Wastewater treatment plant water inlet floating garbage salvage machine

A technology for waste water treatment and water inlet, which is applied in the direction of open water surface cleaning, water conservancy engineering, construction, etc., can solve the problems of low work efficiency and trouble, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

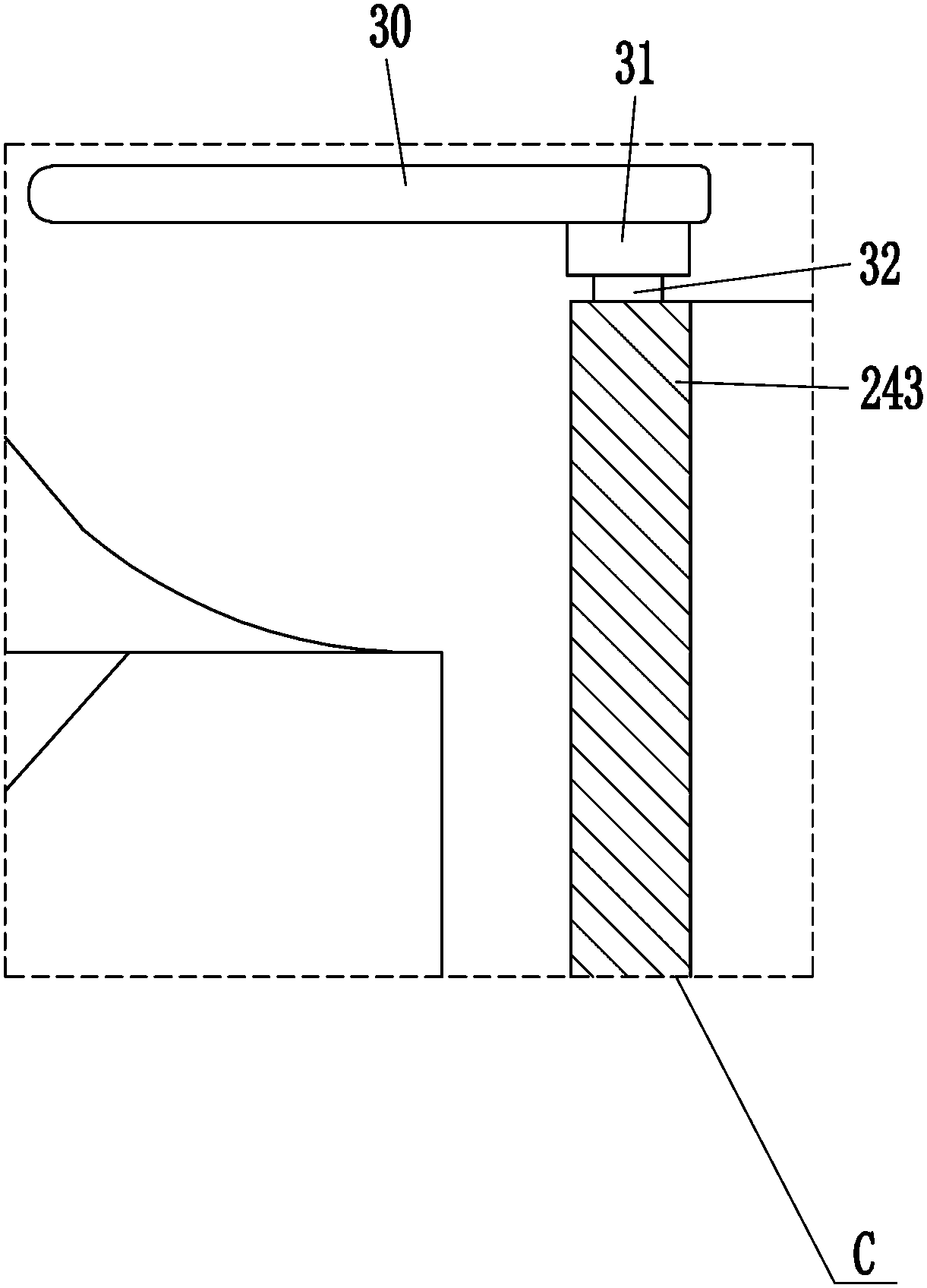

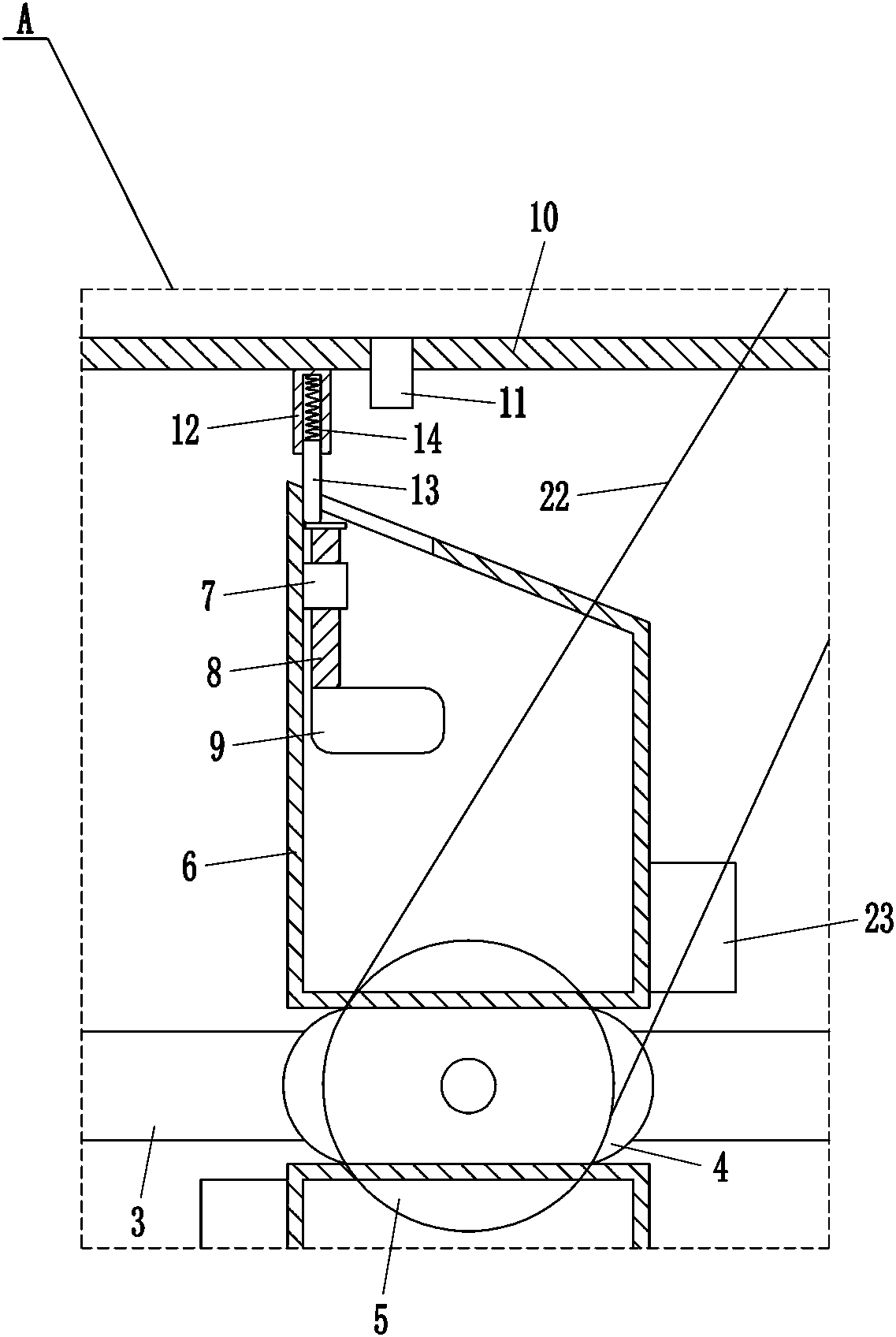

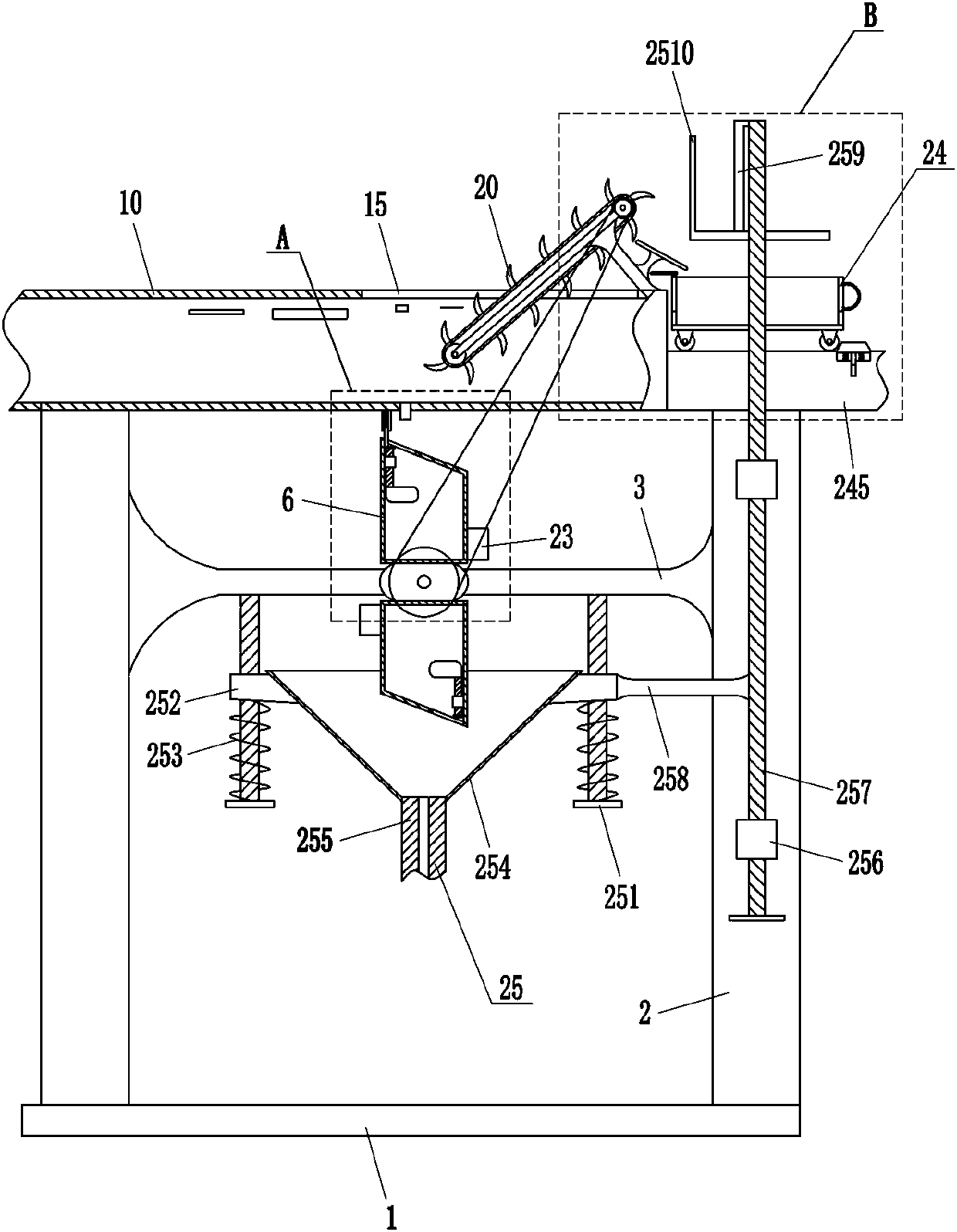

[0022] A waste water treatment plant water inlet floating garbage salvage machine, such as Figure 1-4As shown, it includes bottom plate 1, support rod 2, cross bar 3, oval block 4, large pulley 5, box body 6, guide sleeve 7, guide rod 8, floating block 9, water inlet pipe 10, small water pipe 11, sleeve 12. Sleeve rod 13, first spring 14, inclined plate 16, mounting plate 17, conveying roller 18, conveying belt 19, lever 20, small pulley 21, flat belt 22, weight 23 and collecting mechanism 24, bottom plate 1 top The left and right sides are connected with support rods 2, and the upper part between the two support rods 2 is connected with a cross bar 3, and the middle part of the front side of the cross bar 3 is rotatably equipped with an ellipse block 4, and the front side of the ellipse block 4 is equipped with a large belt pulley 5. There are two water-filled tanks 6, which are respectively arranged on the upper and lower sides of the ellipse block 4. The upper left side of...

Embodiment 2

[0024] A waste water treatment plant water inlet floating garbage salvage machine, such as Figure 1-4 As shown, it includes bottom plate 1, support rod 2, cross bar 3, oval block 4, large pulley 5, box body 6, guide sleeve 7, guide rod 8, floating block 9, water inlet pipe 10, small water pipe 11, sleeve 12. Sleeve rod 13, first spring 14, inclined plate 16, mounting plate 17, conveying roller 18, conveying belt 19, lever 20, small pulley 21, flat belt 22, weight 23 and collecting mechanism 24, bottom plate 1 top The left and right sides are connected with support rods 2, and the upper part between the two support rods 2 is connected with a cross bar 3, and the middle part of the front side of the cross bar 3 is rotatably equipped with an ellipse block 4, and the front side of the ellipse block 4 is equipped with a large belt pulley 5. There are two water-filled tanks 6, which are respectively arranged on the upper and lower sides of the ellipse block 4. The upper left side o...

Embodiment 3

[0027] A waste water treatment plant water inlet floating garbage salvage machine, such as Figure 1-4 As shown, it includes bottom plate 1, support rod 2, cross bar 3, oval block 4, large pulley 5, box body 6, guide sleeve 7, guide rod 8, floating block 9, water inlet pipe 10, small water pipe 11, sleeve 12. Sleeve rod 13, first spring 14, inclined plate 16, mounting plate 17, conveying roller 18, conveying belt 19, lever 20, small pulley 21, flat belt 22, weight 23 and collecting mechanism 24, bottom plate 1 top The left and right sides are connected with support rods 2, and the upper part between the two support rods 2 is connected with a cross bar 3, and the middle part of the front side of the cross bar 3 is rotatably equipped with an ellipse block 4, and the front side of the ellipse block 4 is equipped with a large belt pulley 5. There are two water-filled tanks 6, which are respectively arranged on the upper and lower sides of the ellipse block 4. The upper left side o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap