Multifunctional milling head mounting device for electrolyzing-electric spark milling

A mounting device and multi-functional technology, which is applied in the field of multi-functional milling head mounting device for electrolytic EDM, can solve the problems of poor installation and use flexibility, insufficient liquid supply in the processing area, and poor processing stability, etc., and achieves a compact structure , good chip removal and cooling function, and the effect of overall device stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example 1

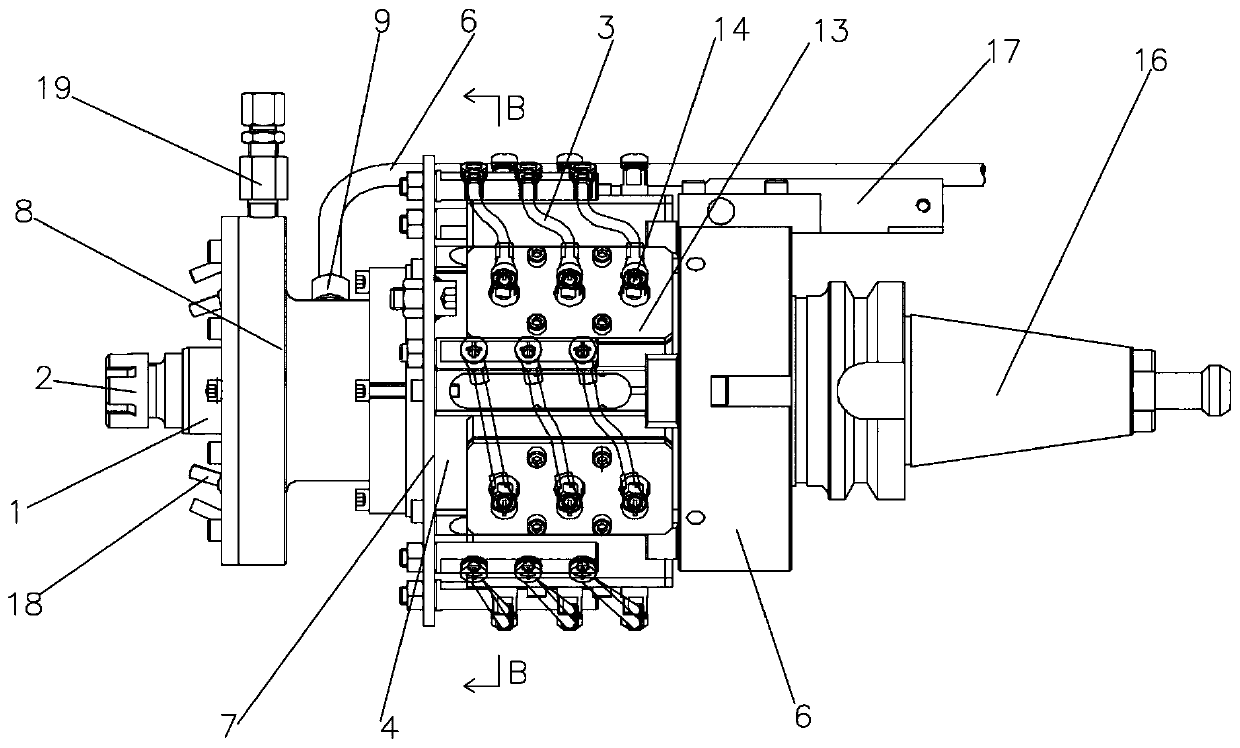

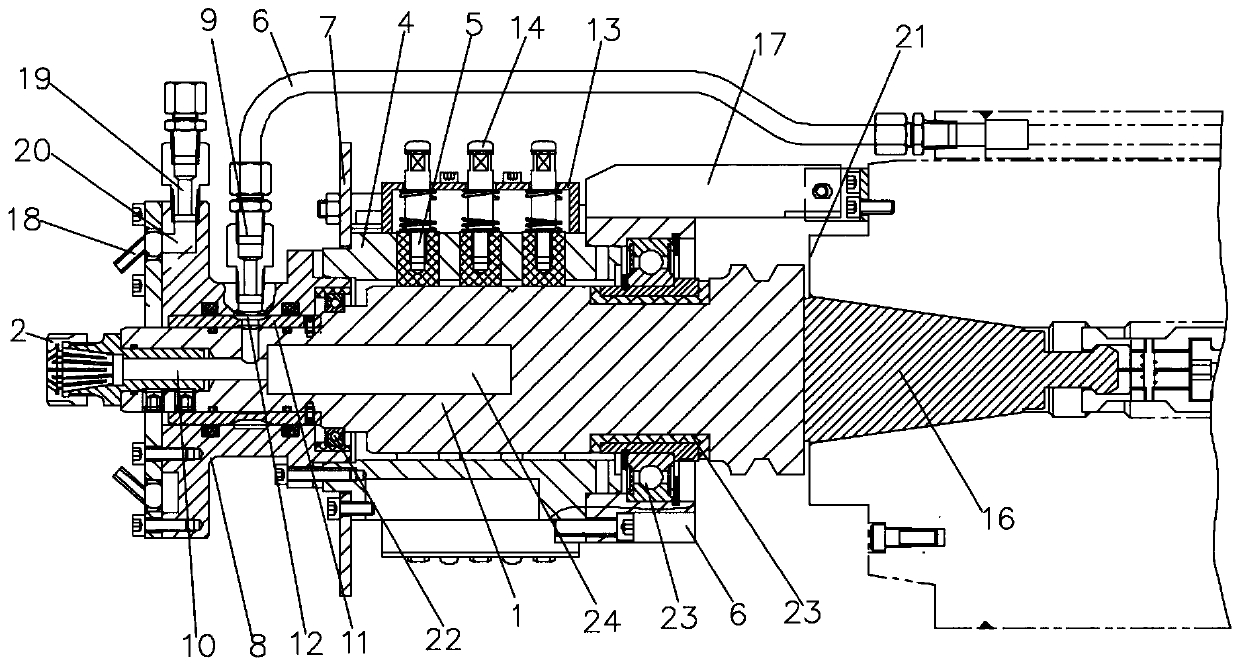

[0033] Such as Figure 1 to Figure 3 As shown, this embodiment provides a multifunctional milling head mounting device for electrolytic electric discharge milling, including a conductive shaft 1. The right end of the conductive shaft 1 is provided with a joint assembly connected to a driving mechanism provided on a basic processing platform, and the conductive shaft The left end of 1 is equipped with a ferrule 2 for fixing the milling head. The ferrule 2 can be selected in different specifications, and can be clamped and replaced with electrode milling heads of different specifications. It can also realize the quick replacement of ordinary milling heads and electrode milling heads. In the embodiment, the ferrule 2 preferably uses an ER32 ferrule; a mounting sleeve 8 and a brush holder 4 are sequentially sleeved on the conductive shaft 1 from left to right. The mounting sleeve 8 and the brush holder 4 are connected by a national standard, and the mounting sleeve...

