Assembly type wallboard mounting structure capable of realizing step type leveling

A kind of installation structure and stepped technology, which is applied in the field of leveling and installation of prefabricated wall panels, can solve the problems of not meeting the requirements of prefabricated construction, large installation errors of wall panels, and slow construction efficiency, so as to achieve fast leveling and high installation efficiency High, reduce the effect of installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

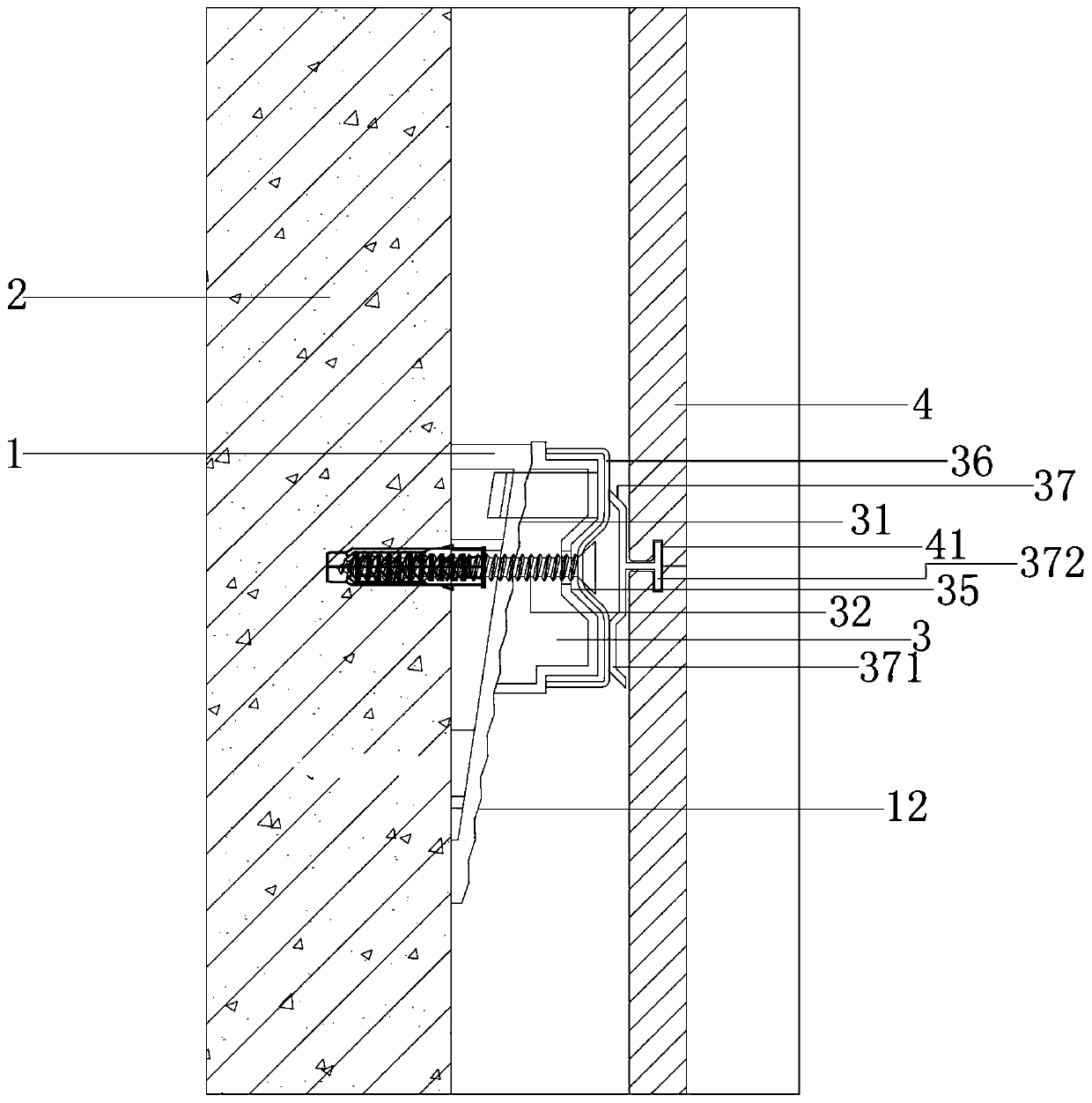

[0036] see Figure 1 to Figure 6 , the figure shows a step-level leveling assembled wall panel installation structure provided by Embodiment 1 of the present invention. First, an adjustment seat 1 is provided, which is fixedly connected to the base layer 2 of the wall surface. The surface of the adjustment seat 1 There is a first slope, the first slope is provided with a first toothed surface 12, the cross section of the adjustment seat 1 is a right triangle; secondly, a connection seat 3 is provided, which is fixedly connected to the adjustment seat 1, and the surface of the connection seat 3 has Butt the second inclined surface of the first inclined surface, the second inclined surface is provided with the second toothed surface 31 butted with the first toothed surface 12, the cross section of the connecting seat 3 is a right angle trapezoid; on the connector 3.

[0037] Specifically, the connection base 3 is connected to the adjustment base 1 through the screw 32, and the ...

Embodiment 2

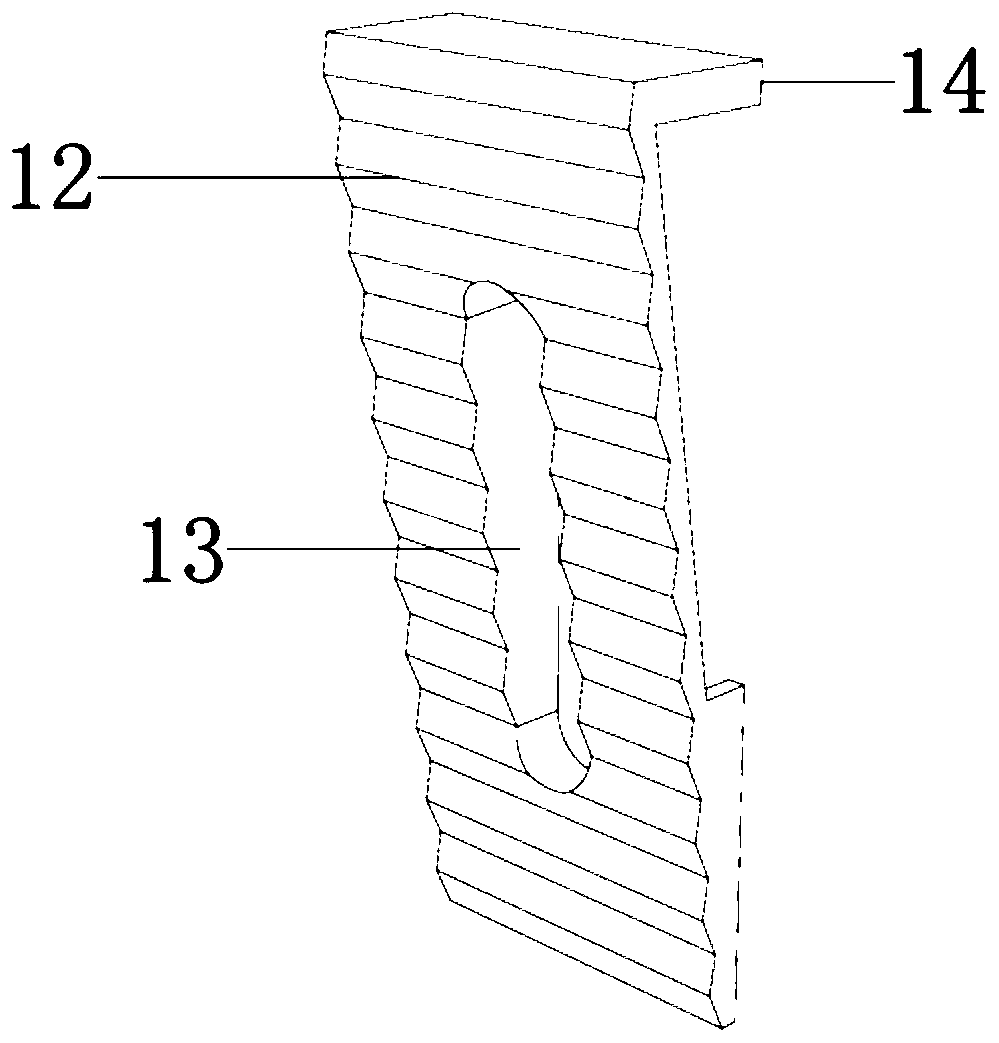

[0039] see Figure 1 to Figure 4 , the figure shows a stepped leveling assembled wall panel installation structure provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments : The adjustment seat 1 is provided with a waist-shaped hole 13 arranged along the length direction of the adjustment seat 1, the waist-shaped hole 13 is used for the screw 32 to pass through, and the adjustment seat can be moved up or down without disassembling the screw , so as to quickly adjust the in and out distance of the wall panel.

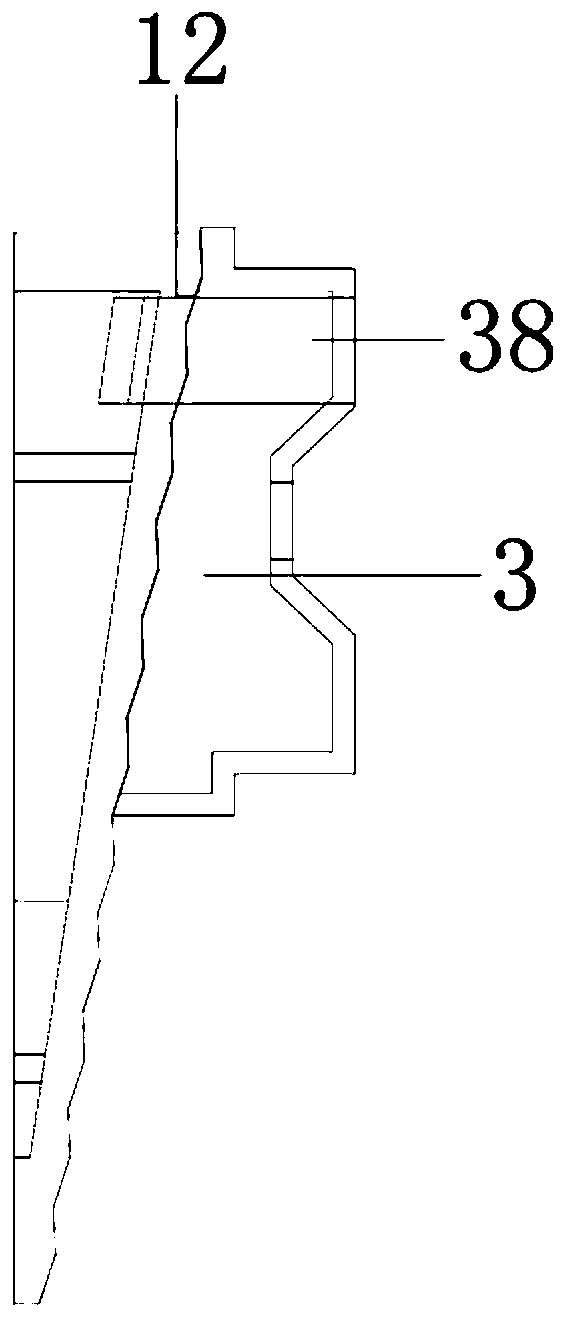

[0040] As a fit, see Figure 1 to Figure 6 , the opposite sides of the second toothed surface 31 are respectively provided with two hooks 38, the hooks 38 are stuck on the opposite sides of the first toothed surface 12, that is, after the adjustment seat moves, the adjustment seat is positioned by the hooks s position.

Embodiment 3

[0042] see Figure 3 to Figure 4 , the figure shows a step-level leveling assembled wall panel installation structure provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments The first connection surface 14 connected to the wall base 2 on the adjustment seat 1 includes a T-shaped connection surface 141 and an E-shaped connection surface 142, the T-shaped connection surface 141 is located at the top of the first connection surface 14, and the E-shaped connection surface 142 is located at the second A bottom of the connection surface 14 . Through the setting of the above structure, on the one hand, the overall weight of the adjusting seat can be reduced, making it easier to move and adjust, and on the other hand, the structural strength of the adjusting seat can also be ensured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com