Device with equipment locking detection and control method thereof

A technology of locking detection and detection devices, which is applied in the field of safety production, can solve the problems of lack of safety accidents of equipment to be detected, and achieve the effect of real-time safety monitoring and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

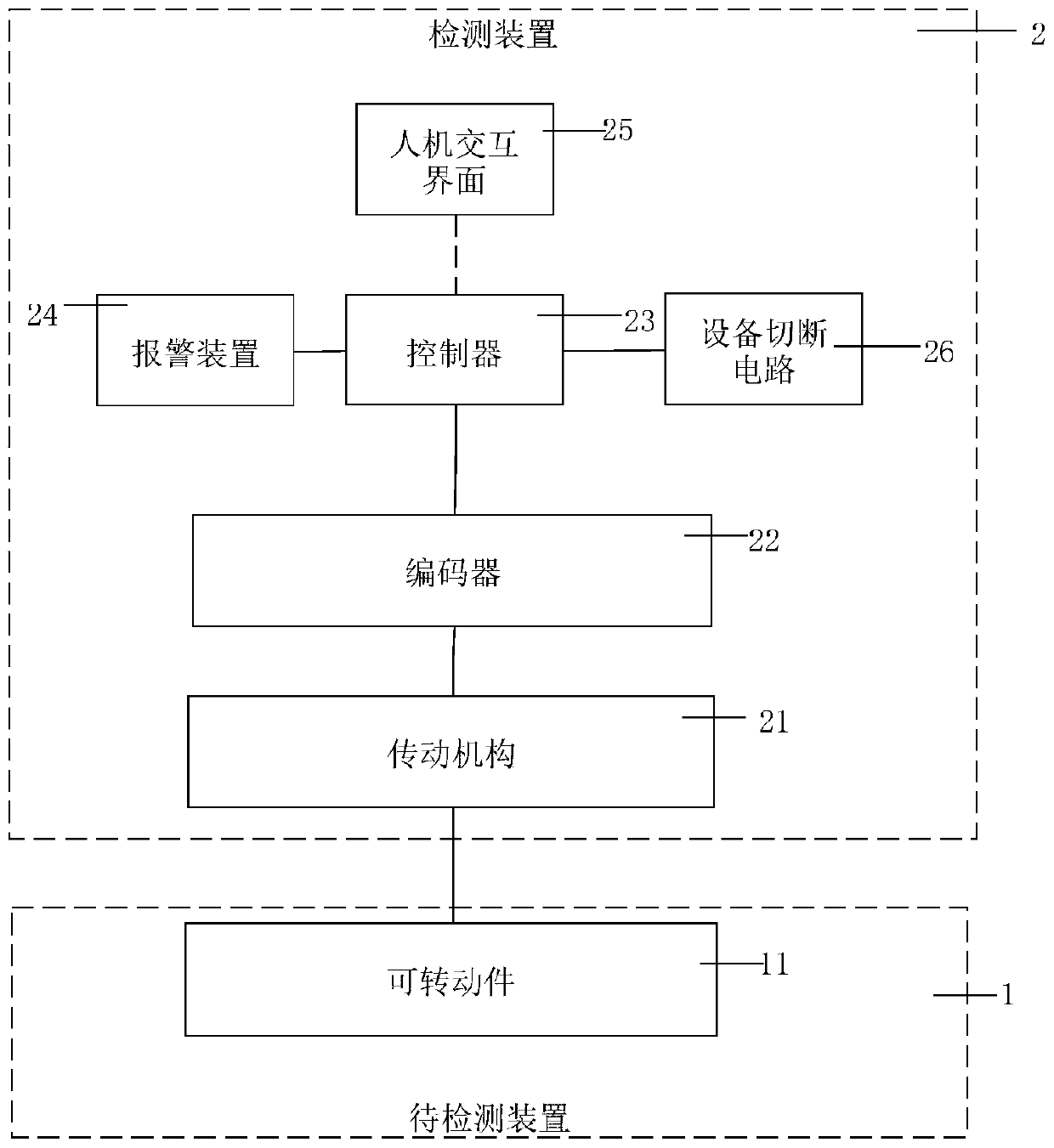

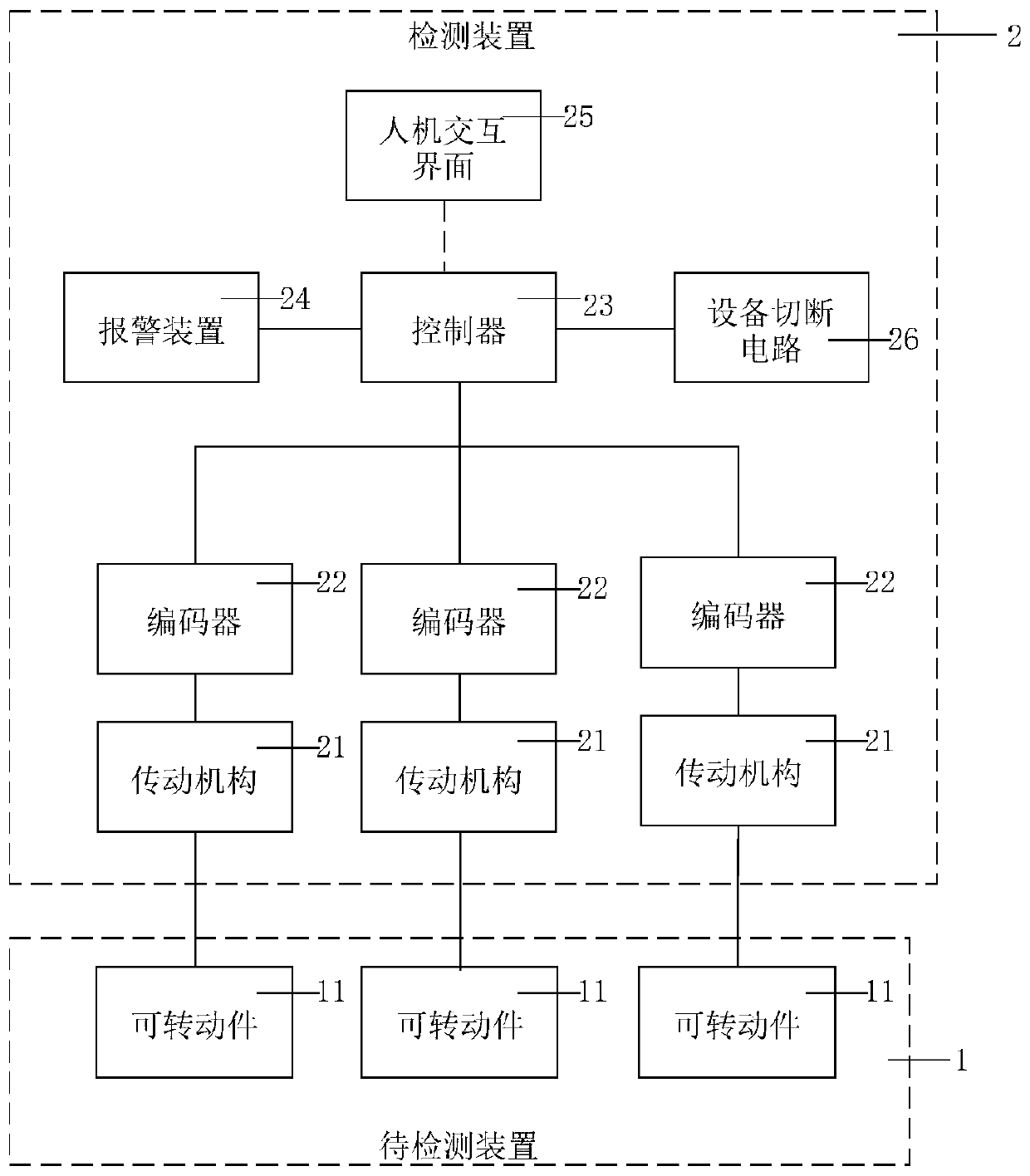

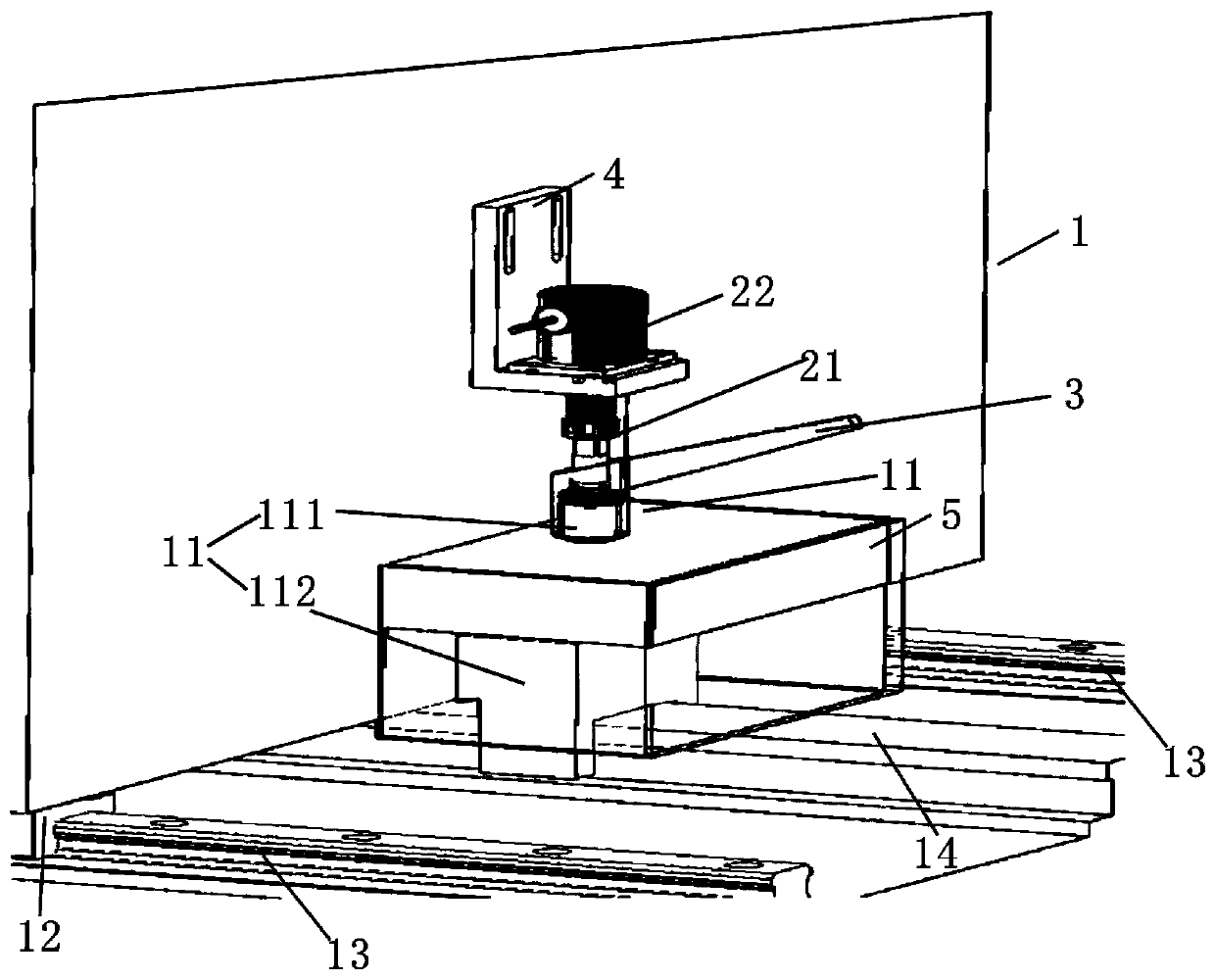

[0038] In the prior art, due to the lack of real-time locking detection of the equipment, the operation of the equipment without confirming the locking or the occurrence of loosening leads to frequent production safety accidents. In order to solve this problem, the present invention implements Example 1 provides a device with equipment lock detection, specifically, refer to Figure 1 ~ Figure 4 Understand, including:

[0039] The device to be tested 1, wherein the device to be tested 1 is provided with a rotatable member 11; when the rotatable member 11 rotates in a circumferential direction, the device to be tested 1 becomes loose;

[0040] The detection device 2 includes a transmission mechanism 21 for transmitting the amount of circumferential rotation and an encoder 22 for detecting the amount of circumferential rotation;

[0041] The lower end surface of the transmission mechanism 21 is coaxially fixed to the upper end surface of the rotatable member 11, and the transmission mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com