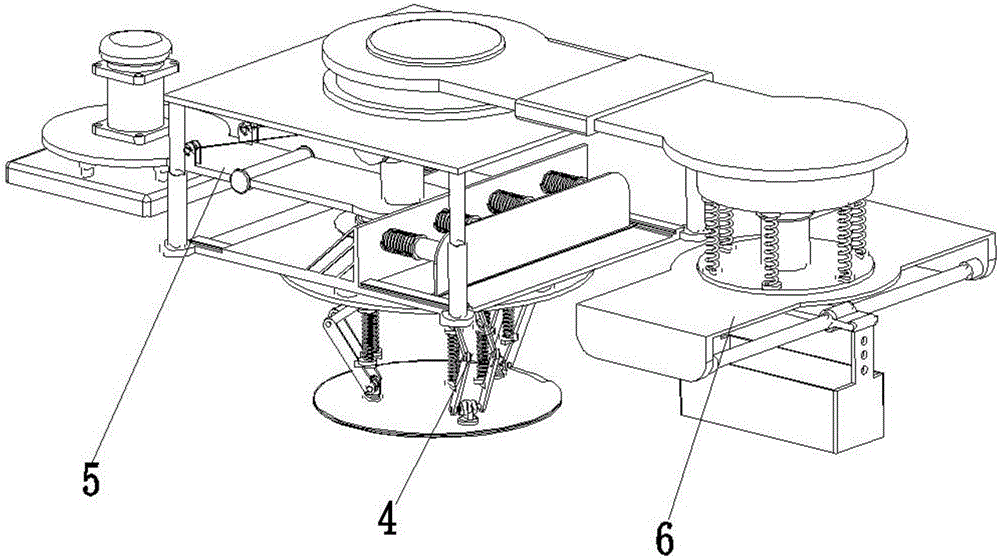

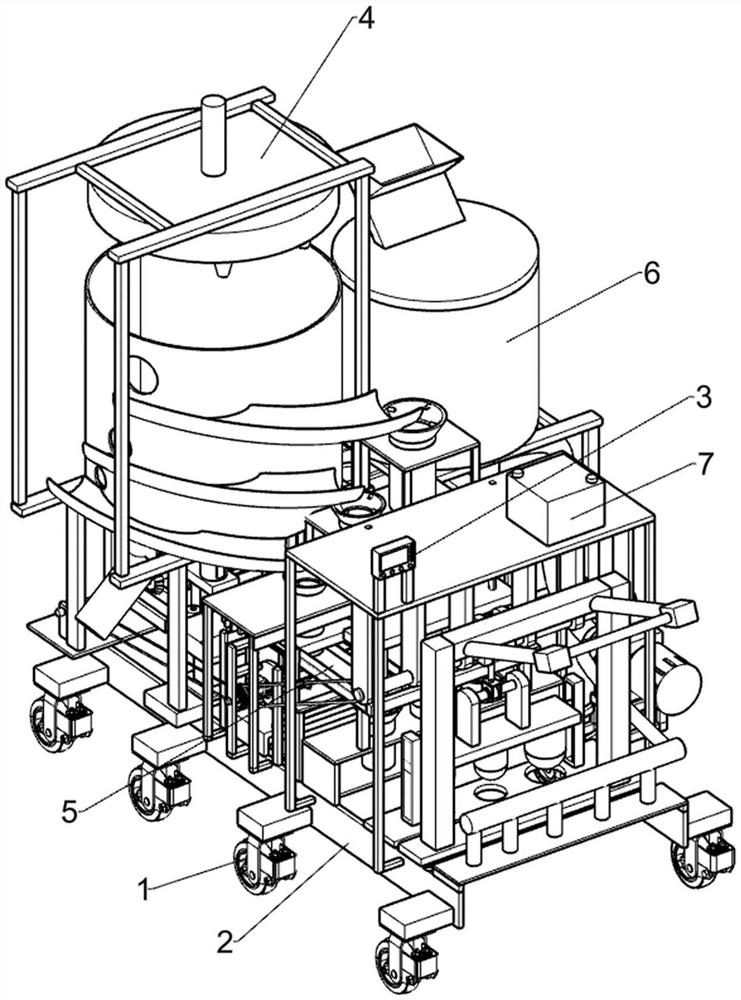

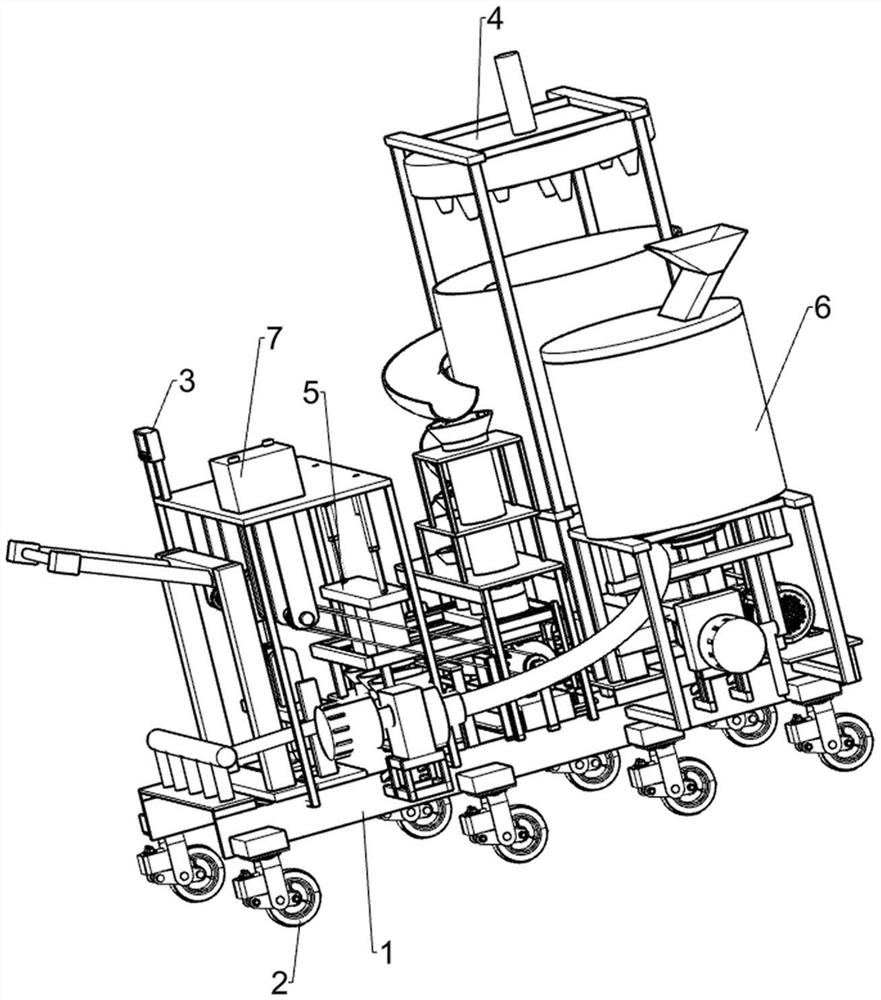

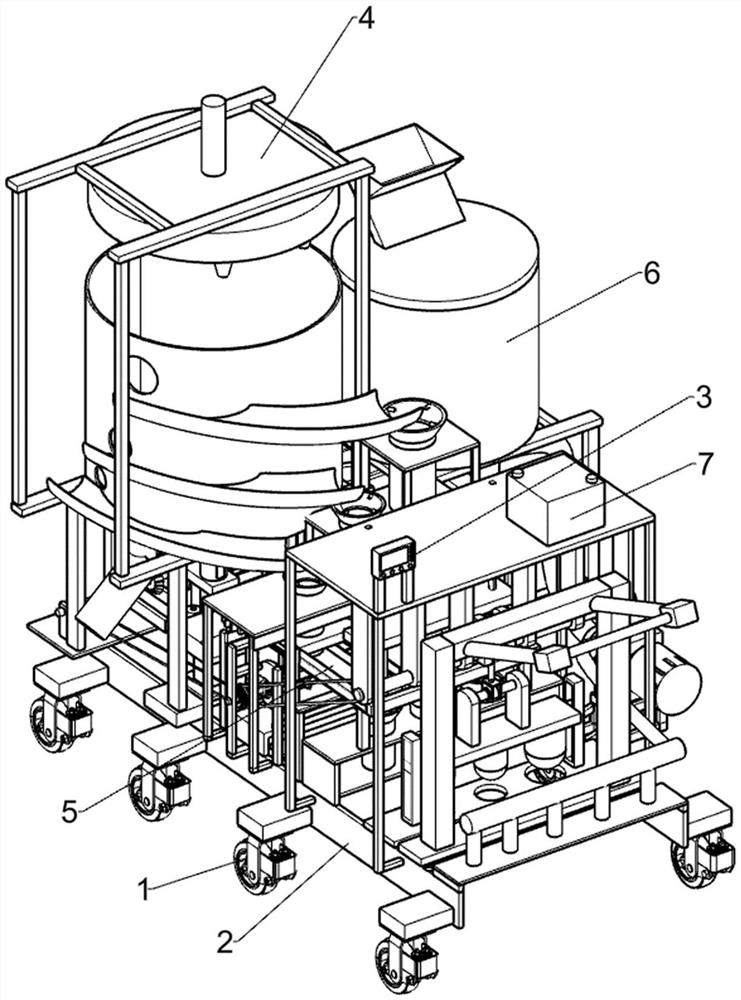

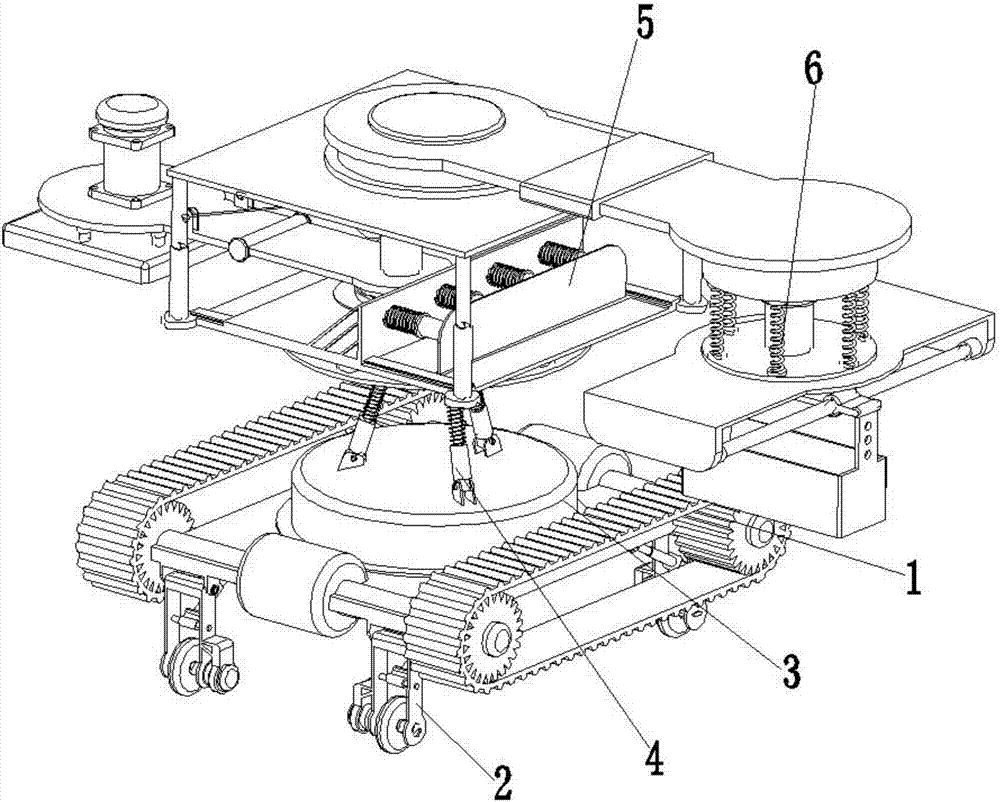

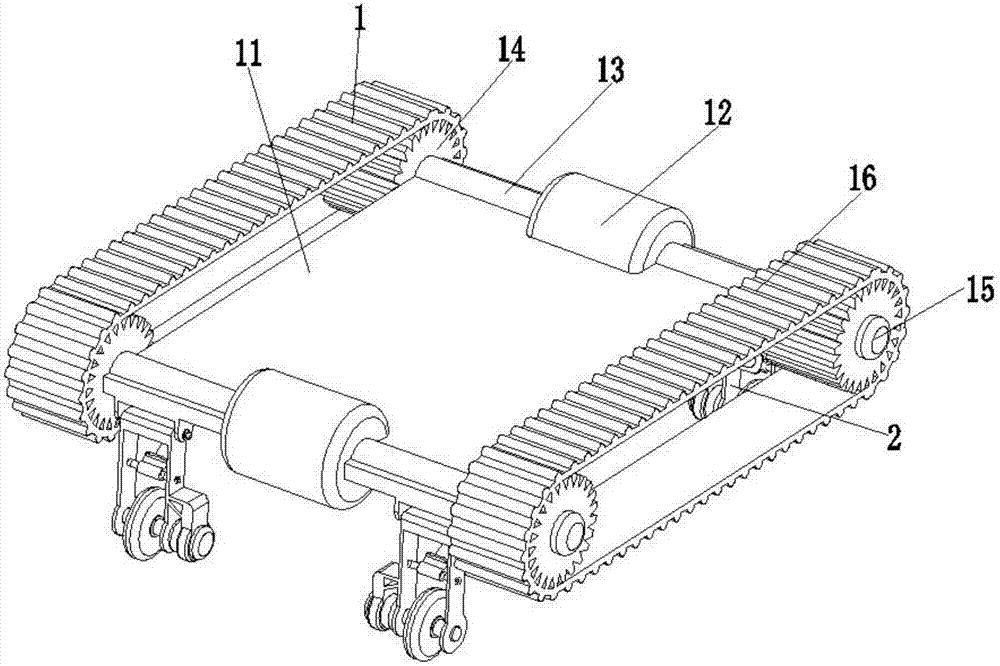

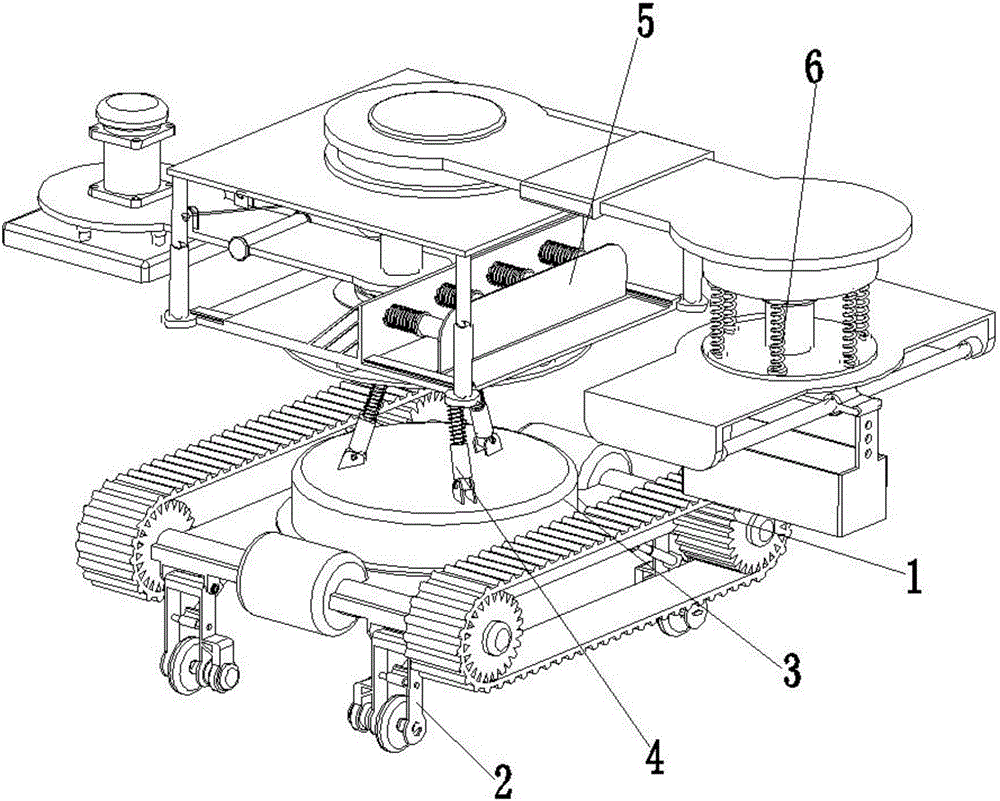

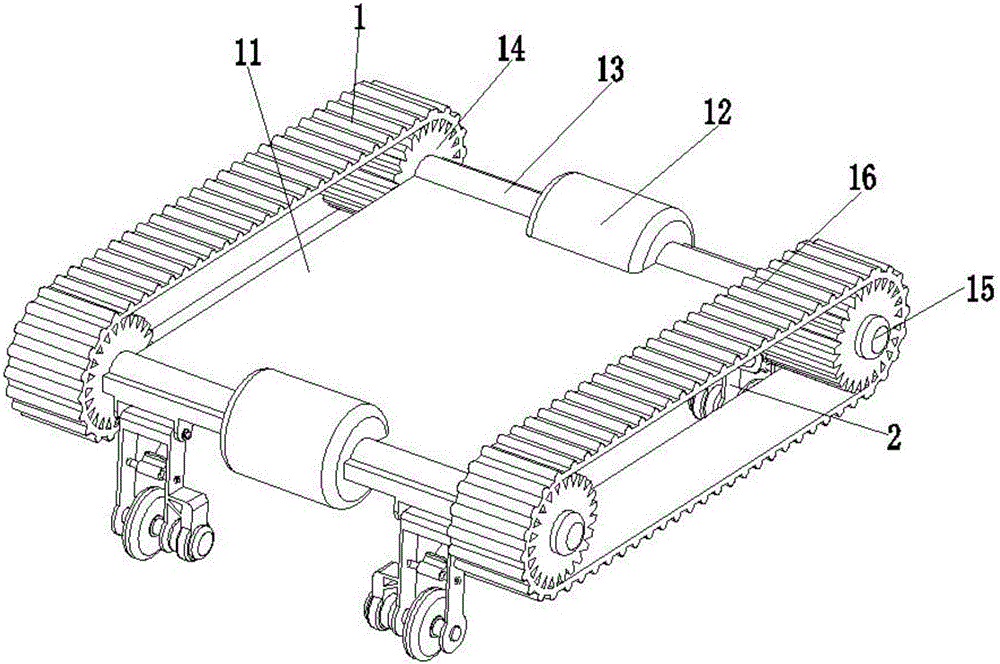

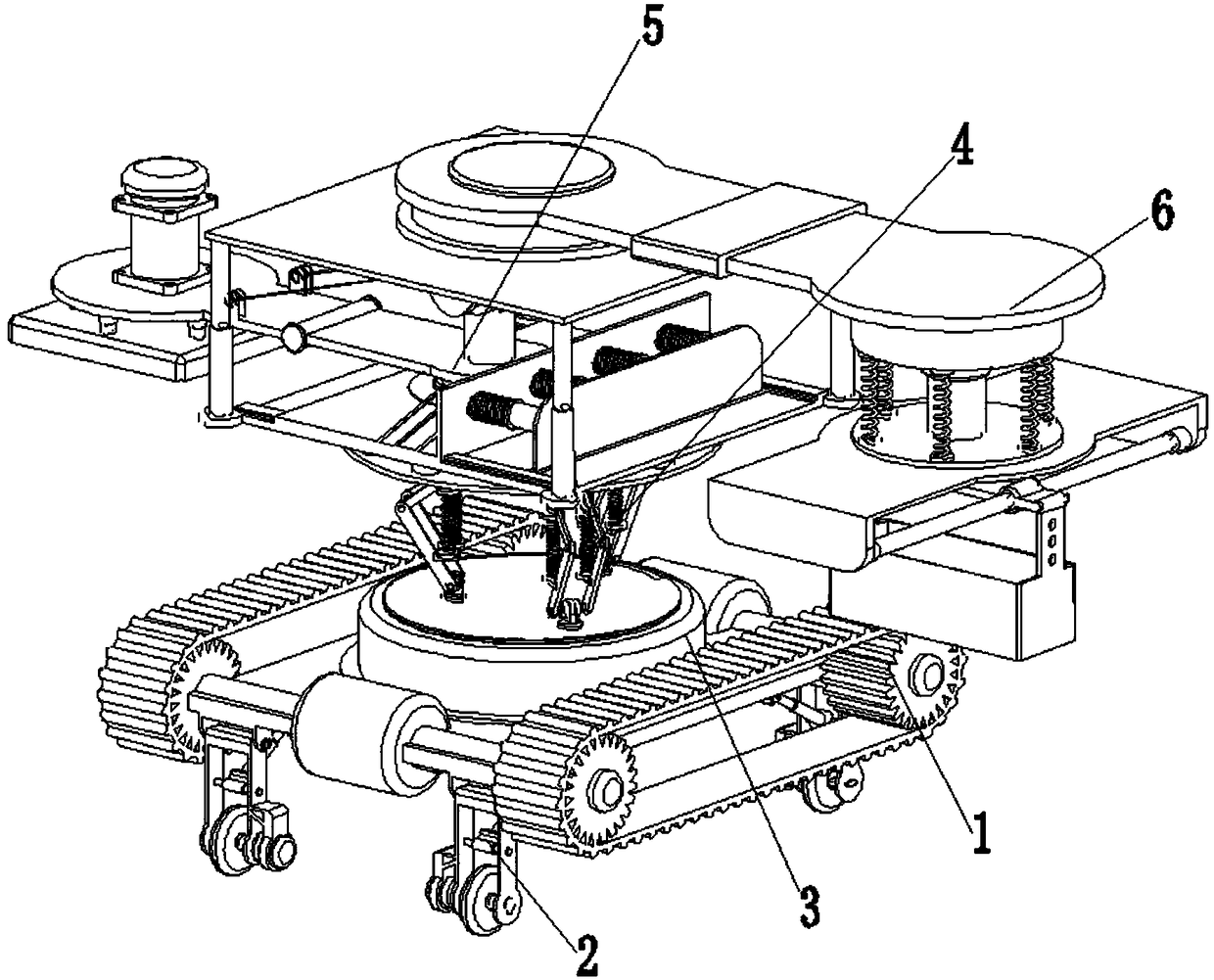

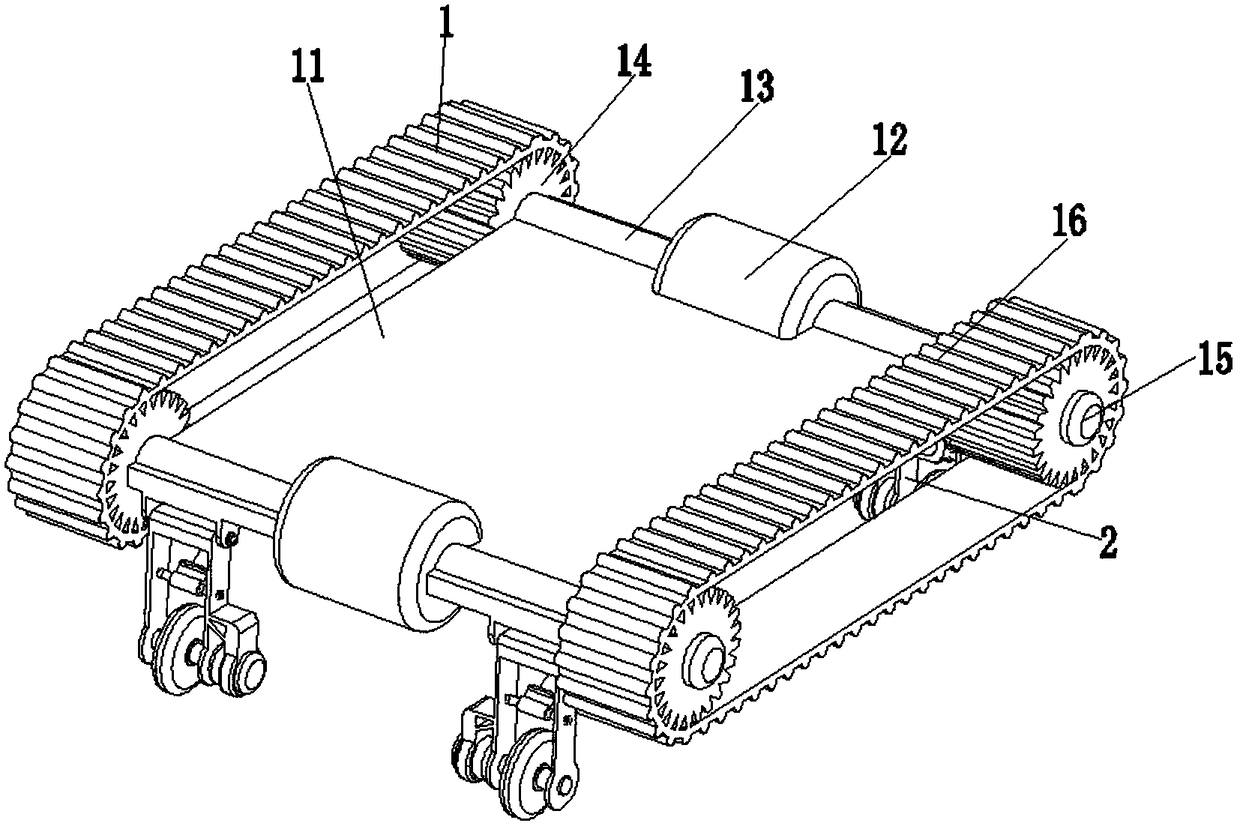

Full-automatic building indoor floor tile laying machine

ActiveCN105926912AHigh degree of automationLaying speed is fastBuilding constructionsBrickMulti degree of freedom

