A pneumatic variable load multi-source impact test device

A technology of impact experiment and variable load, which is applied in the direction of testing the strength of materials with one impact force, which can solve the problems of poor adjustability and achieve the effect of various impact modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

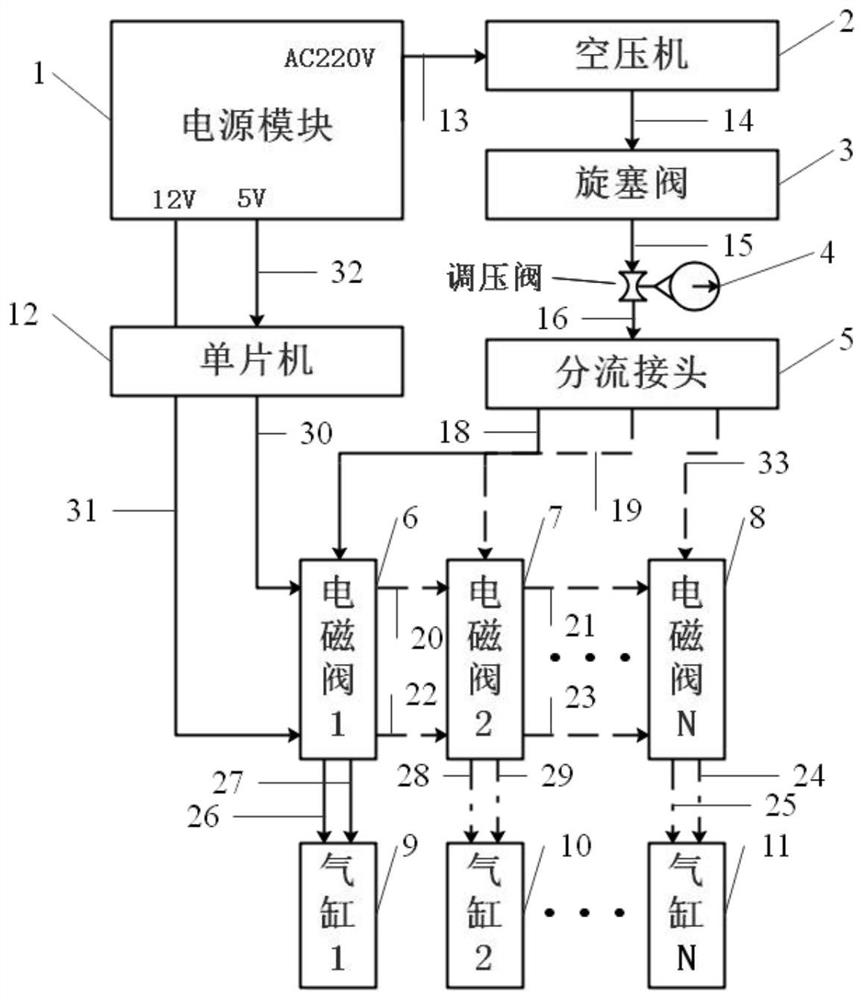

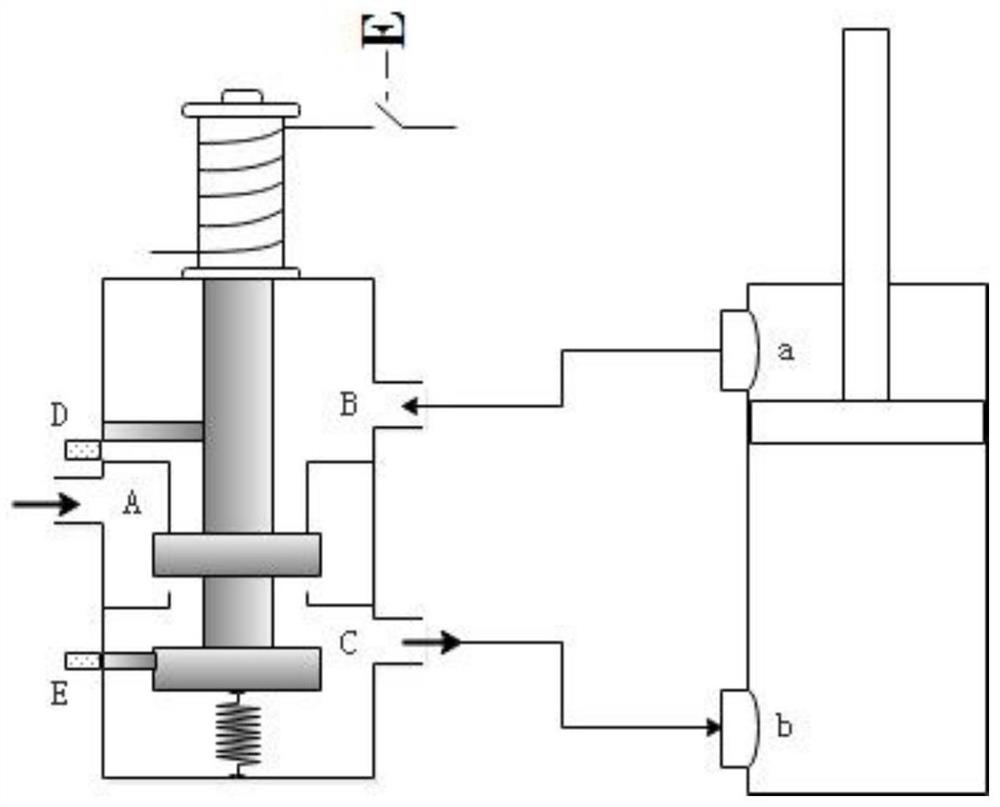

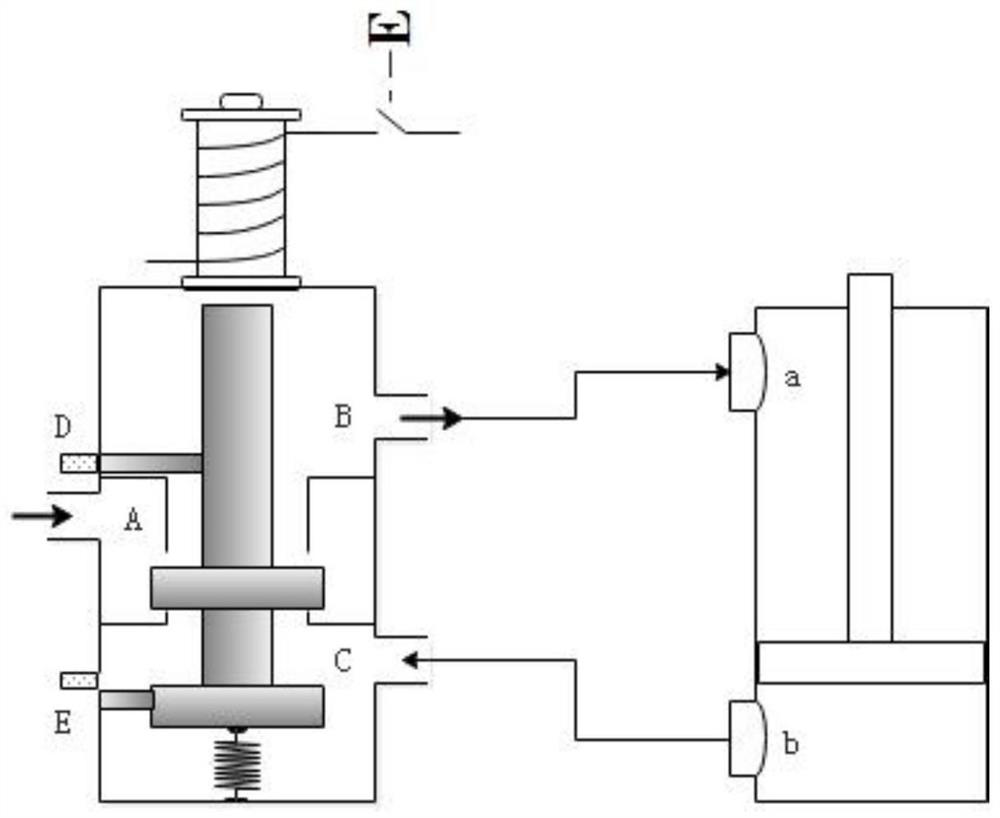

[0057] This embodiment is a pneumatic variable load multi-source impact test device, including hardware modules and software modules, as shown in the accompanying drawings. This device makes the single-chip microcomputer control the on-off of the solenoid valve to indirectly control the impact of the cylinder through the software module, and does not expand the impact source (N=1), as follows:

[0058] The hardware module is composed of an air compressor 2, a cock valve 3, a pressure regulating valve 4, a shunt joint 5, a power module 1, a single-chip microcomputer 12, a solenoid valve 6, and a cylinder 9. The air compressor 2, single-chip microcomputer 12, and solenoid valve 6 are all wired and electrically connected to the power module 1; the air compressor 2, cock valve 3, pressure regulating valve 4, shunt joint 5, solenoid valve 6, and cylinder 9 connected to each other by air ducts. In particular, the power supply module 1 supplies AC220V, DC5V, and DC12V to the air com...

Embodiment 2

[0071] On the basis of Embodiment 1, the cylinder 9 is changed to a standard cylinder SC63×25, and its theoretical output table is as follows:

[0072] Table 2 Standard cylinder SC63×25 theoretical output table

[0073]

[0074] The unit of force in Table 2 is N. The calculation method of the actual output value is the same as that of the standard cylinder SC32×25 in Embodiment 1.

Embodiment 3

[0076] On the basis of Embodiment 1, one impact source is expanded, and the total number of impact sources is two, that is, N=2.

[0077] After the splitter joint 5 divides the gas delivered by the air guide tube 16 , it is delivered to the solenoid valves 6 , 7 through the air guide tubes 18 , 19 .

[0078] Further, the single-chip microcomputer 12 controls the on-off of the solenoid valves 6, 7, and further controls the impact of the cylinders 9, 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com