Lens light scattering plate, backlight module and modular lamp box

A technology of astigmatism plate and lens, which is applied in optics, optical components, instruments, etc., can solve the problems such as the inability to realize shadowless splicing, and achieve the effect of realizing waterproof requirements, low manufacturing cost, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the embodiments of the present invention will be clearly and completely described below in combination with the drawings in the embodiments of a lens diffuser plate, a backlight module and its modular light box of the present invention.

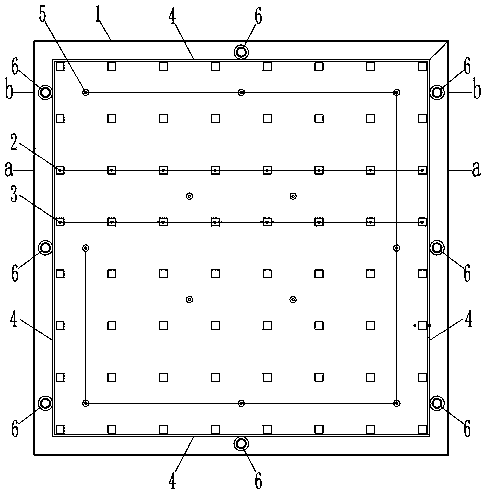

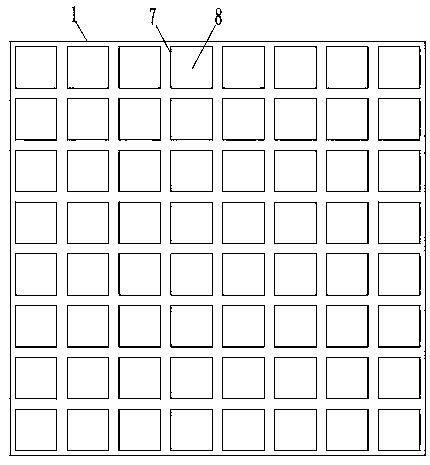

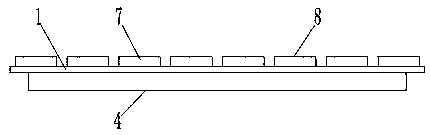

[0036] An embodiment of a lens astigmatism plate of the present invention, such as Figure 1 to Figure 5 As shown, the lens diffuser plate is composed of: a substrate 1, a plurality of lamp holes 2 arranged in rows on one side of the substrate 1, and a concave spherical structure 3 at the bottom of the lamp holes 2; and: surrounding all the lamp holes 2 The enclosure 4; several first screw hole base columns 5 arranged at a certain distance within the enclosure 4; several second screw hole base columns 6 arranged at a certain distance outside the enclosure 4; located on the base plate 1 The bumps 7 on the substrate arranged corresponding to the lamp holes 2 on the other side are integrally formed; and the micros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com