Wheeled crane and chassis hydraulic control system thereof

A hydraulic control system and chassis technology, applied in cranes, mechanical equipment, belts/chains/gears, etc., to achieve the effects of timely action response, reliable action balance, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

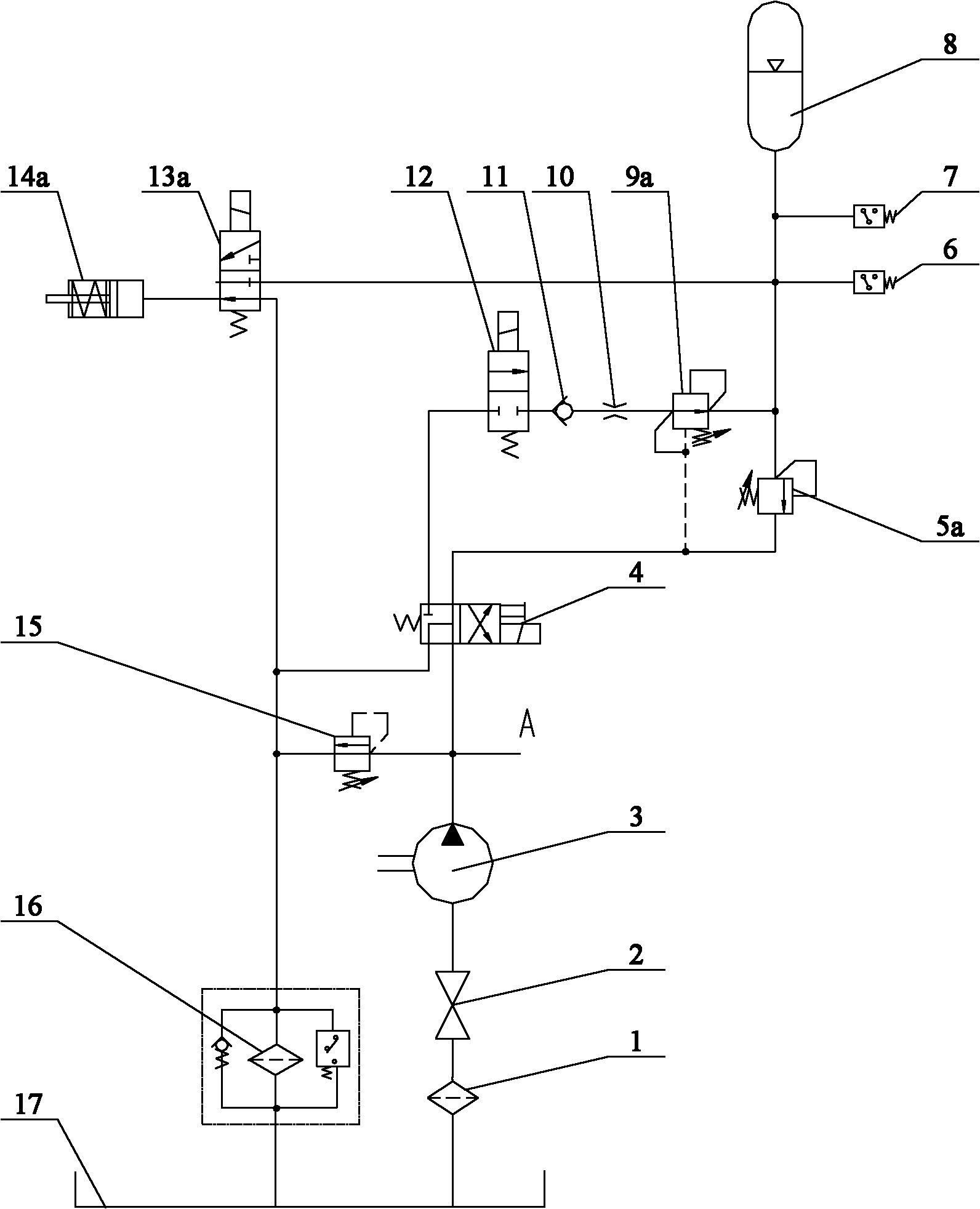

[0034] The core of the present invention is to provide a chassis hydraulic control system, which greatly increases the output force on the basis of effectively improving the action accuracy and stability of the corresponding control components. The specific implementation will be described in detail below in conjunction with the accompanying drawings.

[0035] See figure 2 , which is a working principle diagram of the first embodiment of the chassis hydraulic control system.

[0036]This system is used to control the action of the first chassis actuator 14a. The same as the existing air control method, the action is controlled by the pressure fluid output to the actuator. The system controls the communication between the working oil port of the first chassis actuator 14a and the system pressure oil circuit P or oil return oil circuit T through the first directional control valve 13a; the working oil port of the accumulator 8 is connected with the first directional control va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com