Texture surface defect detection and segmentation device and method in industrial environment

A defect detection, textured surface technology, applied in image analysis, image data processing, instrumentation, etc., can solve problems such as poor adaptability and generalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

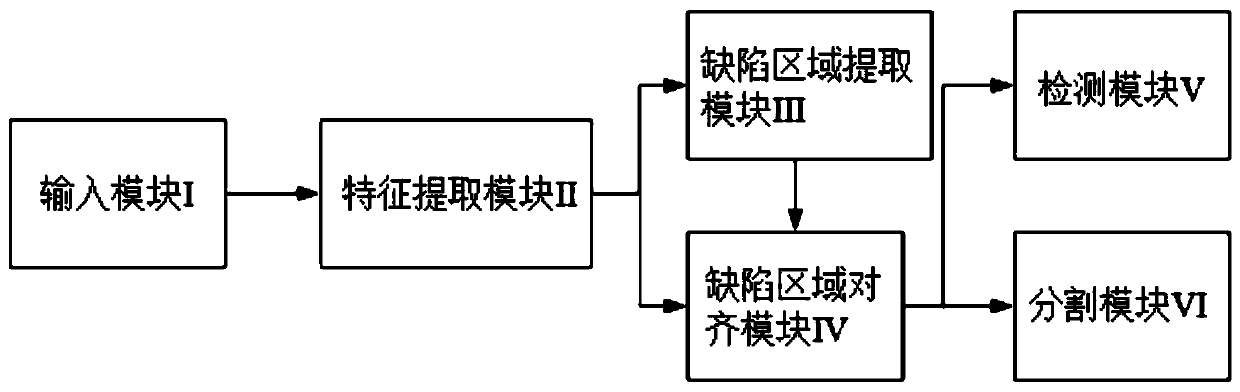

[0063] Embodiment 1: as Figure 1-5 As shown, a texture surface defect detection and segmentation device in an industrial environment includes an input module I, a feature extraction module II, a defect region extraction module III, a defect region alignment module IV, a detection module V, and a segmentation module VI;

[0064] The input module I outputs to the feature extraction module II, the feature extraction module II outputs to the defect area extraction module III and the defect area alignment module IV, the defect area extraction module III outputs to the defect area alignment module IV, and the defect area alignment module IV outputs to Detection module V and segmentation module VI.

[0065] Further, the feature extraction module II is used to extract multi-scale features of defect images;

[0066] The defect area extraction module III is a candidate area extraction network RPN, which is used to predict the multi-scale features of the extracted defect image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com