A potassium sodium niobate-based lead-free piezoelectric ceramic and its manufacturing process and application

A potassium sodium niobate-based, lead-free piezoelectric technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of unfavorable industrial production and automation, complex assembly process, solder joint Solving problems such as virtual welding, to avoid failure of lead solder joints, improve assembly structure, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

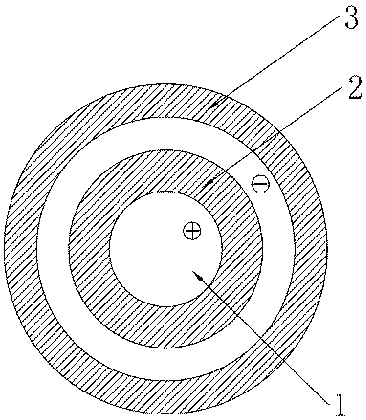

Image

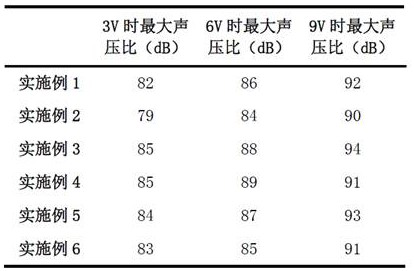

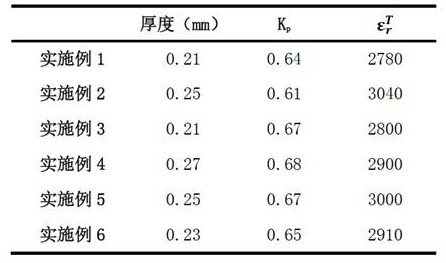

Examples

Embodiment 1

[0025] Embodiment 1: a kind of potassium sodium niobate base lead-free piezoelectric ceramics, comprises the chemical composition of following molar percentage: 92% (K 0.6 Na 0.4 )NbO 3 , 2% (Ca 0.5 Mg 0.5 )TiO 3 and 6% SrHfO 3 , the preparation method comprises the following steps:

[0026] (1) Raw material pretreatment: Put potassium carbonate, sodium carbonate, niobium pentoxide, calcium carbonate, basic magnesium carbonate, titanium dioxide, strontium carbonate and hafnium oxide into a petri dish, place in an oven, and keep warm at 180°C for 3 hours , get the preparation material;

[0027] (2) Mixed preparatory material: The preparatory material is dispersed in absolute ethanol according to the chemical composition ratio, put into a ball mill for wet milling, the speed of the ball mill is 450rpm, and the wet milling time is 45h. After the wet milling is completed, take it out and put it in the oven Dried, ground with an agate mortar, passed through an 80-mesh sieve,...

Embodiment 2

[0032] Embodiment 2: a kind of potassium sodium niobate base lead-free piezoelectric ceramics, comprises the chemical composition of following molar percentage: 91% (K 0.6 Na 0.4 )NbO 3 , 4% (Ca 0.5 Mg 0.5 ) TiO 3 and 5% SrHfO 3 , the preparation method comprises the following steps:

[0033] (1) Raw material pretreatment: Put potassium carbonate, sodium carbonate, niobium pentoxide, calcium carbonate, basic magnesium carbonate, titanium dioxide, strontium carbonate and hafnium oxide into a petri dish, place in an oven, and keep warm at 200°C for 4 hours , get the preparation material;

[0034] (2) Mixed preparatory material: The preparatory material is dispersed in absolute ethanol according to the chemical composition ratio, put into a ball mill for wet milling, the speed of the ball mill is 500rpm, and the wet milling time is 46h. After the wet milling is completed, take it out and put it in the oven Dried, ground with an agate mortar, passed through a 100-mesh sieve...

Embodiment 3

[0039] Embodiment 3: a kind of potassium sodium niobate base lead-free piezoelectric ceramics, comprises the chemical composition of following molar percentage: 90% (K 0.6 Na 0.4 )NbO 3 , 4% (Ca 0.5 Mg 0.5 ) TiO 3 and 6% SrHfO 3 , the preparation method comprises the following steps:

[0040] (1) Raw material pretreatment: Put potassium carbonate, sodium carbonate, niobium pentoxide, calcium carbonate, basic magnesium carbonate, titanium dioxide, strontium carbonate and hafnium oxide into a petri dish, place in an oven, and keep warm at 220°C for 4 hours , get the preparation material;

[0041] (2) Mixed preparatory material: The preparatory material is dispersed in absolute ethanol according to the chemical composition ratio, put into a ball mill for wet milling, the speed of the ball mill is 550rpm, and the wet milling time is 50h. After the wet milling is completed, take it out and put it in the oven Dried, ground with an agate mortar, passed through a 120-mesh sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com