Cutter drive device of eccentric multi-axial type tunnelling machine

A technology of cutterhead drive and drive device, which is applied in mining equipment, earthwork drilling, tunnels, etc., and can solve the problems of undiscovered literature reports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

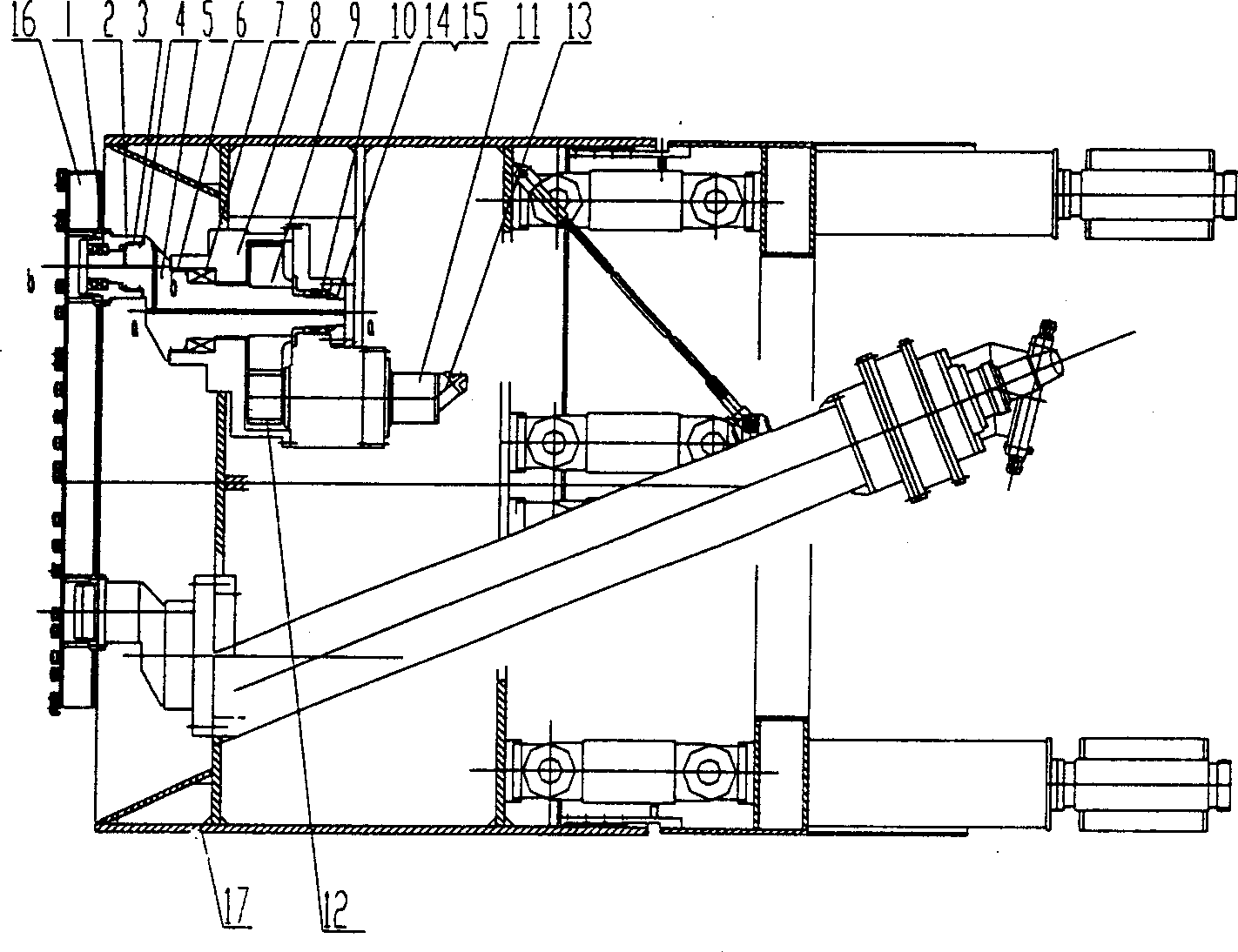

[0015] Such as figure 1 As shown, the present invention includes: a first bearing group 1, a bearing support 2, a first tooth seal 3, a labyrinth seal 4, an eccentric shaft 5, a second tooth seal 6, a second bearing group 7, a bearing seat 8, Gear 9, third bearing 10, reducer 11, pinion shaft 12, hydraulic motor 13, round nut 14 and stop washer 15. The soil-sand sealing method is as follows: between the bearing support 2 and the eccentric shaft 5, a double seal of a labyrinth seal 4 and a first toothed seal 3 is provided, and between the bearing seat 8 and the eccentric shaft 5, a labyrinth seal 4 and a second seal are provided. The double seal of the two-tooth seal 5 is connected in the following way: the hydraulic motor 13 of the driving device and the base of the reducer 11 are connected with one end of the bearing seat 8 with bolts, and the output pinion shaft 12 of the reducer 11 is externally meshed with the gear 9. The gear 9 is set in the eccentric shaft 5 and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com