A fabric wear resistance detection system and detection method

A detection system and wear resistance technology, applied in the direction of testing wear resistance, measuring devices, analyzing materials, etc., can solve problems such as testing fabric wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

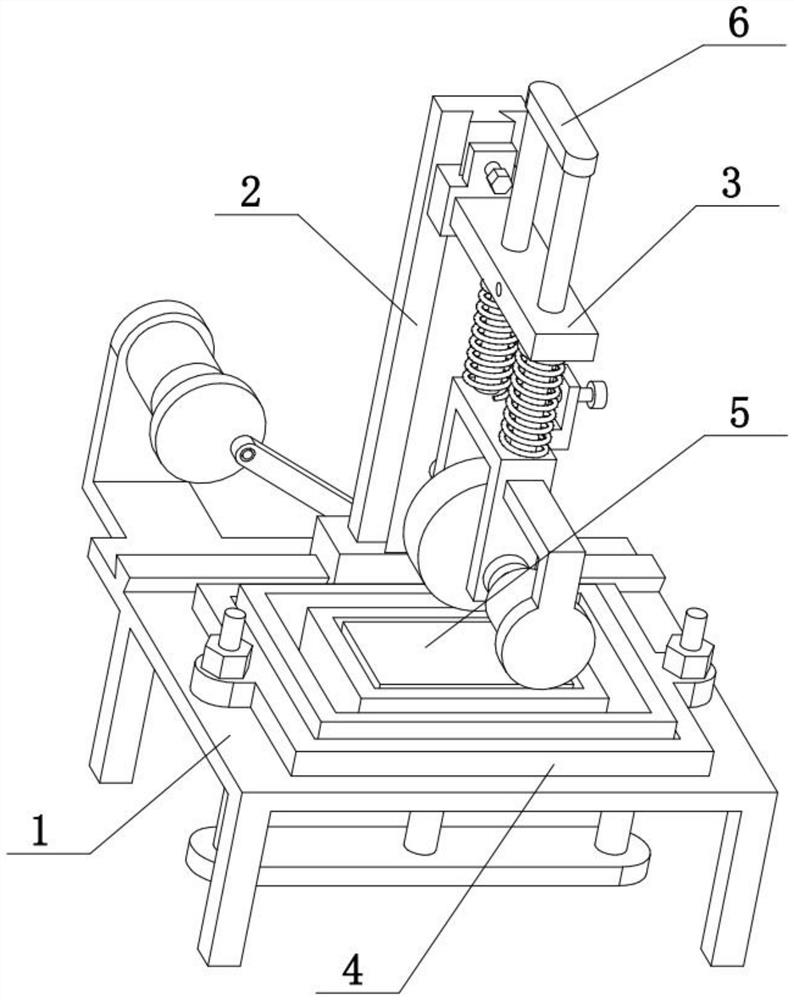

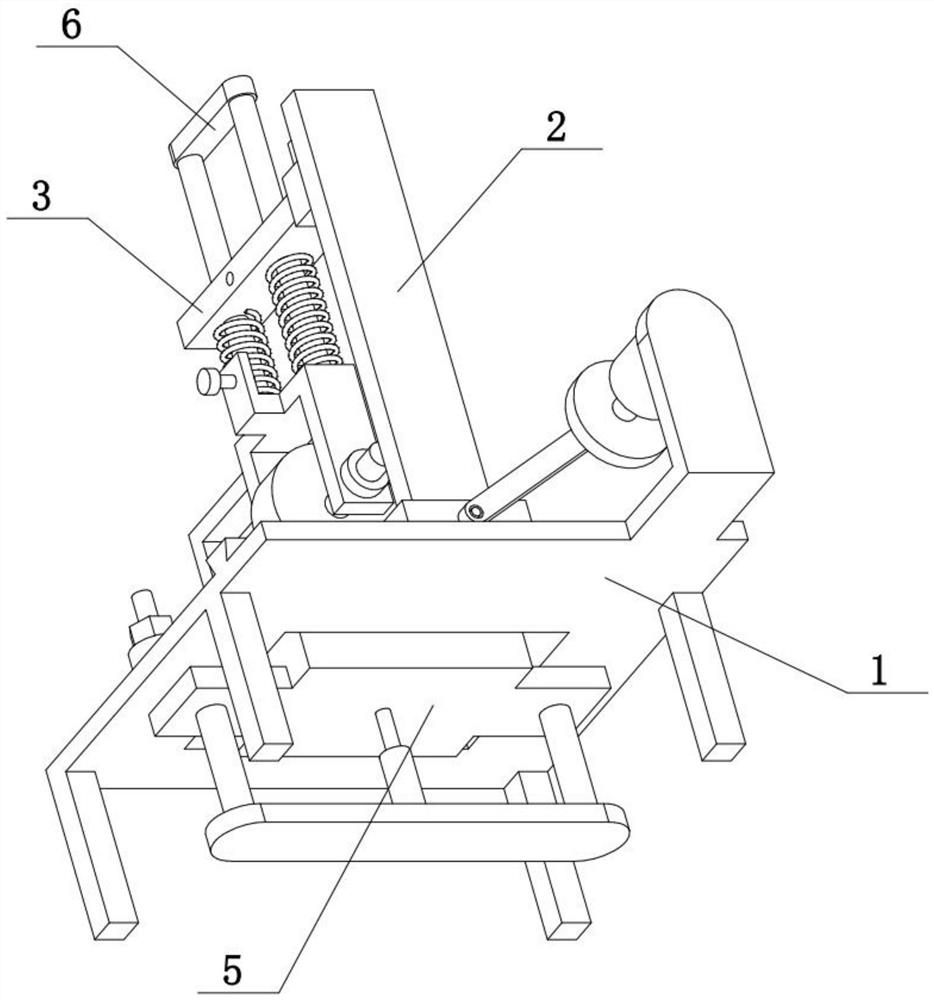

[0038] Combine below Figure 1-10 This embodiment is described. The present invention relates to the field of fabric detection, more specifically, a fabric wear resistance detection system and detection method, including a chassis 1, a vertical seat 2, a horizontal seat 3, a rectangular fixed frame 4, and a bottom pad 5 And friction mechanism 6, the present invention can test the abrasion resistance of fabric under various conditions.

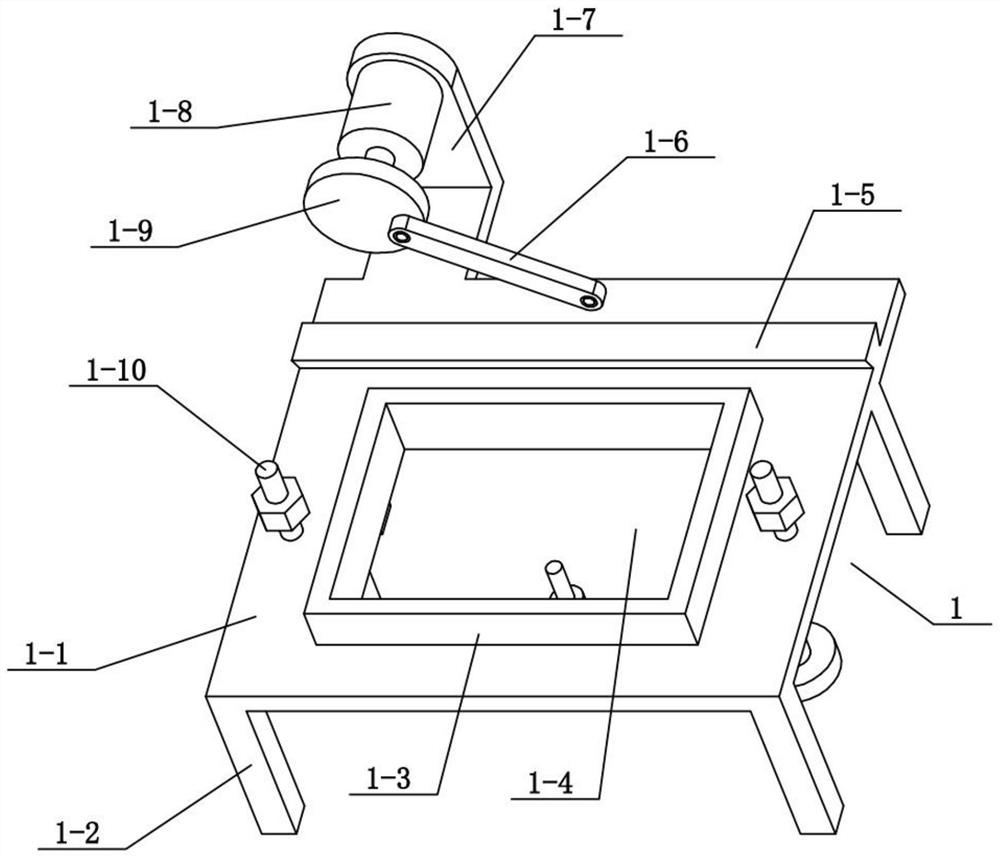

[0039] The chassis 1 includes a flat plate 1-1, a support column 1-2, a rectangular convex edge 1-3, a rectangular hole 1-4 and a threaded stub 1-10, and the four corners of the lower end of the flat plate 1-1 are fixedly connected There are support columns 1-2, and the flat plate 1-1 is provided with a rectangular hole 1-4, and the outer periphery of the rectangular hole 1-4 on the flat plate 1-1 is fixedly connected with a rectangular convex edge 1-3, and the left and right sides of the flat plate 1-1 Both ends are fixedly connected with thr...

specific Embodiment approach 2

[0043] Combine below Figure 1-10 To illustrate this embodiment, the underframe 1 also includes a trapezoidal slide rail I1-5, an inclined connecting rod 1-6, a motor frame I1-7, a motor I1-8 and a turntable 1-9, and the upper end of the flat plate 1-1 is fixedly connected There is a trapezoidal slide rail I1-5, a motor frame I1-7 is fixedly connected to the flat plate 1-1, a motor I1-8 is fixedly connected to the motor frame I1-7, and a turntable 1-8 is fixedly connected to the output shaft of the motor I1-8. 9. One end of the oblique connecting rod 1-6 is hingedly connected to the eccentric position of the turntable 1-9.

specific Embodiment approach 3

[0044] Combine below Figure 1-10 To illustrate this embodiment, the underframe 1 also includes a horizontal bottom plate 1-11, a cylindrical vertical rod 1-12 and an electric telescopic rod 1-13, and the left and right ends of the lower end of the flat plate 1-1 are fixedly connected with a cylindrical vertical rod 1-13. 12. A horizontal bottom plate 1-11 is fixedly connected between the lower ends of the two cylindrical vertical rods 1-12, and an electric telescopic rod 1-13 is fixedly connected in the middle of the upper end of the horizontal bottom plate 1-11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com