LED display screenquick front mounting locking mechanism

A technology of LED display screen and locking mechanism, which is applied in the direction of identification devices and instruments, can solve the problems of time-consuming installation and disassembly, inconvenient installation and maintenance, inconvenience of module installation and maintenance personnel, etc. Improve installation efficiency and reduce the number of screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with accompanying drawing and embodiment:

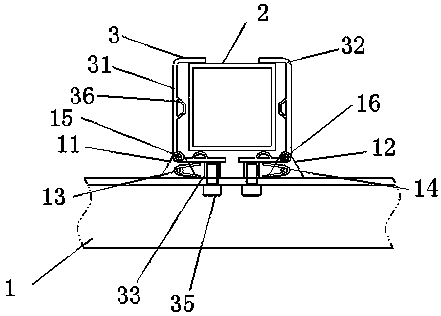

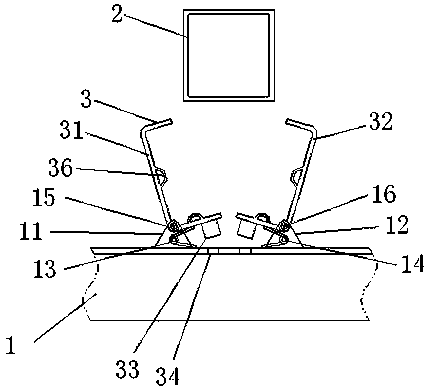

[0020] Such as Figure 1-2 As shown, a fast front-mounted locking mechanism for an LED display includes an LED module 1, a steel structure box 2 and a locking structure. The LED module 1 is fixed on the steel structure box 2 through the locking structure.

[0021] The locking structure includes a hoop 3, and the hoop 3 includes a first hoop assembly 31 and a second hoop assembly 32, and the space surrounded by the first hoop assembly 31 and the second hoop assembly 32 is connected to the steel structure box 2. Suit. Preferably, the first hoop assembly 31 and the second hoop assembly 32 are provided with protrusions 36 inside, and the protrusions 36 are in contact with the steel structure box body 2 .

[0022] Preferably, the bottoms of the first hoop assembly 31 and the second hoop assembly 32 are both provided with screw fixing posts 33 , and the screw fixing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com