Intelligent surface treatment method for workpiece

A surface treatment and workpiece technology, applied in the field of intelligent surface treatment of workpieces, can solve problems such as poor applicability, and achieve the effect of comprehensive and effective shot blasting treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] refer to Figure 9 In this embodiment, a method for intelligent surface treatment of workpieces is proposed, which includes the following steps:

[0085] Step 1: Hang the workpiece to be processed on the hanger, and set the identity label containing the shape parameters of the workpiece on the hanger, and then transport the hanger to the shot blasting treatment room;

[0086] Step 2: The shot blasting treatment room identifies the identity tag, and selects the shot blasting parameters of the shot blasting nozzle that matches it according to the identified workpiece shape parameters;

[0087] Step 3: According to the selected shot blasting parameters, perform shot blasting on the workpiece on the hanger, and rotate the hanger at the same time;

[0088] Step 4: After the shot blasting treatment is completed, the hanger is transported out of the shot blasting treatment room, and the workpiece is removed.

[0089] Through the above method, the information of the shape of ...

Embodiment 2

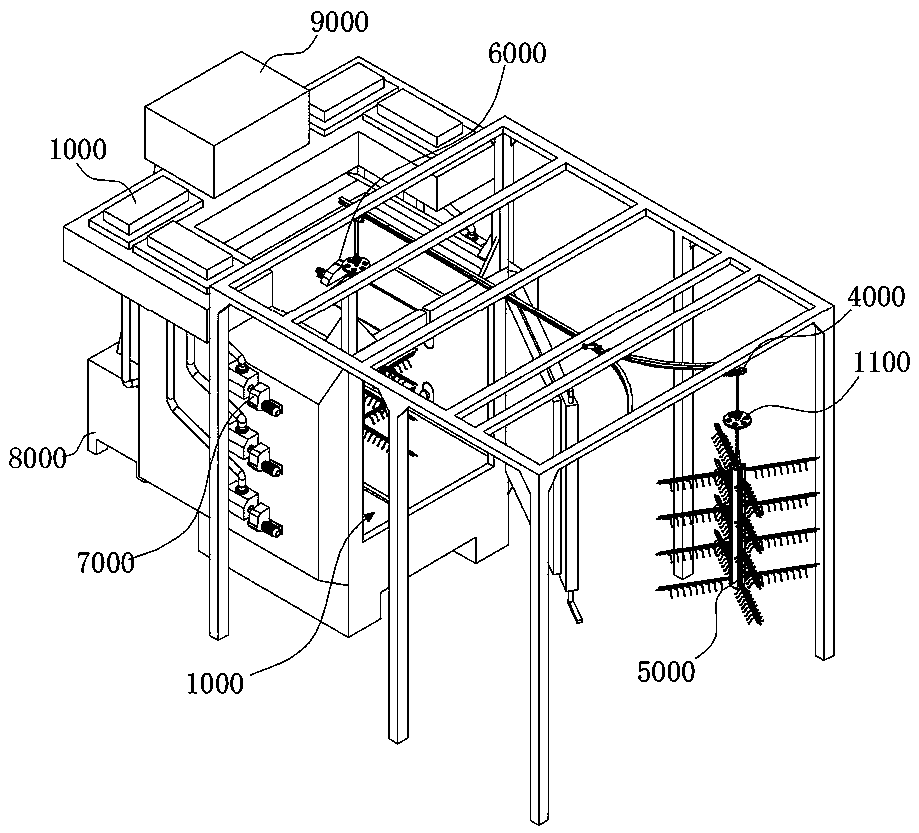

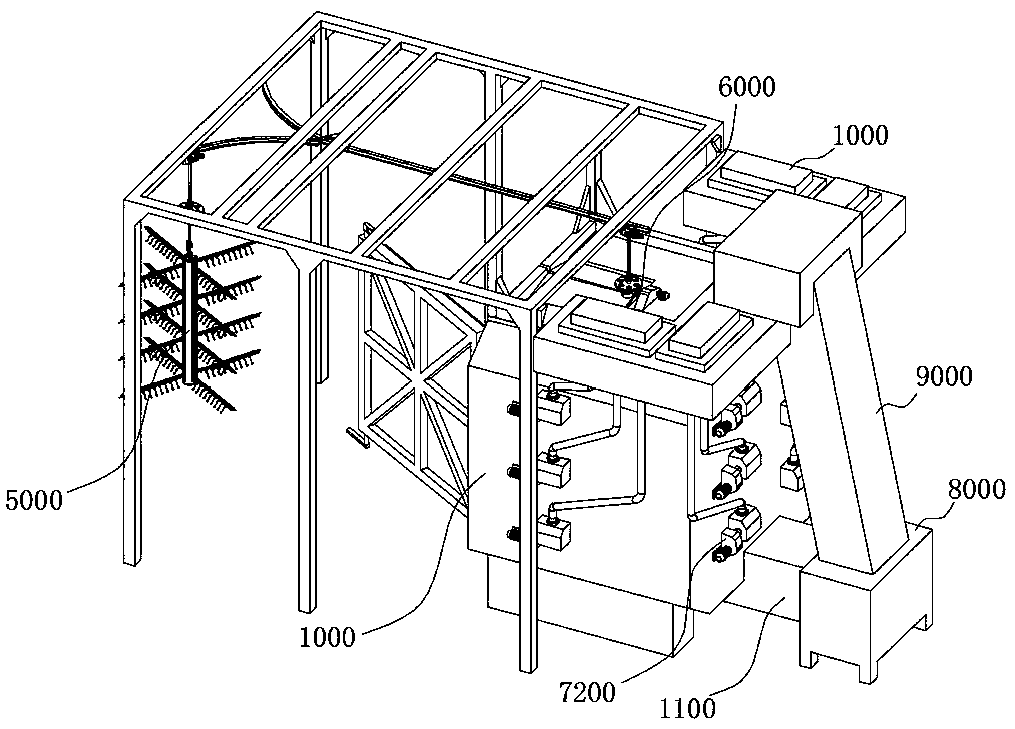

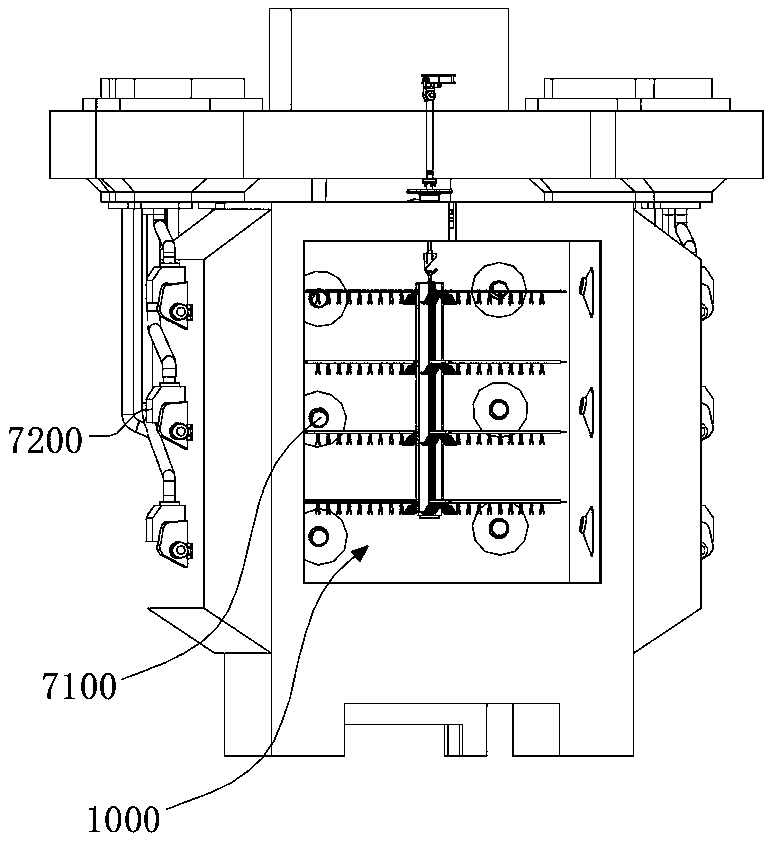

[0152] refer to Figure 1-8 According to the present invention, a shot blasting machine suitable for processing different workpieces is proposed in this embodiment, including a shot blasting treatment chamber 1000, which is equipped with a shot blasting unit 7000 and a control unit, and the shot blasting unit 7000 includes The shot blasting nozzle 7100 that sprays shot sand into the shot blasting treatment chamber 1000, the control unit controls the shot blasting unit 7000 according to the shape of the workpiece to be processed, and selects the appropriate shot blasting parameters to perform shot blasting on the workpiece. The shot blasting parameters It includes one or more of the orientation and rotation direction of the shot blasting nozzle 7100.

[0153] Through the setting of the shot blasting treatment chamber 1000 and the shot blasting unit 7000, the shot blasting treatment function to the workpiece is realized, and through the setting of the control unit, the function ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com