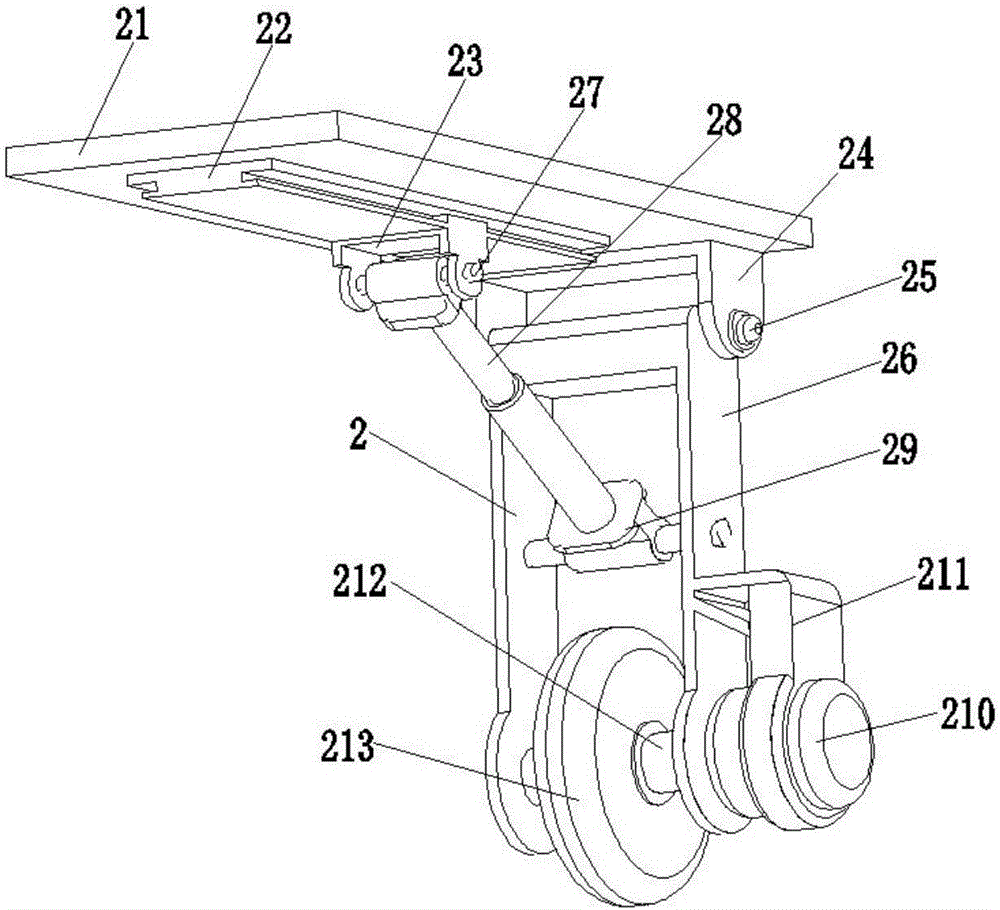

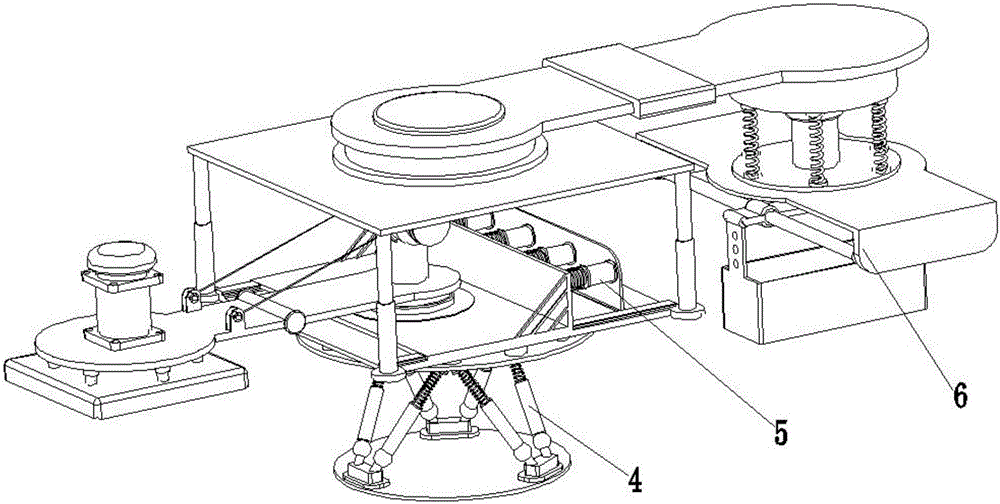

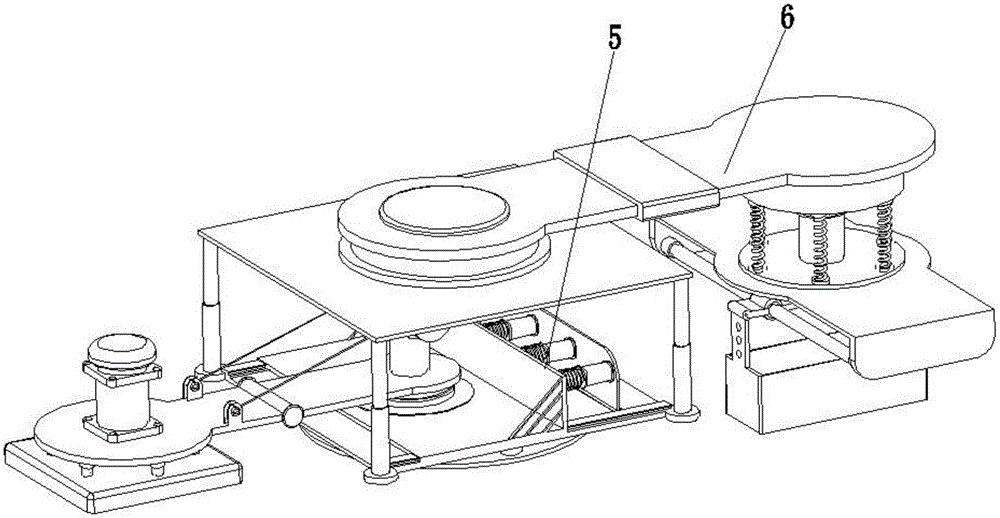

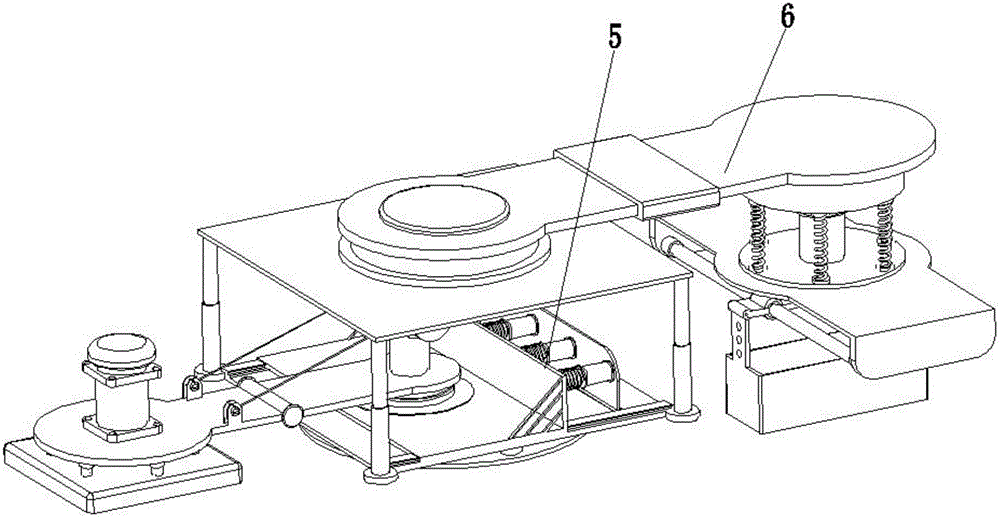

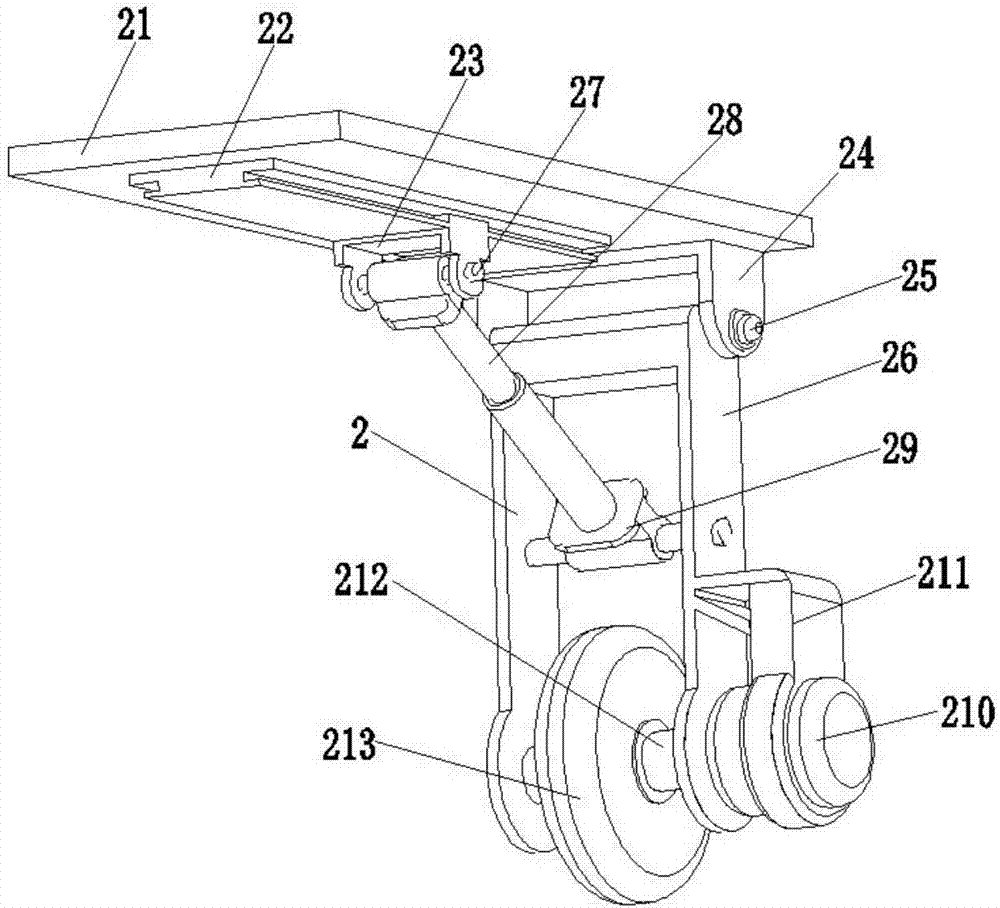

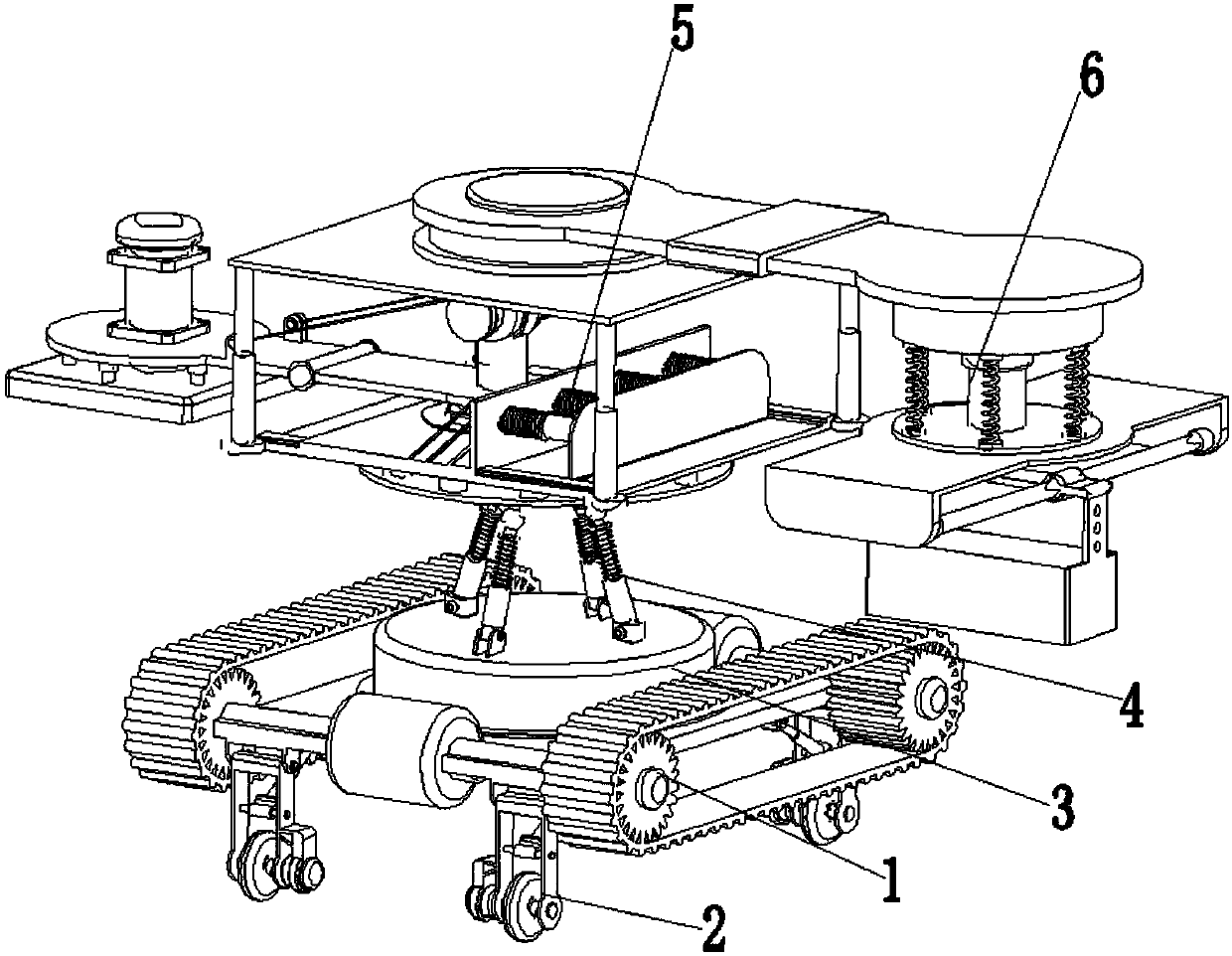

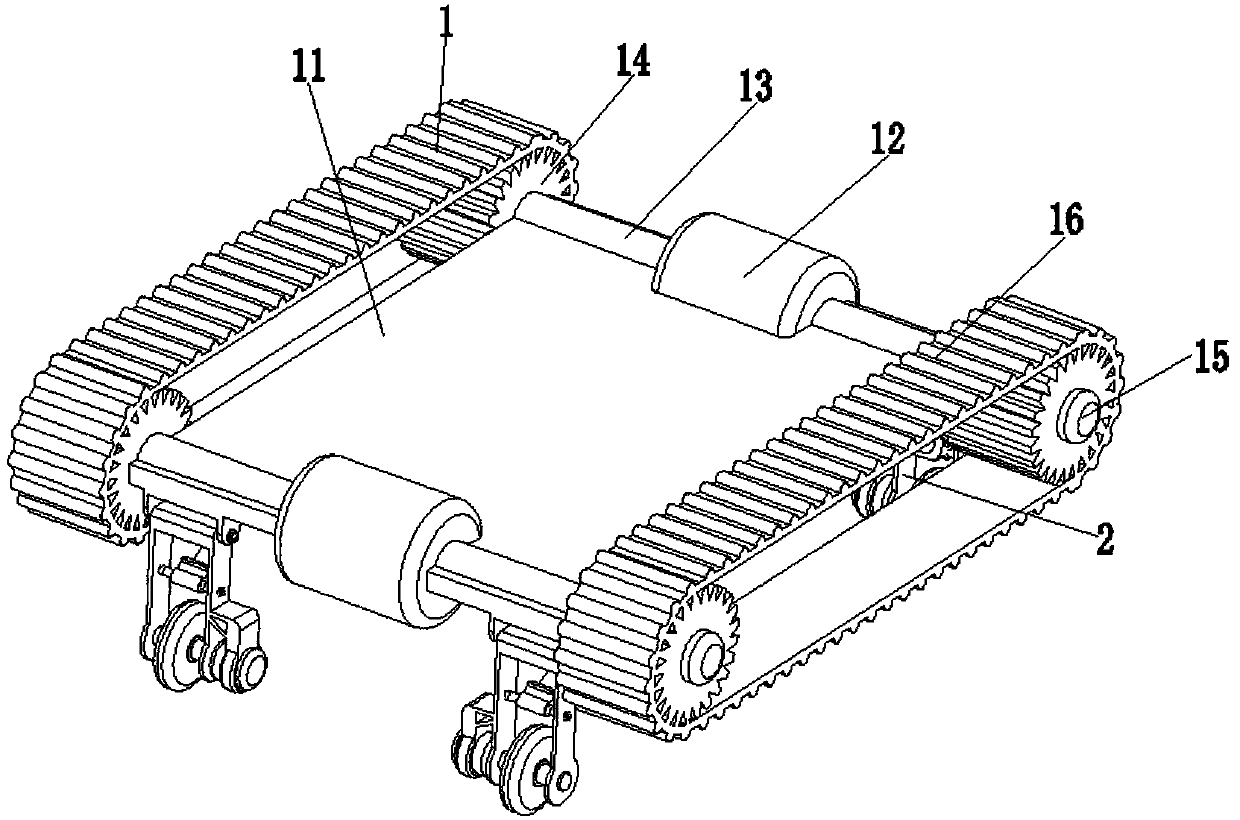

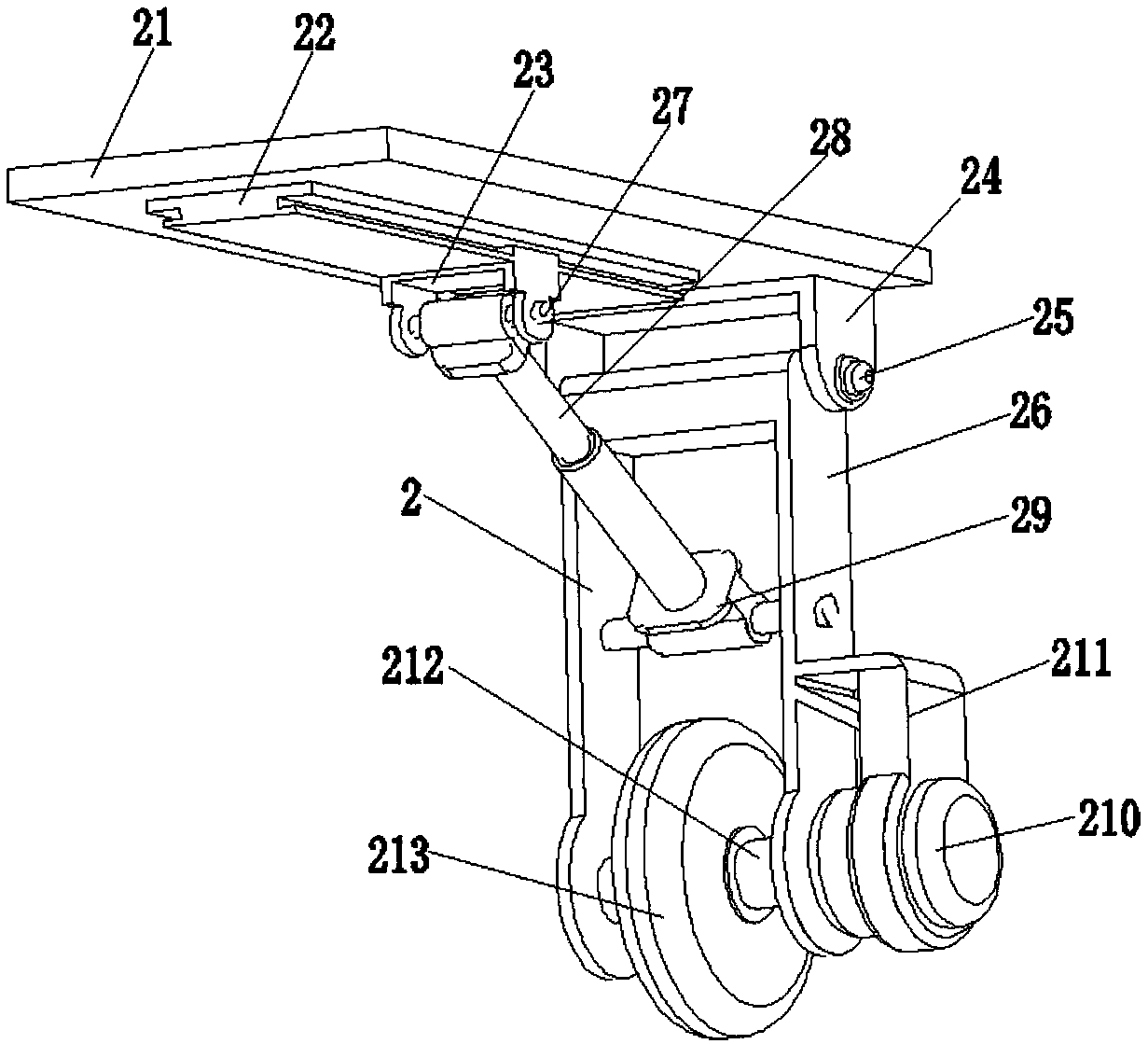

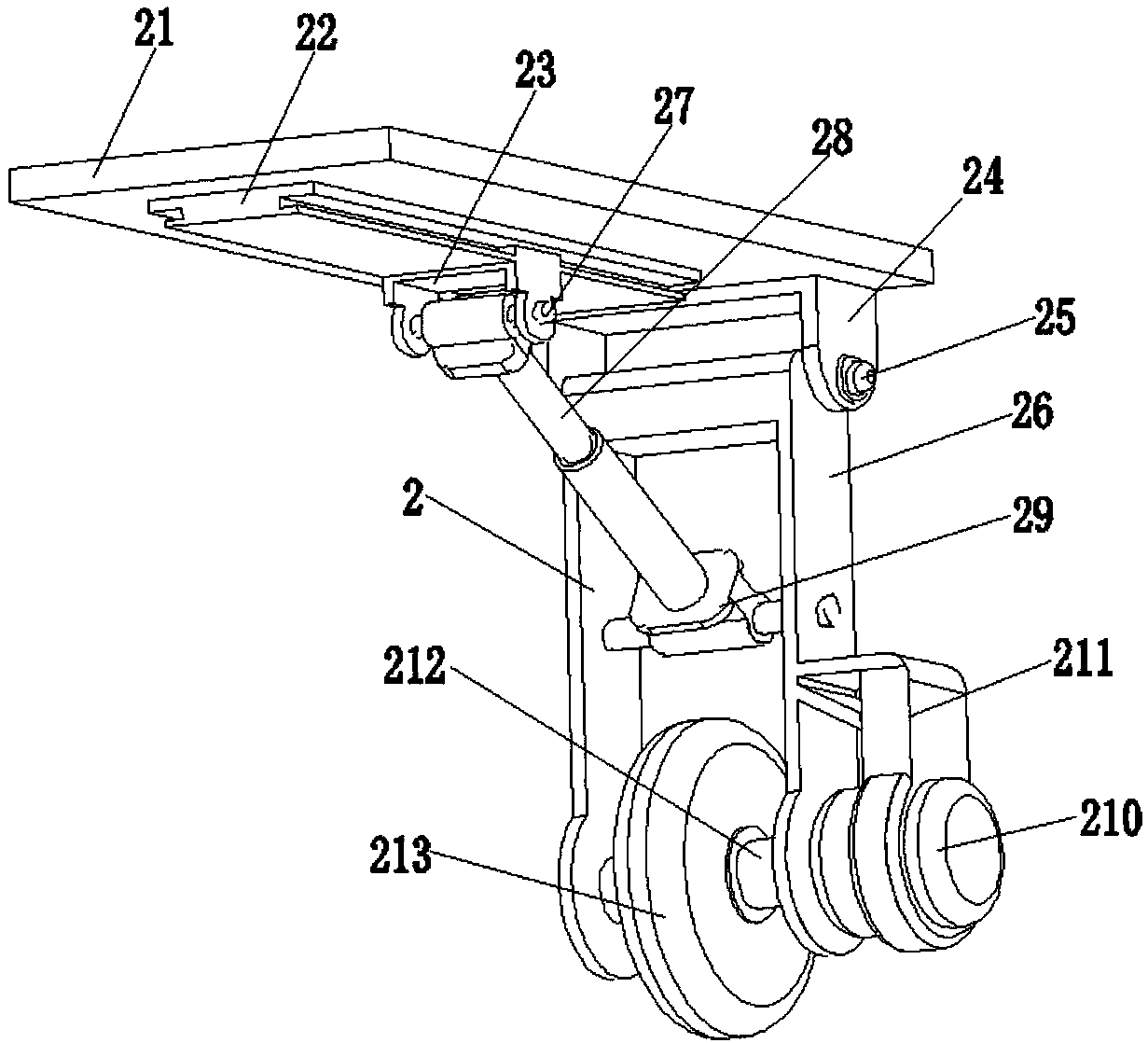

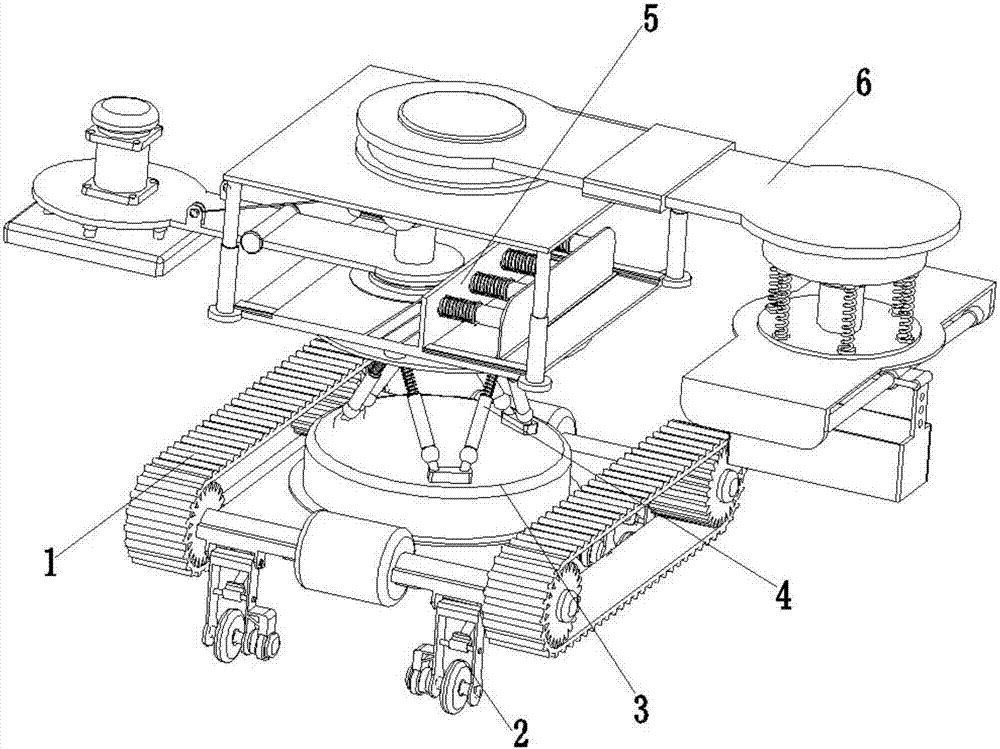

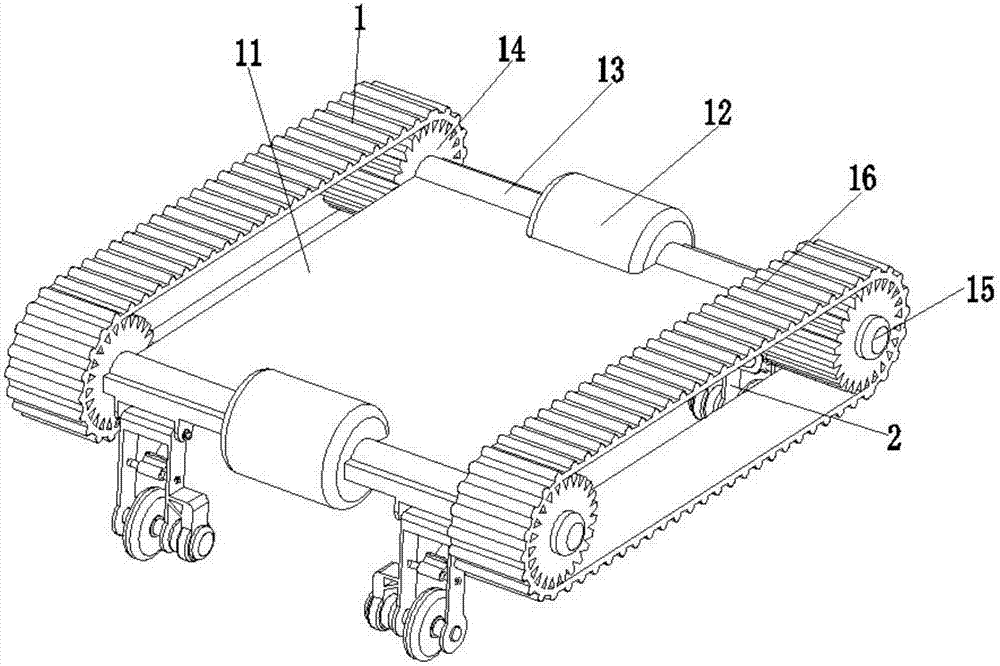

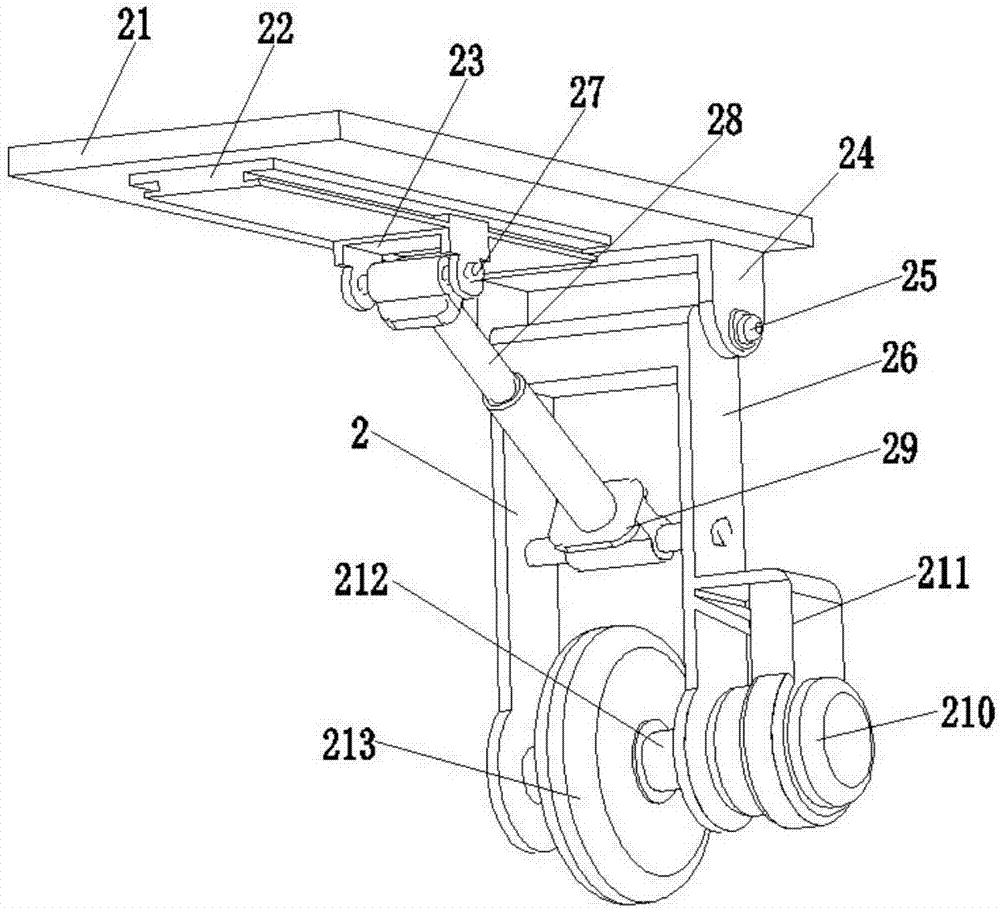

The invention relates to a full-automatic building indoor floor tile laying machine which comprises a crawler traveling device, wheeled traveling devices, an electric turntable, a redundancy parallelization mechanism, a suction device and a tile seam putty filling device. The wheeled traveling devices are symmetrically arranged on the left side and the right side of the crawler traveling device respectively, the electric turntable is positioned at the center of the upper end of the crawler traveling device and fixedly connected with the crawler traveling device, the redundancy parallelization mechanism is positioned between the electric turntable and the suction device, the lower end of the redundancy parallelization mechanism is connected with the electric turntable while the lower end of the same is connected with the suction device, and the tile seam putty filling device is positioned right above the suction device. The full-automatic building indoor floor tile laying machine integrates various functions of compound traveling, multi-degree-of-freedom direction adjusting, floor tile sucking and tile seam puffy filling fixing, can be used for laying floor tiles for municipal sidewalks and is high in automation level, laying speed and laying attractiveness, and the problem that existing floor tile laying is large in occupied space, low in laying efficiency and high in laying cost is solved.

Owner:重庆绿泰园林装饰工程有限公司

Garden greening floor tile construction intelligent equipment

The invention relates to garden greening floor tile construction intelligent equipment. The garden greening floor tile construction intelligent equipment comprises a crawler walking device, wheeled walking devices, an electric rotating platform, a hybrid mechanism, a suction device and a tile seam mud filling device. The wheeled walking devices are symmetrically arranged on the left side and the right side of the crawler walking device correspondingly. The electric rotating platform is located in the center of the upper end of the crawler walking device and fixedly connected with the crawler walking device. The hybrid mechanism is located between the electric rotating platform and the suction device. The lower end of the hybrid mechanism is connected with the electric rotating platform. The upper end of the hybrid mechanism is connected with the suction device. The tile seam mud filling device is located over the suction device. According to the garden greening floor tile construction intelligent equipment, the multiple functions of composite walking, multi-freedom-degree direction adjustment, floor tile suction, tile seam mud filling fixing and the like are integrated, and thus floor tile laying operation can be conducted on municipal sidewalks; and in addition, the automation degree is high, the laying speed is high, and the laying aesthetics is good, so that the problems that existing floor tile laying is large in occupied labor force, low in laying efficiency, large in laying cost and the like are solved.

Owner:徐鹏

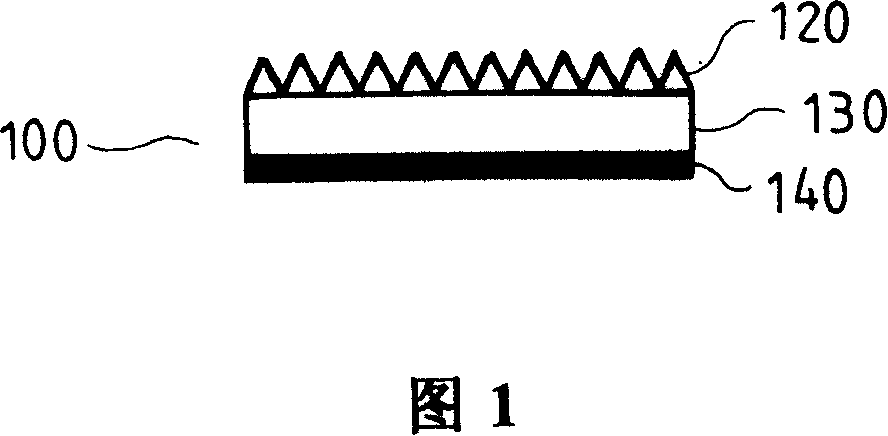

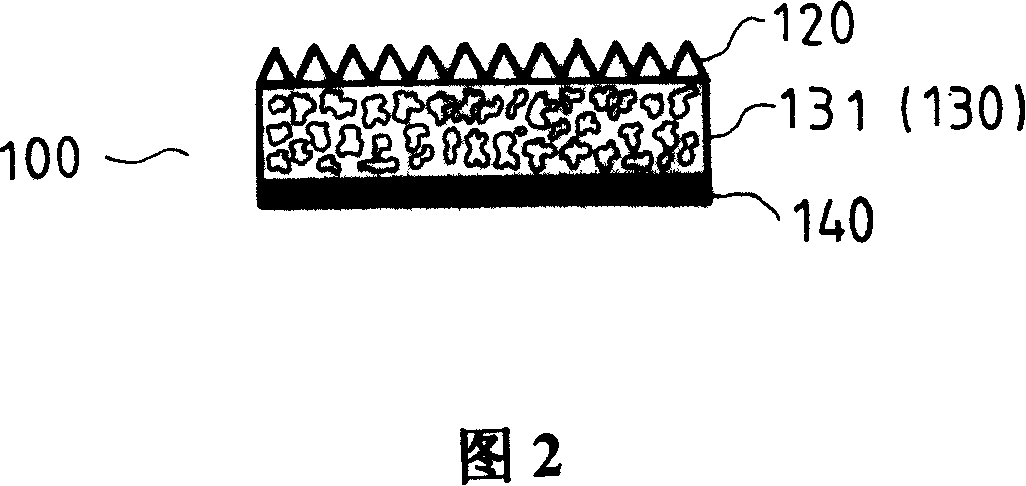

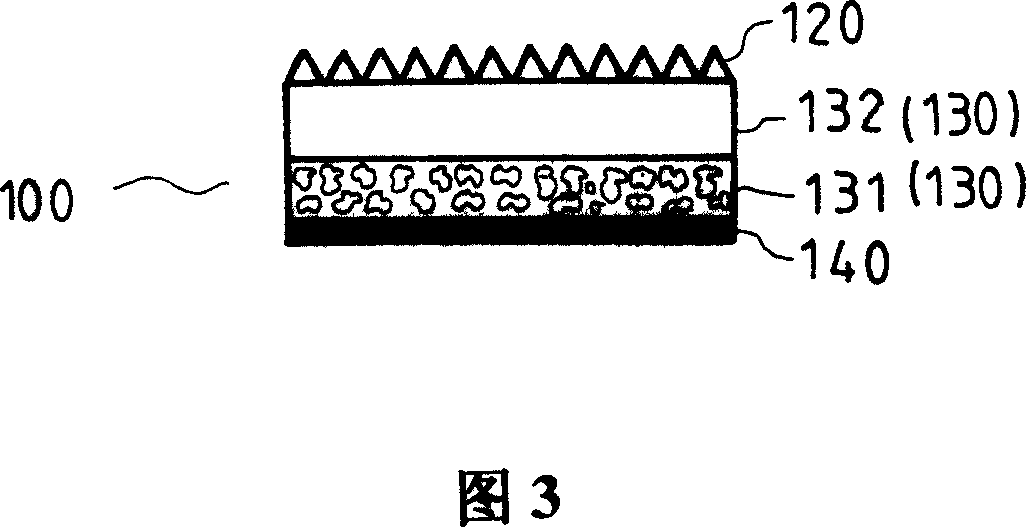

Material for covering outside of deivce and manufacturing method thereof

InactiveCN101048043AAchieve waterproofAchieve crack resistanceSynthetic resin layered productsLaminationEngineeringSurface layer

The invention relates to one kind of coating material and its manufacturing method. The manufacturing method is that: it covers PU fabric layer on the detachable base-paper, after its drying, and then it covers PU bottom layer. After drying, coiling and cooking, it detaches the detachable base-paper off to achieve the PU covering material with colorful texture. In the invention, the surface layer with at least one colorful texture layer and the PU basal layer can be used for covering electronic products, which can increases users' good feeling for electronic products.

