Automobile fuel tank

A technology for fuel tanks and automobiles, which is applied to vehicle components, the arrangement combined with the fuel supply of internal combustion engines, and the substructure, etc. It can solve problems such as tank damage, easily damaged fuel tanks, and fuel sloshing in the fuel tank, so as to reduce impact force and reduce noise , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

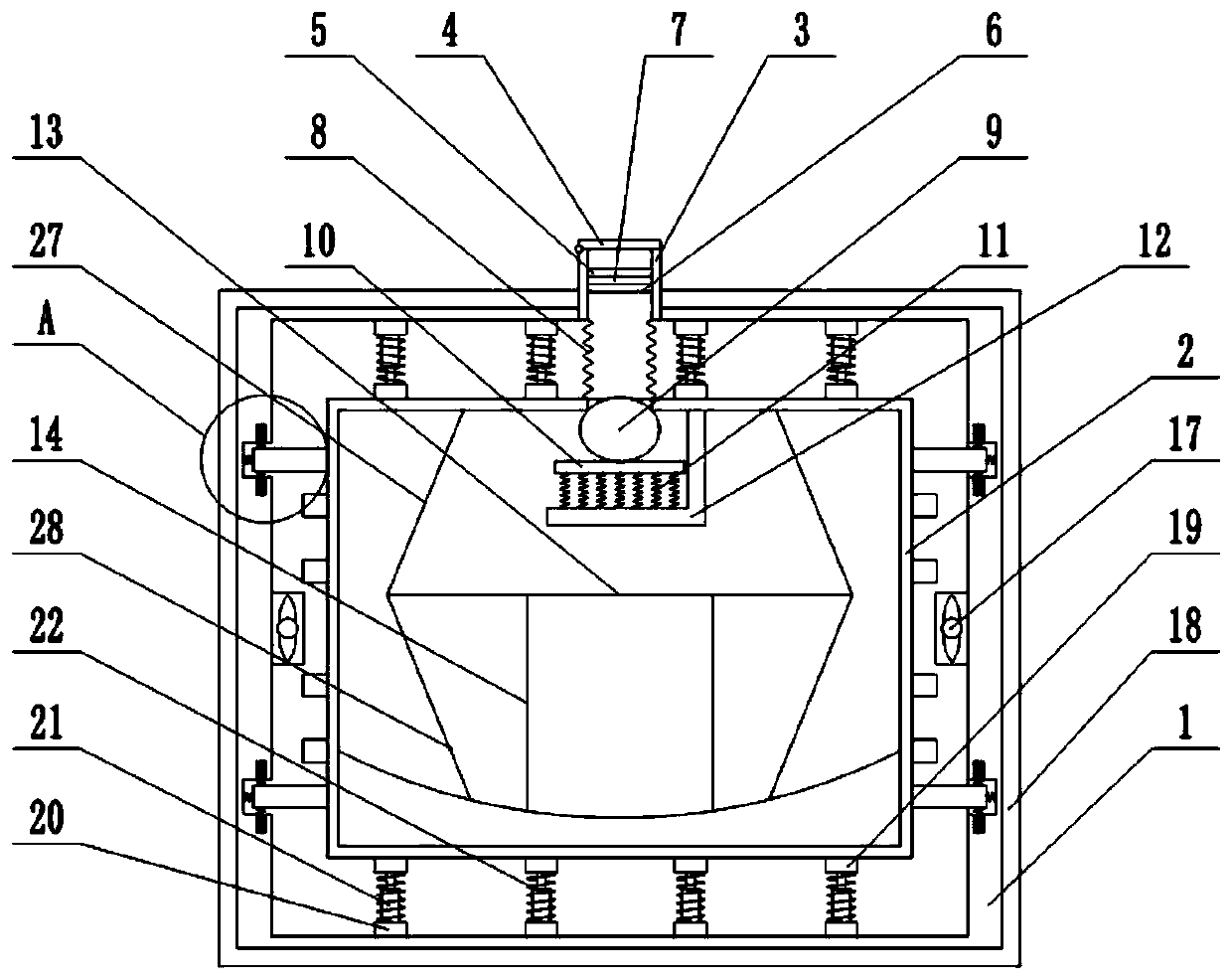

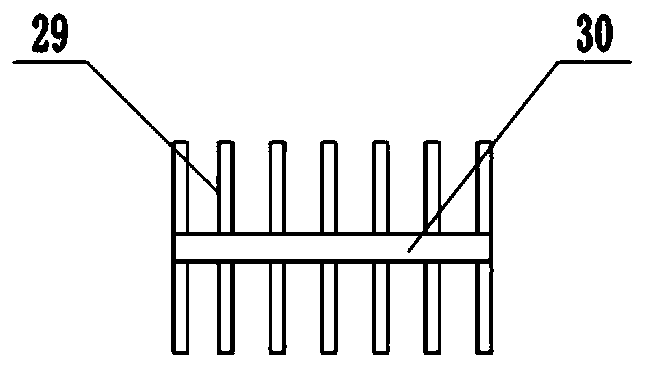

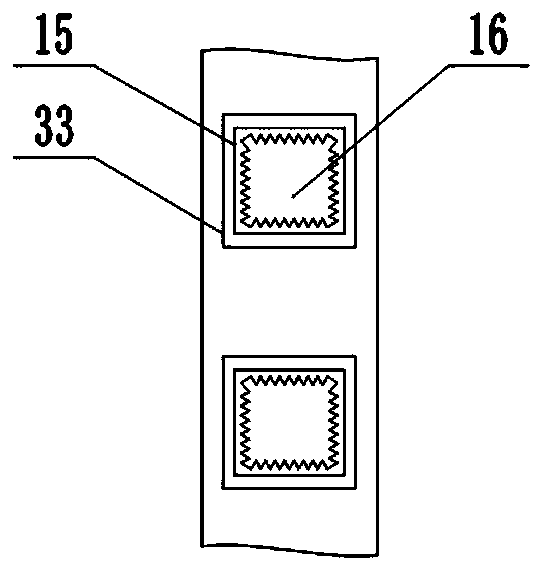

[0018] Embodiment 1 As shown in the figure, an automobile fuel tank includes an outer casing 1 and an inner casing 2 arranged inside the outer casing 1, the top and bottom of the inner casing 2 and the inner top and inner bottom of the outer casing 1 A number of first buffer devices are arranged between them, and a number of second buffer devices are arranged between the outer wall of the inner shell 2 and the inner wall of the outer shell 1. An oil injection pipe 3 is arranged in the center of the top of the outer shell 1, and the top end of the oil injection pipe 3 A cover 4 is provided, and a cylindrical sieve body is detachably provided inside the oil injection pipe 3. The cylindrical sieve body includes a first filter net 5 and a second filter net 6, and the first filter net 5 and the second filter net 6 The space is filled with a sponge layer 7, and the lower end of the oil injection pipe 3 communicates with the oil injection port provided at the top center of the inner c...

Embodiment 2

[0025] Embodiment 2 As shown in the figure, an automobile fuel tank includes an outer casing 1 and an inner casing 2 arranged inside the outer casing 1, the top and bottom of the inner casing 2 and the inner top and inner bottom of the outer casing 1 A number of first buffer devices are arranged between them, and a number of second buffer devices are arranged between the outer wall of the inner shell 2 and the inner wall of the outer shell 1. An oil injection pipe 3 is arranged in the center of the top of the outer shell 1, and the top end of the oil injection pipe 3 A cover 4 is provided, and a cylindrical sieve body is detachably provided inside the oil injection pipe 3. The cylindrical sieve body includes a first filter net 5 and a second filter net 6, and the first filter net 5 and the second filter net 6 The space is filled with a sponge layer 7, and the lower end of the oil injection pipe 3 communicates with the oil injection port provided at the top center of the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com