Rotary leveling wall plate mounting structure and method

A technology for installing structures and wall panels, applied in building construction, covering/lining, construction, etc., can solve the problems of fire performance, slow construction efficiency, unsatisfactory, etc., achieve high installation efficiency, reduce installation steps, and construction The effect of high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

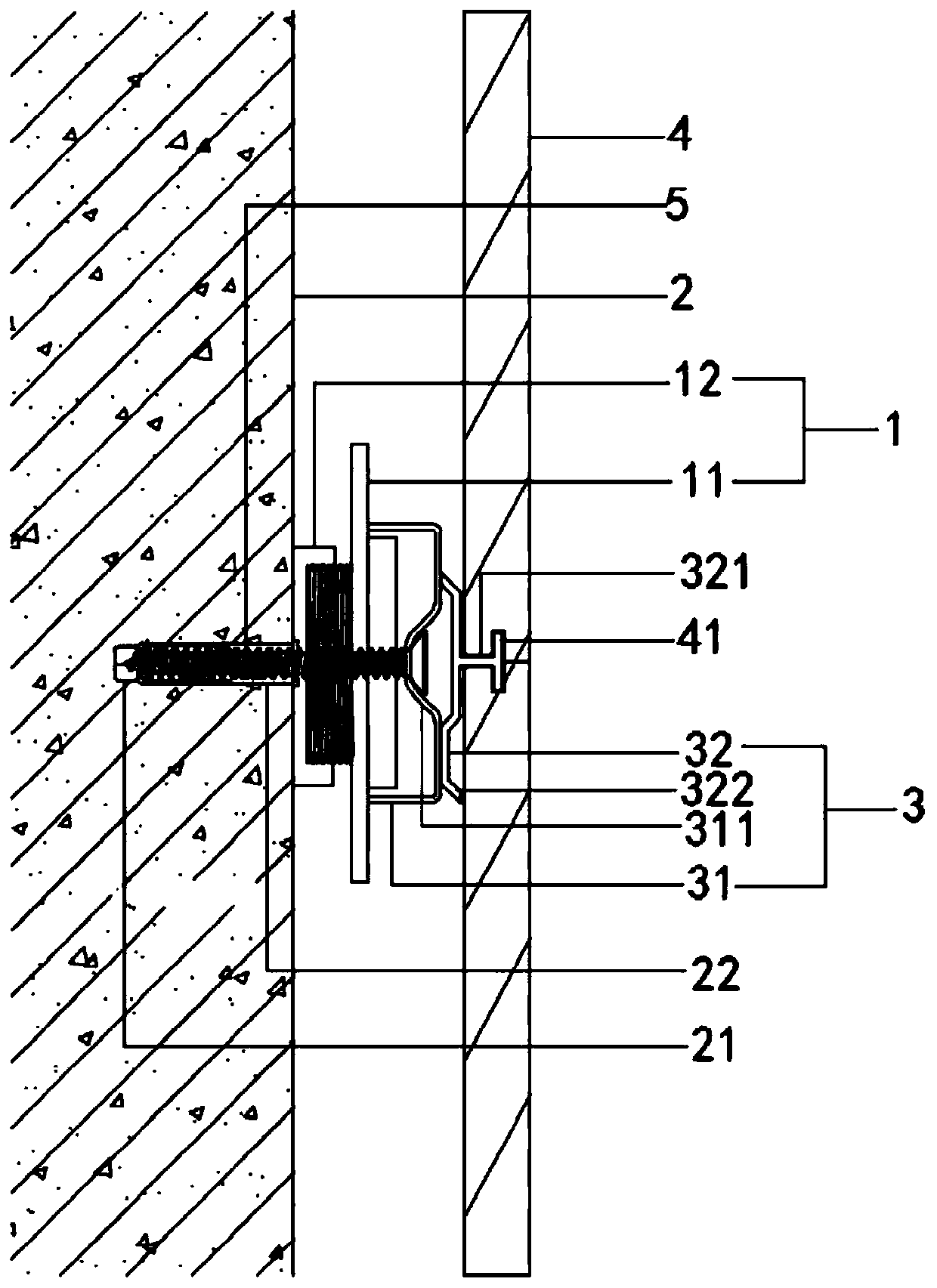

[0035] see Figure 1 to Figure 5 , the figure shows a rotating and leveling wall panel installation structure provided by Embodiment 1 of the present invention. Firstly, a leveling assembly 1 is provided, which includes a rotating part 11 and a leveling base 12, and the leveling base 12 is fixedly installed. On the wall 2, the rotating part 11 is screwed to the leveling base 12. The keel member 3 includes a first connecting part 31 and a second connecting part 32. The first connecting part 31 is detachably mounted on the rotating part 11. The wallboard The body 4 is clamped to the second connecting part 32 and the second connecting part 32 is fixedly connected to the first connecting part 31 .