Owner:SAN FANG CHEM IND

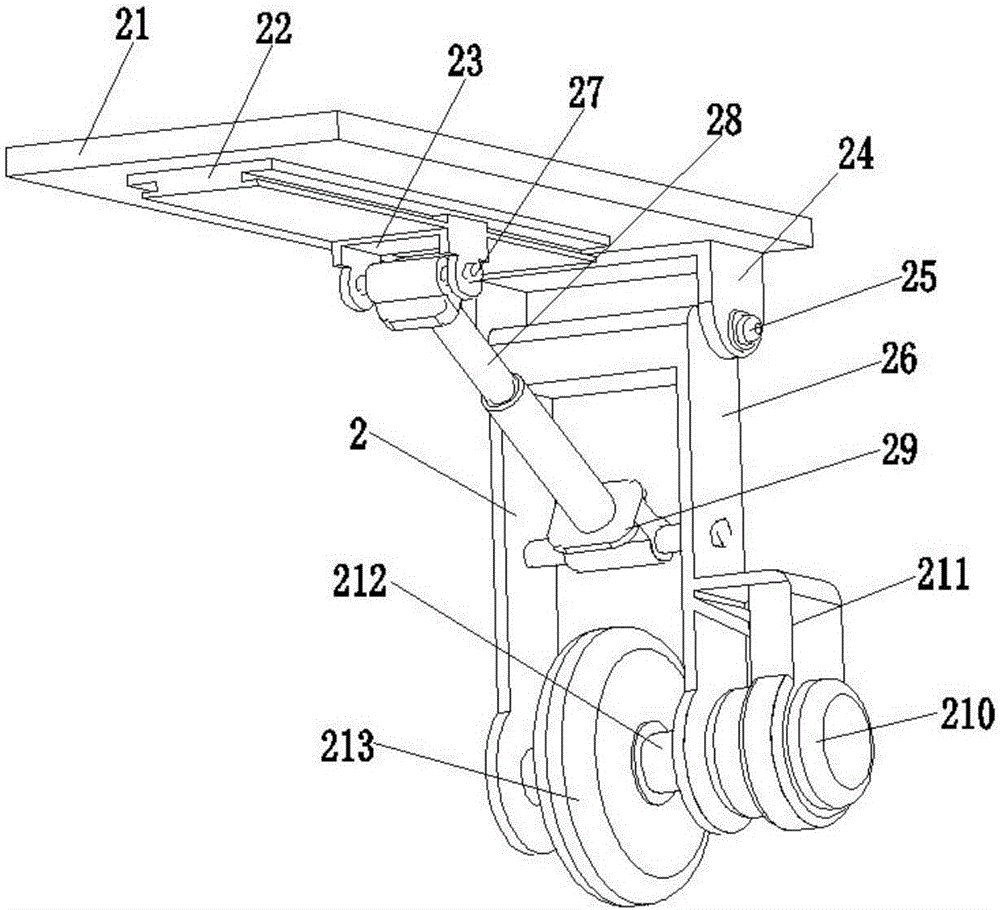

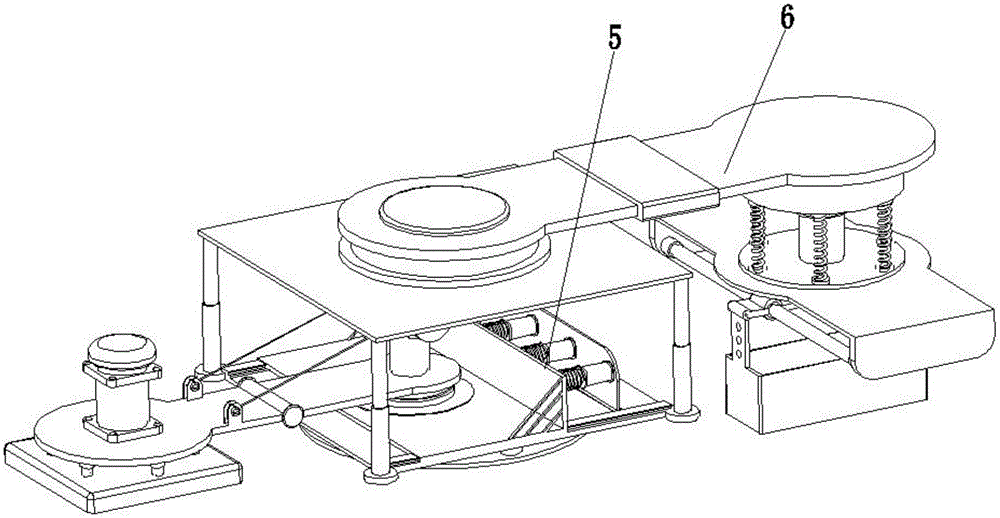

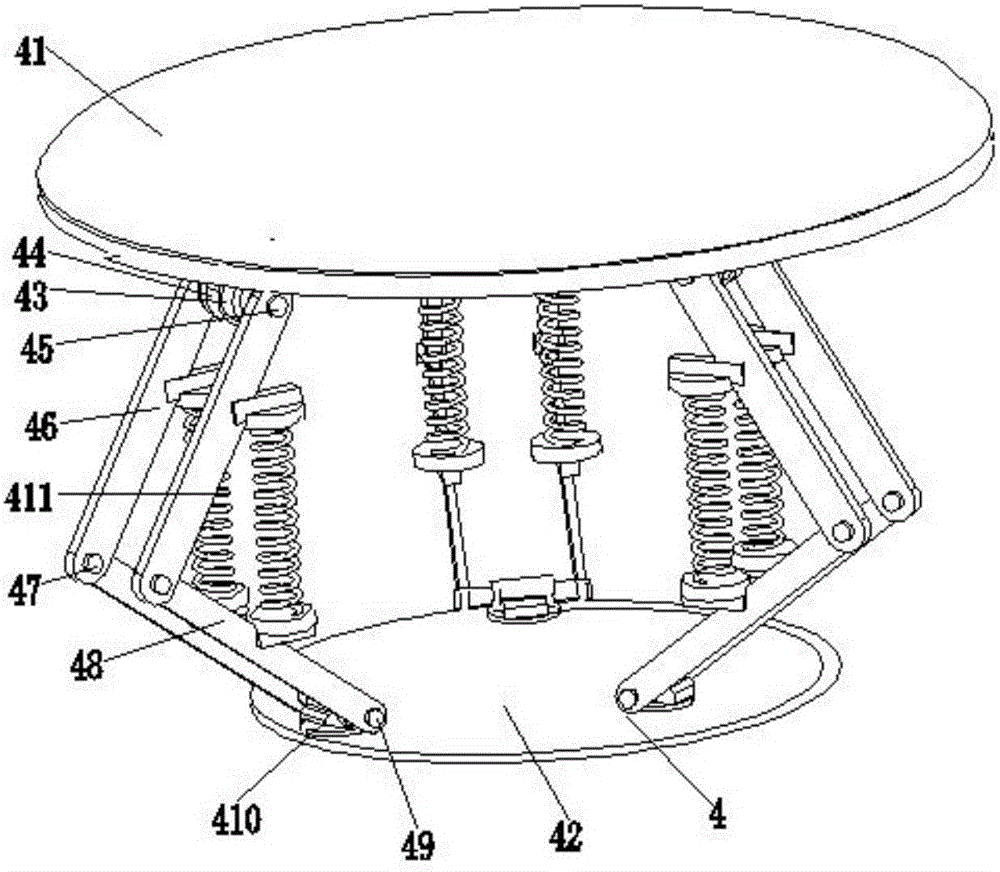

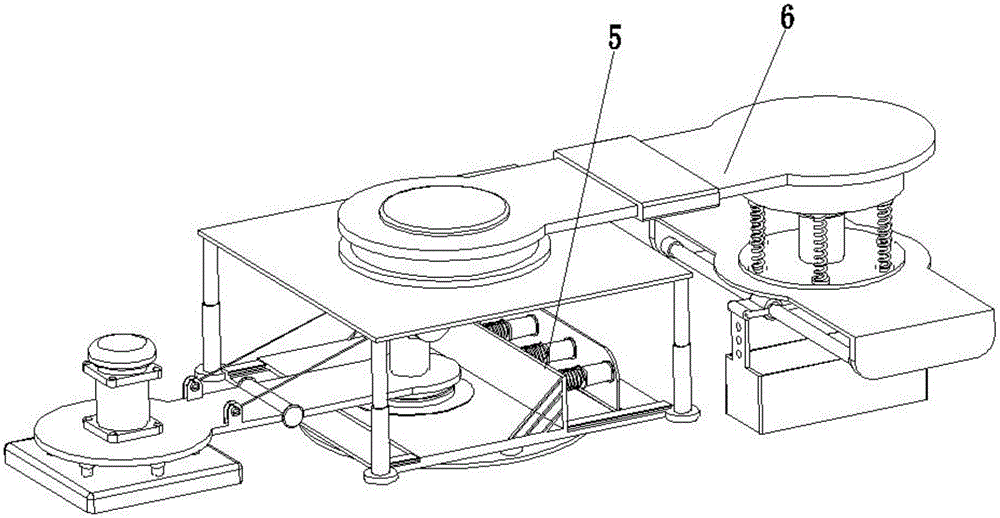

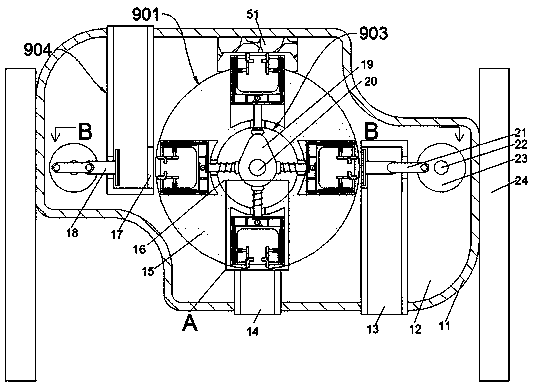

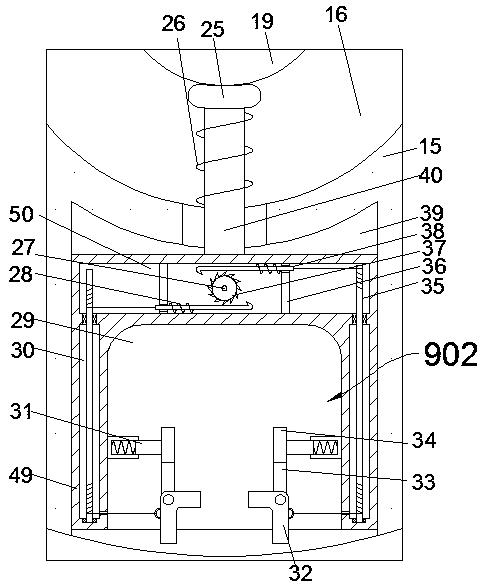

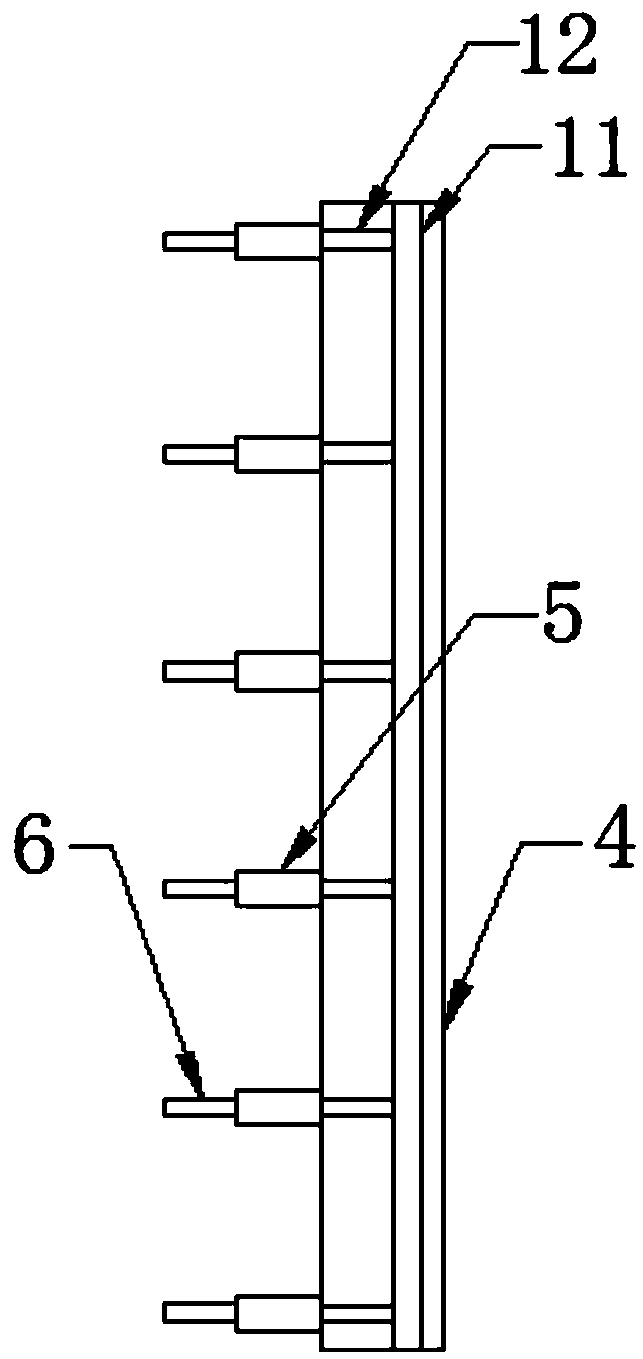

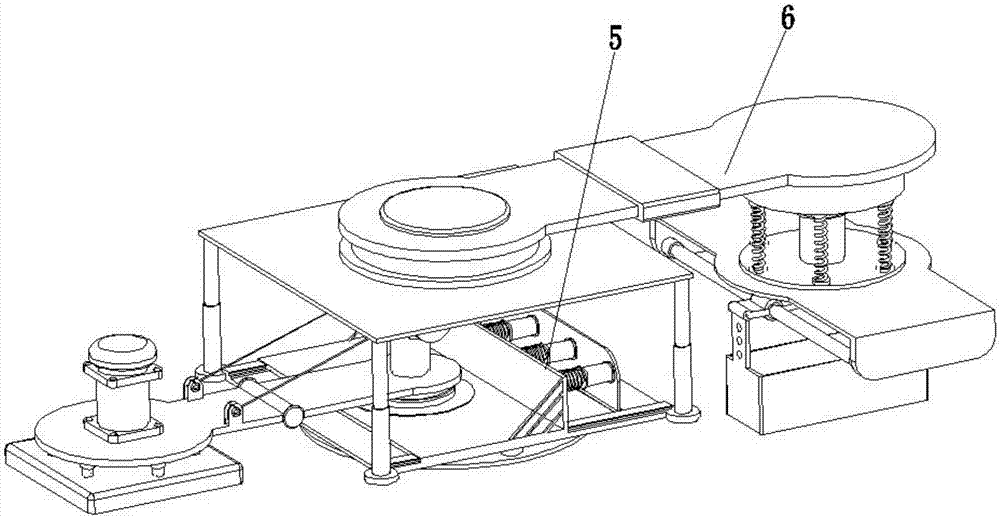

Full-automatic actuating device of building indoor floor tile laying machine

ActiveCN106121206AHigh degree of automationLaying speed is fastBuilding constructionsMulti degree of freedomMultiple function

The invention relates to a full-automatic actuating device of a building indoor floor tile laying machine. The full-automatic actuating device comprises a redundant parallel mechanism, a sucking device and a tile joint mud filling device. The redundant parallel mechanism is located under the sucking device, and the upper end of the redundant parallel mechanism is connected with the sucking device. The tile joint mud filling device is located over the sucking device. According to the full-automatic actuating device, multiple functions of multi-degree-of-freedom direction adjusting, floor tile sucking, tile joint mud filling and fixing and the like are integrated, floor tile laying operation can be conducted on municipal pavements, the automation degree is high, the laying speed is high, the laying aesthetic degree is high, and the problems that according to an existing floor tile laying mode, the occupied labor amount is large, the laying efficiency is low, and the laying cost is high are solved.

Owner:HUNAN INST OF TECH

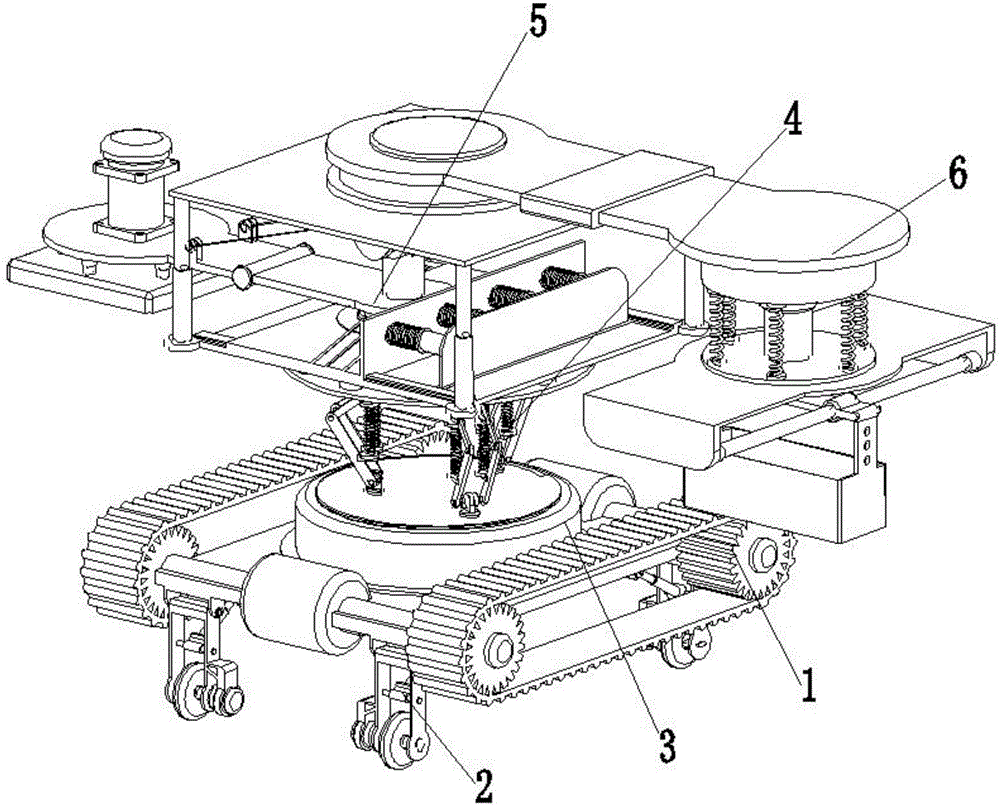

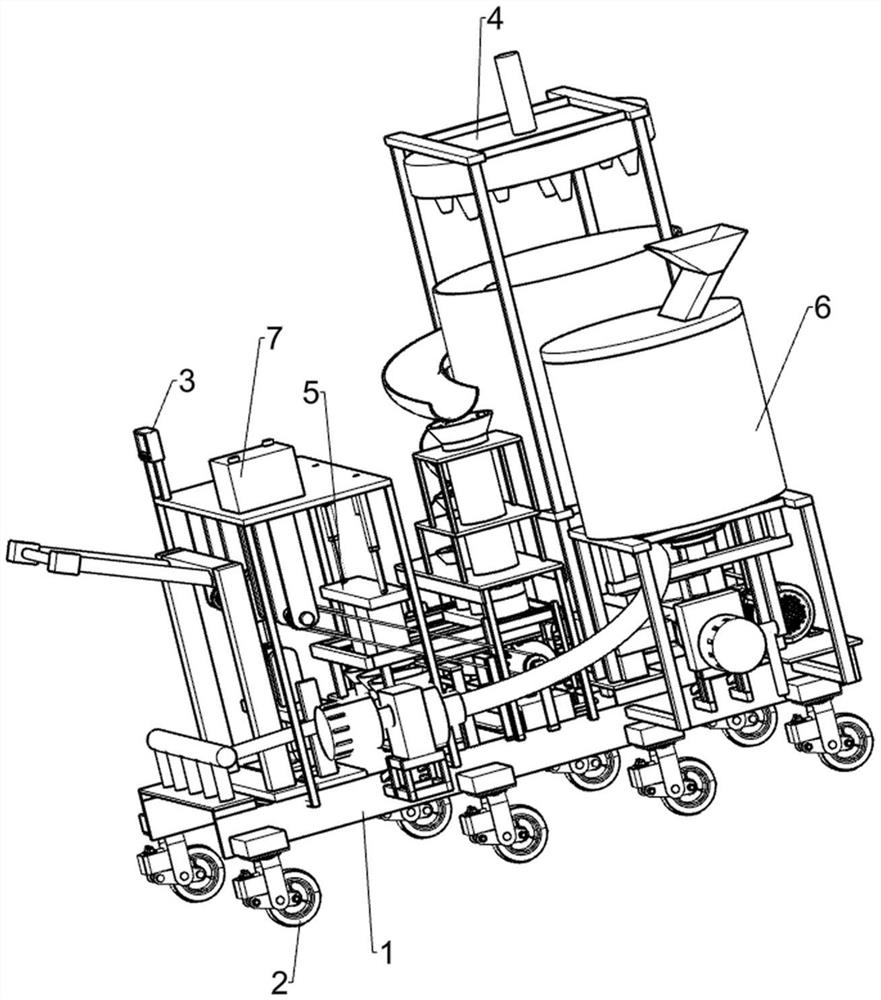

Robot for pavement floor tile laying work

ActiveCN106087672AHigh degree of automationLaying speed is fastProgramme-controlled manipulatorRoads maintainenceMulti degree of freedomAutomation

The invention relates to a robot for pavement floor tile laying work. The robot for pavement floor tile laying work comprises a crawler traveling device, wheel type traveling devices, an electric rotary table, a delta parallel mechanism, a suction device and a tile joint mud filling device. The wheel type traveling devices are symmetrically arranged on the left side and the right side of the crawler traveling device correspondingly. The electric rotary table is located in the center of the upper end of the crawler traveling device. The delta parallel mechanism is located between the electric rotary table and the suction device. The lower end of the delta parallel mechanism is connected with the electric rotary table, and the upper end of the delta parallel mechanism is connected with the suction device. The tile joint mud filling device is located over the suction device. The robot integrates various functions such as a combined traveling function, a multi-degree-of-freedom direction adjustment function, a floor tile suction function and a tile joint mud filling and fixing function, can be used for floor tile laying of municipal pavements, and is high in automation degree and laying speed and good in laying attractiveness, and the problems that in the prior art, labor consumption of floor tile laying is high, the laying efficiency is low, and the laying cost is high are solved.

Owner:陈雅婷

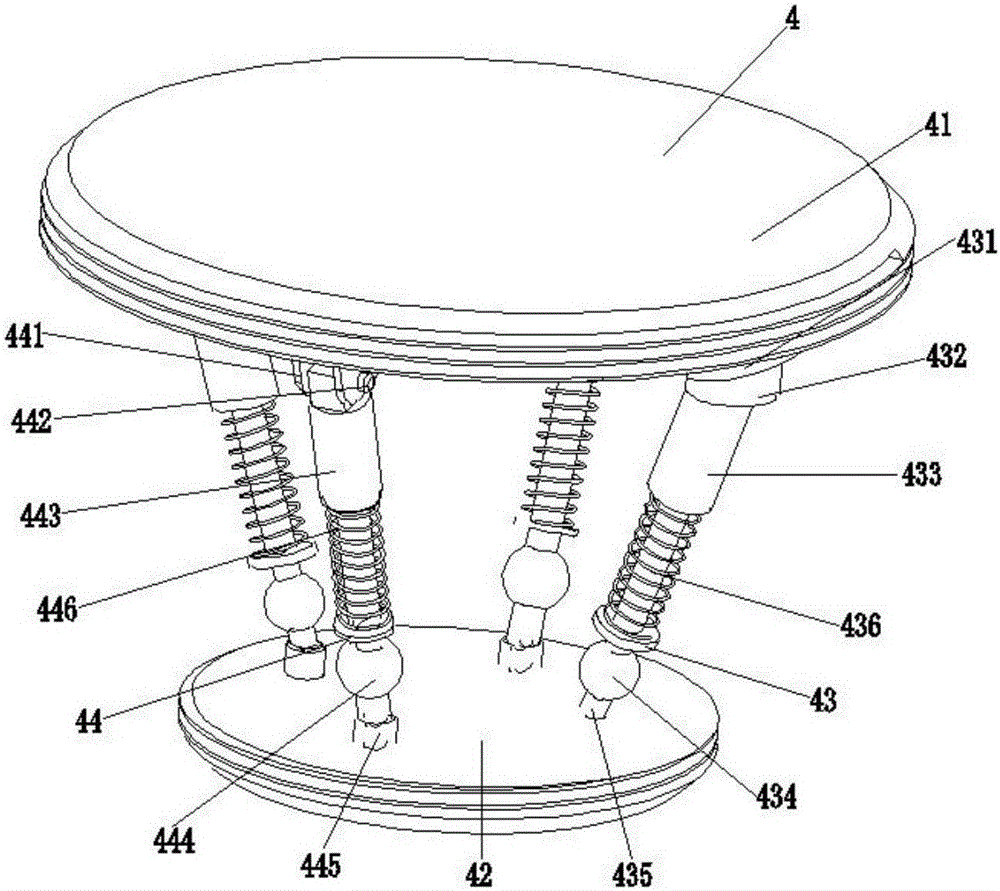

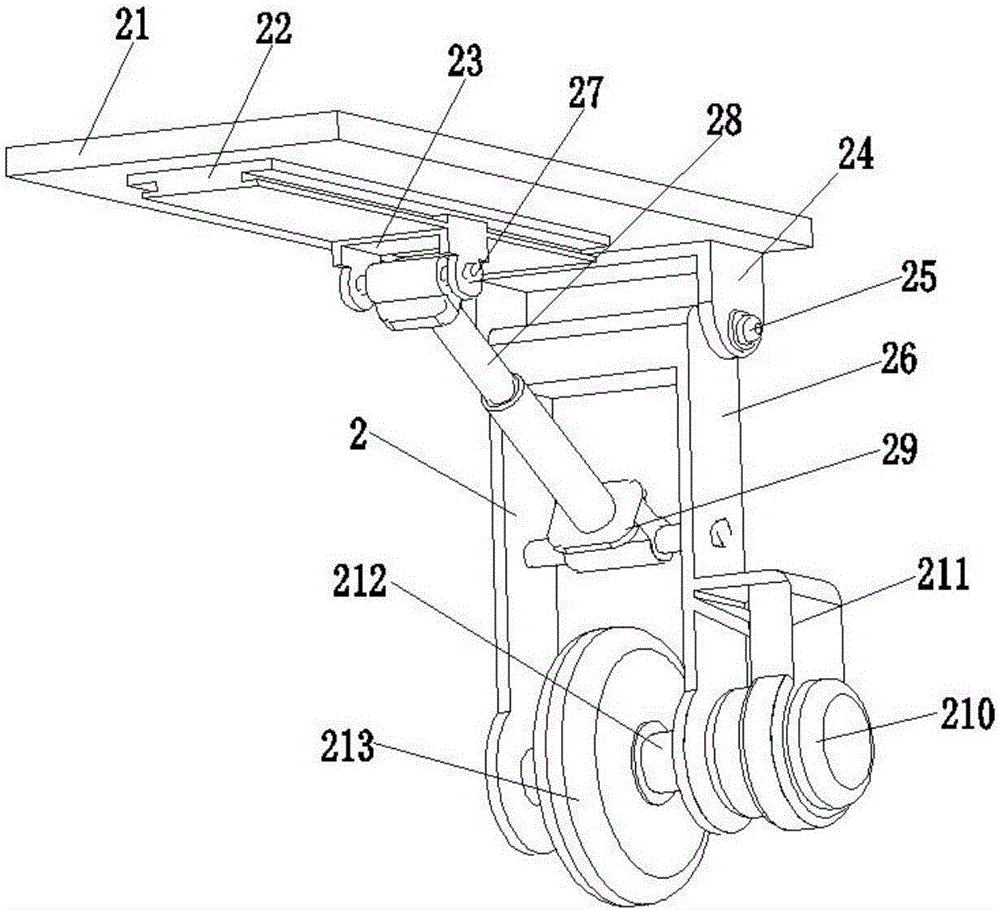

Robot for laying floor tiles on urban municipal sidewalks

ActiveCN106087673AHigh degree of automationLaying speed is fastRoads maintainenceBrickMulti degree of freedom

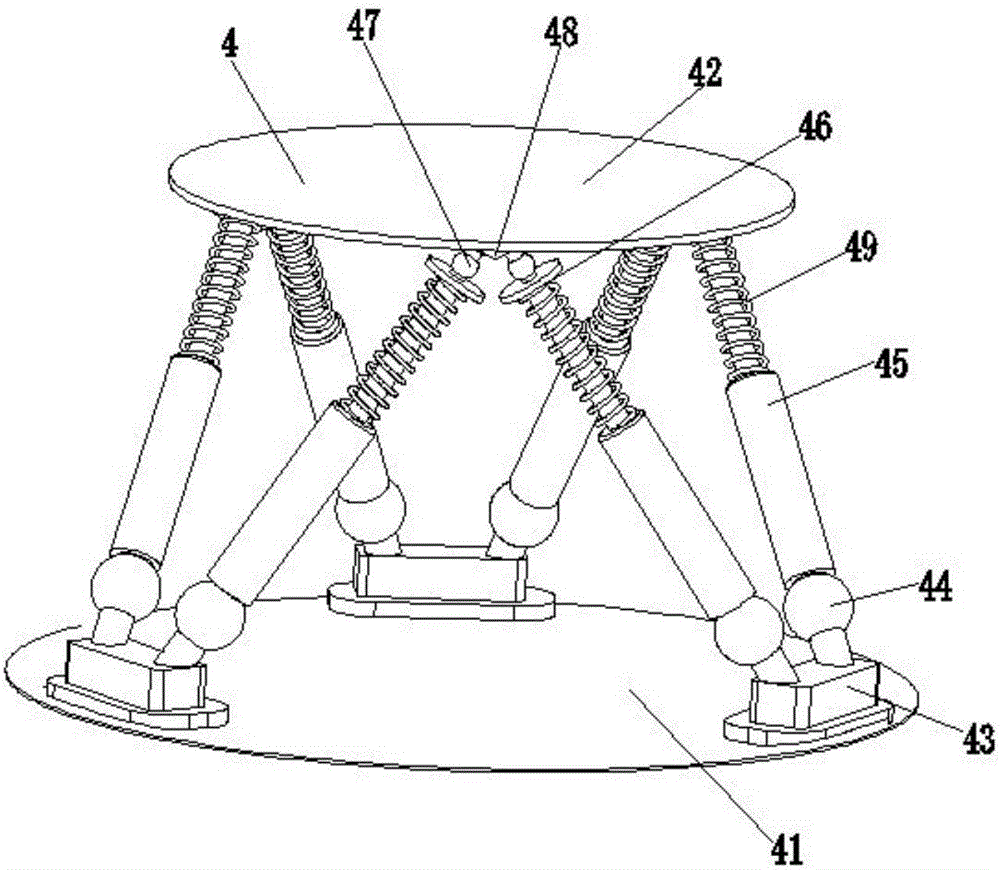

The invention relates to a robot for laying floor tiles on urban municipal sidewalks. The robot comprises a crawler traveling device, wheel type traveling devices, an electric rotary table, a Stewart parallel mechanism, a suction device and a tile joint mud filling device. The wheel type traveling devices are symmetrically arranged on the left side and the right side of the crawler traveling device correspondingly. The electric rotary table is located in the center of the upper end of the crawler traveling device. The lower end of the Stewart parallel mechanism is connected with the electric rotary table, and the upper end of the Stewart parallel mechanism is connected with the suction device. The tile joint mud filling device is located over the suction device. The robot integrates various functions such as a combined traveling function, a multi-degree-of-freedom direction adjustment function, a floor tile suction function and a tile joint mud filling and fixing function, can be used for laying the floor tiles on the urban municipal sidewalks, and is high in automation degree and laying speed and good in laying attractiveness, and the problems that in the prior art, labor consumption of floor tile laying is high, the laying efficiency is low, and the laying cost is high are solved.

Owner:华赣城建集团股份有限公司

Laying device for laying operation robot for floor tiles of road surface

ActiveCN106120522AHigh degree of automationLaying speed is fastRoads maintainenceEngineeringMultiple function

The invention relates to a laying operation robot for floor tiles of a road surface. The laying operation robot comprises a crawler walking mechanism, wheel type walking devices, an electric rotary table, a delta parallel connection mechanism, a drawing and picking device and a device for filling brick cracks with cement, wherein the wheel type walking devices are separately and symmetrically arranged on the left side and the right side of the crawler walking mechanism; the electric rotary table is positioned in a central position of the upper end of the crawler walking mechanism; the delta parallel connection mechanism is positioned between the electric rotary table and the drawing and picking device, and the lower end of the delta parallel connection mechanism is connected with the electric rotary table; the upper end of the delta parallel connection mechanism is connected with the drawing and picking device; and the device for filling brick cracks with cement is positioned directly over the drawing and picking device. According to the laying device disclosed by the invention, multiple functions of compositely walking, adjusting multi-freedom degree directions, drawing and picking floor tiles, filling the brick cracks with cement and fixing, and the like are integrated, floor tile paving operation can be performed on the urban municipal sidewalk, the laying operation robot disclosed by the invention is high in automation degree, high in paving speed, and good in paving appearance degree, and problems that conventional floor tile paving is high in occupied labor, low in paving efficiency, large in paving cost and the like are solved.

Owner:安徽祺瑞建设工程有限公司

Granular arabinose as well as preparation method and application thereof

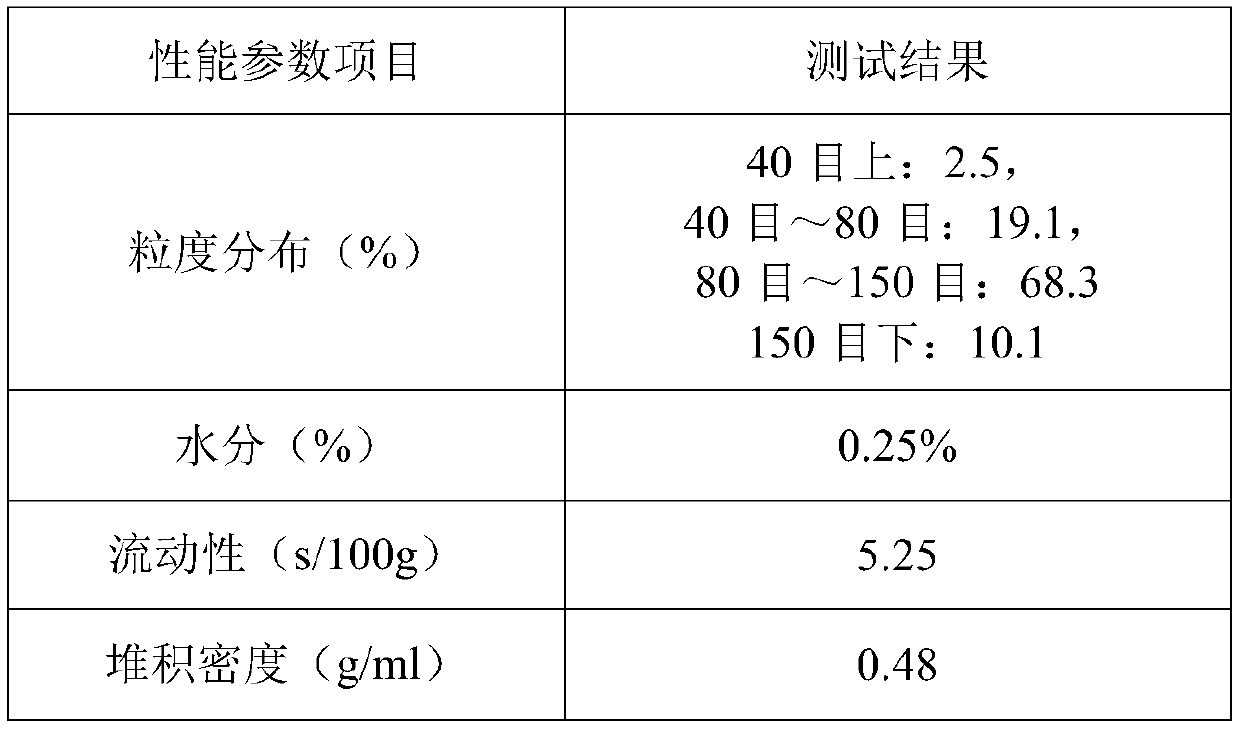

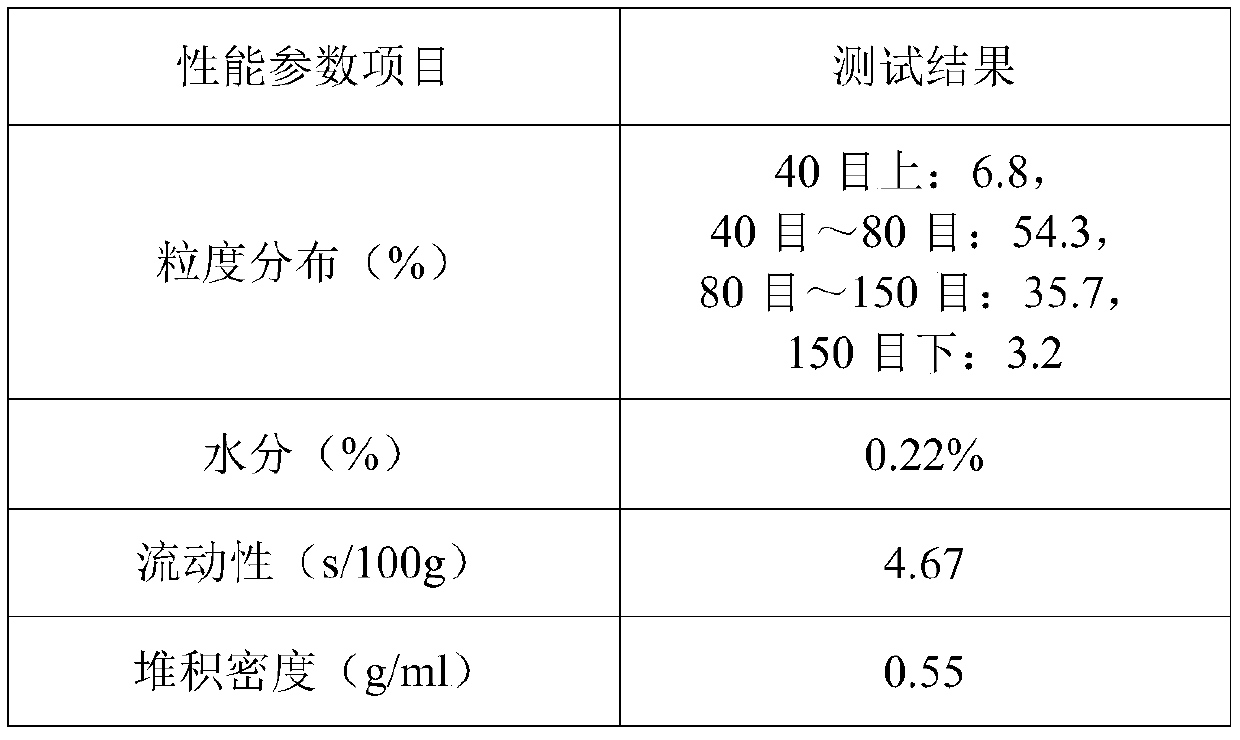

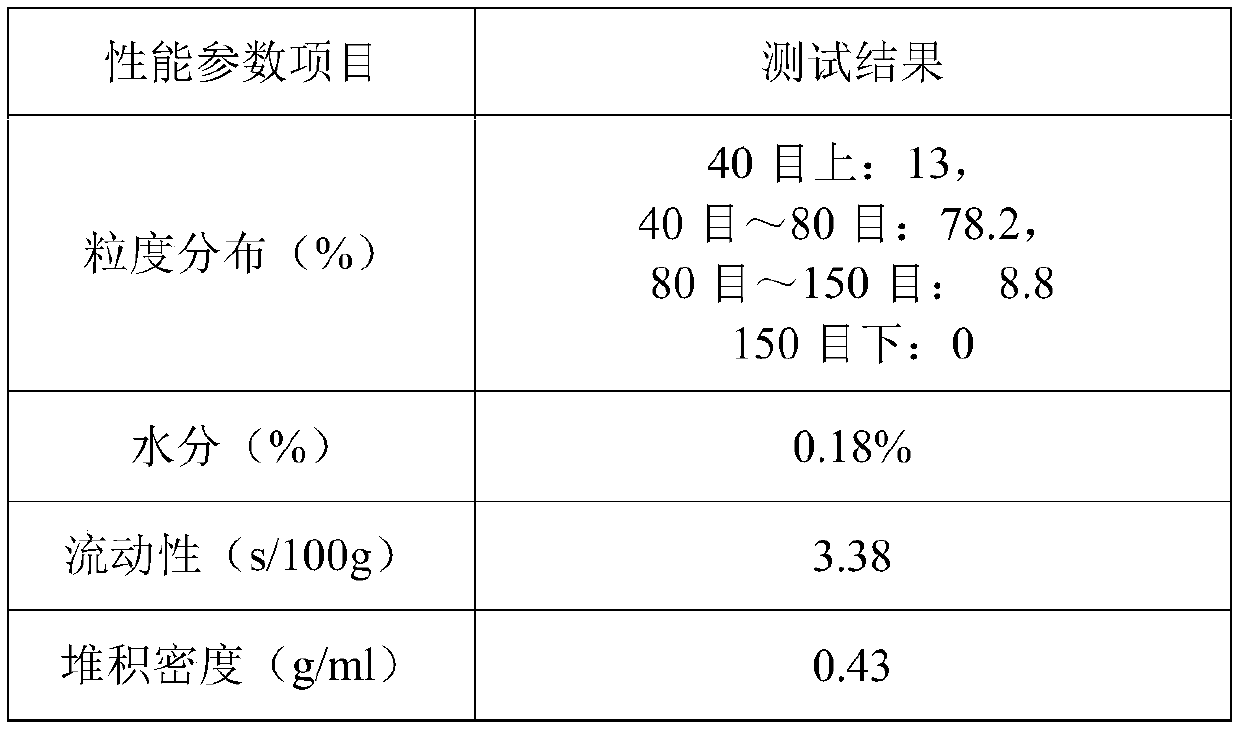

InactiveCN111202244AWell mixedImprove liquidityPharmaceutical non-active ingredientsFood ingredientsBiochemistryArabinose

The invention relates to granular arabinose which is arabinose granules with a moisture content of 0.1%-0.3%, fluidity of 3.0 s / 100 g-6.0 s / 100 g and a bulk density of 0.3 g / mL-0.6 g / mL. The inventionfurther discloses a preparation method and application of the granular arabinose. Existing needle-like arabinose is produced into granules under the condition that no adhesive is contained, so that the granular arabinose reaches certain fluidity, filling ability, compressibility and grain size uniformity. The application effect of a related product can be realized, for example, the product is prone to compression forming while the accurate dose of the product is guaranteed, and tablets can be prepared; and the granular arabinose can be uniformly mixed with other granular auxiliary materials to obtain granules or subpackaged in capsules to prepare capsules and the like.

Owner:ZHEJIANG HUAKANG PHARMA

Aging quality inspection device before aluminum electrolytic capacitor leaves factory

InactiveCN110756463AAchieve fillingRealize detectionSortingMechanical engineeringAluminum electrolytic capacitor

The invention discloses an aging quality inspection device before an aluminum electrolytic capacitor leaves a factory. The aging quality inspection device comprises an identification box, wherein a quality inspection cavity is arranged in the identification box, a central shaft is rotatably connected in the quality inspection cavity, a transposition disc is arranged on the central shaft, four centrally symmetrical sliding cavities are arranged in the transposition disc, transposition devices are slidably connected in the sliding cavities, and the transposition devices comprise connecting blocks which are slidably connected in the sliding cavities and receiving grooves arranged inside the connecting blocks. The circumferential rotation type station exchange is adopted, filling, detection and classified discharge of capacitors are orderly realized, repeated circulation work can be carried out, manual repeated operation is replaced, automatic capacitor quality inspection work is realized,actual requirements of large-scale chemical plants are met, the quality inspection speed is improved, and quality of discharged capacitors is guaranteed.

Owner:XINCHANG CIZHANG ELECTRONICS TECH CO LTD

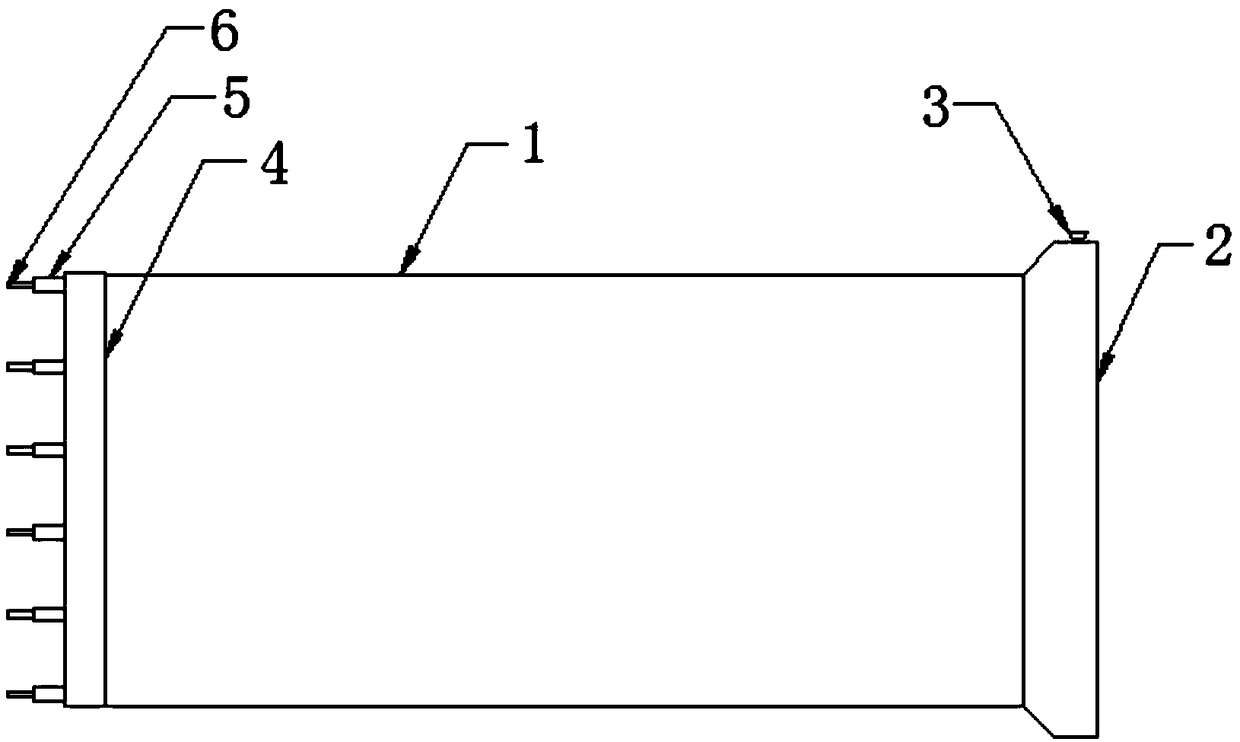

Spliced type concrete pipe

The invention discloses a spliced type concrete pipe. The pipe comprises a concrete pipe body, a bearing opening and a connector, wherein the socket is fixedly arranged at one end of the concrete pipebody, an annular cavity is formed inside the bearing opening, and a plurality of annular trapezoid grooves are uniformly formed in the inner wall of one side of the annular cavity; a plurality of inserting holes are formed in one side of the bearing opening and one side of the concrete pipe body at intervals, and the other end of the concrete pipe body is fixedly provided with the connector; anda plurality of intubation pipes are arranged on one side of the connector at intervals, reinforcing steel bars are arranged in the inserting pipes in a penetrating mode, and an annular groove is formed in the outer wall of the connector. According to the pipe, the two ends of the concrete pipe body are correspondingly provided with the bearing opening and the connector, so that the two concrete pipes can be quickly connected in a butt joint mode; and the design that a pouring bucket arranged at the top end of the bearing opening communicates with the annular trapezoid grooves through through holes can improve compactness of the connection of the inner poured concrete of the concrete pipe.

Owner:ANHUI YUTE CONCRETE STRUCTURE TECH

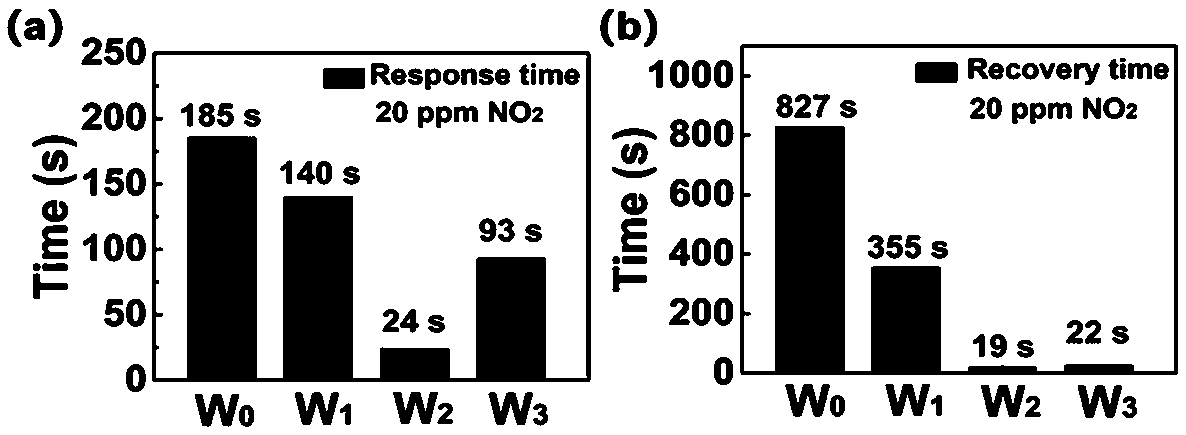

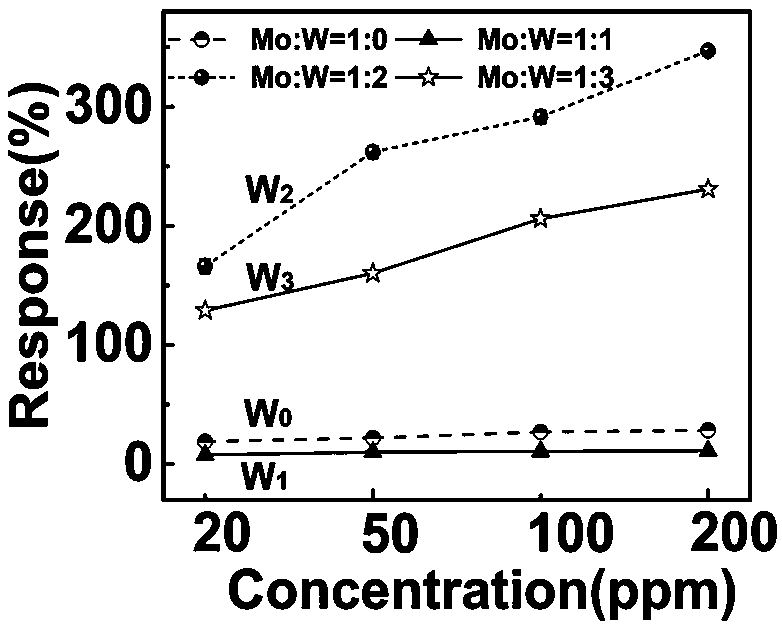

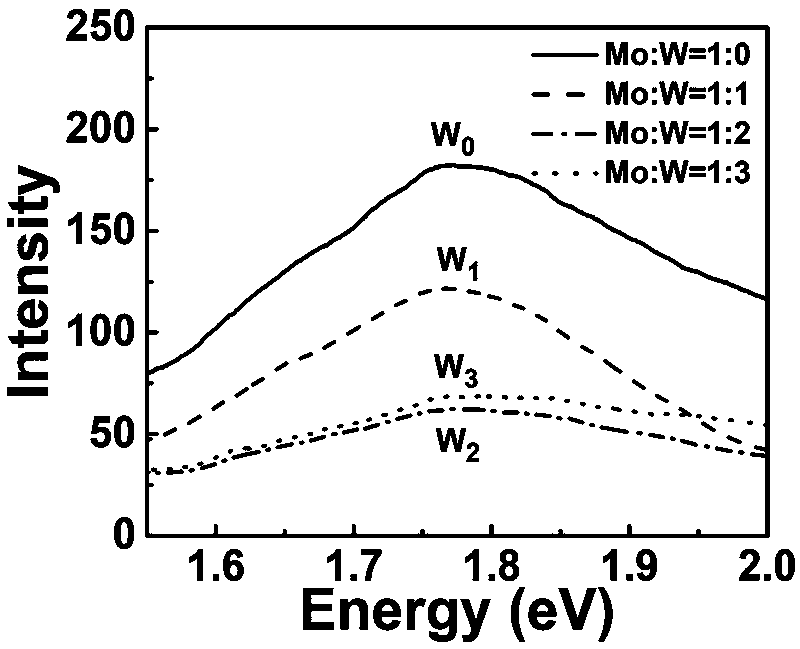

Method for improving performance of MoS2 gas sensor by adopting W doping

ActiveCN110455873AImproved adsorption/desorption behaviorImproved response/recovery behaviorMaterial resistanceMolybdenum sulfidesIonChemistry

The invention provides a method for improving the performance of an MoS2 gas sensor by adopting W doping. The method comprises the following steps of introducing W<4+> ions which are similar to Mo<4+>ions in radius in the growth process of MoS2 and achieving filling of vacancies in a material, thereby improving the adsorption / desorption behavior of gas molecules on the surface of the material. AW-doped MoS2 material is synthesized through a hydrothermal method and a planar interdigital NO2 gas sensor is further manufactured. The result shows that the response / recovery behavior of the MoS2 gas sensor to an NO2 gas is greatly improved through W doping, and the response / recovery time is shortened by an order of magnitude and is shortened to tens of seconds from hundreds of seconds. The method has the advantages that vacancy compensation is achieved and the response / recovery rate of the MoS2 gas sensor is improved by using the economical and effective hydrothermal method; the preparationprocess is simple; the requirements of reaction conditions on required instruments are low; and the method is simple in process and low in cost, and has a great application prospect in the field of fast gas detection at room temperature.

Owner:XIANGTAN UNIV

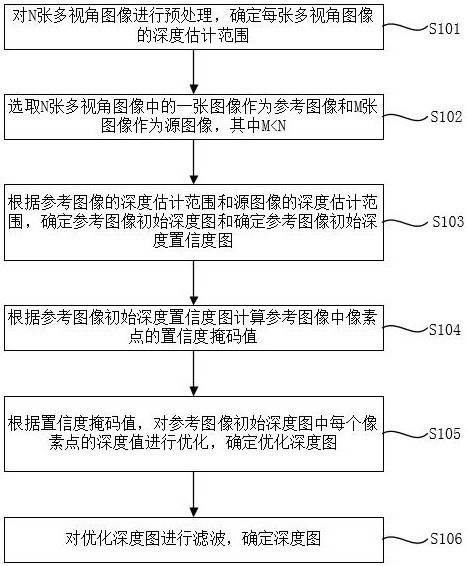

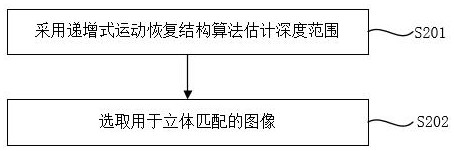

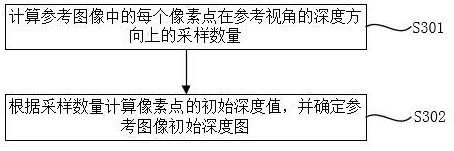

Depth map optimization method and device for large-scale scene reconstruction and storage medium

PendingCN113808063ASolve the problem of poor integrationAchieve fillingImage enhancementImage analysisPattern recognitionImaging processing

The invention discloses a depth map optimization method for large-scale scene reconstruction, and relates to the technical field of image processing, and the method comprises the steps: carrying out the preprocessing of N multi-view images, and determining the depth estimation range of each multi-view image; selecting one of the N multi-view images as a reference image and M images as source images, and determining an initial depth map and an initial depth confidence map of the reference image according to the depth estimation range of the reference image and the depth estimation range of the source images; calculating a confidence mask value of a pixel point in the reference image according to the initial depth confidence map of the reference image; according to the confidence mask value, optimizing the depth value of each pixel point in the initial depth map of the reference image, and determining an optimized depth map; and filtering the optimized depth map, and determining the depth map, thereby solving the problem that the fusion degree of the texture region is not high, realizing that the depth map of the weak texture region can fill the missing position, and effectively reconstructing the large outdoor scene.

