Granular arabinose as well as preparation method and application thereof

An arabinose and granular technology, applied in the field of granular arabinose and its preparation, can solve the problems of difficulty in mixing uniformly, affecting the application effect of products, and being unable to be used as excipients and fillers for tablet products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention also discloses a method for preparing the granular arabinose as described above, comprising the following steps:

[0020] 1) Dissolving crystalline arabinose to obtain a 50% to 60% arabinose aqueous solution, and transporting it to a constant temperature bath, controlling the temperature at 40°C to 70°C, and using it as a binder.

[0021] 2) Using a crusher to crush another group of crystalline arabinose into powder to obtain arabinose powder.

[0022] 3) Add the obtained arabinose powder into the granulator, turn on the air intake of the granulator, and pass dehumidified air into the granulation chamber (temperature 25°C, relative humidity about 5%), and the fan frequency is 25HZ~30HZ , turn on the heating, heat the air to 60°C-65°C through steam, and dry the arabinose powder in a boiling fluidized state for 30min-40min.

[0023] 4) Turn on the spray, adjust the pressure of the compressed air passing through the spray gun to 0.35MPa ~ 0.45MPa, an...

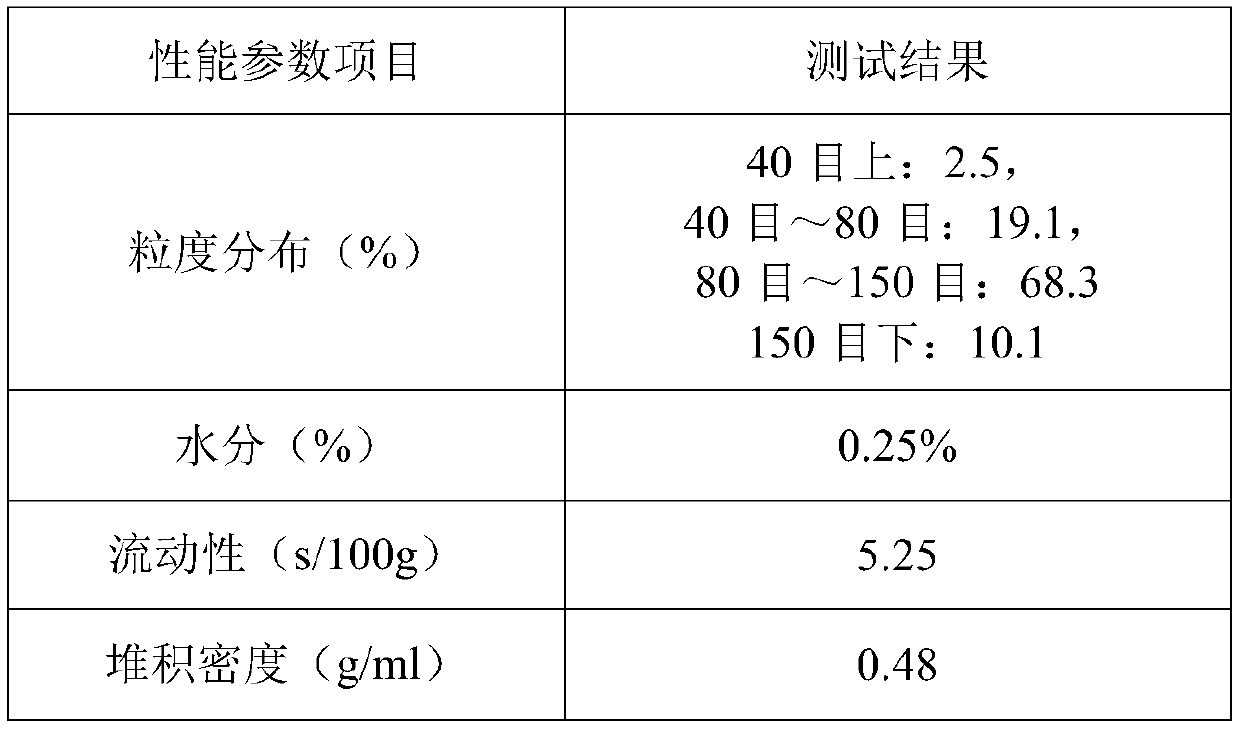

Embodiment 1

[0030] The first embodiment of the preparation method of granular arabinose of the present invention comprises the following steps:

[0031] 11) Dissolving crystalline arabinose to obtain a 50% arabinose aqueous solution, and transporting it to a constant temperature tank, controlling the temperature to 40°C, and using it as a binder.

