Motor end cover and its motor

A technology of motor end cover and end cover, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of unfavorable operation, low coaxiality, easily damaged bearing internal roller clearance, etc., and achieves convenient installation The effect of disassembly and positioning range change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

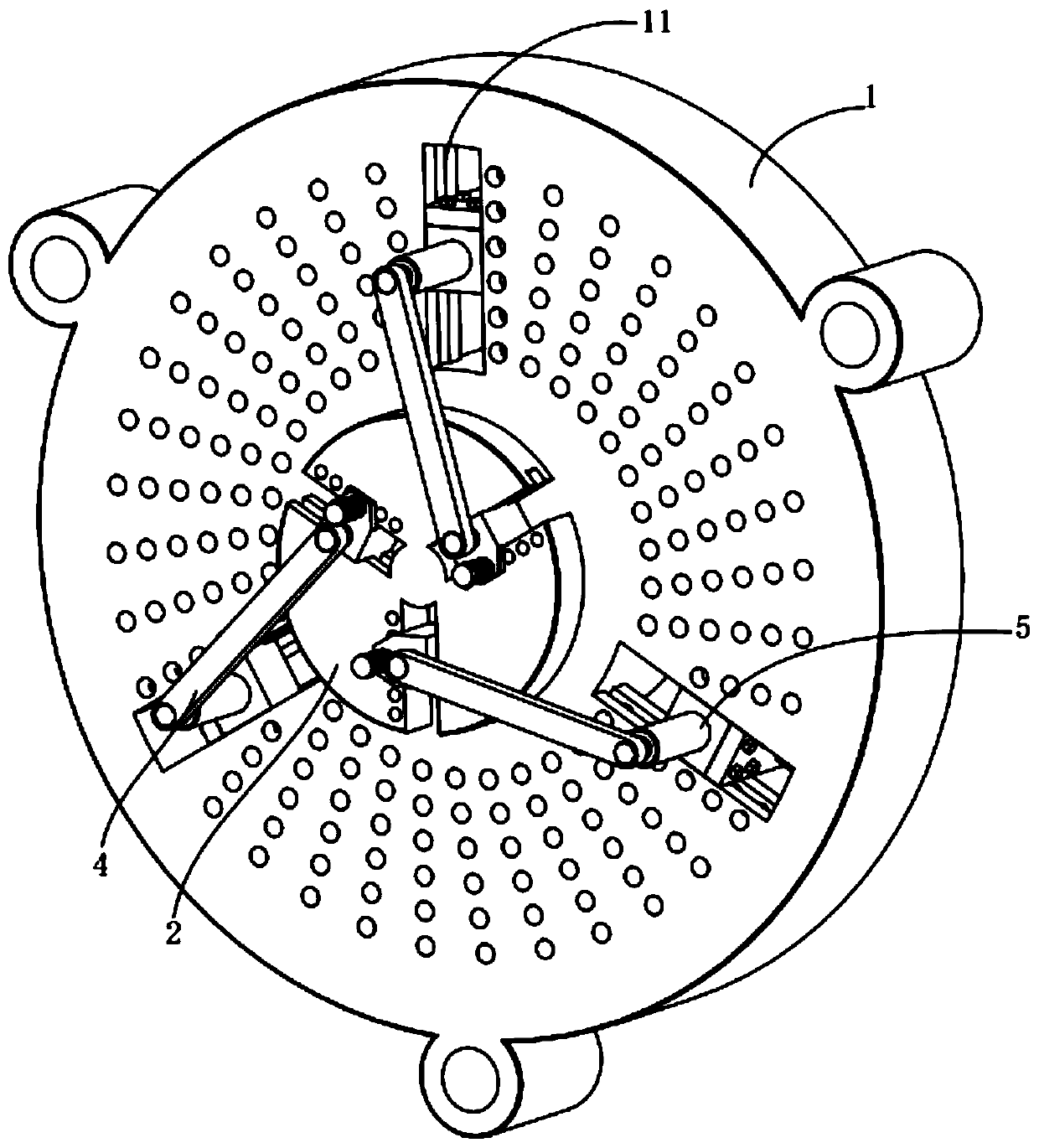

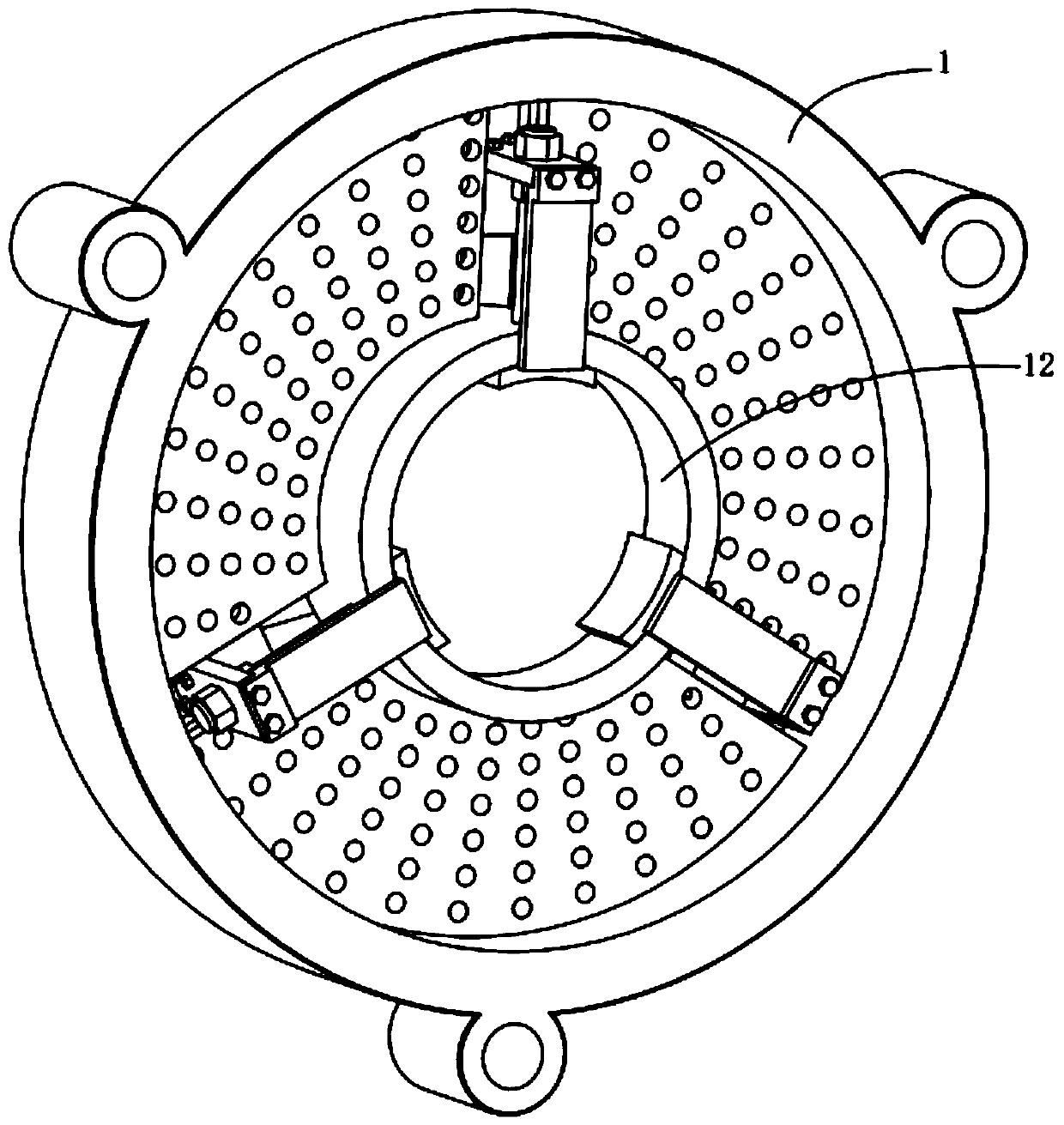

[0021] see Figure 1 to Figure 4 , the present invention provides a technical solution:

