Wearability testing device for textile fabric

A wear-resistant testing and textile fabric technology, applied in the testing of wear resistance and other directions, can solve the problems of no dust removal and cooling function, inconvenient use of the testing device, etc., to prevent pollution of the air environment, enhance practicability, and prevent excessive temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

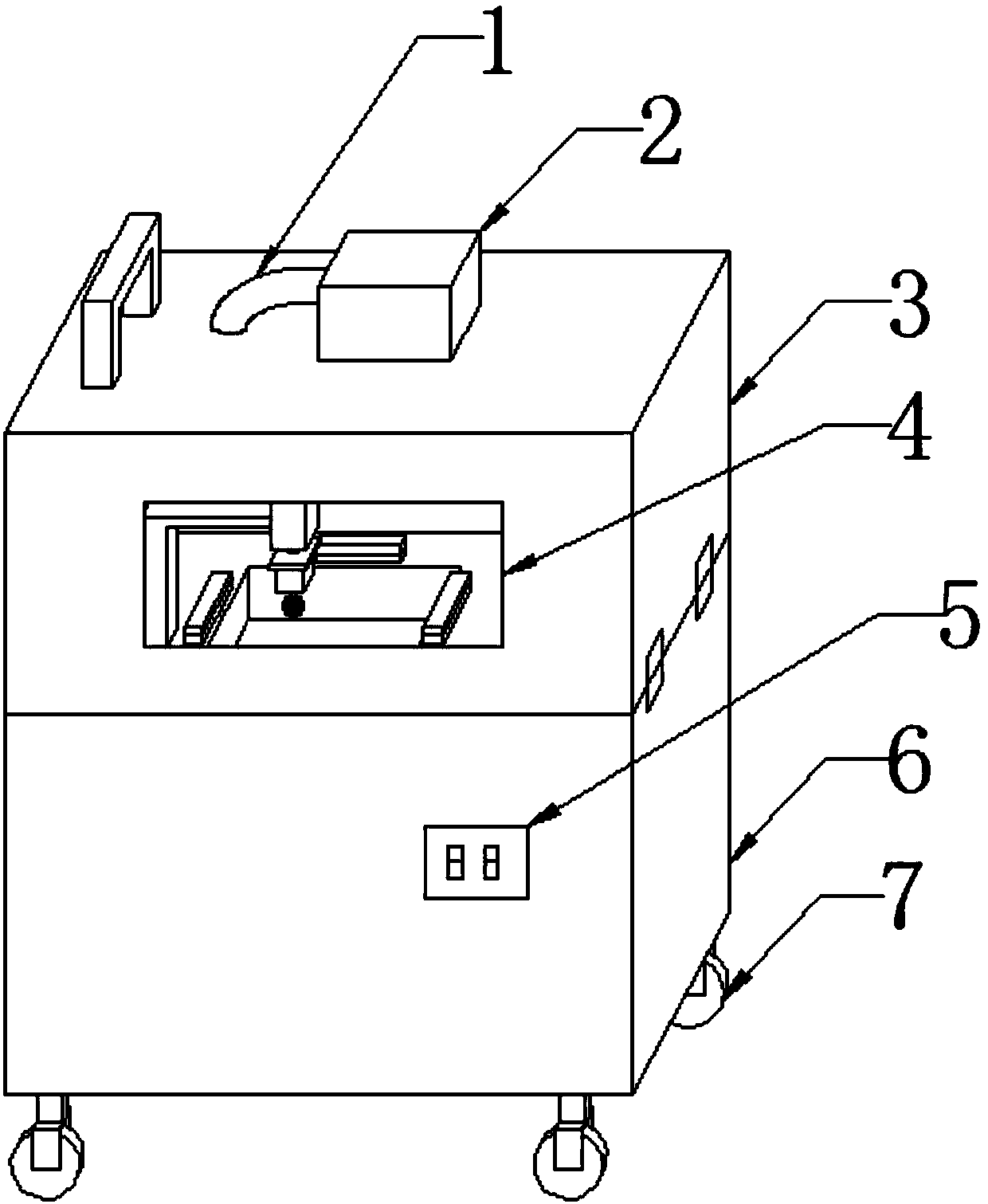

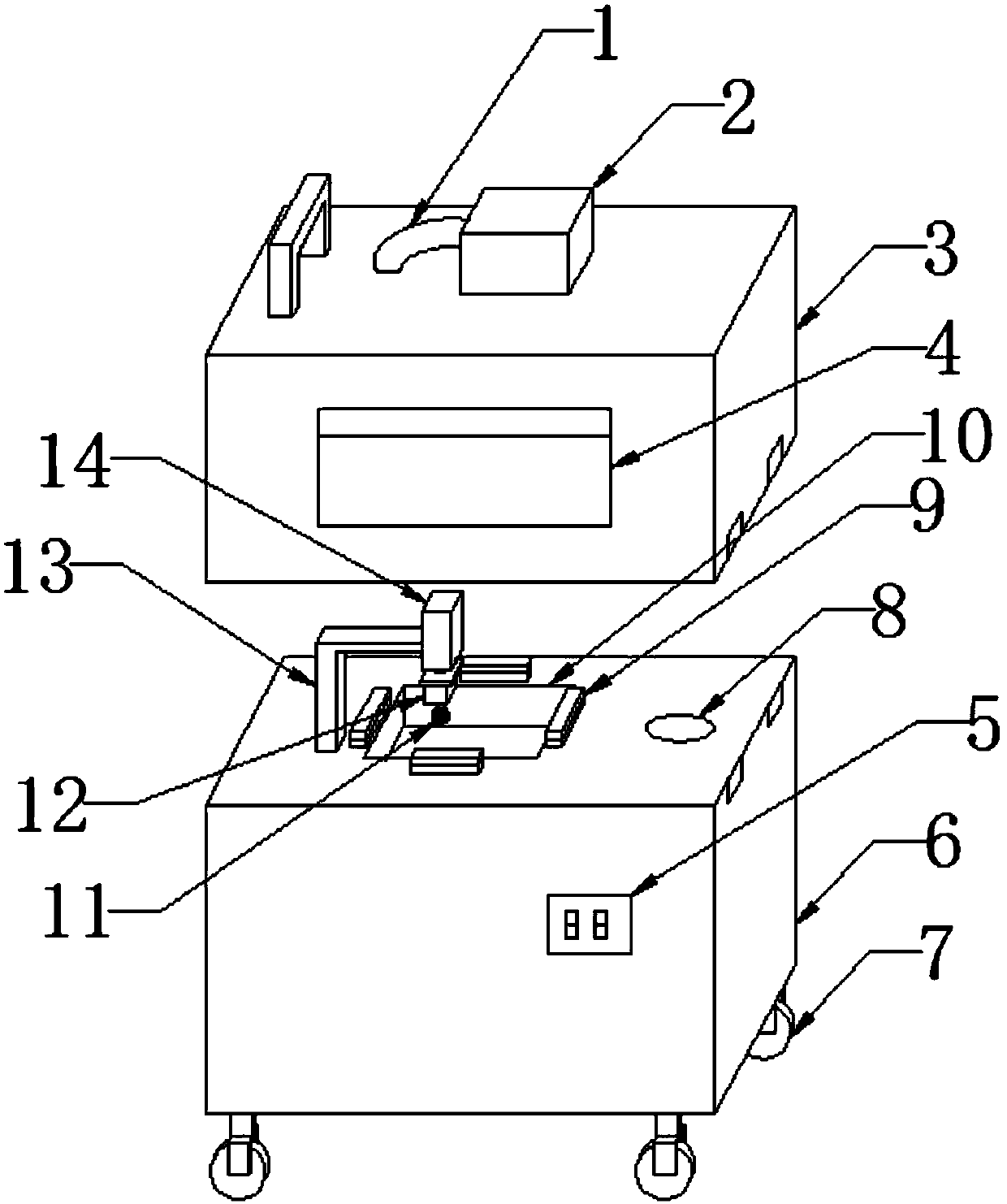

