Fast fit connecting device for connecting backflow connector to internal combustion engine fuel injector

A technology of injectors and connectors, which is applied to fuel injection devices, special fuel injection devices, connecting components, etc., can solve problems such as missing valve needles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

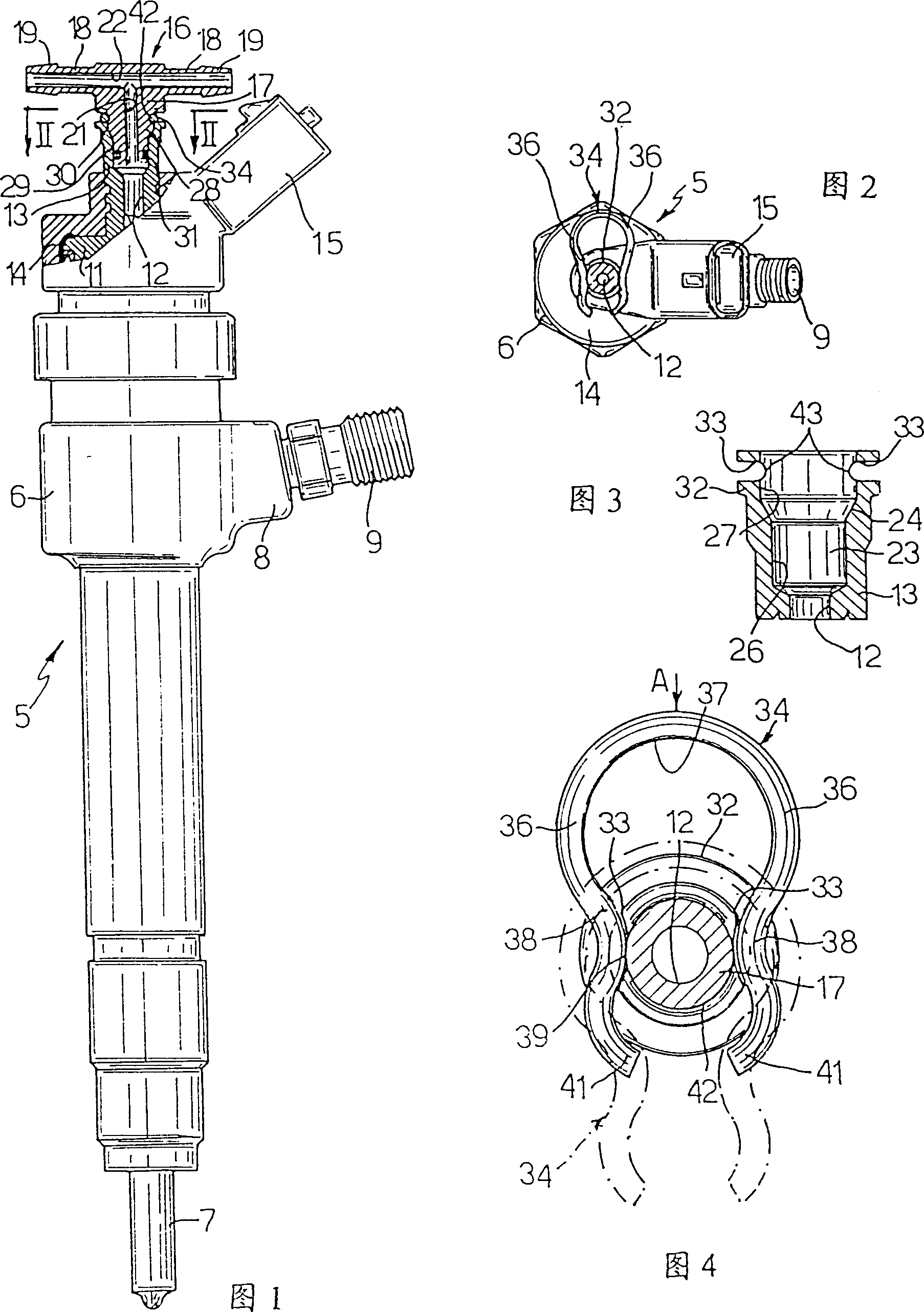

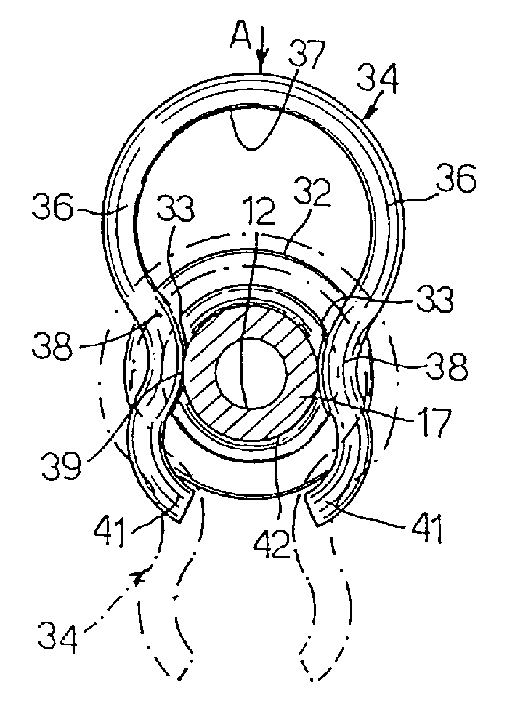

[0012] Reference numeral 5 among Fig. 1 represents the fuel injector of internal combustion engine such as diesel engine; Injector 5 comprises a body 6 that is connected with nozzle 7, and this nozzle 7 is controlled by a standard electromagnetic metering valve; The pipe 8 and the oil nozzle 9 are connected to a standard oil supply pump.

[0013] The injector 5 comprises a cover 11 integral with the body 6, and the cover 11 comprises a return duct 12 for returning the fuel of the metering valve and any fuel leaking between the joint surfaces of the components of the injector 5; the return duct 12 Comprising a generally cylindrical end piece 13; the cover 11 covers a plastic molding 14; the plastic molding 14 includes a delivery tube 15 for supporting the electromagnet of the solenoid metering valve.

[0014] The end piece 13 is connected to a return connection, indicated at 16 . More specifically, the connector 16 consists of a connecting piece 17 inserted into the end piece ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap