Luminous module

A light-emitting module and astigmatism technology, which is applied in the field of backlight, can solve the problems of thick backlight and the inability to realize shadowless splicing, and achieve the effects of low manufacturing cost, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

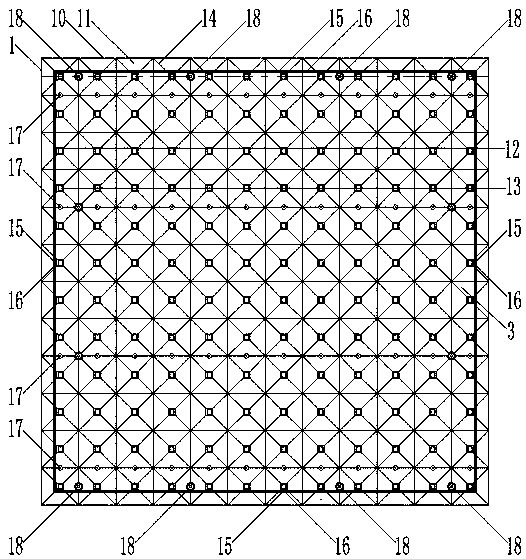

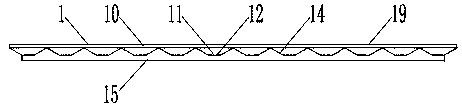

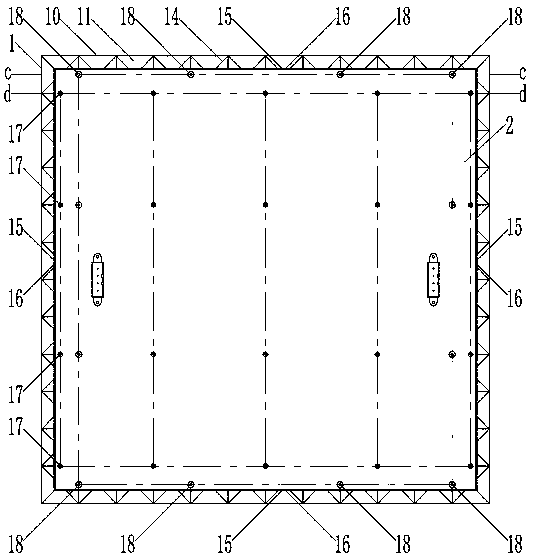

[0026] The technical solution in the embodiment of the present invention will be clearly and completely described below in conjunction with the drawings in an embodiment of the light-emitting module of the present invention.

[0027] The description of the front side, the back side, and the surroundings in a light-emitting module embodiment of the present invention is based on the attached figure 1 based on the view direction.

[0028] An embodiment of a light-emitting module of the present invention, such as Figure 1 to Figure 5 As shown, it is characterized in that: the light-emitting module includes: a plurality of frustums 11 uniformly distributed in an array on the rear side of the panel 10, protruding backwards, and the top surface 12 of the frustum of the frustum facing backwards, The lamp socket 13 located in the center of the frustum body 11 and the protective edge 15 that surrounds all the lamp sockets 13 and protrudes backward, and a circle located inside the prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com