Infrared confocal wide-angle lens

A wide-angle lens and infrared confocal technology, applied in the field of infrared confocal wide-angle lens, can solve the problems of increased weight, increased cost, unfavorable promotion and use, etc., and achieve the effect of reducing weight and cost, good infrared confocal, and realizing large aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

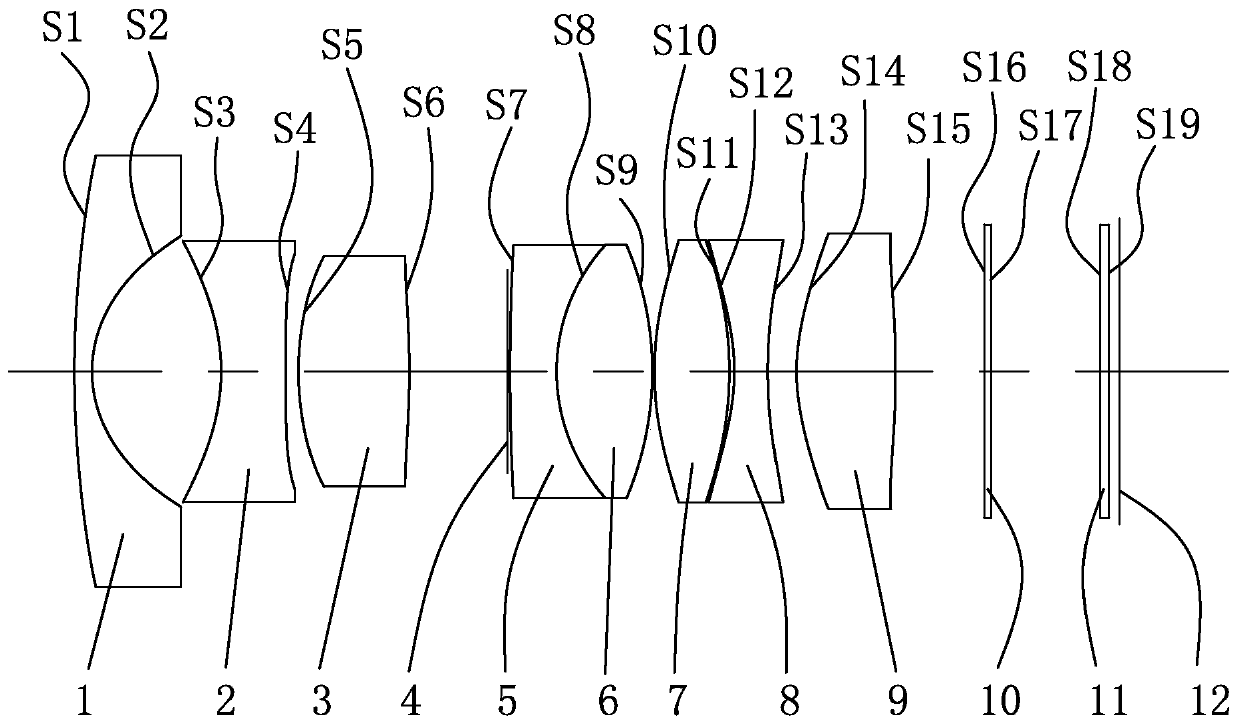

[0047] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0048] like figure 1 As shown, an infrared confocal wide-angle lens is sequentially provided with: a front lens group, a diaphragm 4, a rear lens group, a filter 10, a protective glass 11 and a photosensitive chip 12 from the object side to the image side;

[0049] The refractive power of the front lens group is negative, and the front lens group includes:

[0050] The first lens 1, the refractive power of the first lens 1 is negative, the side of the first lens 1 facing the object side is a convex surface, and the side facing the image side is a concave surface;

[0051] The second lens 2, the refractive power of the second lens 2 is negative, and both surfaces of the second lens 2 are concave;

[0052] The third lens 3, the refractive power of the third lens 3 is positive, and both surfaces of the third lens 3 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com