Rotary gravity unloading device

A gravity unloading and rotary technology, which is applied to the simulation device of space navigation conditions, transportation and packaging, space navigation equipment, etc., can solve the problem of insufficient unloading accuracy and achieve the effect of avoiding additional deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

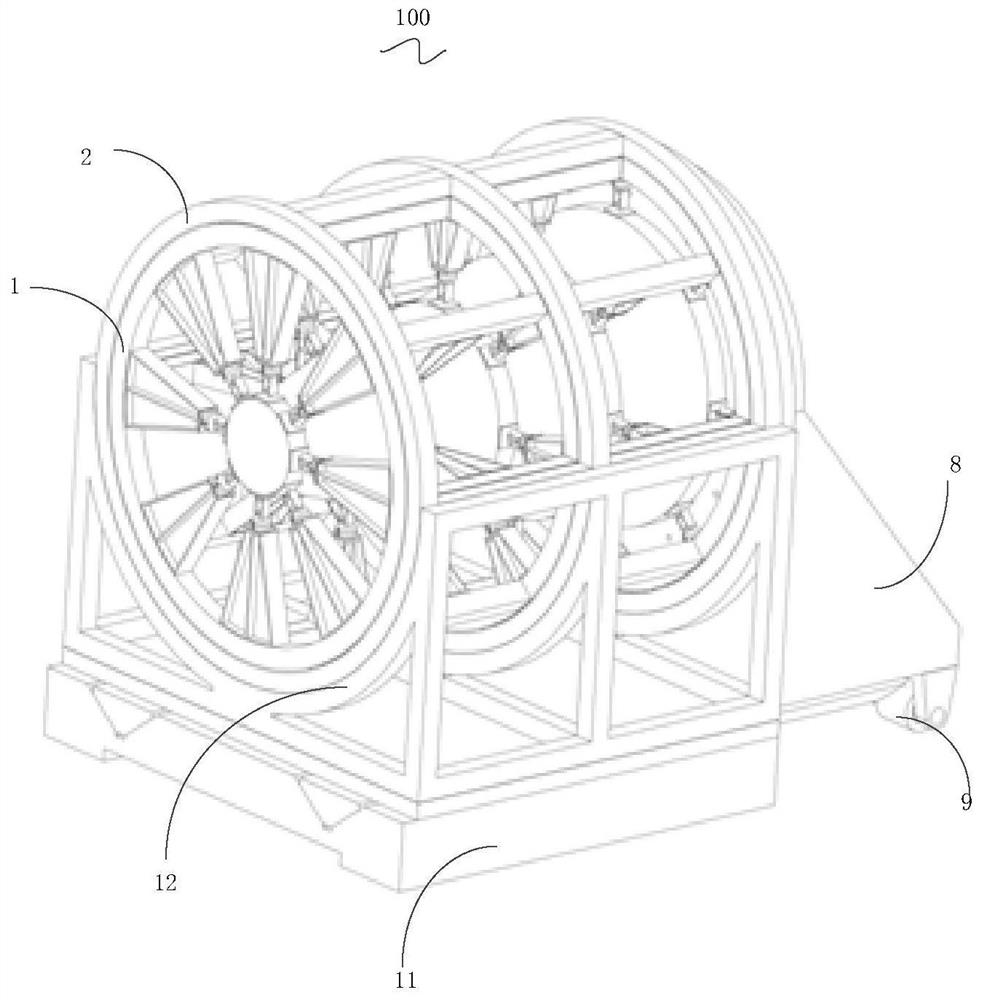

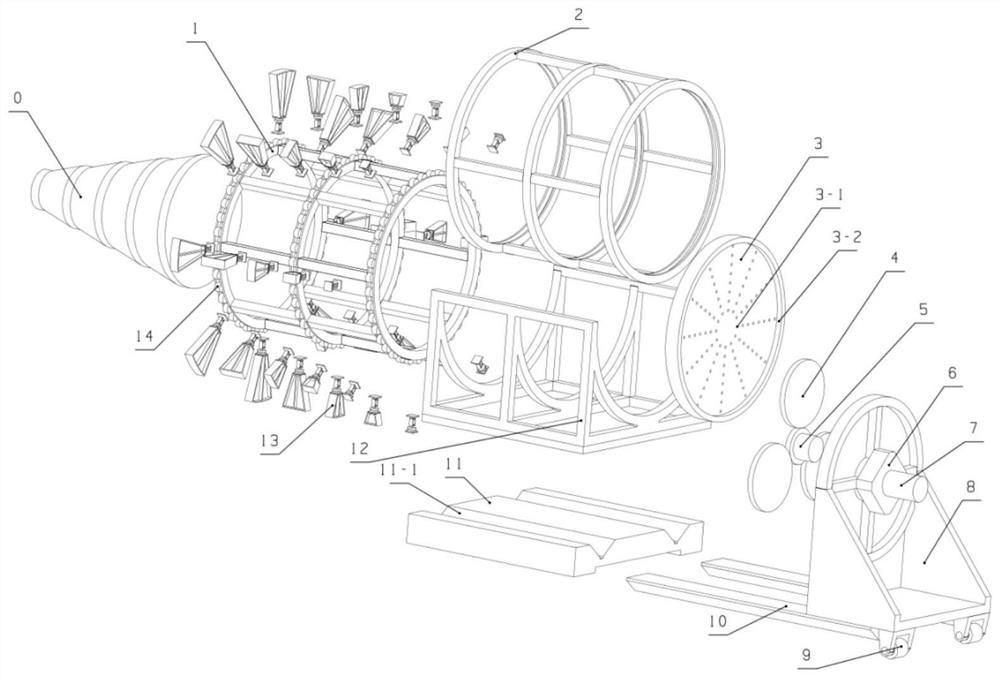

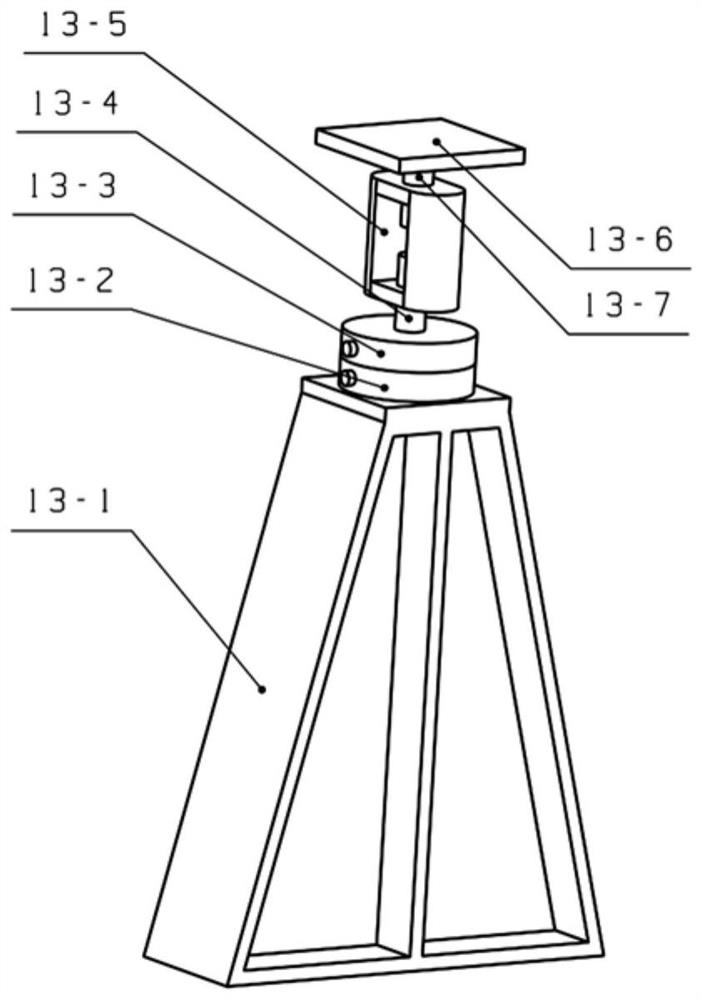

[0024] see Figure 1 to Figure 5 , the present invention provides a rotary gravity unloading device 100, including a supporting device, a plurality of combined loading frames and a driving device. The supporting device comprises a moving cage 1, a fixed cage 2 ring mounted on the moving cage 1, a cage bearing 14 connecting the moving cage 1 and the fixed cage 2, the moving cage 1 rotates along the fixed cage 2, and moves The cage 1 constitutes a pair of rotary kinematics with the fixed cage 2 through the cage bearing 14 . Furthermore, the support device also includes a U-shaped bracket 12 arranged on the fixed base 11 , and the U-shaped bracket 12 is used to support the fixed cage frame 2 .

[0025] The driving device includes a tooling backboard 3 arranged at one end of the moving cage frame 1, a planetary gear train (comprising an internal ring gear 3-2, three planetary gears 4, and a sun gear 5) connected to the tooling backboard, a reduction box 6, and a motor 7. The pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com