Owner:土豆数据科技集团有限公司

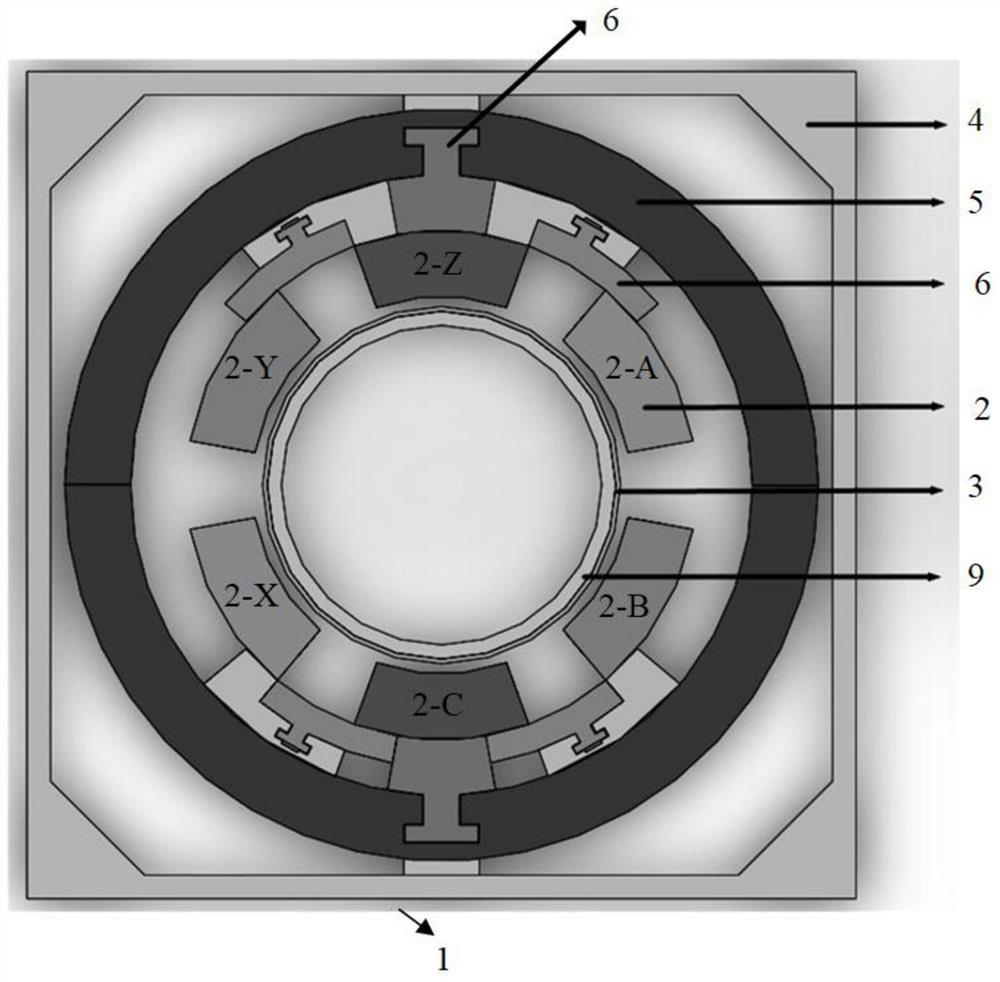

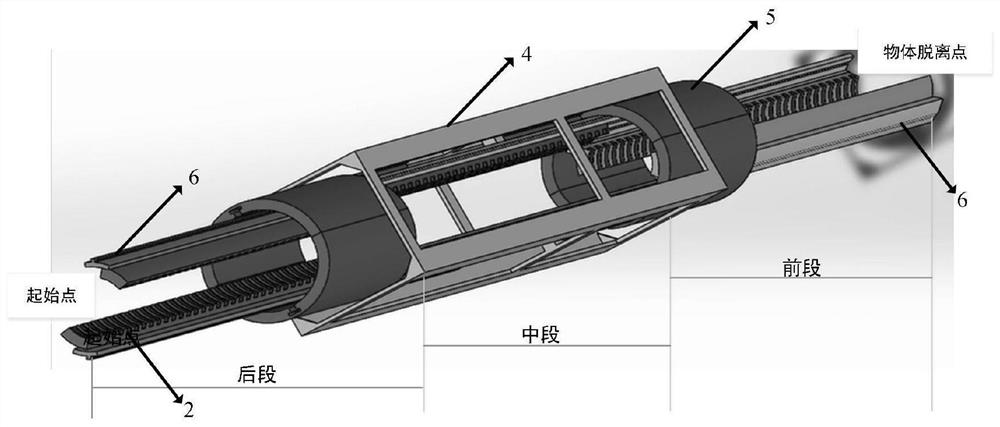

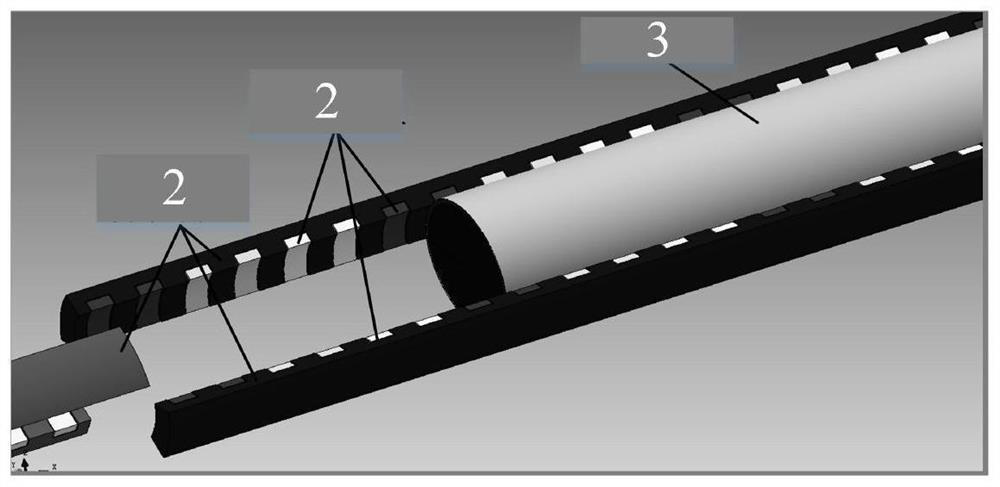

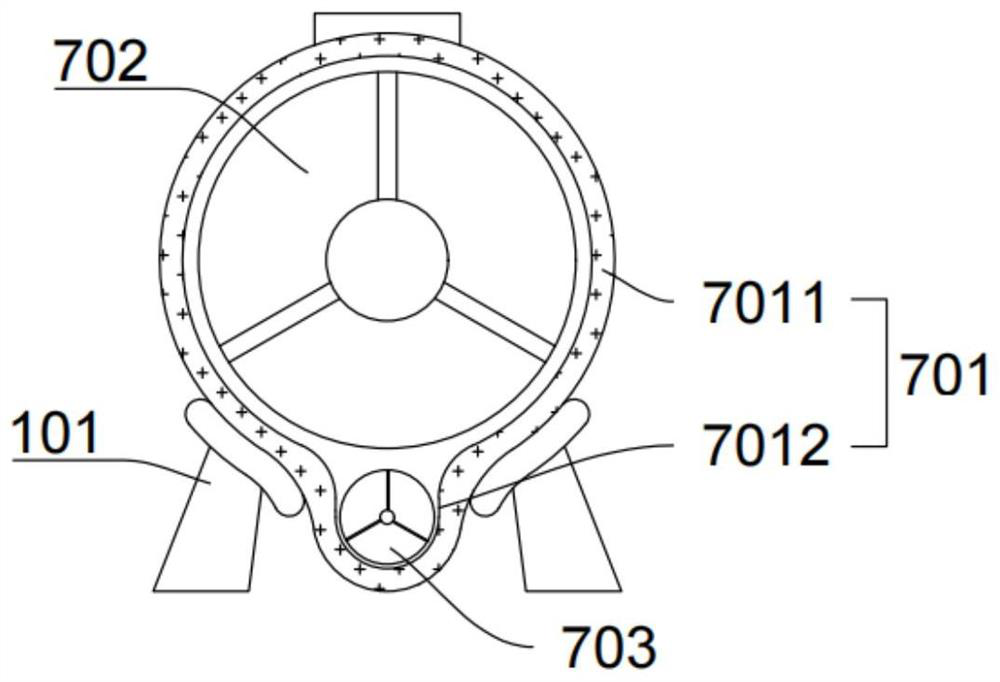

Electromagnetic driving device and driving method suitable for object load

ActiveCN113541436AImprove work efficiencyAchieve fillingMechanical energy handlingPropulsion systemsElectric machineLinear motor

The invention provides an electromagnetic driving device and method suitable for an object load. The device comprises a cylindrical linear induction motor and an auxiliary mechanism. The cylindrical linear induction motor comprises an arc-shaped single-side linear induction motor primary part and a cylindrical linear induction motor secondary part. The arc-shaped single-side linear induction motor primary part comprises six single-side linear induction motors, and in a contraction state, the cross sections of the six single-side linear induction motors of the primary part are of a circular structure, and the six single-side linear induction motors operate in pairs. The cylindrical linear induction motor comprises three sections of structures after extending in the length direction, and the three sections are respectively defined as a front section, a middle section and a rear section. The front section, the middle section and the rear section of the linear induction motor jointly form a boosting power cylinder of the cylindrical linear induction motor in storage and transportation states when the electromagnetic driving equipment is in a non-operation state, so that pushing, loading and locking of an object load are achieved, and secondary electromagnetic braking, automatic reset and position detection of the linear motor can also be achieved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

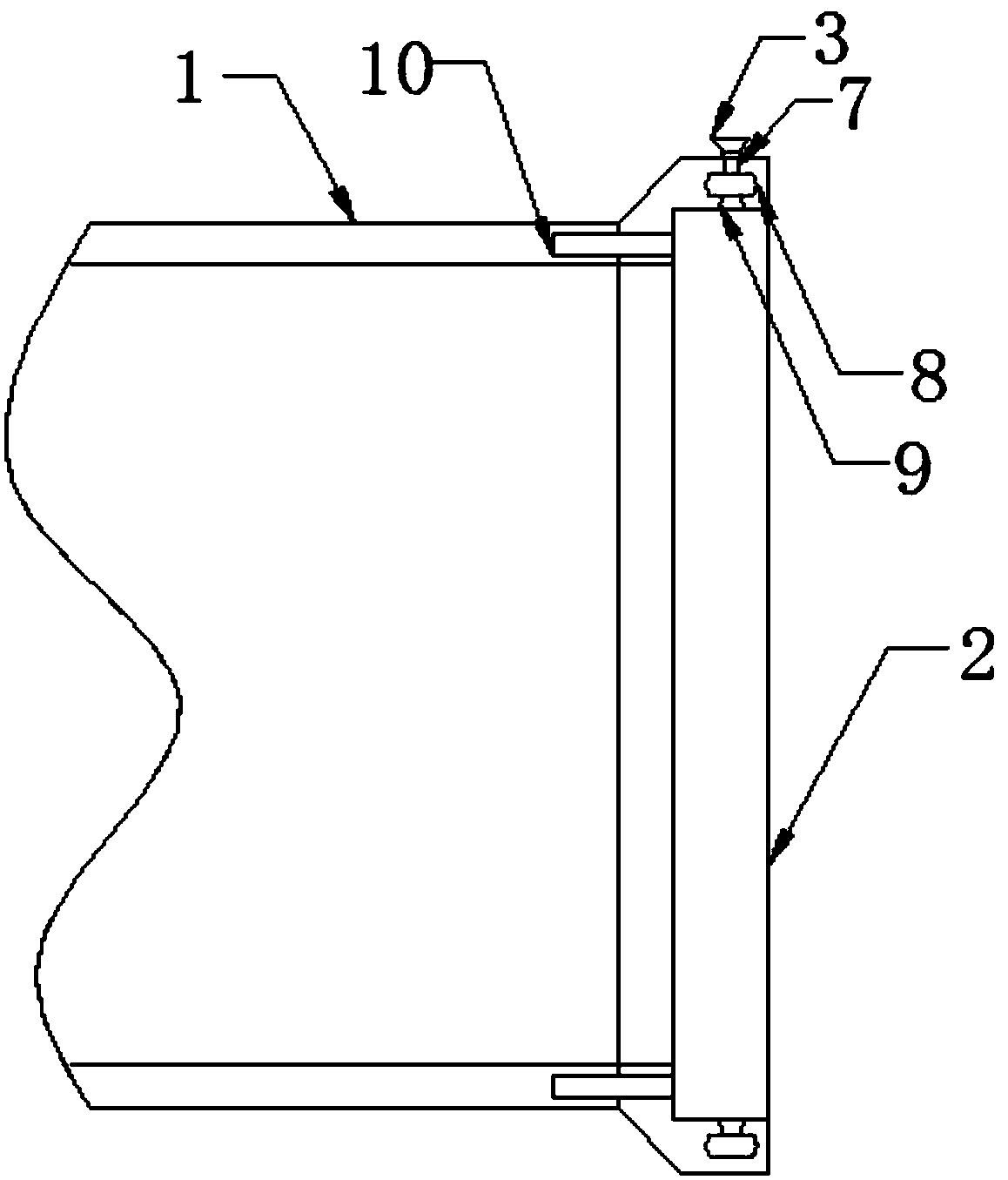

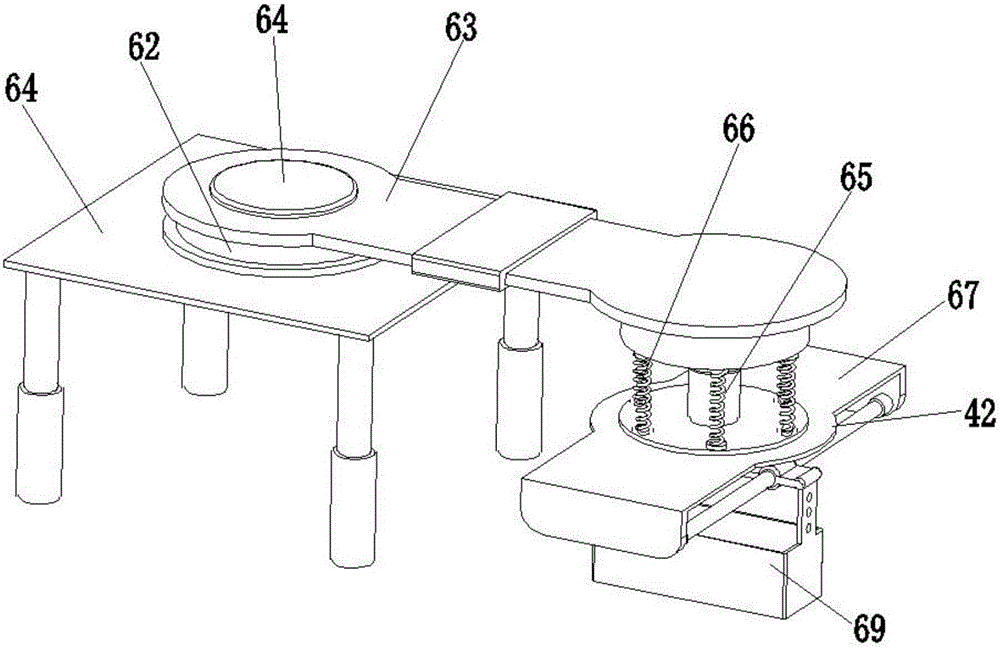

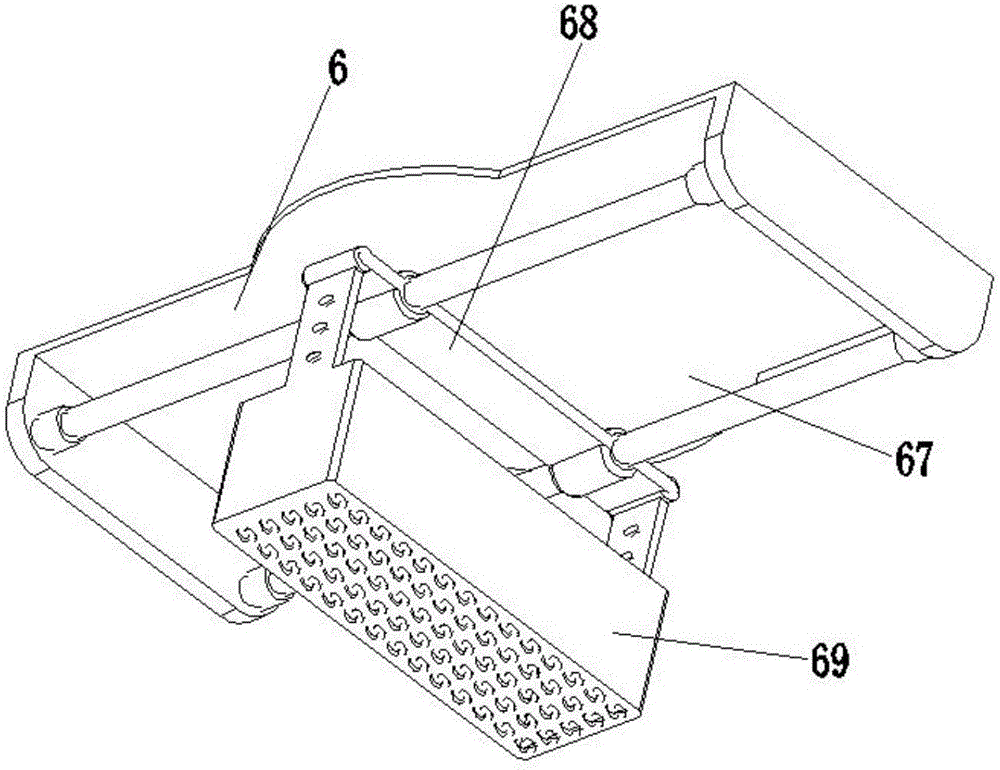

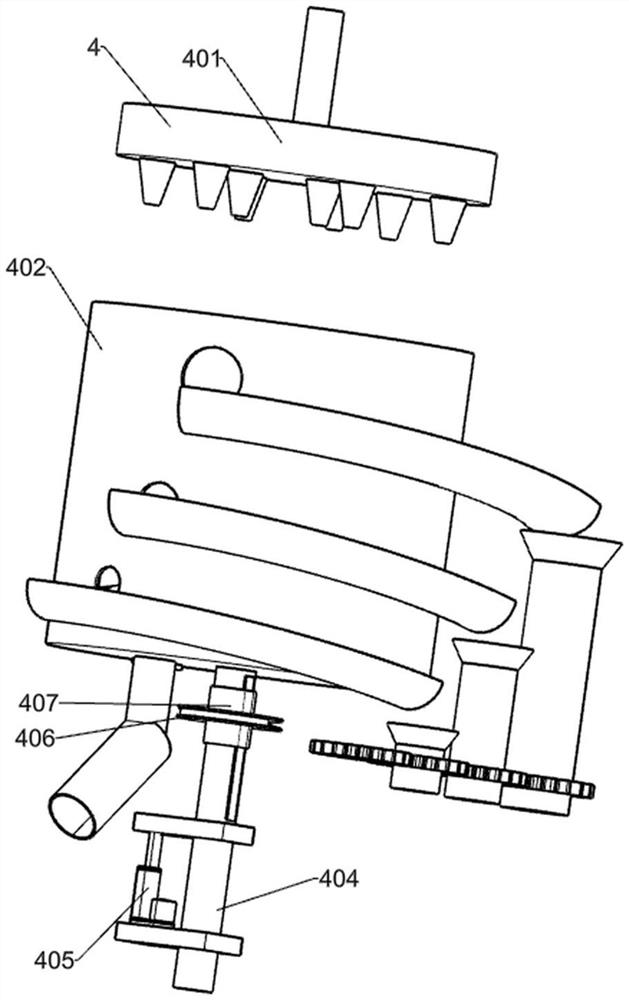

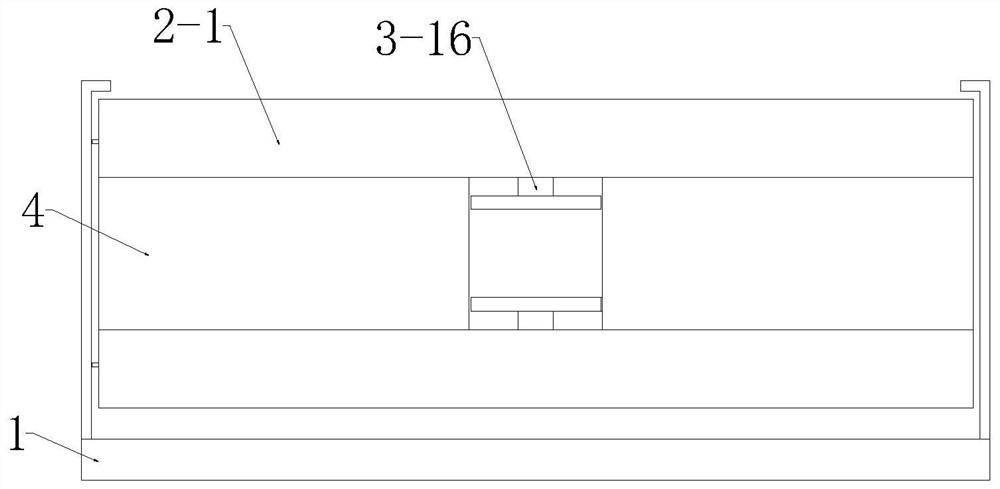

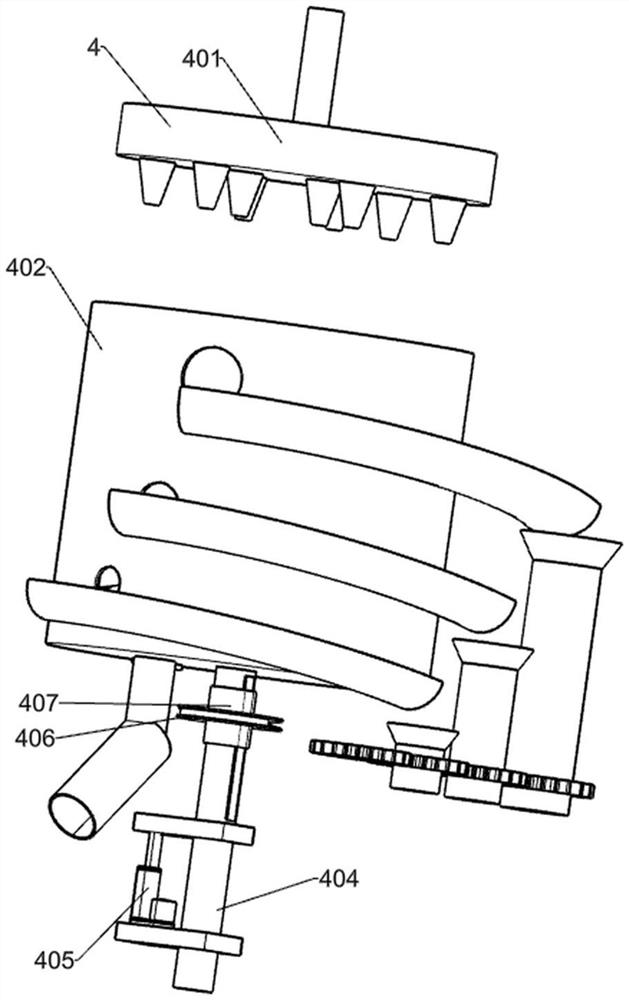

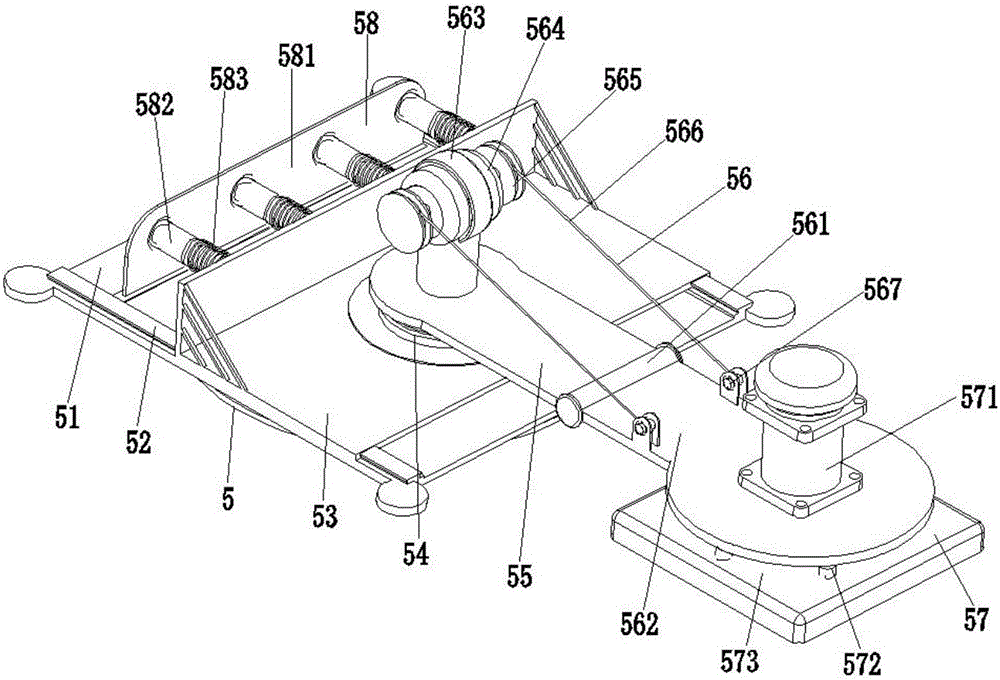

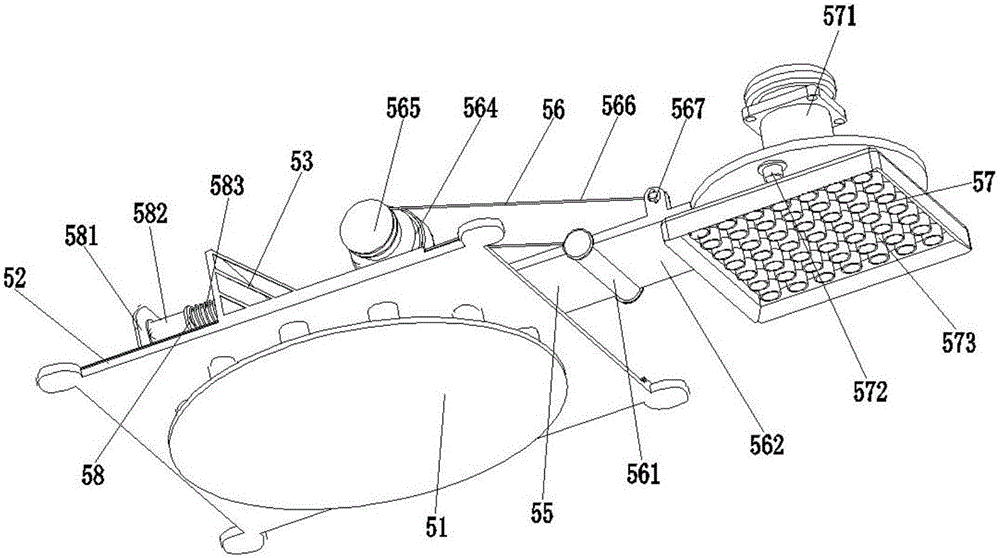

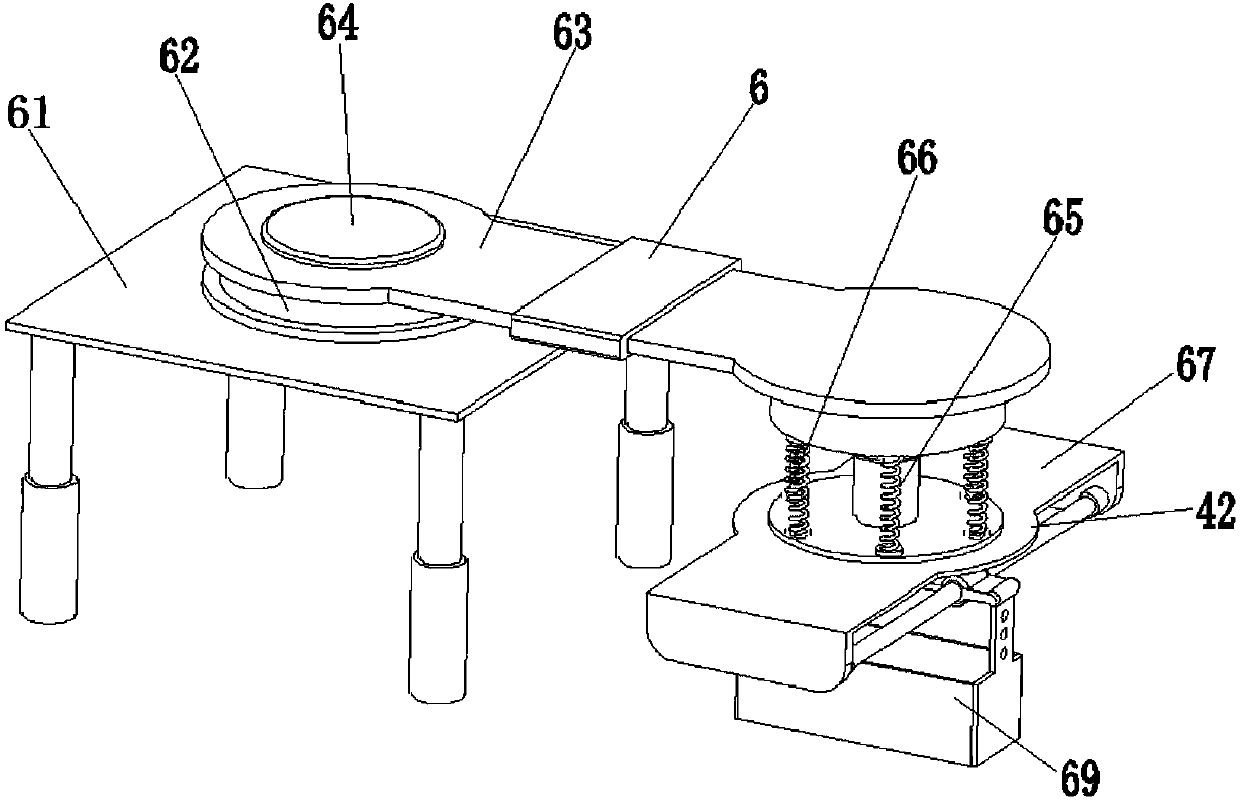

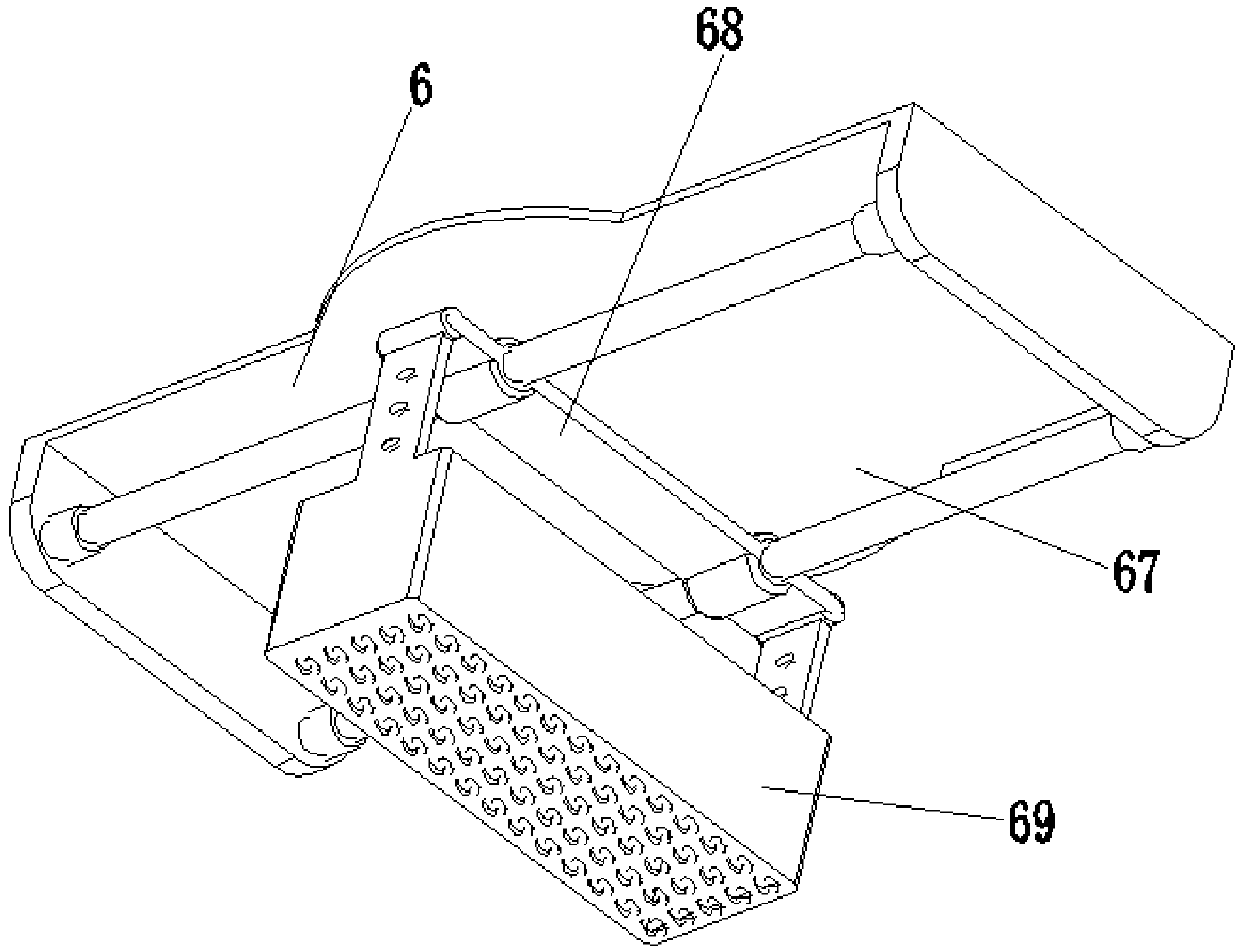

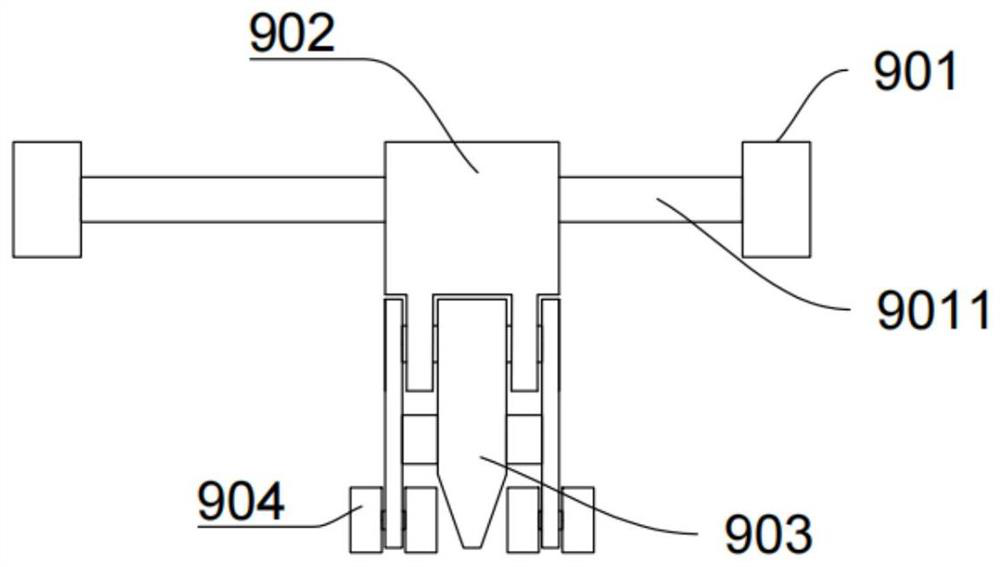

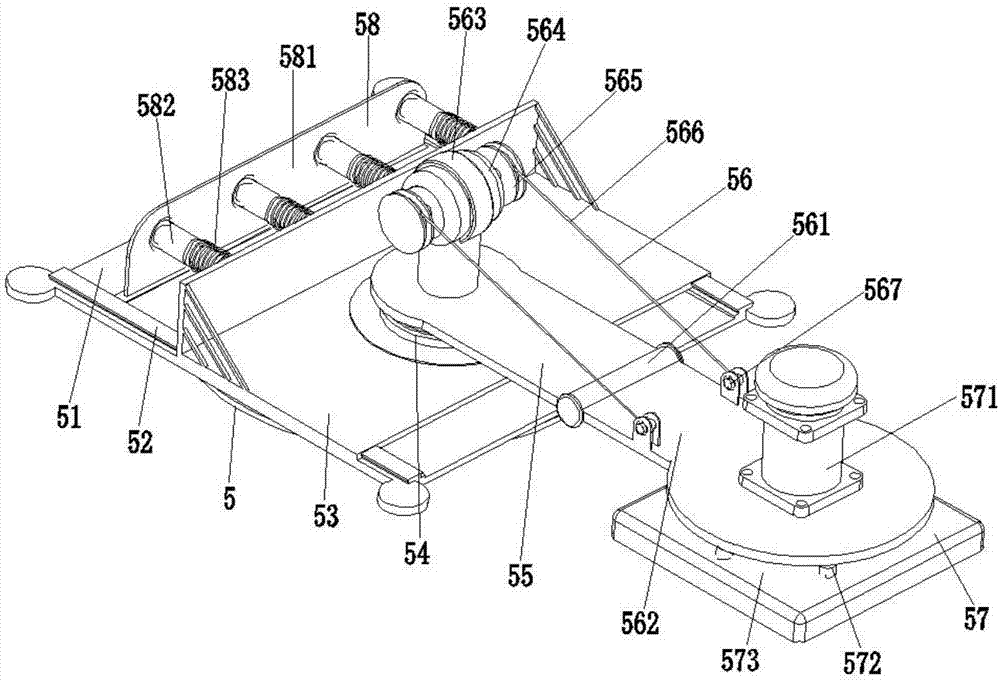

Device for filling brick cracks with cement for floor tile paving robot for urban municipal sidewalk

ActiveCN106120526AIncrease jitterFlexible movementRoads maintainenceMaterials scienceThree degrees of freedom

The invention relates to a device for filling brick cracks with cement for a floor tile paving robot for an urban municipal sidewalk. The device comprises a cement filling bracket, a cement filling rotary table, a telescopic bracket, a locking cover, cement filling lifting rods, vibration tension springs, a vibration supporting seat, a cement filling sliding block and a cement filling leaking basket, wherein the lower ends of the cement filling lifting rods are fixed to the vibration supporting seat; the upper ends of the vibration springs namely the vibration tension springs are connected with the telescopic bracket, and the lower ends of the vibration springs namely the vibration tension springs are connected with the vibration supporting seat; the cement filling sliding block is mounted on a guiding sliding rod at the lower end of the vibration supporting seat; the cement filling leaking basket is fixed just below the cement filling sliding block; and discharging holes are uniformly formed in the bottom end surface of the cement filling leaking basket. According to the device disclosed by the invention, movements of the device in three freedom degree directions including two translation directions and a rotation direction can be performed in space, so that the cement filling leaking basket can be partially adjusted to align with an accurate position of a crack between floor tiles; and through the adoption of a shaking principle, discharging cement paste is realized, and filling the crack between the floor tiles and fixing the floor tiles are realized. The device disclosed by the invention is flexible in movement, accurate in aligning and high in working efficiency.

Owner:广州华仁跨境贸易有限公司

Paving device utilizing cobblestones

ActiveCN112281589AAchieving consistent tip orientationHighly consistentDischarging apparatusRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to the field of buildings and particularly relates to a paving device utilizing cobblestones. A technical problem of the invention is to provide the device for paving the road byutilizing the cobblestones. The paving device utilizing cobblestones comprises wheels, a bottom frame, a screening mechanism, a stone paving mechanism, a cement paving and water absorbing mechanism and the like, wherein the wheels are in bolted connection with the underframe; a stone paving mechanism and a cement paving and water absorbing mechanism are connected; the screening mechanism is connected with the stone paving mechanism; the screening mechanism is connected with the cement laying and water absorbing mechanism; and the stone paving mechanism is connected with the cement paving andwater absorbing mechanism. The paving device is advantaged in that the paving device is designed for mechanical paving of cobblestones, working efficiency is improved, the cobblestone pavement is flattened, heights of the cobblestones exposed out of the ground are consistent, and the risk of spraining feet of a walker is reduced; the current situation that existing equipment cannot conduct automatic paving treatment on cobblestones, and the heights, exposed out of the ground, of the cobblestones cannot be kept consistent is changed.

Owner:泰安久荣建筑工程有限公司

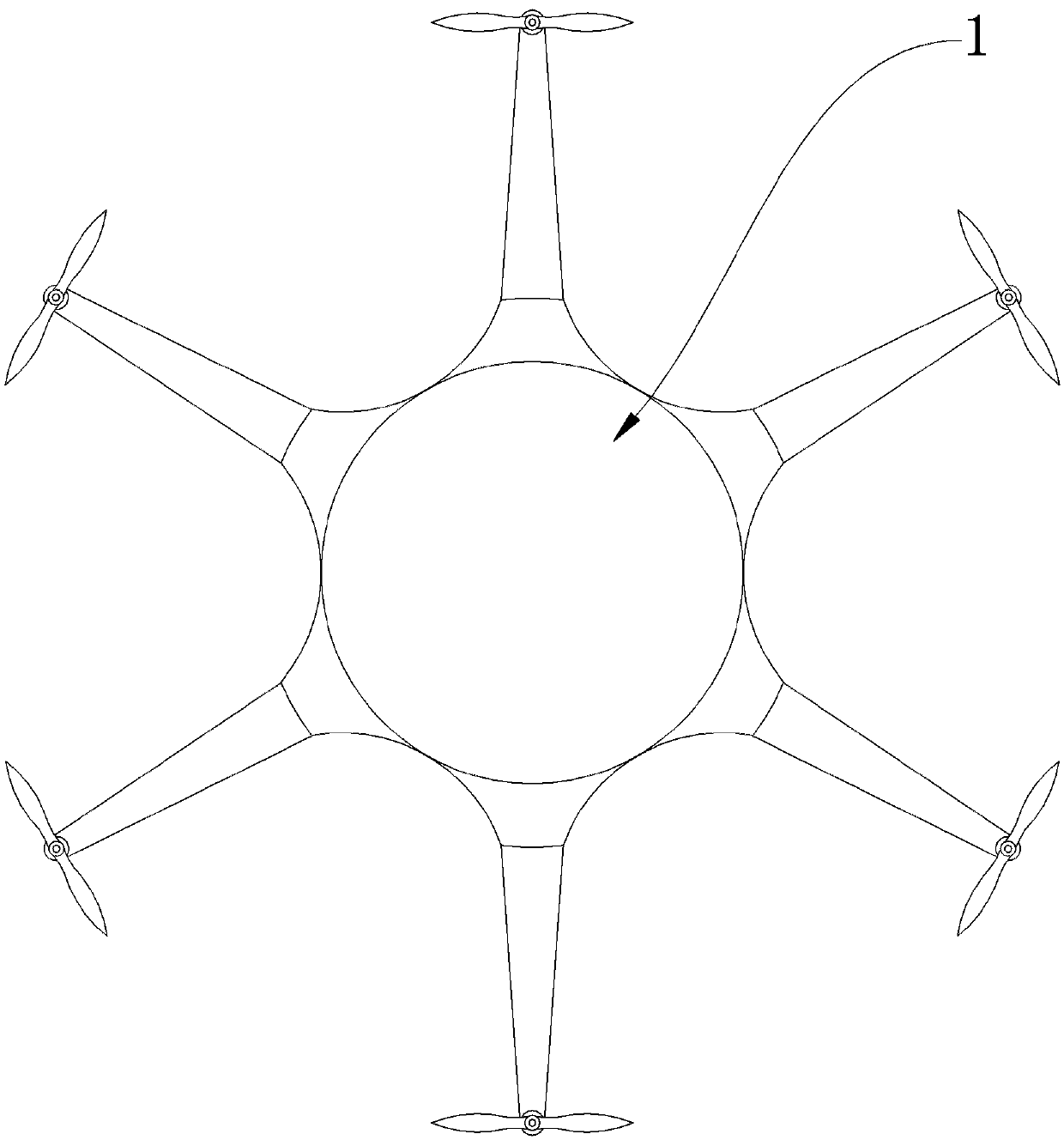

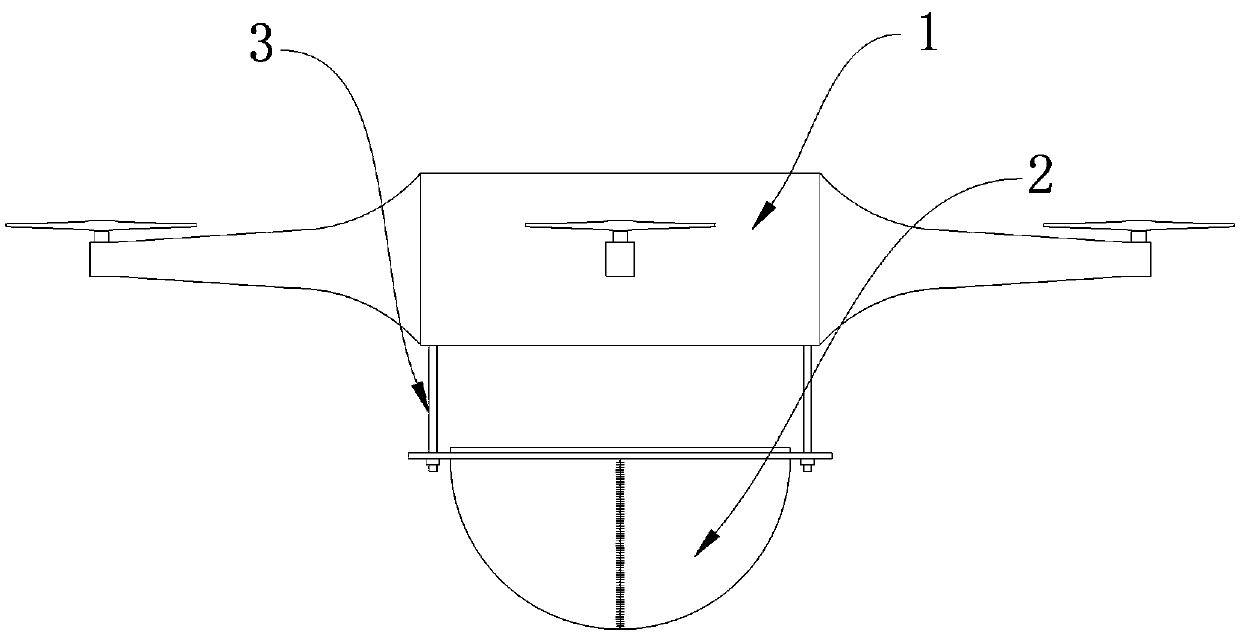

Multi-rotor unmanned aerial vehicle tea collecting device and tea collecting system thereof