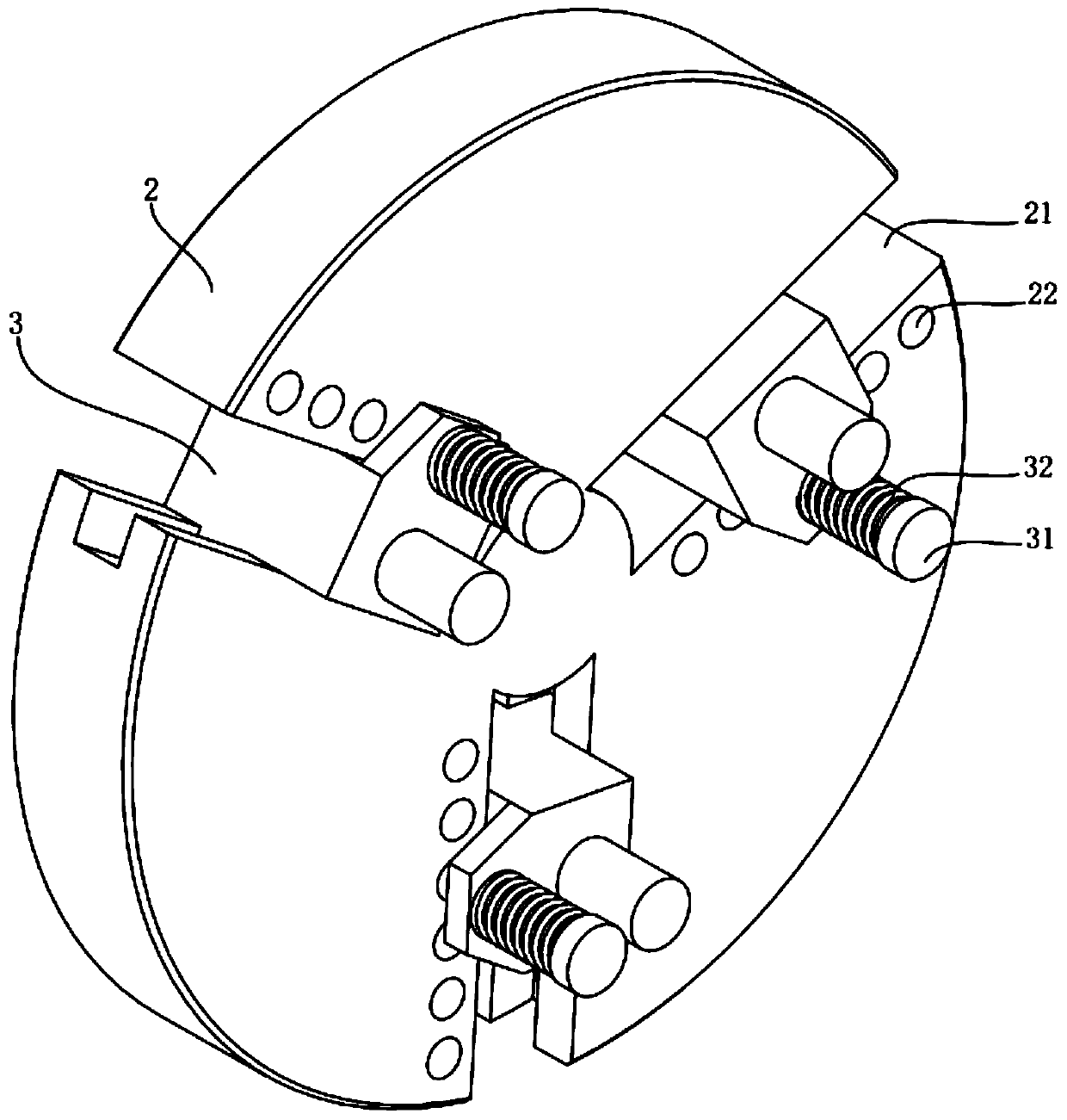

[0022] A motor end cover, including an end cover 1, a turntable 2, a luffing block 3, a connecting rod 4, a slider 5, a transmission plate 6, a radial limit plate 7 and an axial limit plate 8, wherein:

[0023] The end cover 1 is provided with three guide grooves 11 at equal angles and the inside is provided with a bearing installation ring 12, wherein the bearing installation ring 12 is used to install the bearing, and the turntable 2 is installed on the outside of the end cover 1 in rotation. There are three mounting slots 21, and a number of limiting holes 22 are arranged equidistantly beside the mounting slots 21. The three luffing blocks 3 respectively fit in the mounting slots 21 and form a moving pair in the mounting slots 21. The luffing block 3 A limit rod 31 is movable installed, wherein the end of the limit rod 31 extends into the limit hole 22, thereby realizing the limit of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com