Example Embodiment

[0039] Example 2

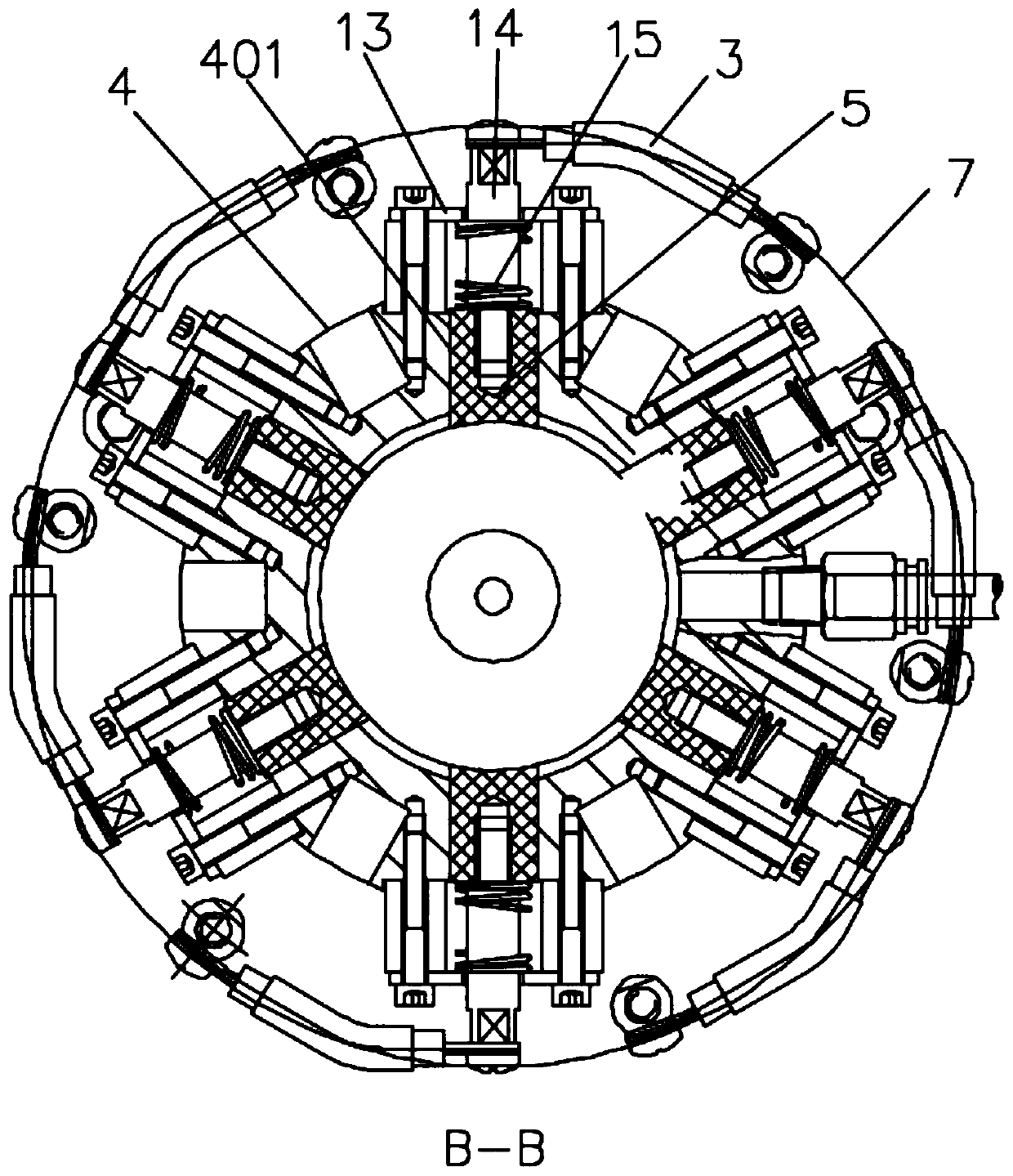

[0040] Combine figure 2 with image 3 As shown, this embodiment is further optimized on the basis of Embodiment 1, specifically:

[0041] There are three groups of 6 through holes 401 in each group evenly running through the brush holder 4, and the axis of each through hole 401 is perpendicular to and intersects with the axis of the conductive shaft 1, and the axis of each group of through holes 401 The core lines are in the same plane and intersect perpendicularly to the axis of the conductive shaft 1, and each group of through holes 401 are distributed at equal angles with the intersection as the center of the circle. The brush assembly includes 18 uniformly arranged in the through holes 401 and the conductive The brush 5 in contact with the shaft 1, one brush 5 in each through hole 401, the brush 5 is a graphite brush, the brush holder 4 is located directly above the through hole 401, and a backing plate 13 is fixedly connected to the backing plate 13 A cond...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap