Beading die capable of pressing eight ribs on rotating shaft and using method thereof

The technology of a bead pressing mold and a rotating shaft, which is applied in the field of bead pressing molds, can solve problems such as hidden dangers of production safety, low production efficiency, and impact on quality, and achieve the effects of reducing hidden dangers of safety, improving production efficiency, and simplifying operation procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

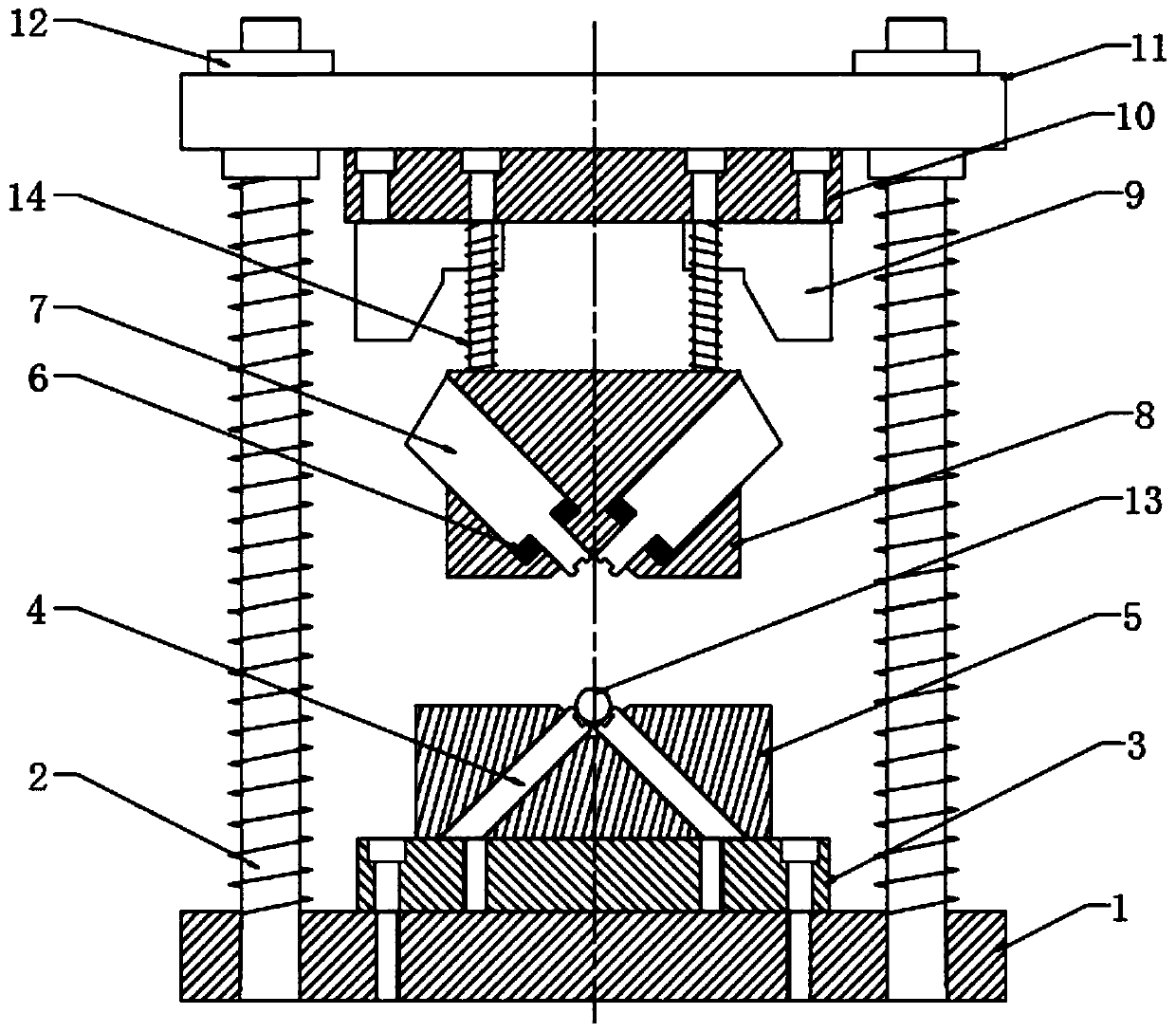

[0063] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

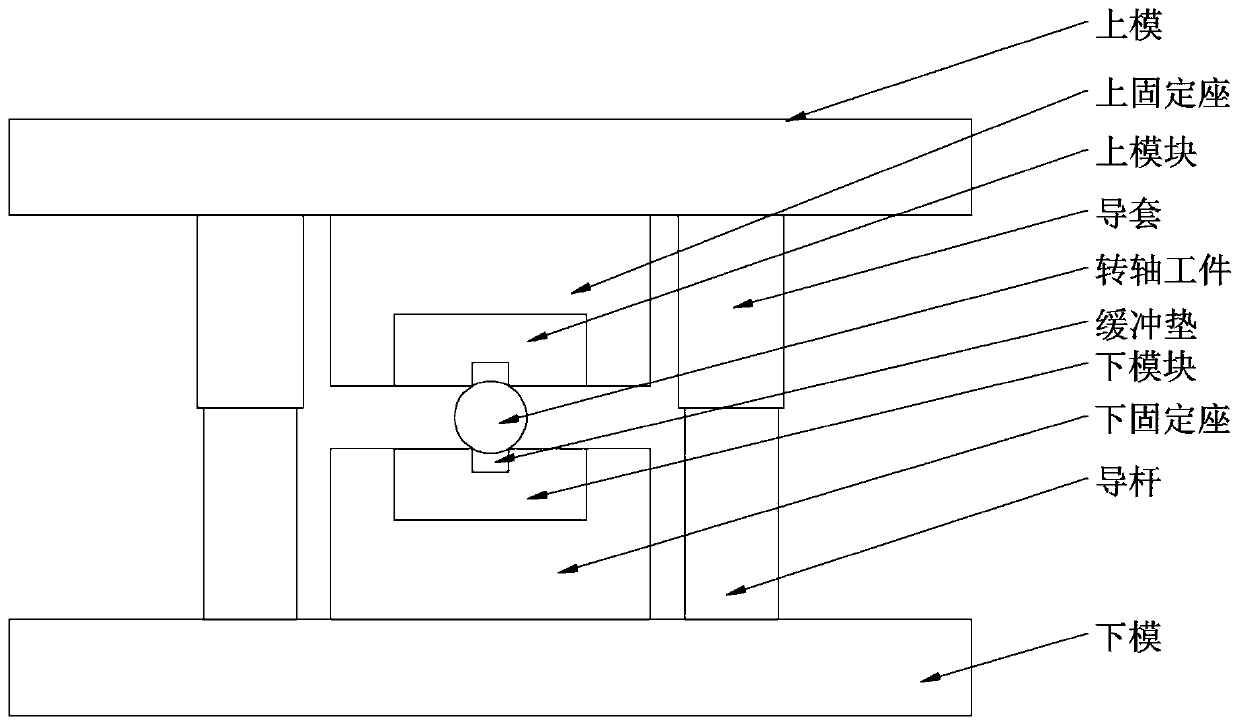

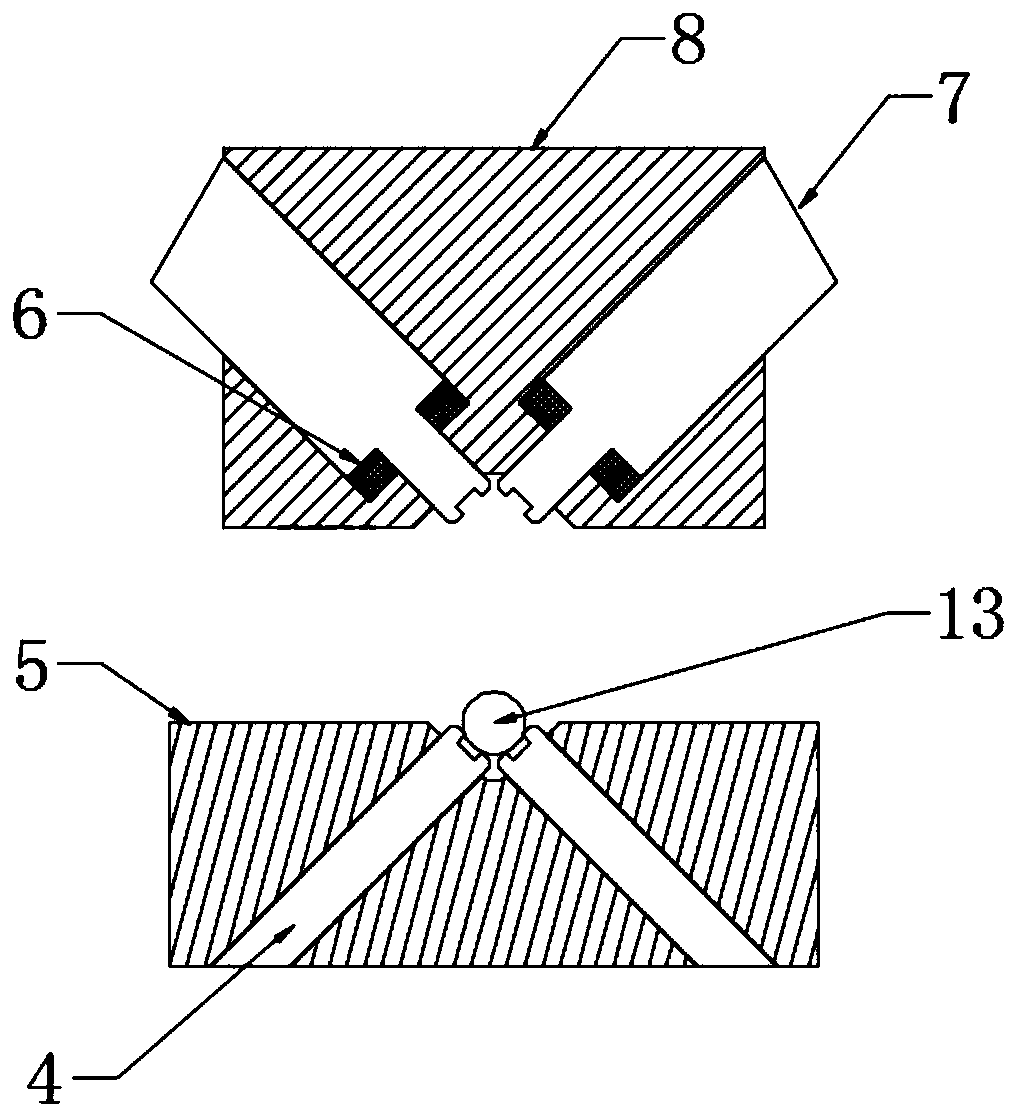

[0064] A kind of rotating shaft pressing 8-rib mold provided by the invention, such as Figure 2 to Figure 23 As shown, it includes bottom plate 1, lower mold backing plate 3, lower module 5, upper module 8, upper mold pressing block 9, upper mold backing plate 10 and top plate 11 arranged sequentially from bottom to top; wherein:

[0065] The lower mold backing plate 3 is fastened on the base plate 1 by bolts, and the lower module 5 is fastened on the lower mold backing plate 3 by bolts;

[0066] The upper module 8 and the lower module 5 are facing each other, and are connected elastically with the upper mold backing plate 10 through the spring bolts 14. The upper mold pressing block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com