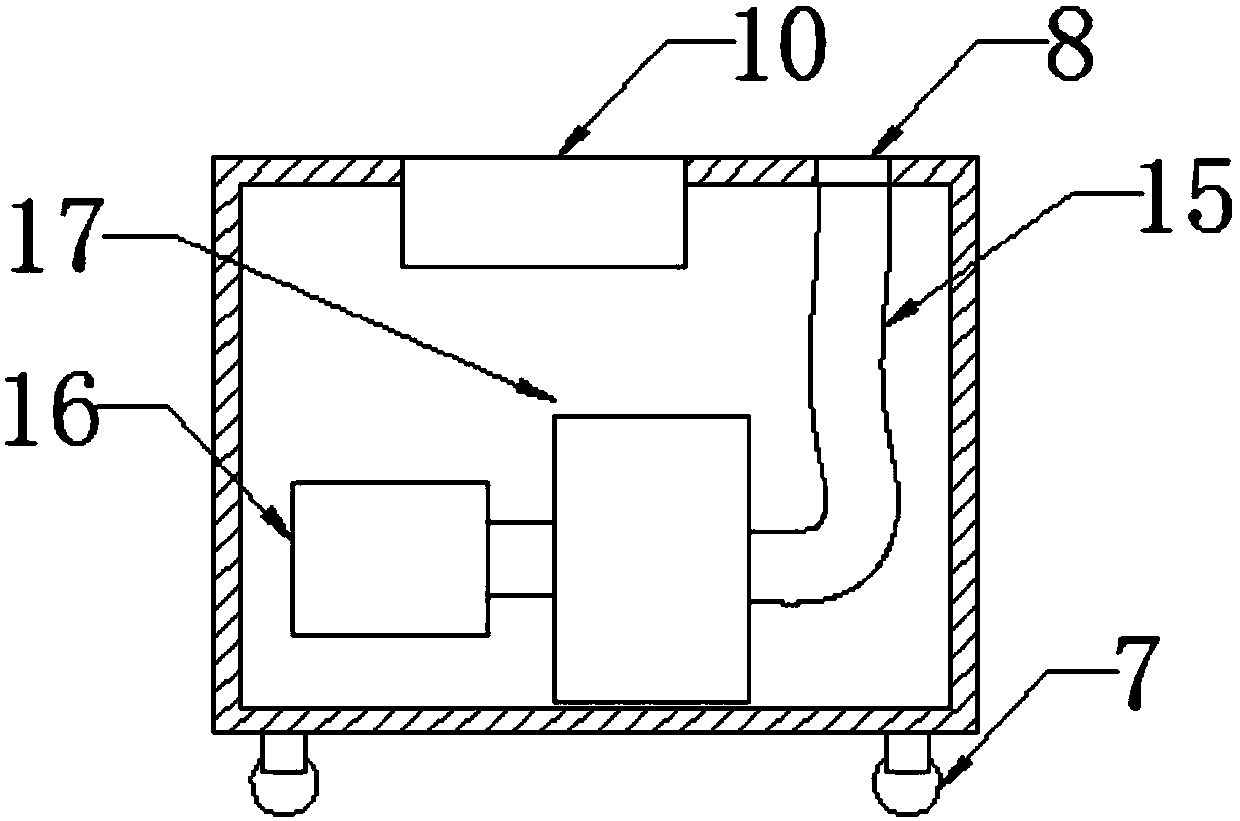

[0018] Example: such as Figure 1-4 As shown, a wear-resistant test device for textile fabrics of the present invention includes a workbench 6, a protective cover 3 and a grinding head 11, one side of the top of the workbench 6 is provided with a slot 10, and four sides of the slot 10 are provided with Fixed clip 9, one side of slot 10 is provided with connecting rod 13, and one end of connecting rod 13 is fixedly provided with pneumatic cylinder 14, and one end of the piston rod of pneumatic cylinder 14 is fixedly provided with motor 12, and one end of the rotating shaft of motor 12 is provided with grinding The other side of the head 11 and the top of the workbench 6 is provided with a dust removal port 8, and the interior of the workbench 6 is respectively provided with an exhaust fan 16 and a dust receiving box 17, and the dust removal port 8 communicates with one side of the dust receiving box 17 through a connecting pipe 15 , the other side of the dust box 17 communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com