[0032] 12) Use a crusher to crush another group of crystalline arabinose into powder to obtain arabinose powder. The particle size distribution of the powder is 2.3% above 100 mesh, 18.4% from 100 mesh to 150 mesh, and 41.4% from 150 mesh to 320 mesh , 37.9% under 320 mesh.

[0033] 13) Add the obtained arabinose powder into the granulator, and turn on the air intake of the granulator, and pass dehumidified air into the granulation chamber (temperature 25°C, relative humidity about 5%), the fan frequency is 30HZ, turn on Heating, the air is heated to 65°C by steam, and the arabinose powder is dried for 40 minutes in a boiling fluidized state. ...

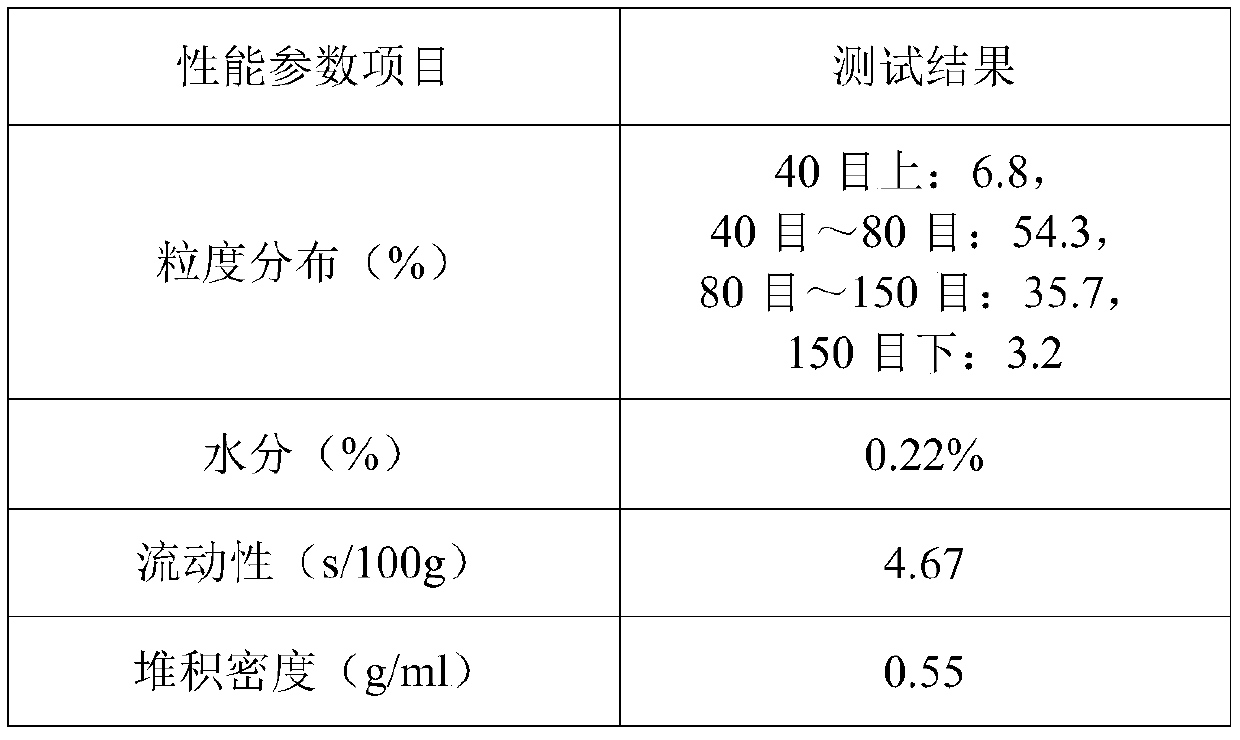

Embodiment 2

[0042] The second embodiment of the preparation method of granular arabinose of the present invention comprises the following steps:

[0043] 21) Dissolving the crystalline arabinose to obtain a 55% aqueous solution of arabinose, and transporting it to a constant temperature bath, controlling the temperature to 55° C., and using it as a binder.

[0044]22) Use a crusher to crush another group of crystalline arabinose into powder to obtain arabinose powder. The particle size distribution of the powder is 2.3% above 100 mesh, 18.4% from 100 mesh to 150 mesh, and 41.4% from 150 mesh to 320 mesh , 37.9% under 320 mesh.

[0045] 23) Add the obtained arabinose powder into the granulator, and turn on the air intake of the granulator, and pass dehumidified air into the granulation chamber (temperature 25°C, relative humidity about 5%), the fan frequency is 28HZ, turn on Heating, the air is heated to 63°C by steam, and the arabinose powder is dried for 35 minutes in a boiling fluidize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com