Automobile seat height adjusting device

A technology for height adjustment devices and car seats, which is applied to vehicle seats, movable seats, and special positions of vehicles, etc. The effect of convenient operation and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

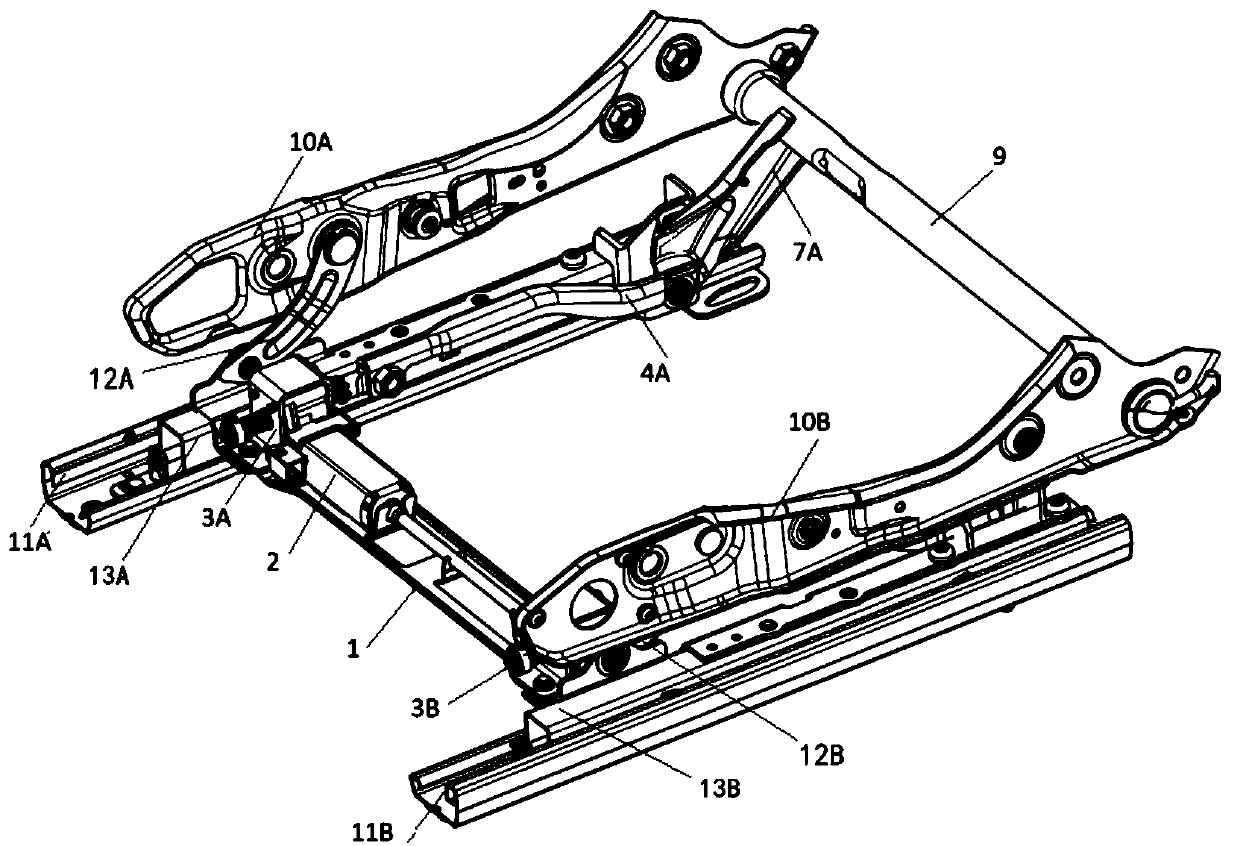

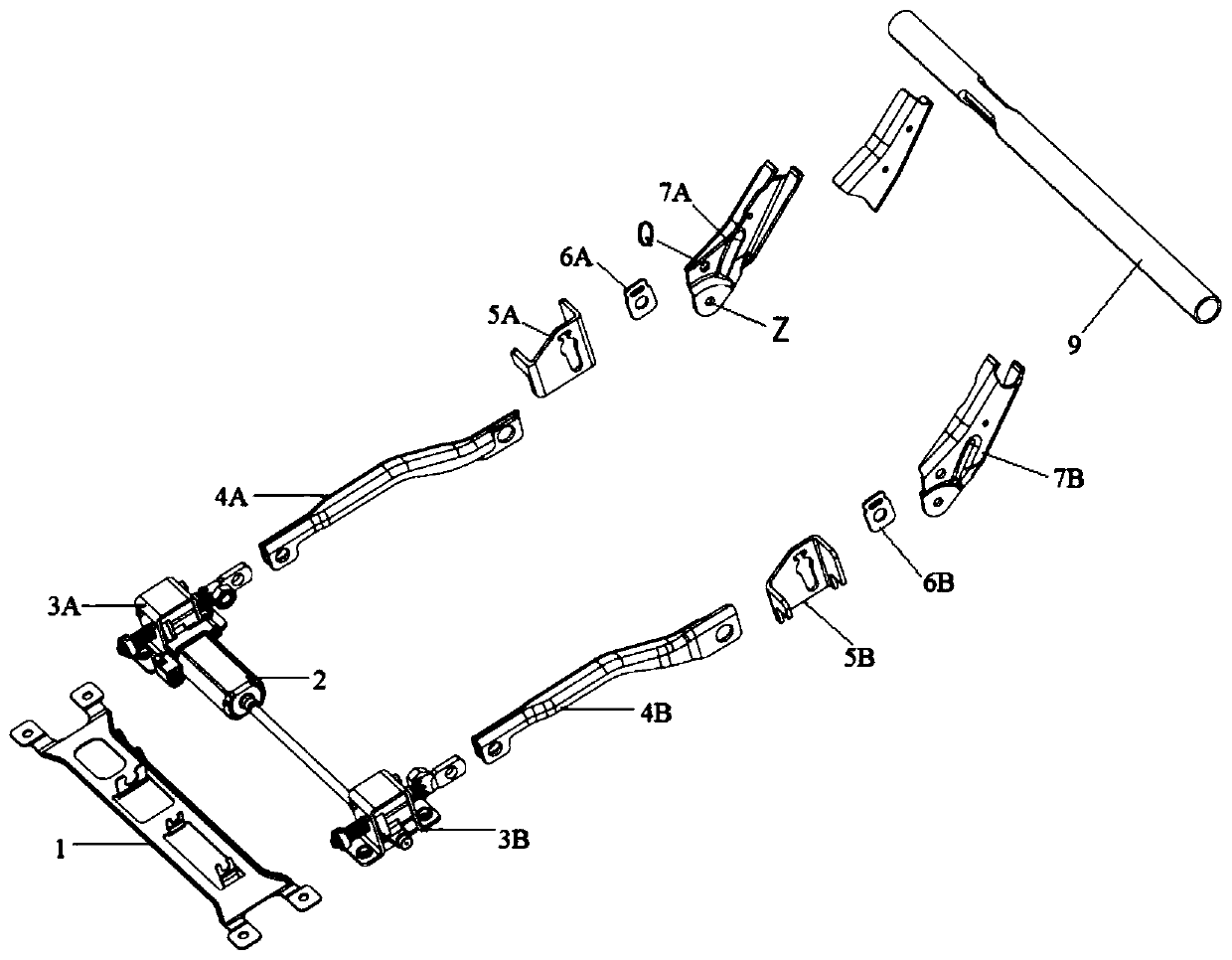

[0024] Embodiment 1: as figure 1 As shown, a car seat height adjustment device has two sliding rails 11A / 11B fixed side by side on the bottom of the vehicle body, and the codes A and B respectively represent the left component and the right component; the two sliding rails 11A / 11B Each is equipped with an upper slide rail 13A / 13B, and the two-way upper slide rail 13A / 13B is horizontally fixedly connected to a double-axis motor 2 through a motor installation bracket 1. The double-axis motor 2 is a stepping motor with shaft extension at both ends, and the stepping motor has The advantage of accurate and