Spliced type concrete pipe

A technology of splicing and concrete pipes, applied in the direction of pipes/pipe joints/fittings, non-detachable pipe connections, passing components, etc., can solve the problems of low splicing efficiency of concrete pipes, low structural strength, and poor sealing performance, and achieve Improve structural strength and connection stability, improve connectivity, and improve the effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

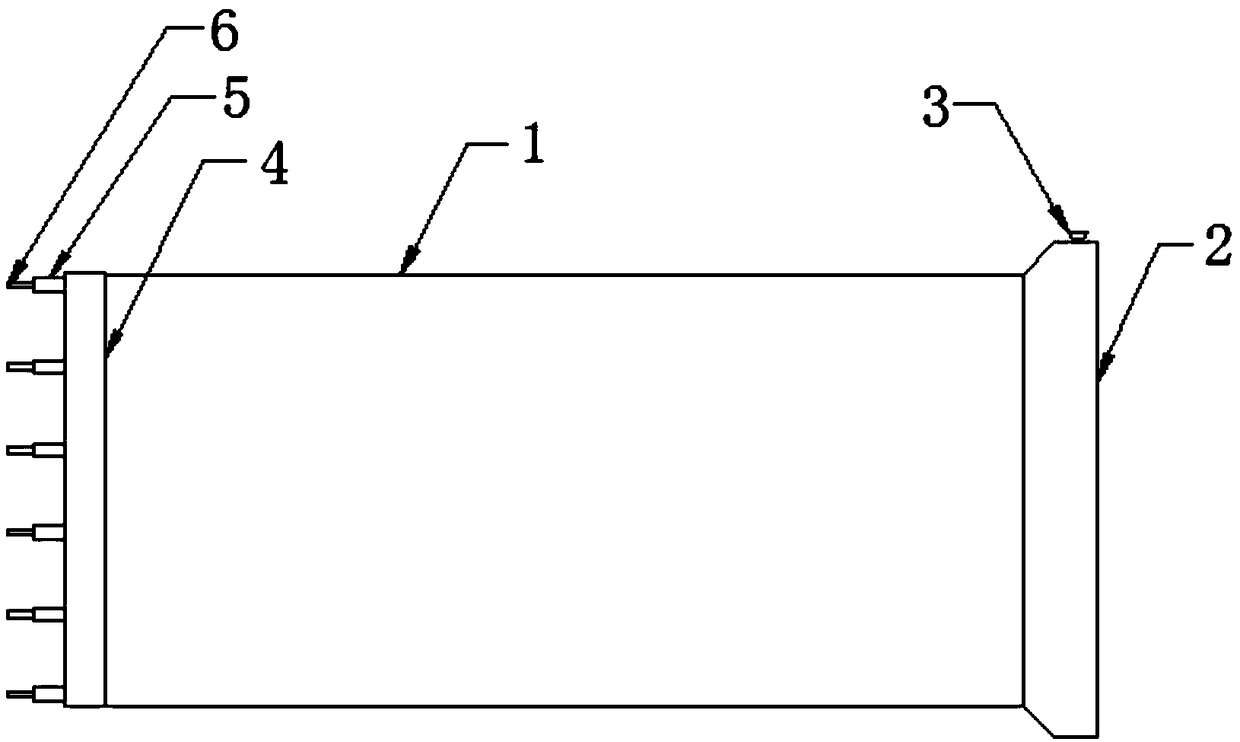

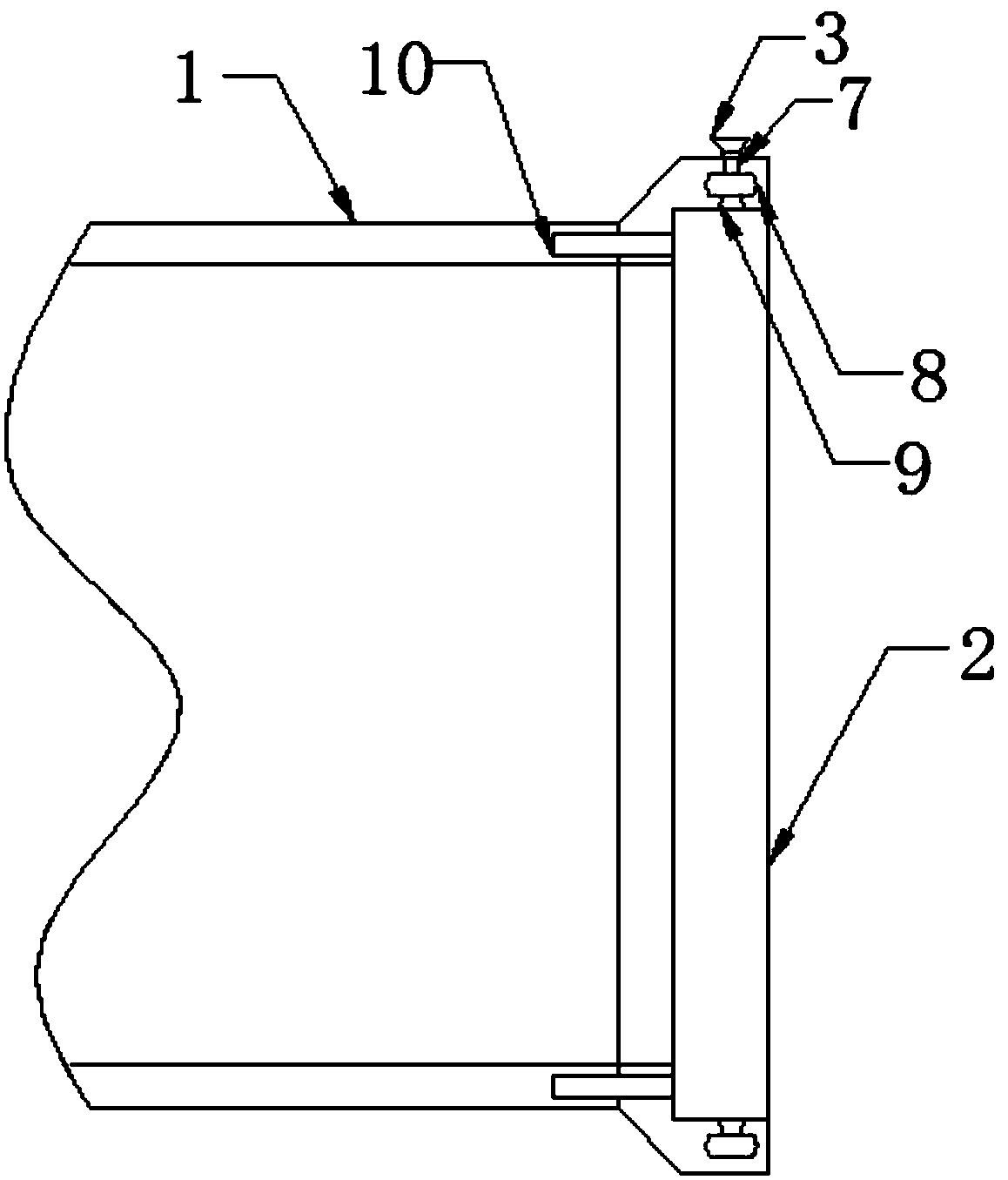

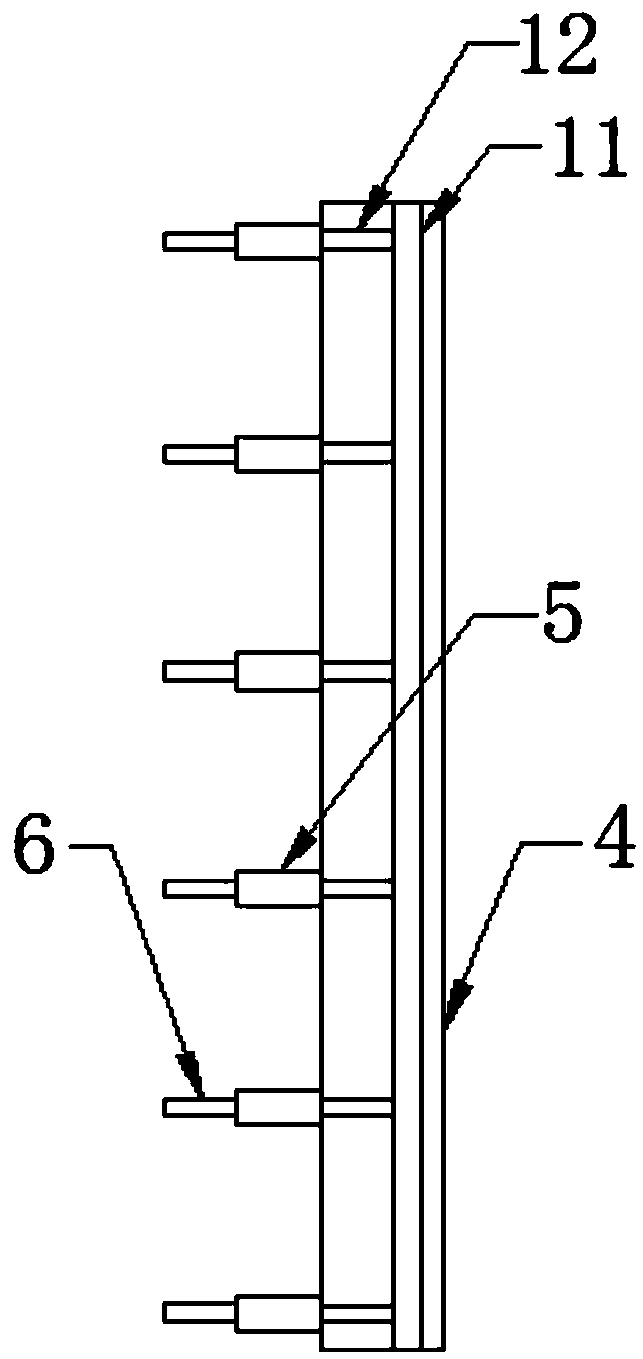

[0025] Such as Figure 1-5 As shown, a spliced concrete pipe of the present invention includes a concrete pipe main body 1, a socket 2 and an interface 4, one end of the concrete pipe main body 1 is fixed with a socket 2, and the inside of the socket 2 is provided with an annular cavity 8, The inner wall of one side of the annular cavity 8 is evenly provided with several annular trapezoidal grooves 9, one side of the socket 2 and one side of the concrete pipe main body 1 are respectively provided with several sockets 10, and the other end of the concrete pipe main body 1 is fixed An interface 4 is provided, and several intubation tubes 5 are arranged at intervals on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com