Side plate hinge structure and large container

A large container and side plate technology, applied in the field of side plate hinge structure and large container, can solve the problems of inconvenient installation and disassembly, achieve the effect of convenient rotation, lighten labor intensity and reduce resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

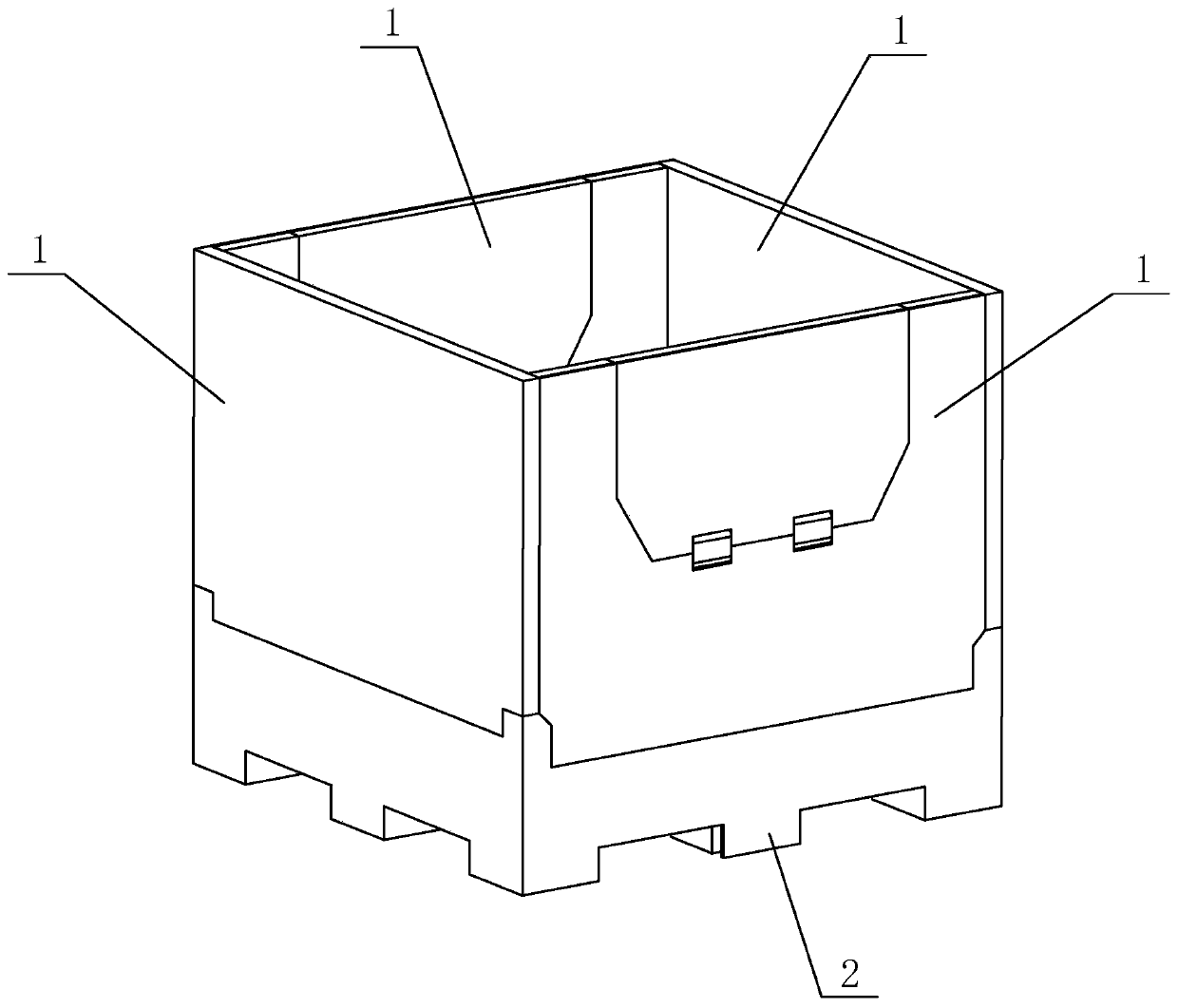

[0040] A large container, combined with figure 2 It can be seen that in this implementation, the large-scale container is disclosed by using a plastic folding box. The folding box includes four side panels 1 and a base 2, and the four side panels 1 are all rotatably mounted on the base 2, so that the side panels 1 can be folded and folded conveniently. It is stored on the base 2, and the empty plastic folding box is stored. In order to facilitate the rotational installation of the side plate 1 on the base 2 , a side plate hinge structure is provided between the side plate 1 and the base 2 .

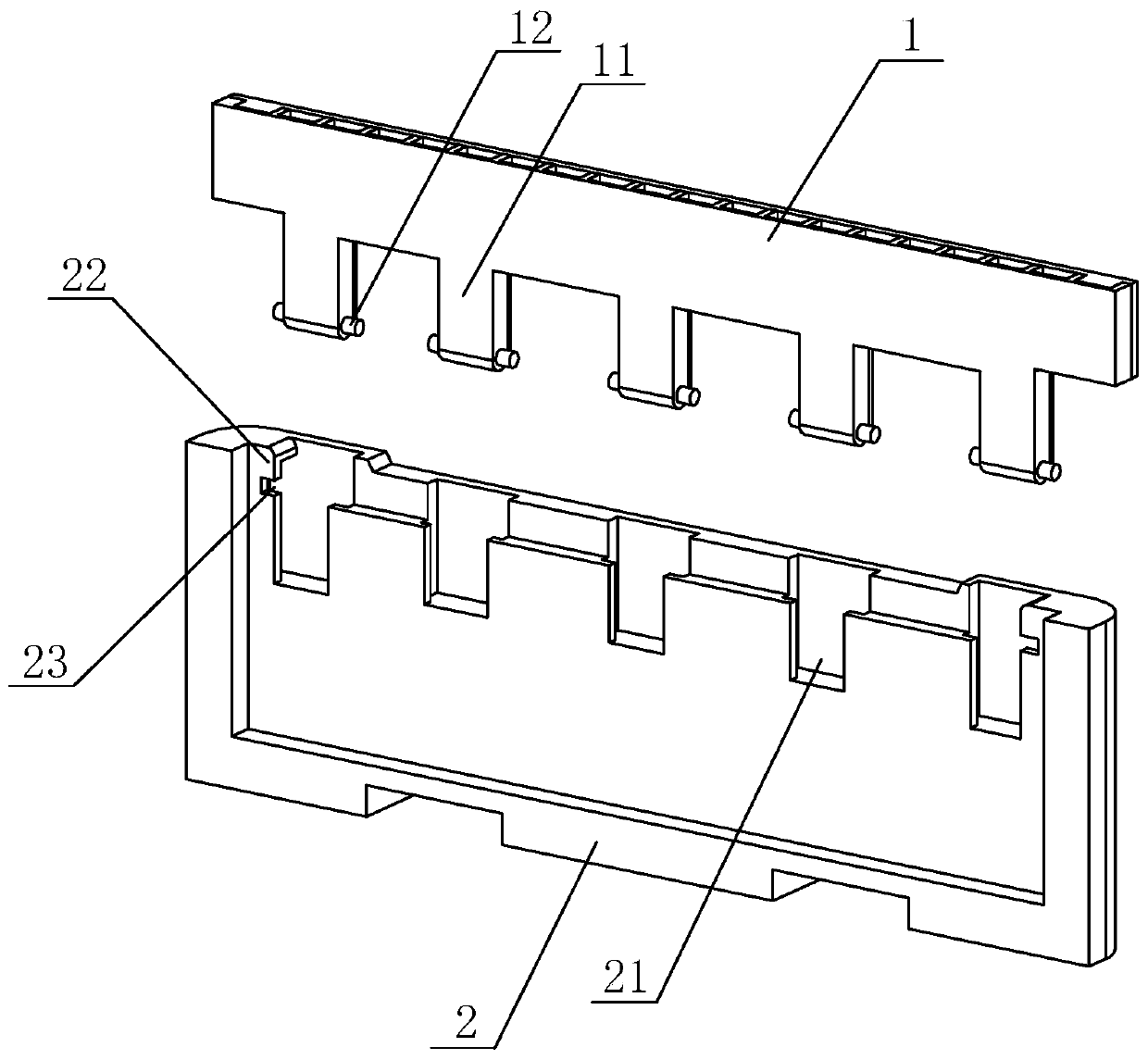

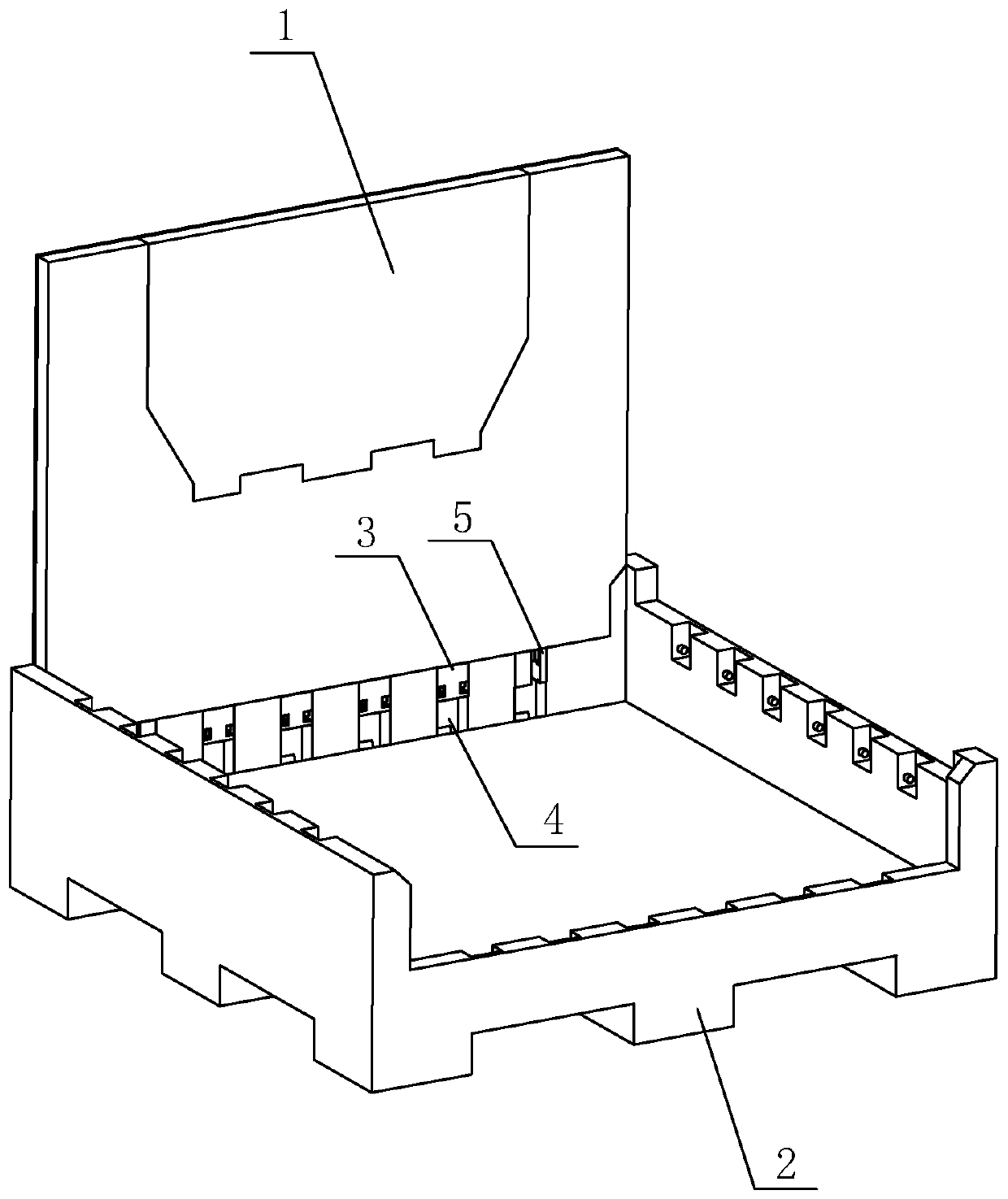

[0041] Specifically, combine image 3 and Figure 4It can be seen that the hinged structure of the side plate includes the above-mentioned side plate 1 and the above-mentioned b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com