convenient control is that the shaft extensions at both ends can be used in one machine, especially to ensure the synchronization of the left and right transmission chains. The left and right output ends of the biaxial motor 2 are respectively connected to the input ends of the gear box 3A / 3B fixed at both ends of the motor mounting bracket 1, and the vertical output ends of the ...

Embodiment 2

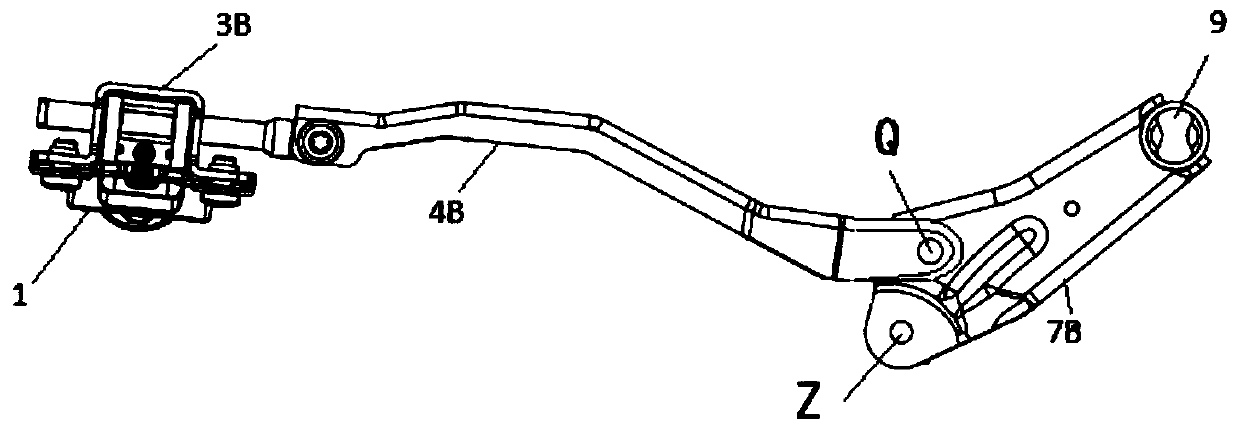

[0030] Embodiment 2: The optimal initial setting angle between the rear rocker 7A / 7B and the upper slide rail 13A / 13B is 25°. At this time, the traction point Q, the front connection point of the height adjustment link 4A / 4B and the rear rocker The rotation point Z of 7A / 7B, the three-point relationship should take the traction point as the apex to form a right-angle relationship, and then the torque generated by the traction force on the rear rocker reaches the maximum value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com