InactiveCN109823553AGuaranteed qualityIncrease incomeAircraft componentsPicking devicesEngineeringHelicopter rotor

The invention discloses a multi-rotor unmanned aerial vehicle tea collecting device, which comprises a multi-rotor unmanned aerial vehicle and a tea container arranged at the bottom of the multi-rotorunmanned aerial vehicle, wherein the tea container comprises a supporting part, a bag sealing part, a first cloth bag and a second cloth bag, the supporting part is provided with an opening, the supporting part is connected with the bottom of the multi-rotor unmanned aerial vehicle, one side of the bag sealing part is fixedly arranged at one side of the opening of the supporting part, the other sides of the bag sealing part are arranged on the corresponding edge of the opening of the supporting part through a first zipper, the first cloth bag and the second cloth bag are fixedly arranged at the bottom of the opening of the supporting part, and the first cloth bag and the second cloth bag are connected through the second zipper. The invention also discloses a tea collecting system of the tea collecting device. By adopting the unmanned aerial vehicle to transport the picked fresh tea leaves, the time interval for transporting the tea leaves is shortened, the quality of the tea leaves isensured, the labor and material costs are saved, and the transportation efficiency of the tea leaves is improved; and the unmanned aerial vehicle is convenient to control, accurate in positioning andstable in signal transmission.

Owner:云南航科智信科技有限公司

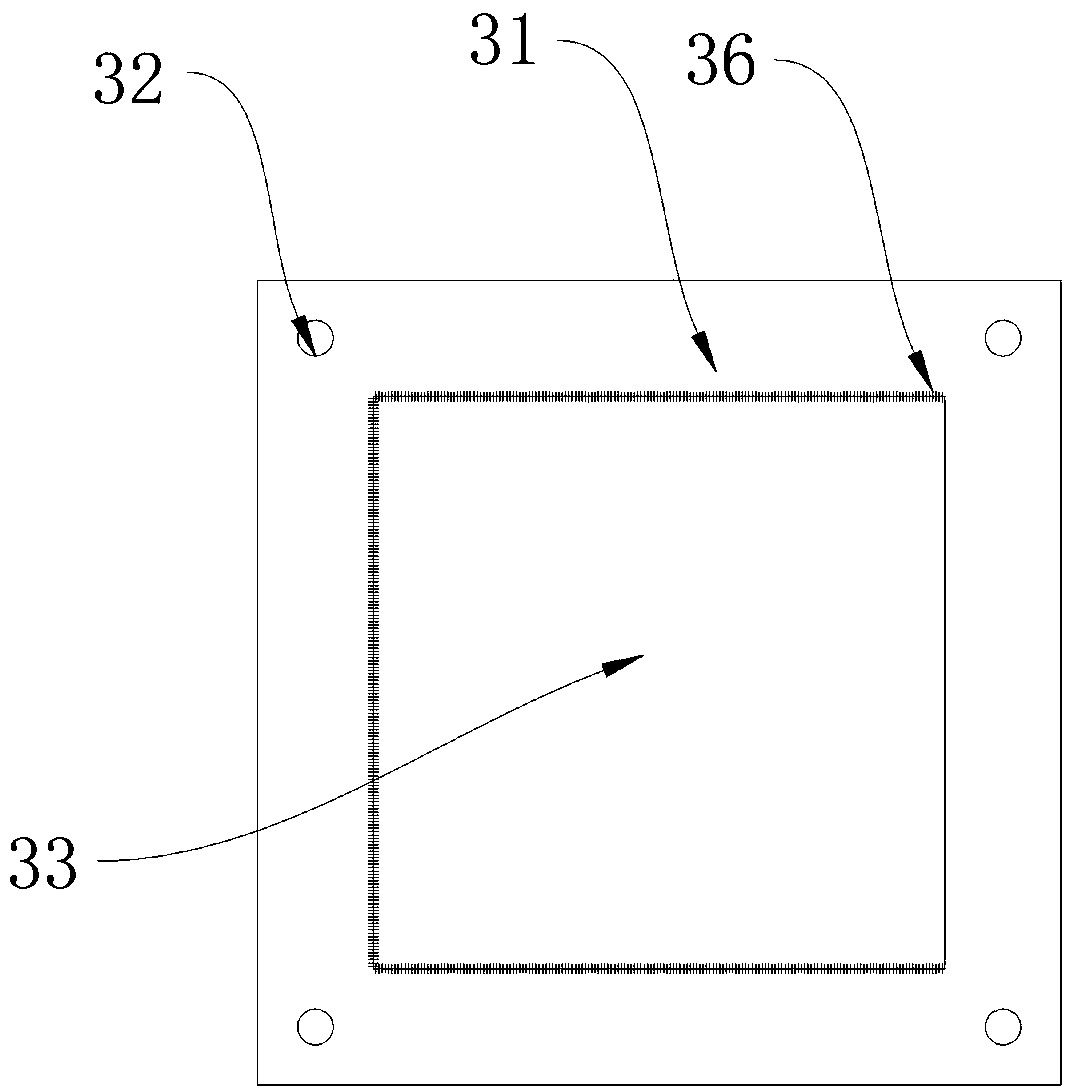

Conveyor belt conveying device with vacuum anti-separation structure

The invention discloses a conveyor belt conveying device with a vacuum anti-separation structure. The conveying device comprises a support, a conveyor belt and adsorption mechanisms. The conveyor beltis arranged on the support. The adsorption mechanisms are arranged on the conveyor belt. A supporting plate is arranged on the support. The conveyor belt is in sliding connection with the supportingplate. The adsorption mechanisms are rotationally connected with the support and the supporting plate. The conveyor belt comprises a plurality of conveying plates. Each conveying plate is provided with the corresponding adsorption mechanism. Each adsorption mechanism obtains power for generating negative pressure through rotational connection with the support and the supporting plate and releasesthe negative pressure through rotational connection again, and energy does not need to be consumed in the negative pressure generating process. The conveyor belt conveying device has the effects of being low in energy consumption and capable of stably adsorbing objects.

Owner:周启燕

A paving device using cobblestones

ActiveCN112281589BHighly consistentAchieve fillingDischarging apparatusRoads maintainenceArchitectural engineeringStructural engineering

Owner:泰安久荣建筑工程有限公司

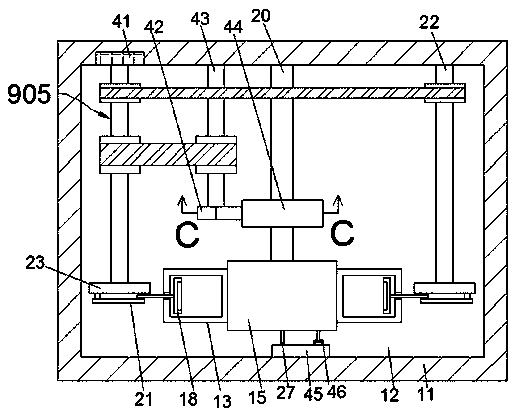

Manipulator of floor tile paving robot for urban municipal sidewalk

The invention relates to a manipulator of a floor tile paving robot for an urban municipal sidewalk. The manipulator comprises a Stewart parallel connection mechanism, a drawing and picking device and a device for filling brick cracks with cement, wherein the Stewart parallel connection mechanism is positioned just below the drawing and picking device, and the upper end of the Stewart parallel connection mechanism is connected with the drawing and picking device; and the device for filling brick crack with cement is positioned directly over the drawing and picking device. According to the manipulator disclosed by the invention, multiple functions of adjusting multi-freedom degree directions, drawing and picking floor tiles, filling the brick cracks with cement, and fixing, and the like are integrated, floor tile paving operation can be performed on the urban municipal sidewalk, the manipulator disclosed by the invention is high in automation degree, high in paving speed, and good in paving appearance degree, and problems that conventional floor tile paving is high in occupied labor, low in paving efficiency, large in paving cost and the like are solved.

