Grinding body

A technology of grinding body and regular tetrahedron, which is applied in the field of grinding body, can solve the problems such as not, and achieve the effects of large throwing area, low power consumption and strong impact effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

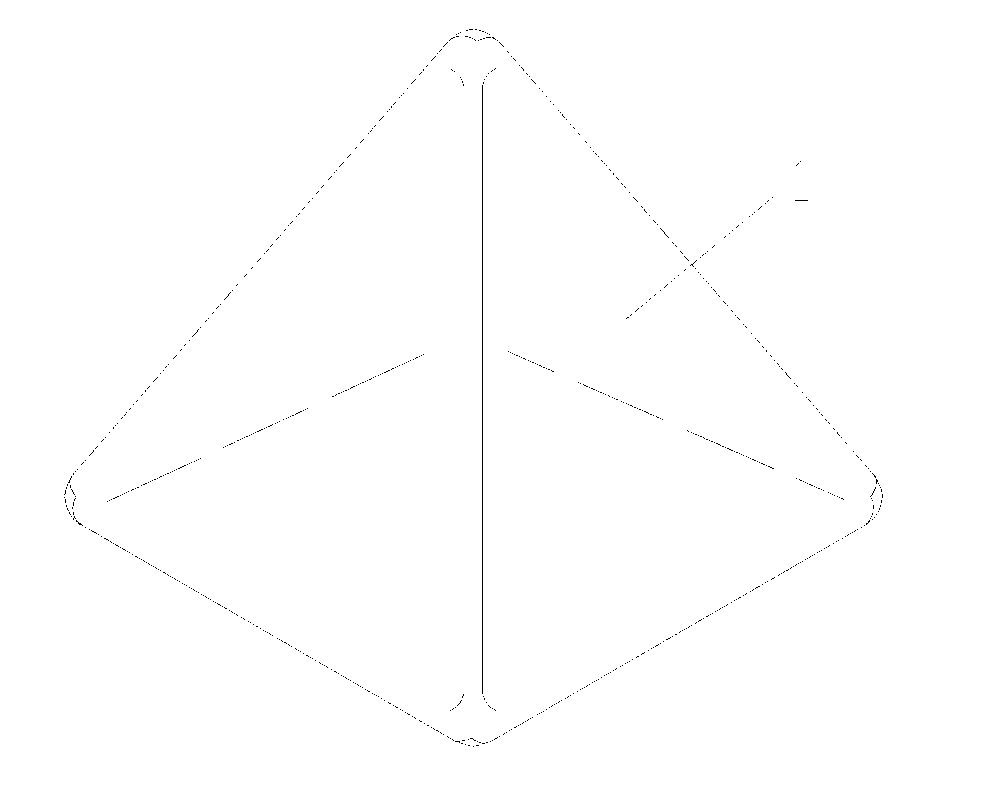

[0019] The shape of the grinding body provided by the invention is as figure 1 As shown, it is a regular tetrahedron structure, and the edges and vertices of the regular tetrahedron 1 are all treated with arc surface transition, so that the planes are connected by arc surface transitions.

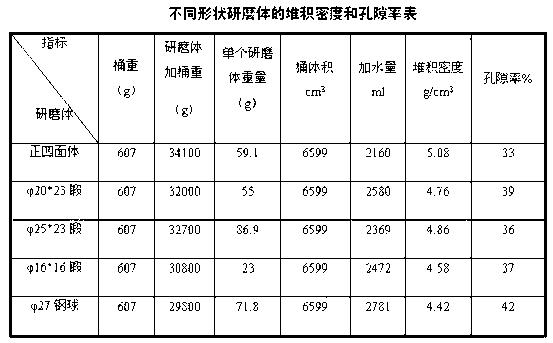

[0020] Using a small mill, the grinding body of the embodiment of the present invention is compared with the traditional ball and forged grinding body. The conclusion shows that the packing density of the regular tetrahedron grinding body is larger than that of the spherical and forged grinding body, the porosity is relatively small, and the grinding effect is good. Increase productivity. The table below shows various comparative data measured by the method of adding water.

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com