A control device for ion implantation in wafer production

An ion implantation and control device technology, which is applied in the manufacture of semiconductor/solid-state devices, discharge tubes, electrical components, etc., and can solve the problems of ion output dispersion, difficulty in direct irradiation, and damage to the output port.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] as attached figure 1 to attach Figure 8 Shown:

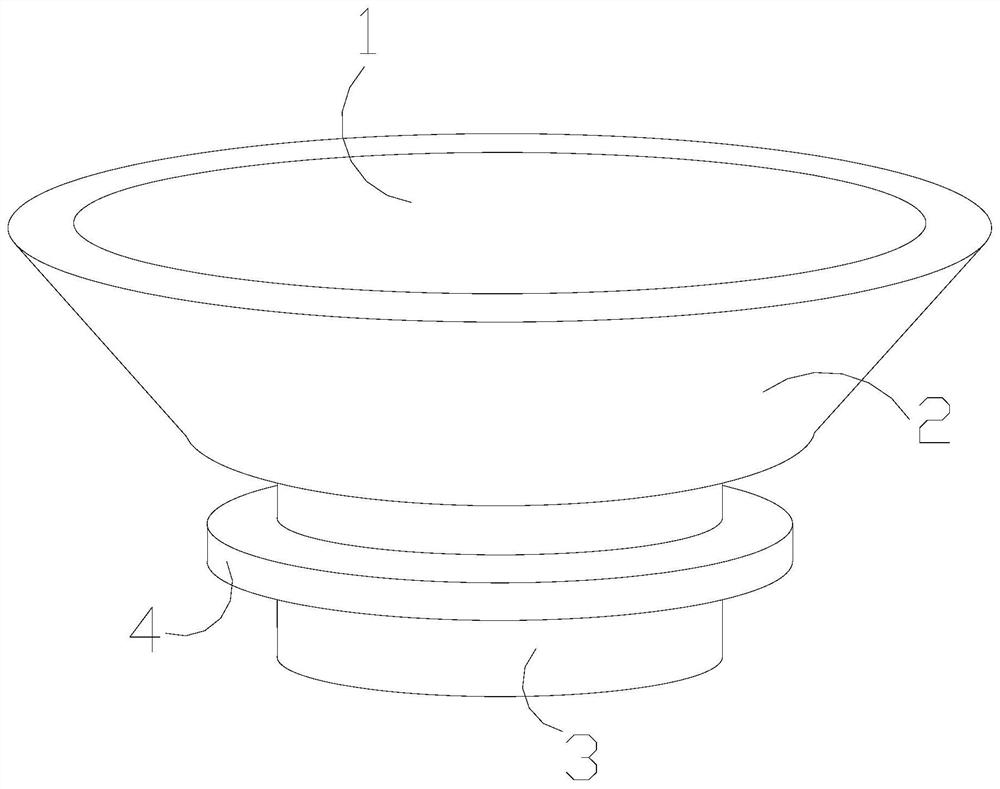

[0031] The invention provides a control device for ion implantation in wafer production, the structure of which includes a movable channel 1 , a connecting operation head 2 , an ion calibration output port 3 , and a guard ring 4 .

[0032] The movable channel 1 is installed inside the connecting operation head 2, the bottom end of the connecting operation head 2 is connected to the top end of the ion calibration output port 3, and the guard ring 4 is nested on the outer surface of the ion calibration output port 3 and is located on the same axis. heart.

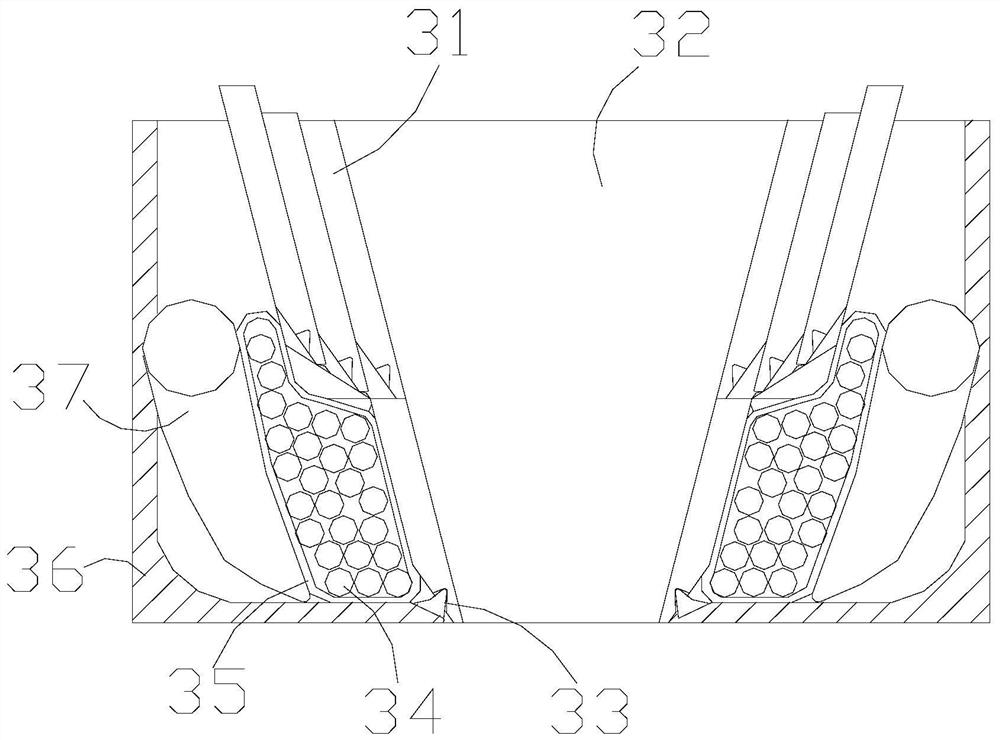

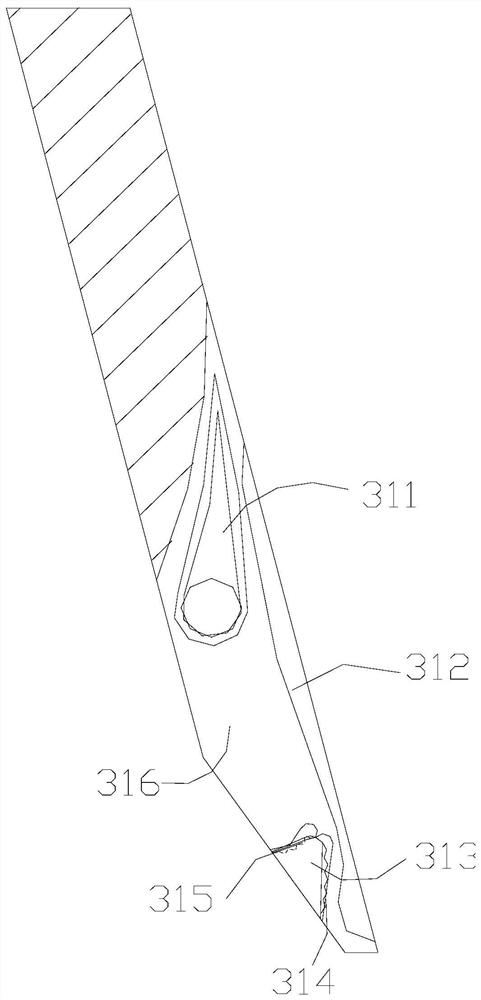

[0033] The ion proofreading output port 3 includes a proofreading mouth rod 31, a direct shot path 32, a complete buckle 33, a flexible pressure ball 34, an integral capsule 35, a partition 36, and a directional ejector rod 37, and the proofreading mouth rod 31 is located at the straight shot path 32 On the left and right sides, the complete buckle 33 and the partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com