Owner:北京昌泰宏业市政工程有限公司

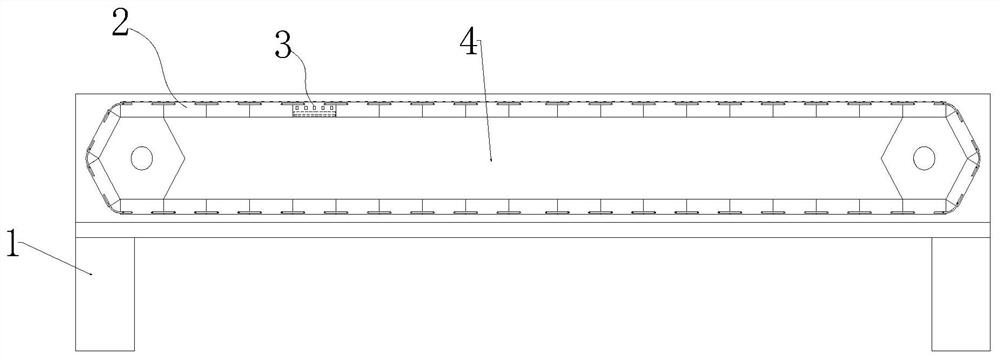

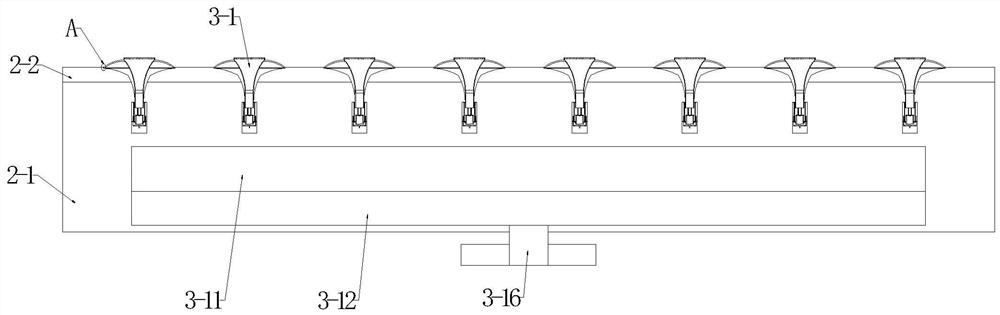

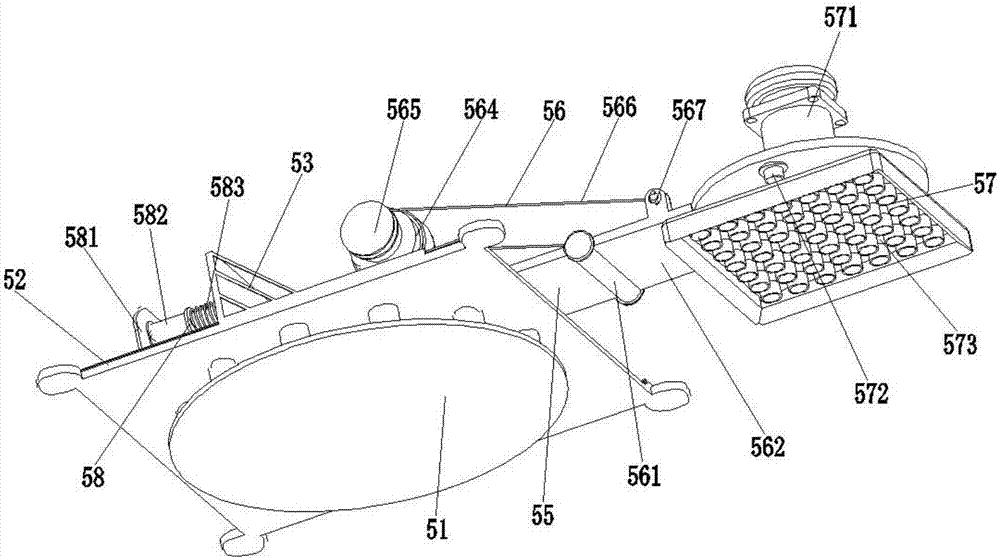

Laying device for urban municipal sidewalk floor tile laying robot

ActiveCN106012775AHigh degree of automationLaying speed is fastRoads maintainenceVacuum pressureBrick

The invention relates to a laying device for an urban municipal sidewalk floor tile laying robot. The laying device comprises a suction unit and a tile seam filling unit, wherein the tile seam filling unit is located right above the suction unit. The laying device integrates multiple functions such as floor tile suction, tile seam filling and fixation and the like, can lay tiles on municipal sidewalks, has the advantages of high automation degree, high laying speed and good laying attractiveness, and solves the problems of large labor occupation, low laying efficiency, high laying cost and the like of existing laying; the suction unit of the laying device sucks and clamp floor tiles with a vacuum pressure difference principle, the suction speed is high, the suction firmness is high, and suction of the floor tiles in a horizontal plane and an inclined plane can be realized through an angle adjusting mechanism, the applicability is high, and the operation object range is wide.

Owner:湖南乐金建设发展有限公司

A brick gap filling device for a city municipal sidewalk floor tile laying robot

The invention relates to a device for filling brick cracks with cement for a floor tile paving robot for an urban municipal sidewalk. The device comprises a cement filling bracket, a cement filling rotary table, a telescopic bracket, a locking cover, cement filling lifting rods, vibration tension springs, a vibration supporting seat, a cement filling sliding block and a cement filling leaking basket, wherein the lower ends of the cement filling lifting rods are fixed to the vibration supporting seat; the upper ends of the vibration springs namely the vibration tension springs are connected with the telescopic bracket, and the lower ends of the vibration springs namely the vibration tension springs are connected with the vibration supporting seat; the cement filling sliding block is mounted on a guiding sliding rod at the lower end of the vibration supporting seat; the cement filling leaking basket is fixed just below the cement filling sliding block; and discharging holes are uniformly formed in the bottom end surface of the cement filling leaking basket. According to the device disclosed by the invention, movements of the device in three freedom degree directions including two translation directions and a rotation direction can be performed in space, so that the cement filling leaking basket can be partially adjusted to align with an accurate position of a crack between floor tiles; and through the adoption of a shaking principle, discharging cement paste is realized, and filling the crack between the floor tiles and fixing the floor tiles are realized. The device disclosed by the invention is flexible in movement, accurate in aligning and high in working efficiency.

Owner:广州火旺火品牌管理有限公司

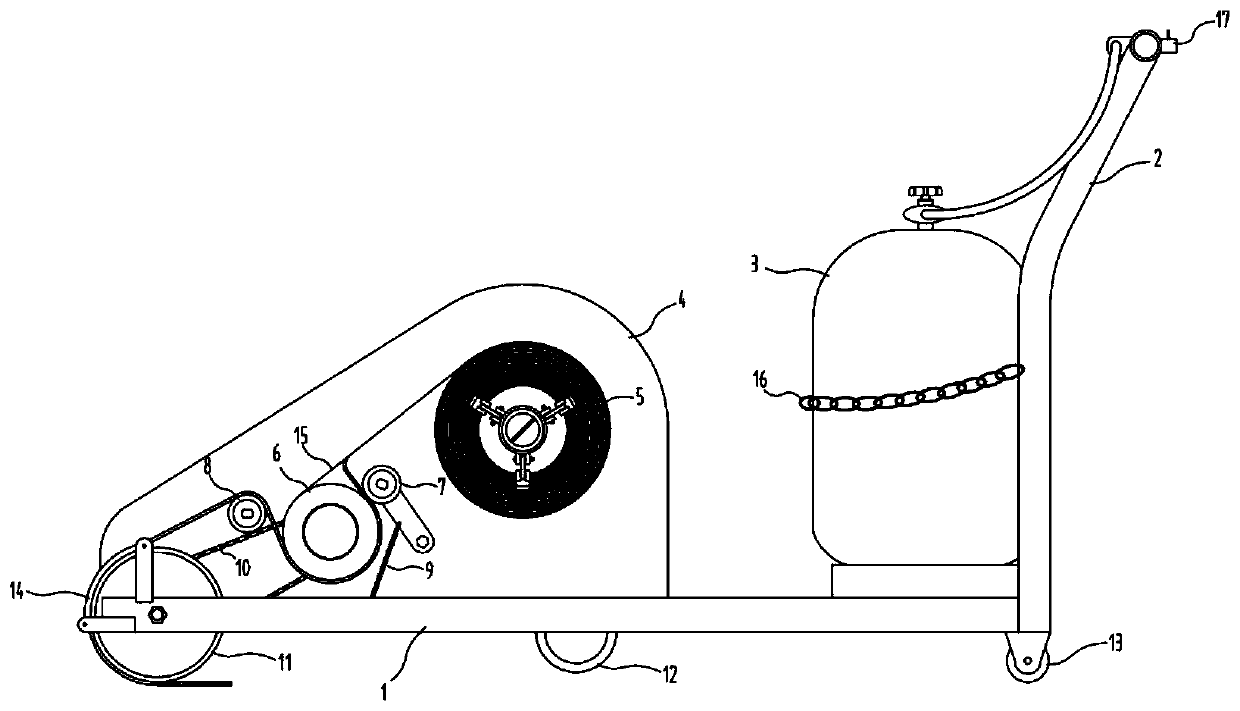

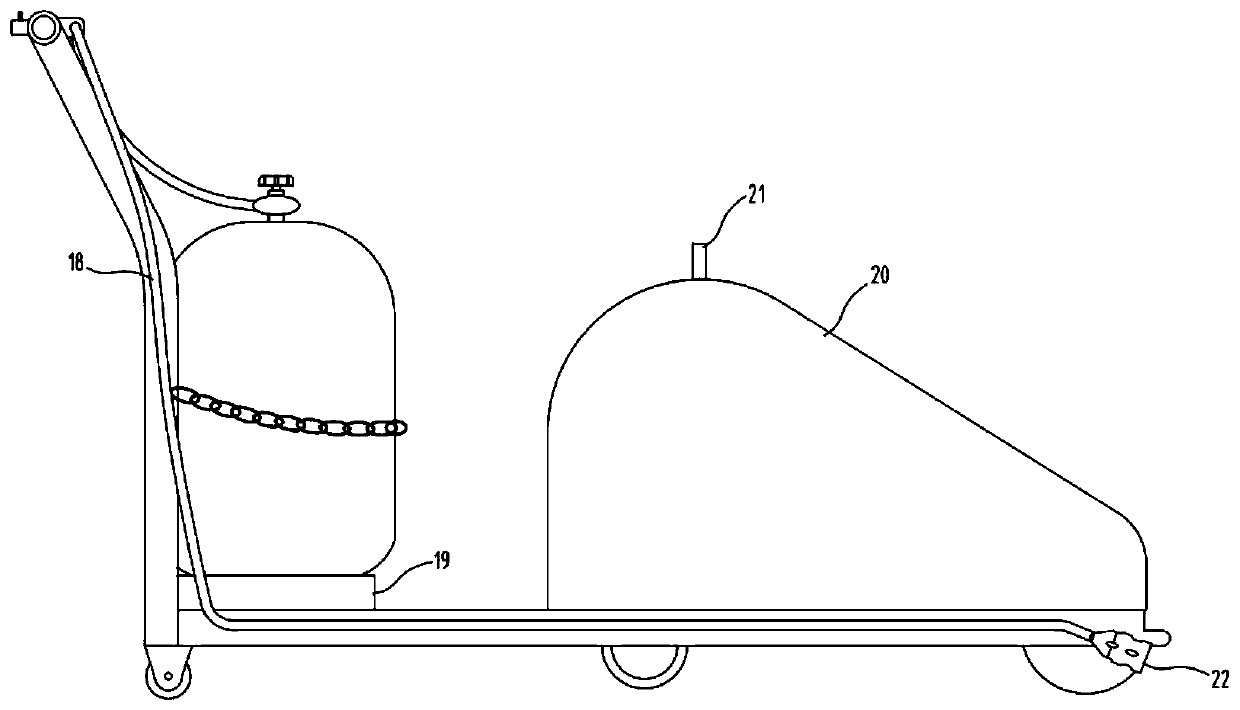

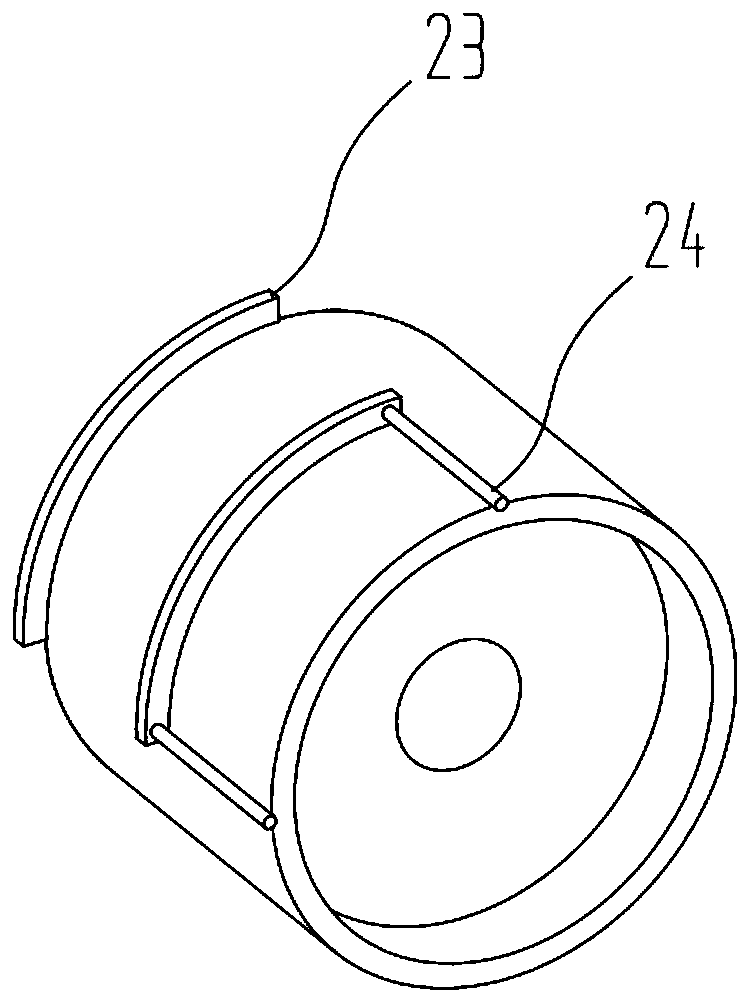

Road surface crack repairing device

The invention discloses a road surface crack repairing device. The road surface crack repairing device comprises a crack pouring adhesive tape, a supporting frame, a fuel gas cylinder, a crack pouringadhesive tape transmission mechanism and a fuel gas conveying pipe; the supporting frame comprises a gripping part and an installing part, wherein the gripping part is welded to one side of the installing part, the installing part is composed of an installing plane used for installing a repairing tape transmission mechanism and an installing skeleton used for installing rolling wheels, and the installing plane is vertically welded to the edge of one side of the installing skeleton; a fuel gas cylinder base used for placing the fuel gas cylinder is further welded to the plane of the installingskeleton; the end, arranged along the edge of the supporting frame, of the fuel gas conveying pipe is connected with the fuel gas cylinder, and the other end of the fuel gas conveying pipe is fixed to the top of the supporting frame; and the crack pouring adhesive tape winds into a coil disk to be arranged on the crack pouring adhesive tape transmission mechanism in a sleeving mode. The road surface crack repairing device has the advantages that only operating personnel needs to push the supporting frame forwards in the whole repairing process, and filling and repairing work can be automatically completed.

Owner:浙江交投高速公路运营管理有限公司温州管理处 +1

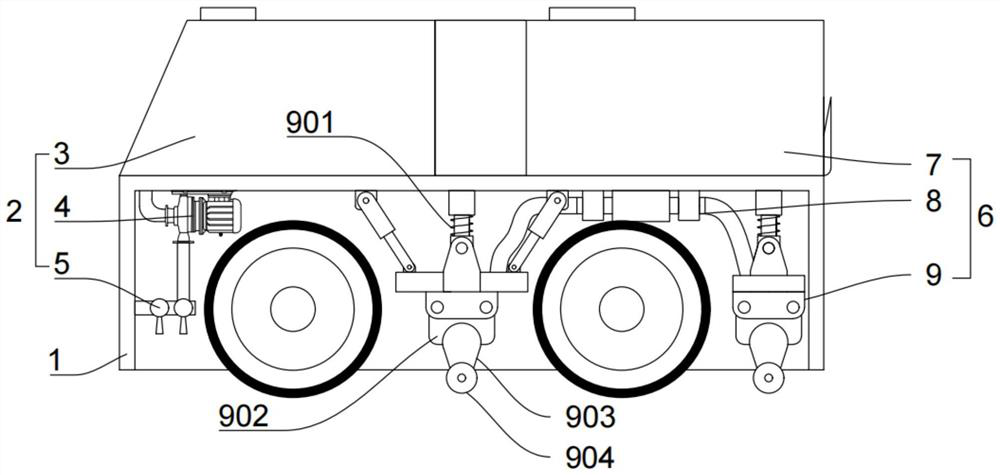

Crack filling and repairing equipment for road maintenance

InactiveCN114427182ARealize automatic sensingAchieve fillingRoads maintainenceArchitectural engineeringStructural engineering

The invention is applicable to the field of road maintenance equipment, and provides crack filling and repairing equipment for road maintenance, the crack filling and repairing equipment comprises a flushing assembly and a filling assembly, and the filling assembly comprises a storage mechanism and a filling mechanism; through the arrangement of the flushing structure, water flushing cleaning can be conducted in advance when a crack is filled, a filling material can be better connected with the crack, meanwhile, through the arrangement of the discharging filling piece which controls horizontal movement through the crack inductor, automatic induction and filling of the crack can be achieved, manual operation and control are not needed, and the working efficiency is improved. And the labor requirement is effectively reduced, the working efficiency is improved, and the filling materials can be further more evenly distributed in the cracks through the arrangement of the vibration rolling wheels.

Owner:阮国忠

An automatic all-in-one machine for building floor tiles in a high-speed railway station square

ActiveCN106087675BHigh degree of automationLaying speed is fastRoads maintainenceBrickThree degrees of freedom

The invention relates to an automatic building all-in-one machine for high-speed rail station square floor tiles. The automatic building all-in-one machine comprises a crawler traveling device, wheel type traveling devices, an electric rotary table, a three-degree-of-freedom parallel mechanism, a sucking device and a tile joint mud filling device. The wheel type traveling devices are symmetrically arranged on the left side and the right side of the crawler traveling device. The electric rotary table is located in the center of the upper end of the crawler traveling device. The three-degree-of-freedom parallel mechanism is located between the electric rotary table and the sucking device, the lower end of the three-degree-of-freedom parallel mechanism is connected with the electric rotary table, and the upper end of the three-degree-of-freedom parallel mechanism is connected with the sucking device. The tile joint mud filling device is located over the sucking device. According to the automatic building all-in-one machine for the high-speed rail station square floor tiles, multiple functions such as composite traveling, multi-degree-of-freedom position adjusting, floor tile sucking and tile joint mud filling and fixing are integrated, tile paving operation can be conducted on municipal sidewalks, the automation degree is high, the paving speed is high, the paving attractiveness is high, and the problems that according to an existing floor tile paving mode, the appropriated labor is high, the paving efficiency is low, and the paving cost is high are solved.

Owner:南通江海港建设工程有限公司

A fully automatic building indoor floor tile laying machine

ActiveCN105926912BHigh degree of automationLaying speed is fastBuilding constructionsBrickMulti degree of freedom

The invention relates to a full-automatic building indoor floor tile laying machine which comprises a crawler traveling device, wheeled traveling devices, an electric turntable, a redundancy parallelization mechanism, a suction device and a tile seam putty filling device. The wheeled traveling devices are symmetrically arranged on the left side and the right side of the crawler traveling device respectively, the electric turntable is positioned at the center of the upper end of the crawler traveling device and fixedly connected with the crawler traveling device, the redundancy parallelization mechanism is positioned between the electric turntable and the suction device, the lower end of the redundancy parallelization mechanism is connected with the electric turntable while the lower end of the same is connected with the suction device, and the tile seam putty filling device is positioned right above the suction device. The full-automatic building indoor floor tile laying machine integrates various functions of compound traveling, multi-degree-of-freedom direction adjusting, floor tile sucking and tile seam puffy filling fixing, can be used for laying floor tiles for municipal sidewalks and is high in automation level, laying speed and laying attractiveness, and the problem that existing floor tile laying is large in occupied space, low in laying efficiency and high in laying cost is solved.

Owner:重庆绿泰园林装饰工程有限公司

Automatic building all-in-one machine for high-speed rail station square floor tiles

ActiveCN106087675AHigh degree of automationLaying speed is fastRoads maintainenceBrickThree degrees of freedom

The invention relates to an automatic building all-in-one machine for high-speed rail station square floor tiles. The automatic building all-in-one machine comprises a crawler traveling device, wheel type traveling devices, an electric rotary table, a three-degree-of-freedom parallel mechanism, a sucking device and a tile joint mud filling device. The wheel type traveling devices are symmetrically arranged on the left side and the right side of the crawler traveling device. The electric rotary table is located in the center of the upper end of the crawler traveling device. The three-degree-of-freedom parallel mechanism is located between the electric rotary table and the sucking device, the lower end of the three-degree-of-freedom parallel mechanism is connected with the electric rotary table, and the upper end of the three-degree-of-freedom parallel mechanism is connected with the sucking device. The tile joint mud filling device is located over the sucking device. According to the automatic building all-in-one machine for the high-speed rail station square floor tiles, multiple functions such as composite traveling, multi-degree-of-freedom position adjusting, floor tile sucking and tile joint mud filling and fixing are integrated, tile paving operation can be conducted on municipal sidewalks, the automation degree is high, the paving speed is high, the paving attractiveness is high, and the problems that according to an existing floor tile paving mode, the appropriated labor is high, the paving efficiency is low, and the paving cost is high are solved.

Owner:南通江海港建设工程有限公司

A laying device for a floor tile laying robot for urban municipal sidewalks

ActiveCN106012775BHigh degree of automationLaying speed is fastRoads maintainenceBrickVacuum pressure

Owner:湖南乐金建设发展有限公司

A pavement and floor brick masonry operation robot

ActiveCN106087672BHigh degree of automationLaying speed is fastProgramme-controlled manipulatorRoads maintainenceBrick masonryRoad surface

The invention relates to a robot for pavement floor tile laying work. The robot for pavement floor tile laying work comprises a crawler traveling device, wheel type traveling devices, an electric rotary table, a delta parallel mechanism, a suction device and a tile joint mud filling device. The wheel type traveling devices are symmetrically arranged on the left side and the right side of the crawler traveling device correspondingly. The electric rotary table is located in the center of the upper end of the crawler traveling device. The delta parallel mechanism is located between the electric rotary table and the suction device. The lower end of the delta parallel mechanism is connected with the electric rotary table, and the upper end of the delta parallel mechanism is connected with the suction device. The tile joint mud filling device is located over the suction device. The robot integrates various functions such as a combined traveling function, a multi-degree-of-freedom direction adjustment function, a floor tile suction function and a tile joint mud filling and fixing function, can be used for floor tile laying of municipal pavements, and is high in automation degree and laying speed and good in laying attractiveness, and the problems that in the prior art, labor consumption of floor tile laying is high, the laying efficiency is low, and the laying cost is high are solved.

Owner:陈雅婷

A city municipal sidewalk floor tile laying robot

ActiveCN106087673BHigh degree of automationLaying speed is fastRoads maintainenceBrickMulti degree of freedom

The invention relates to a robot for laying floor tiles on urban municipal sidewalks. The robot comprises a crawler traveling device, wheel type traveling devices, an electric rotary table, a Stewart parallel mechanism, a suction device and a tile joint mud filling device. The wheel type traveling devices are symmetrically arranged on the left side and the right side of the crawler traveling device correspondingly. The electric rotary table is located in the center of the upper end of the crawler traveling device. The lower end of the Stewart parallel mechanism is connected with the electric rotary table, and the upper end of the Stewart parallel mechanism is connected with the suction device. The tile joint mud filling device is located over the suction device. The robot integrates various functions such as a combined traveling function, a multi-degree-of-freedom direction adjustment function, a floor tile suction function and a tile joint mud filling and fixing function, can be used for laying the floor tiles on the urban municipal sidewalks, and is high in automation degree and laying speed and good in laying attractiveness, and the problems that in the prior art, labor consumption of floor tile laying is high, the laying efficiency is low, and the laying cost is high are solved.

Owner:英格威尔科研(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com