Skeleton structure of a car folding coat rack

A skeleton structure and folding technology, which is applied in the skeleton structure field of automobile folding coat racks, can solve problems such as no locking structure, messy placed items, and folded coat racks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

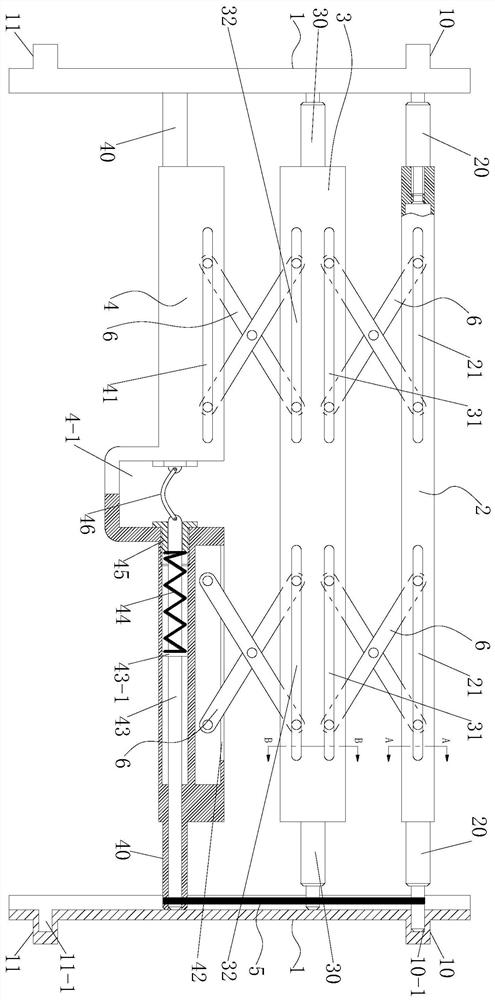

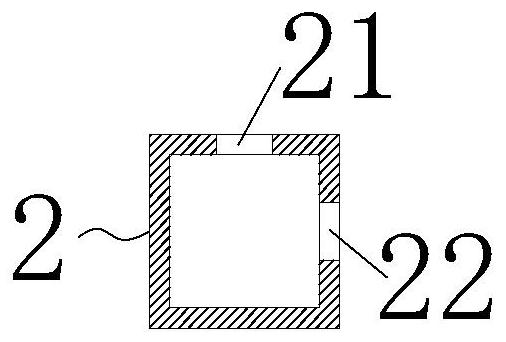

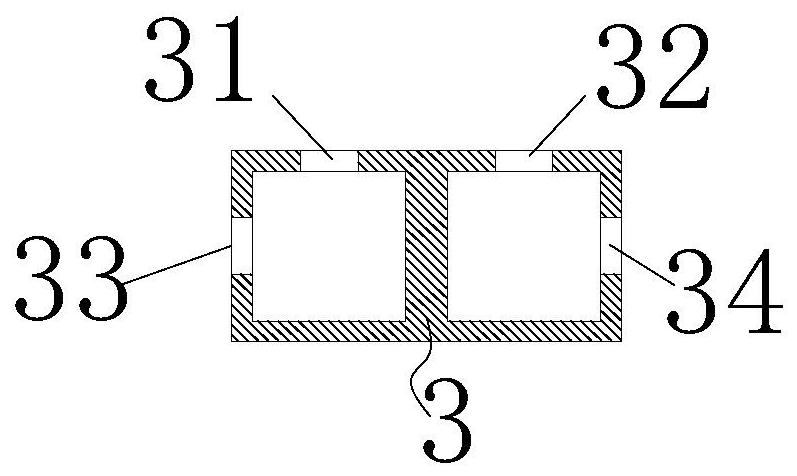

[0024] The skeleton structure of the car folding coat rack, when some higher items need to be installed in the trunk of the car, only the "U" groove 4-1 in the middle of the outer slide bar 4 is held by hand, and then the fingers are hooked Elastic resin sheet 46 uses very little force, and this moment latch lever 43 further compresses compression spring 44 by retaining shoulder 43-1, until latch lever 43 breaks away from hinge hole two 11-1 completely, at this moment in the elasticity of rubber band 5 Under the force, the outer sliding bar 4 is pulled toward the inner fixing bar 2, at the same time, the middle sliding bar 3 approaches the inner fixing bar 2, and the outer sliding bar 4 approaches the middle sliding bar 3, realizing the middle sliding bar 3 and the inner fixing bar 2. Folding and storage of the outer sliding rod 4; since the top of the inner fixing rod 2 is provided with a top long groove 21, and the side is provided with a side long groove 1 22, the top of the...

Embodiment 2

[0026]On the basis of embodiment 1, when some items need to be placed on the coat rack of the car, only the "U" groove 4-1 in the middle part of the outer slide bar 4 needs to be held by hand and pulled outward, and then overcome the rubber band 5, the outer slide bar 4 slides outward along the guide rail 1 until the latch bar 43 slides to the position of hinge hole 2 11-1 along with the outer slide bar 4, because the outer slide bar 4 is provided with a latch bar 43, the latch rod 43 is provided with a shoulder 43-1, the latch rod 43 is covered with a compression spring 44, the inner end of the outer sliding rod 4 is screwed to the end sleeve 45, and one end of the compression spring 44 is in contact with the shoulder 43-1 , the other end is in contact with the end sleeve 45, so under the elastic restoring force of the compression spring 44, the latch rod 43 is pushed outward by the shoulder 43-1, and inserted into the hinge hole 11-1 in the hinge seat 2 11, At the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com