Visual intelligent guidance mistake-proofing tightening operation equipment

A technology of operating equipment and visual intelligence, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of inconvenient use, inconvenient visual observation of staff, and low efficiency, so as to avoid adjustment, improve convenience, and avoid positioning wrong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

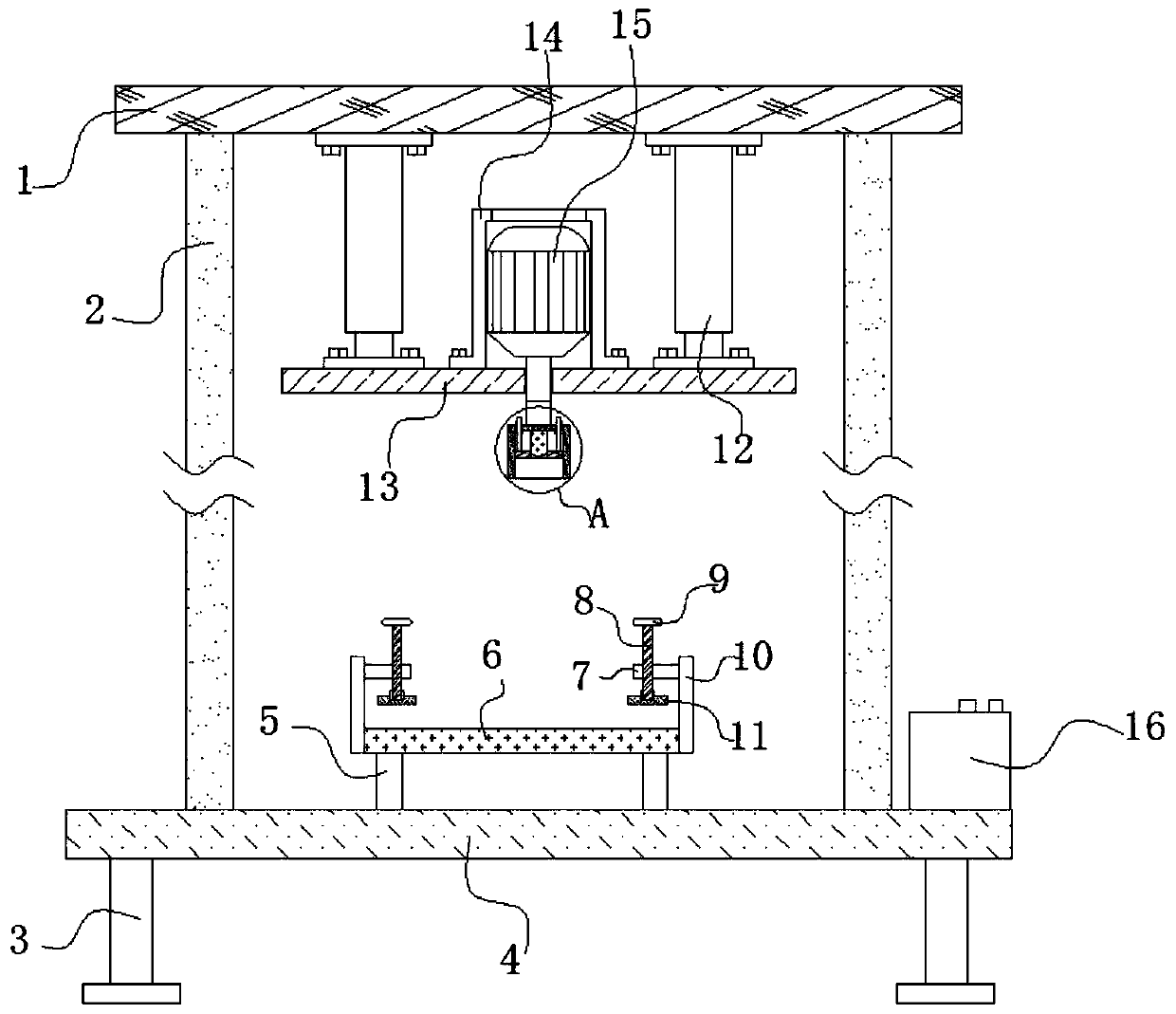

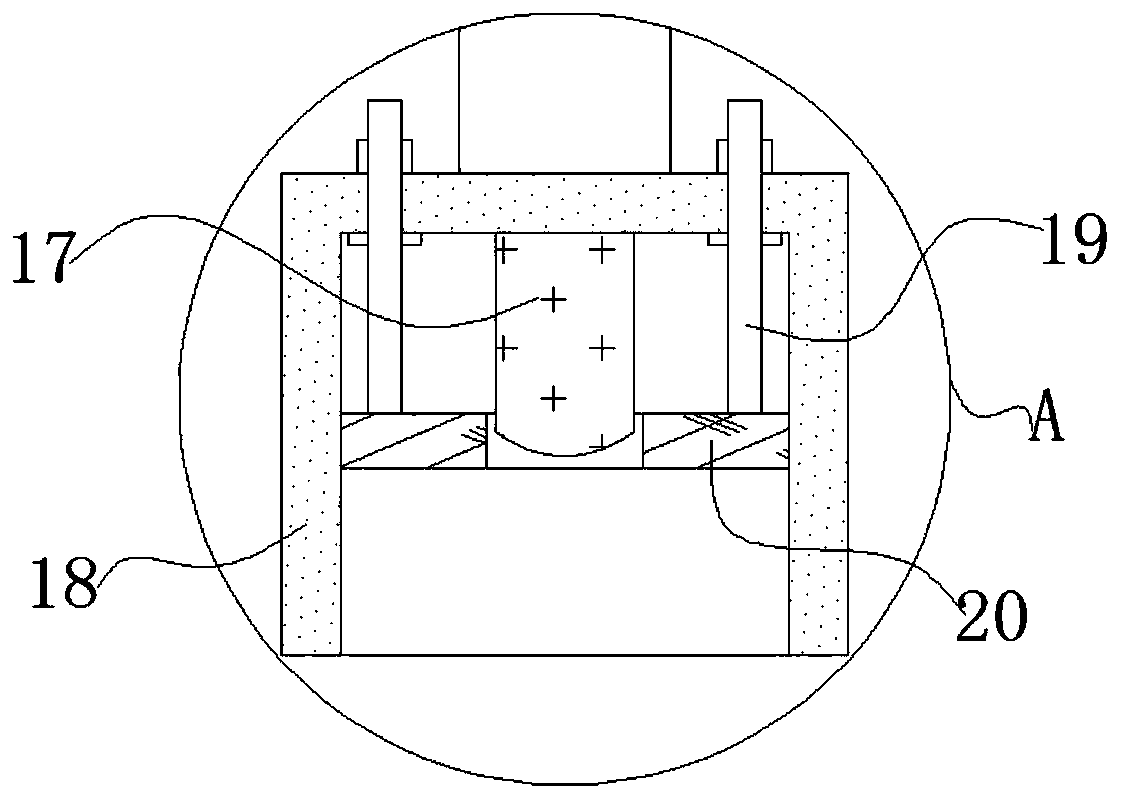

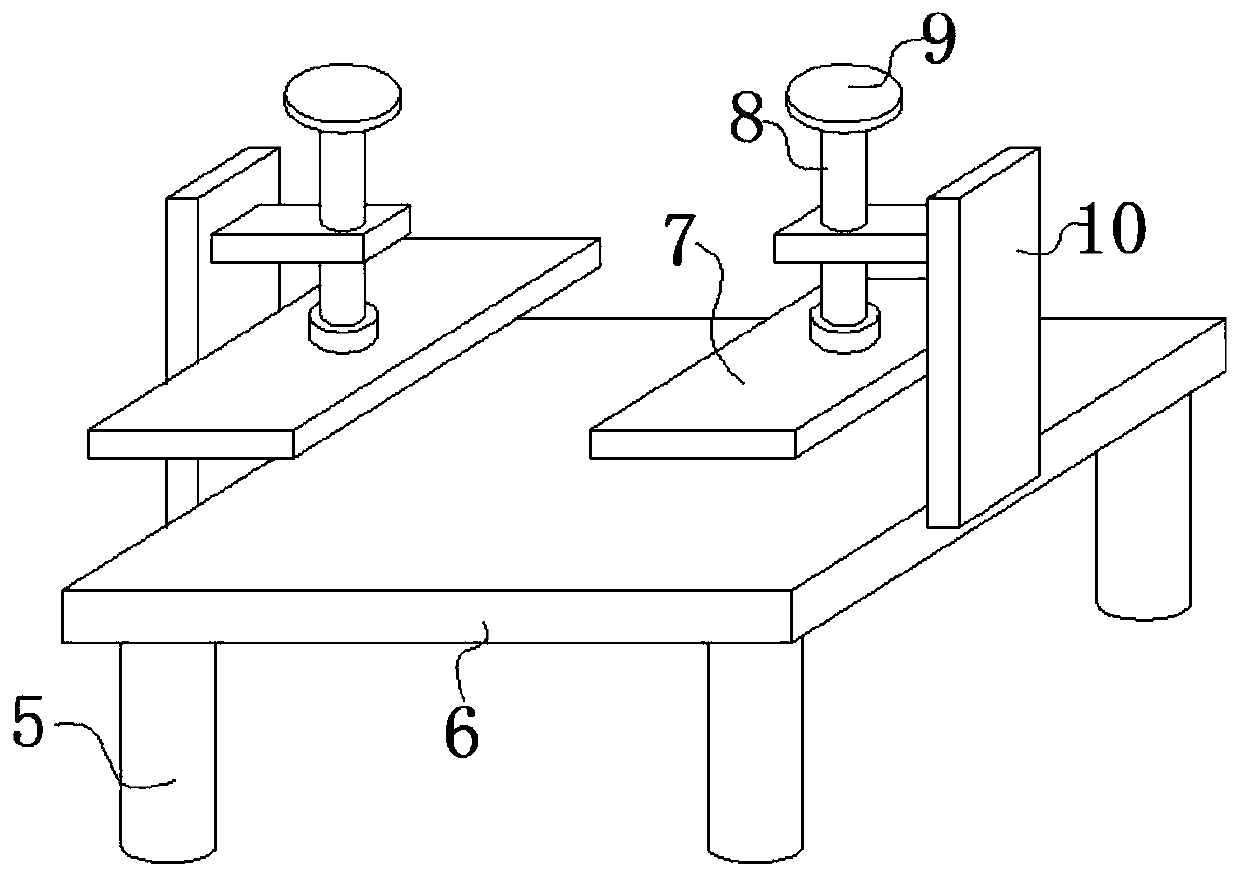

[0025] refer to Figure 1-4 , a visual intelligent guided error-proof tightening operation equipment, including a workbench 4 and a tightening mechanism, four support columns 2 are welded on the top of the workbench 4, the same top plate 1 is welded on the top of the four support columns 2, and the tightening mechanism The top is fixedly connected to the bottom of the top plate 1, and the tightening mechanism includes four electric telescopic rods 12. The top ends of the electric telescopic rods 12 are fixed on the bottom of the top plate 1 by bolts, and the bottom ends of the extension rods of the electric telescopic rods 12 are fixed by bolts. Plate 13, the top of the mounting plate 13 is fixed with the organic cover 14 by bolts, the motor 15 is fixed on the inner wall of the cover 14 by bolts, the bottom end of the output shaft of the motor 15 is keyed to a vertical shaft, and the bottom end of the vertical shaft is fixed by bolts with an organic sleeve 18. There are two th...

Embodiment 2

[0033] refer to Figure 5 , a visual intelligent guidance error-proof tightening operation equipment, the main difference between this embodiment and embodiment 1 is that in this embodiment, the top of the fixing plate 6 and the bottom of the pressure plate 11 are provided with rectangular grooves, and the inner wall of the rectangular groove Rubber pads 21 are all bonded.

[0034] When in use, when the components are fixed, the upper and lower rubber pads 21 can increase the friction with the components, thereby preventing the components from shifting when being tightened, and assisting in improving the accuracy of tightening.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap