High-position stacking and conveying all-in-one machine with automatic hole reserving type grouping function

A high-level code and integrated machine technology, applied in the field of palletizing, can solve the problems of inability to realize automation, integration of conveying and palletizing, and reduced work efficiency, and achieve the effect of flexible and practical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

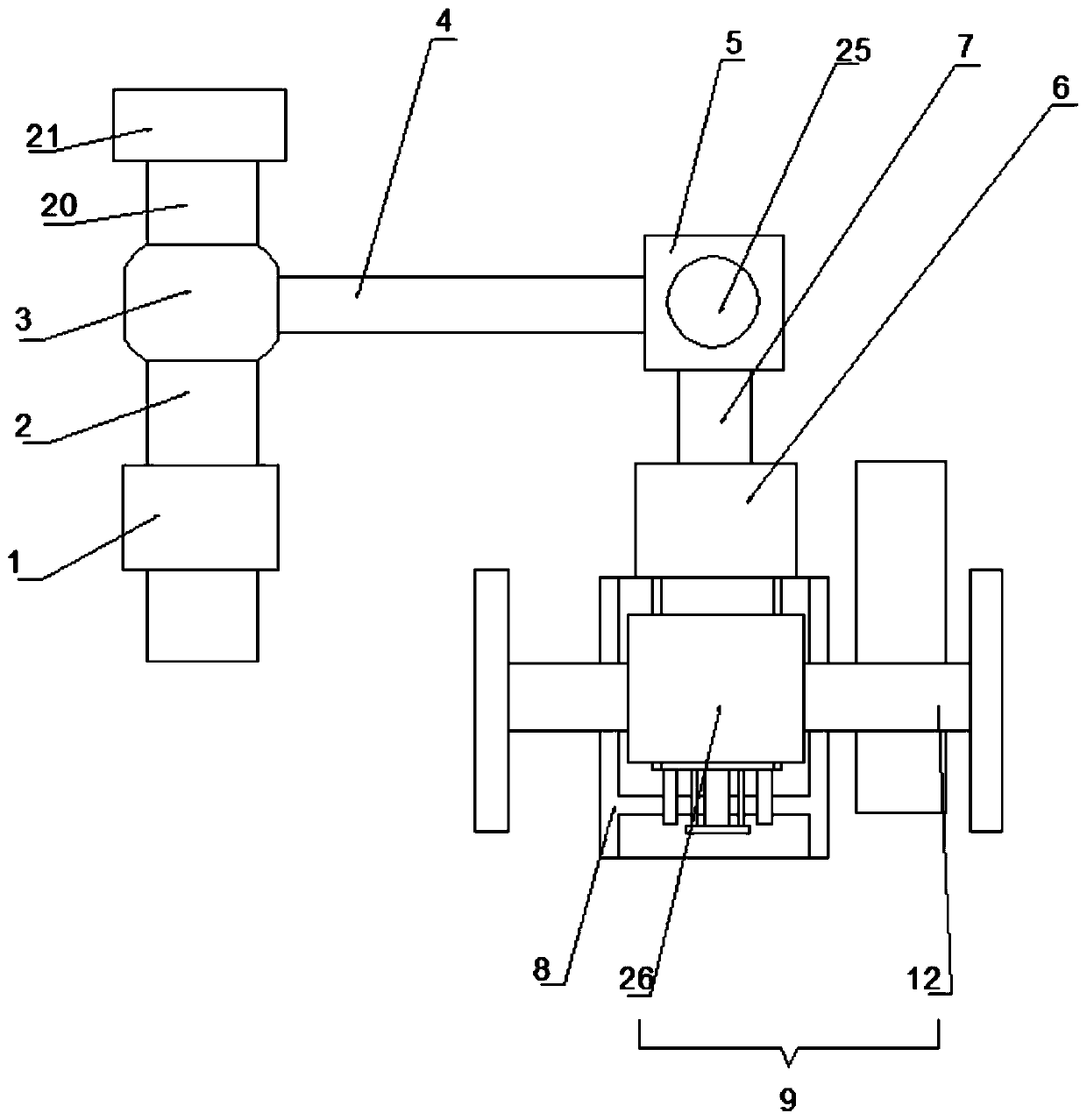

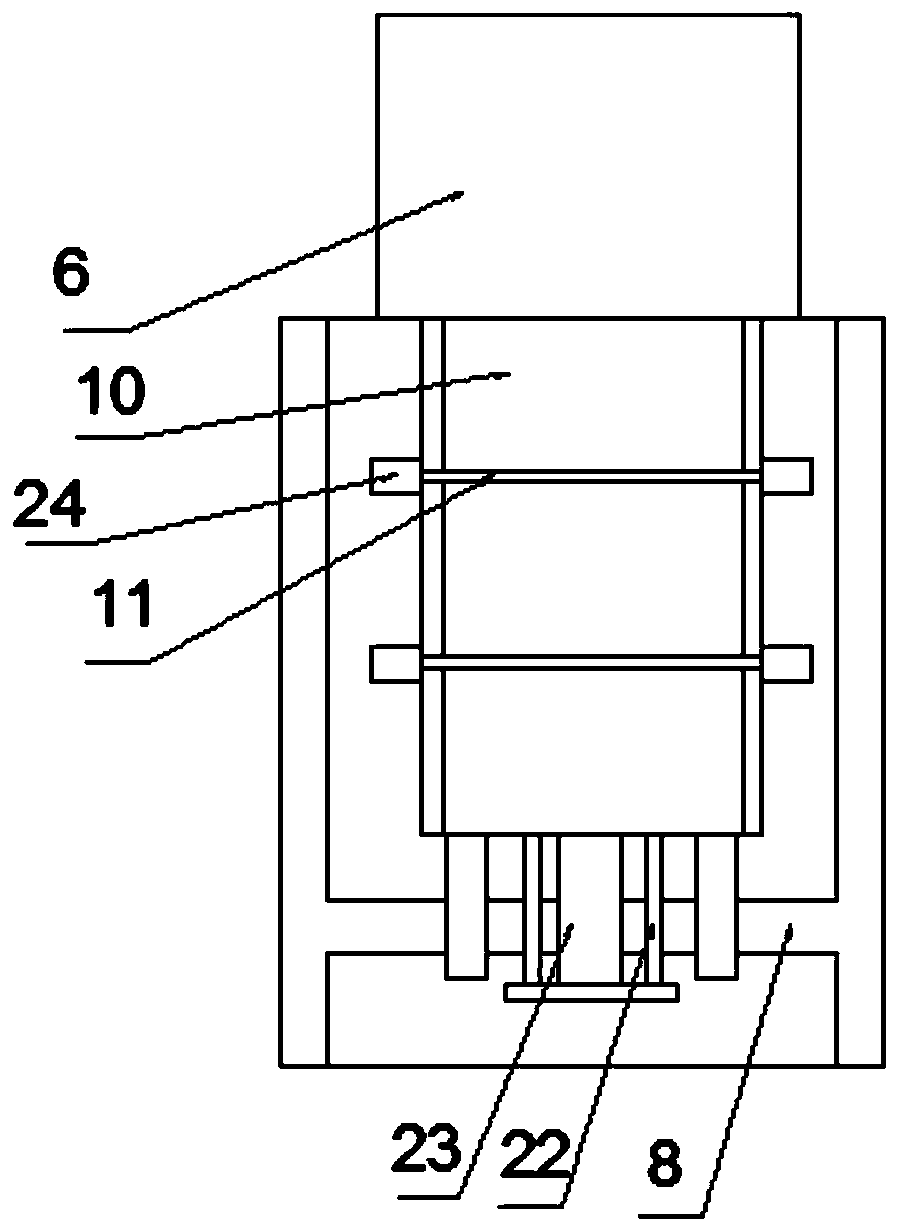

[0024] Such as Figure 1-3 As shown, according to the embodiment of the present invention, the high-position palletizing and conveying integrated machine with self-retaining hole grouping function includes a conveyor 1, and a conveyor belt 2 matching it is provided on one side of the conveyor 1, and the conveyor belt 2 One end away from the conveyor 1 is provided with a separator 3 matching it, one side of the separator 3 is provided with a conveyor belt 4, and the end of the conveyor belt 4 away from the separator 3 is provided with a The transfer machine 5, one side of the transfer machine 5 is provided with a stacking limiter 6, and a transfer conveyor belt 7 is provided between the stacking limiter 6 and the transfer machine 5, and the stacking limiter The side of the bit machine 6 away from the transfer machine 5 is provided with a hole-retaining frame 8, the top of the hole-retaining frame 8 is provided with a stacking device 9, and the inside of the hole-retaining frame...

Embodiment 2

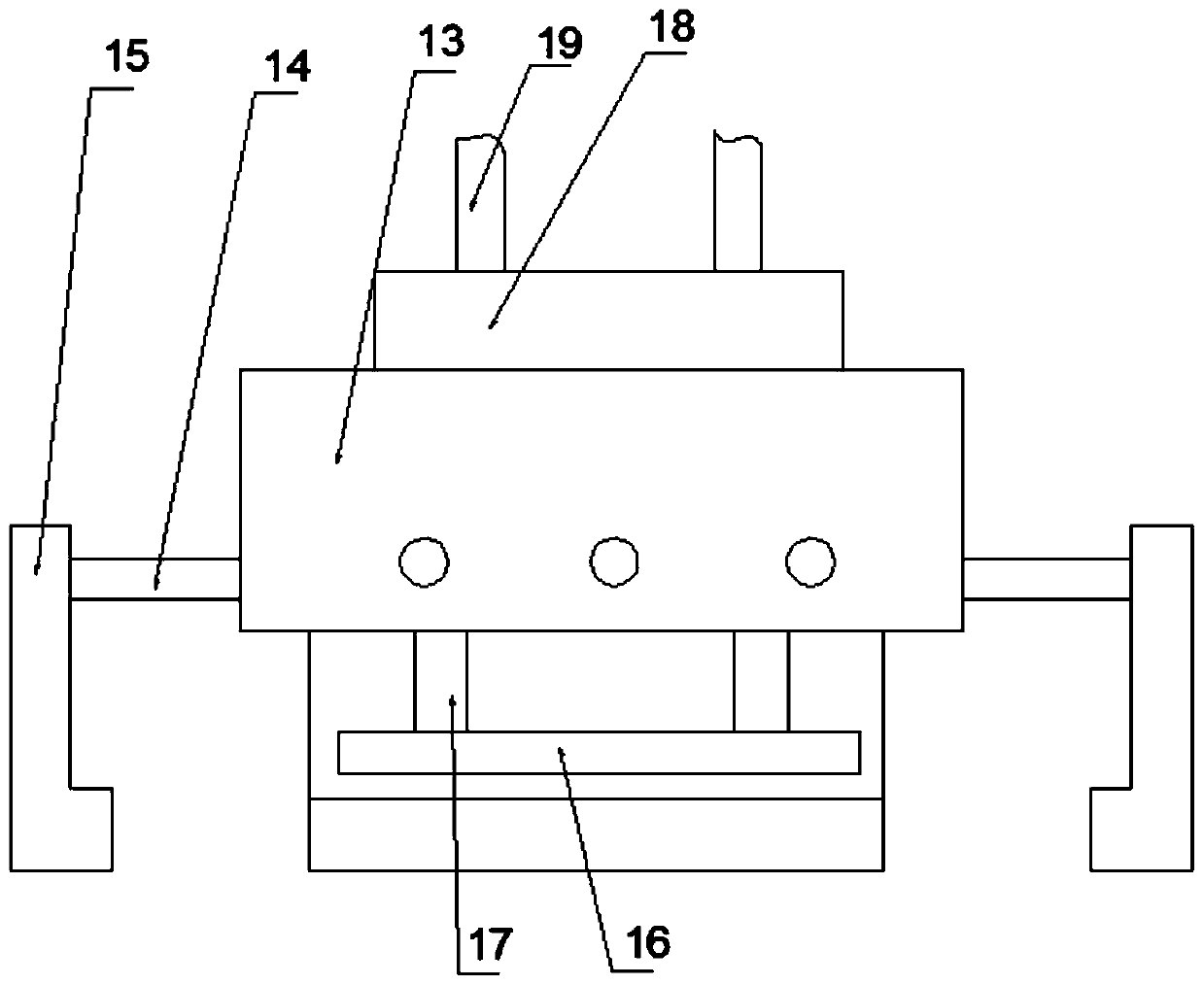

[0028] Such as Figure 1-3 As shown, the palletizing device 9 includes a support frame 12, the top of the support frame 12 is provided with a palletizing conveyor 13 that matches the perforated frame 8, and the four sides of the bottom of the palletizing conveyor 13 Both sides are provided with telescopic rods 14, and the end of the telescopic rods 14 away from the palletizing conveyor 13 is provided with a clamping frame 15, and the bottom end of the palletizing conveyor 13 is provided with a hole-retaining limit plate 16, so that A hydraulic rod 17 is provided between the hole-retaining limit plate 16 and the stacking conveyor 13, and the top of the stacking conveyor 13 is provided with a telescopic adjustment frame 18 matched with it, and the telescopic adjustment frame 18 A telescopic adjustment rod 19 matched with the support frame 12 is provided at the top, a moving frame 26 is arranged between the telescopic adjustment rod 19 and the support frame 12, and the separator ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap