A trackless measurement construction method for the inner ring network of a subway tunnel

A construction method and technology in the tunnel, applied in the directions of measuring device, height/horizontal measurement, surveying and navigation, etc., can solve the problems such as tight construction period of subway power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

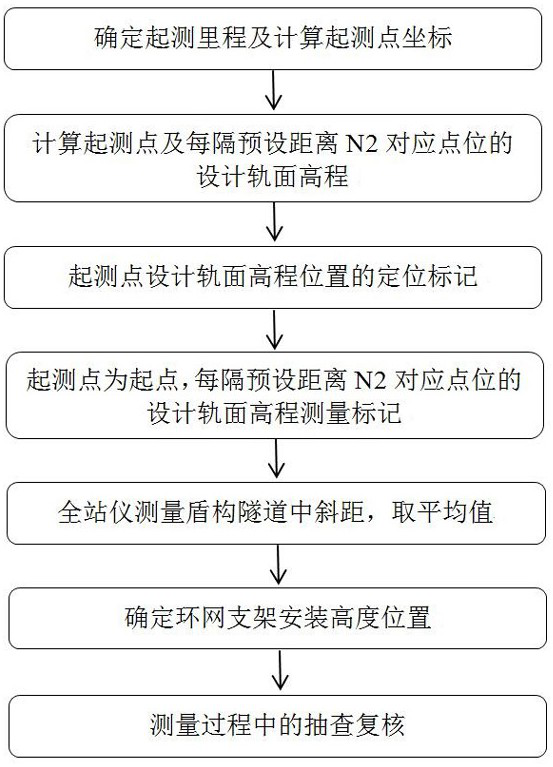

[0046] This embodiment provides a trackless measurement construction method for a ring network in a subway tunnel, which includes the following steps.

[0047] Step 1. Determine the starting mileage and calculate the coordinates of the starting point

[0048] Take the preset distance N1 inward of the tunnel entrance as the starting point, and the mileage obtained by adding the preset distance N1 to the tunnel entrance mileage is the starting measurement mileage.

[0049] When measuring the ring network of the tunnel, considering the convenience of construction, generally select the position 5 meters inward of the opening (that is, N1=5 meters) to start the measurement, and add 5 meters to the mileage of the tunnel opening to get the starting mileage. Combined with the horizontal and vertical section diagram of the line, the starting point of the tunnel entrance is the structural boundary point, and the coordinates of the structural boundary point, as well as the coordinates of...

Embodiment 2

[0080] In the power supply system and comprehensive monitoring system equipment installation project of the first phase of the Beijing Rail Transit New Airport Line, a trackless measurement construction method for the inner ring network of the subway tunnel described in Example 1 was adopted, taking into account both measurement accuracy and efficiency. After practice , achieved good results.

[0081] In terms of economic benefits: first, when there is less cross-interference, the construction efficiency is greatly improved, and the construction efficiency is greatly improved, and the same number of people can complete more projects, which saves construction costs; Coordination expenses, and possible layoff costs.

[0082] Compared with the previous survey construction, after the design rail surface position and slope distance are given, it becomes very simple to determine the installation height of the ring network support. A group of three can quickly and accurately complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com