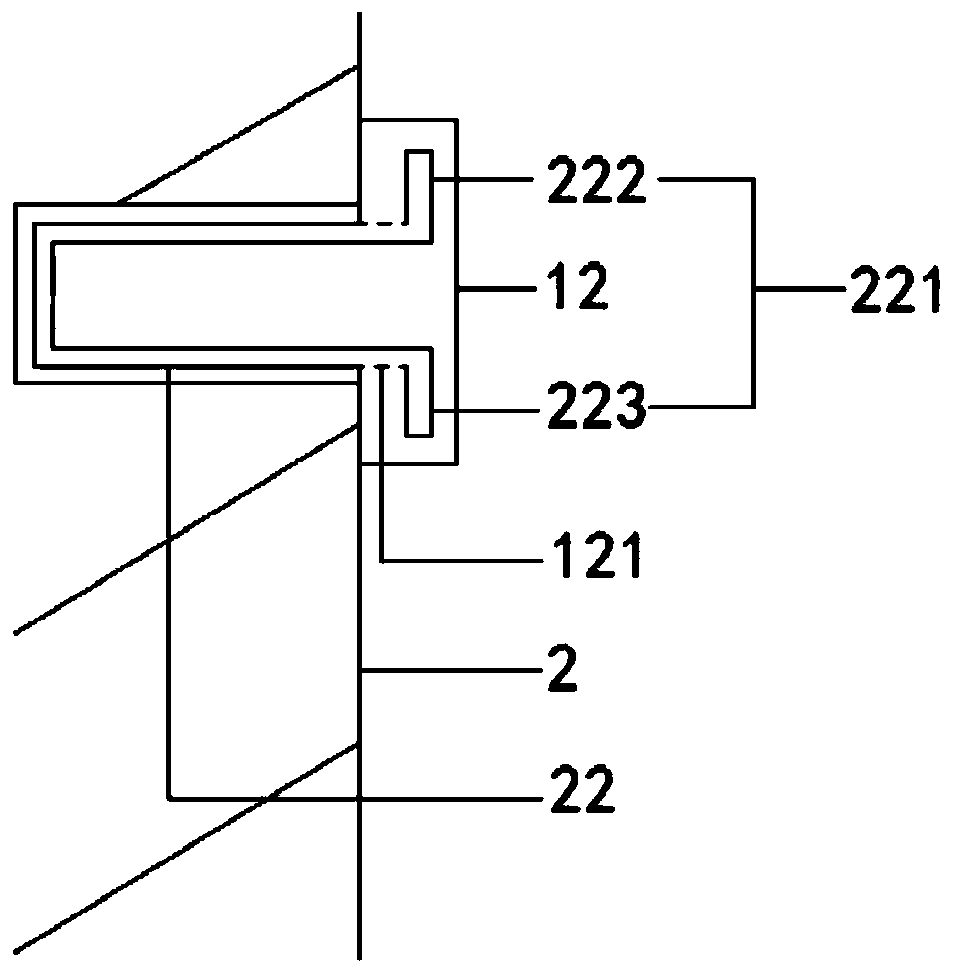

[0036] see Figure 1 to Figure 5 , the wall 2 is provided with a groove 21, the expansion sleeve 22 is installed in the groove 21, the leveling base 12 is detachably installed on the expansion sleeve 22, and the end of the expansion sleeve 22 is fixedly connected with a clamping plate...

Embodiment 2

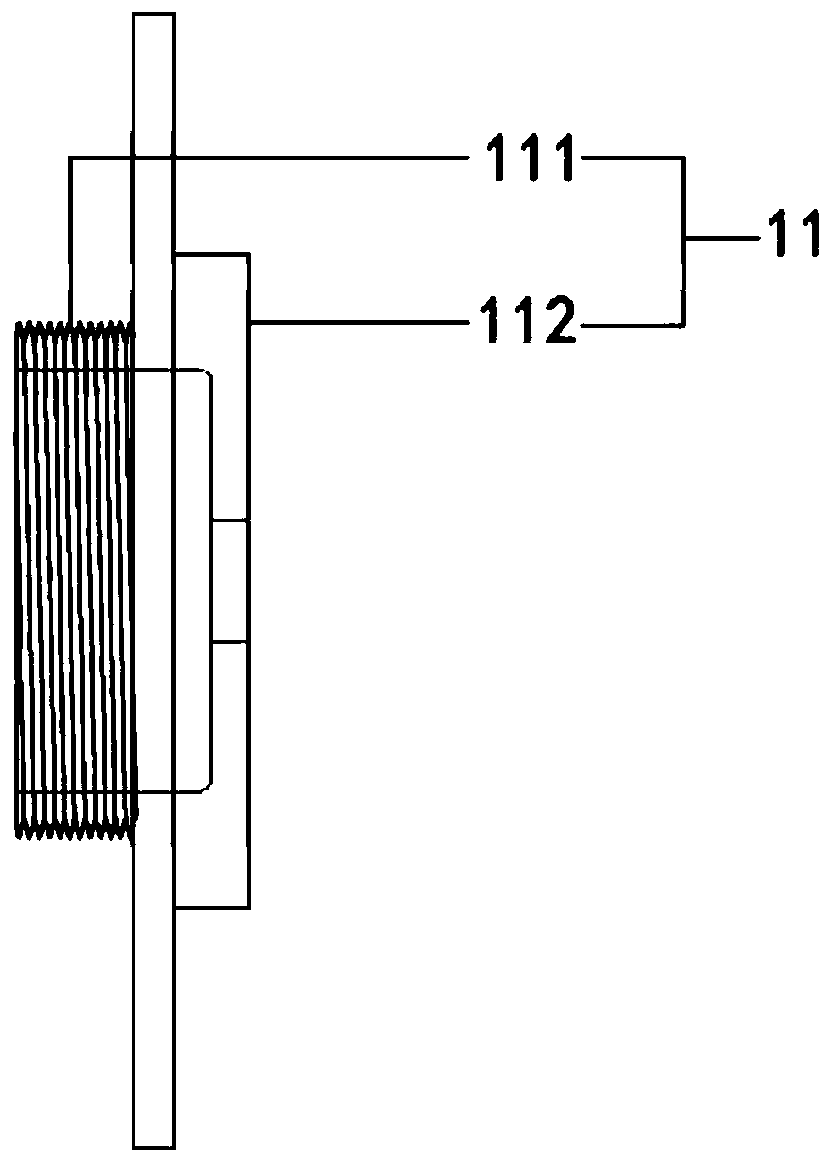

[0046] see Figure 1 to Figure 5 , the figure shows a rotating and leveling wall panel installation structure provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: the rotating part 11 Including bolts 111 and cover plate 112, the cover plate 112 is fixedly connected to the bolt 111 and the bolt 111 is screwed into the leveling base 12, the cover plate 112 is a quincunx structure, specifically, the cover plate 112 includes a main board and an edge board body, the main board It is a circular structure, the edge plate body is a semicircular plate body, and multiple semicircular plate bodies are evenly distributed on the circumference of the main plate, so as to improve the pre-tightening force of the cover plate 112, increase hand friction, and reduce construction adjustment fatigue Spend.

Embodiment 3

[0048] see Figure 1 to Figure 5 , the figure shows a rotating and leveling wall panel installation structure provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: keel member 3 Including a first connecting part 31 and a second connecting part 32, the first connecting part 31 is detachably installed on the rotating part 11, the first end of the first connecting part 31 is provided with a first bending plate, the first connecting part The second end of 31 is provided with a second bending plate, and the rotating part 11 is provided with an annular positioning groove along its circumference, and both the first bending plate and the second bending plate are clamped in the annular positioning groove, thereby avoiding Steps of drilling holes and inserting screws to improve installation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com