Extrusion head for automobile sealing strip

A technology for automotive sealing strips and extrusion heads, which can be applied to household appliances, other household appliances, household components, etc. It can solve the problems of reduced production efficiency, waste of rubber, insufficient cooling, etc., and improve production quality and production efficiency. , reduce production costs and make full use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

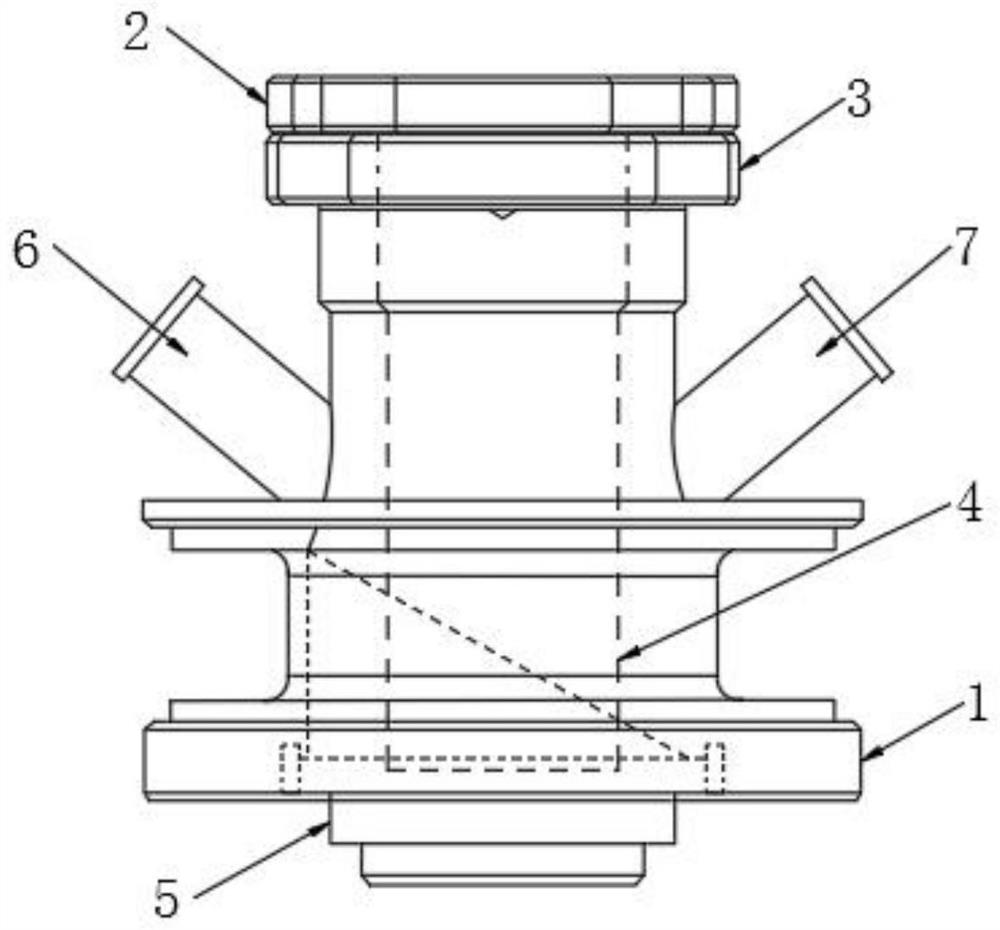

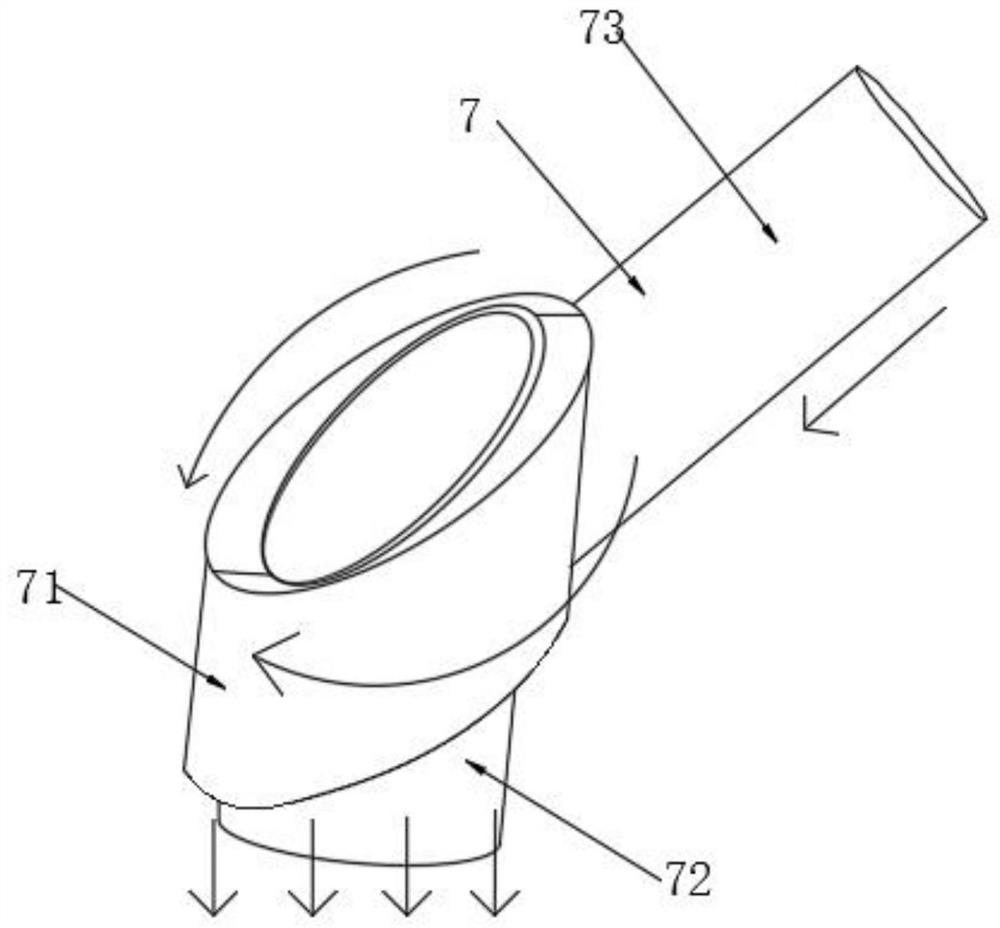

[0033] see Figure 1-7 , the present invention provides the following technical solutions: an automobile sealing strip extrusion head, including a head body 1, a B mandrel 3 is arranged on the machine head body 1, and a D mandrel 4 is fixedly connected to the inner side of the B mandrel 3, The inner side of D mandrel 4 is provided with A mandrel 2, A mandrel 2 is fixedly connected with D mandrel 4, C mandrel 5 is fixed inside the bottom end of machine head body 1, and the top of machine head body 1 is close to B mandrel The left side of 3 is provided with a sponge rubber flow channel 6, and the top of the machine head body 1 is provided with a dense rubber flow channel 7 on the right side close to the B mandrel 3. 1 fixed connection;

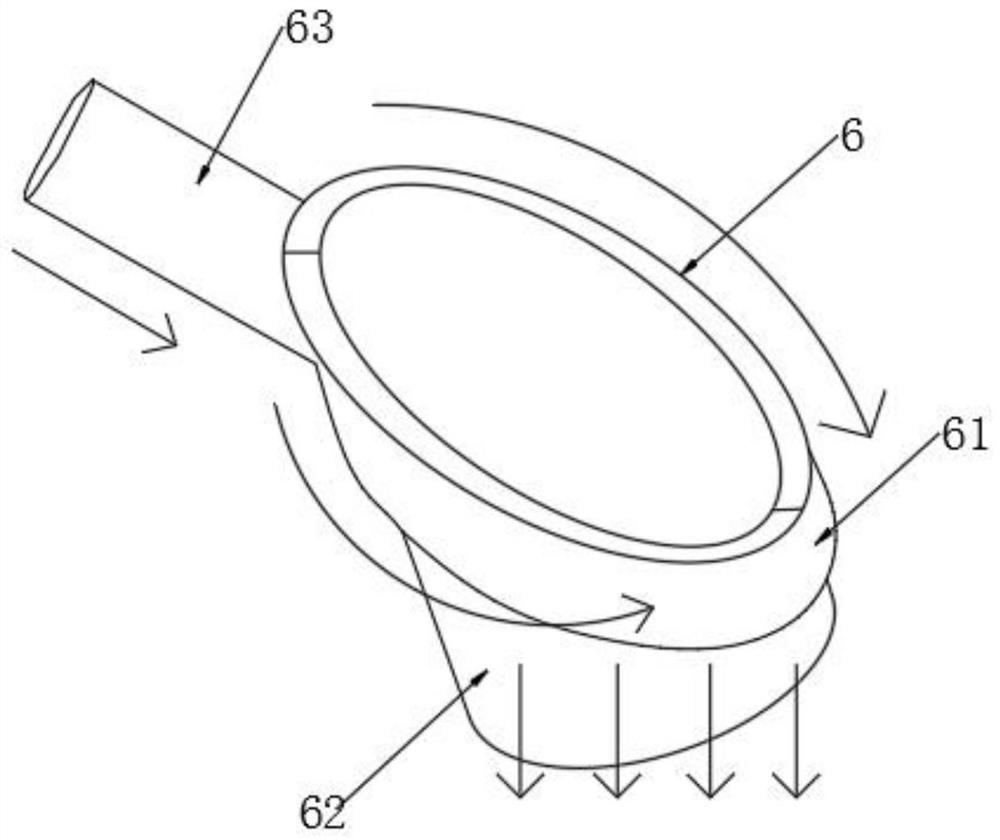

[0034] The sponge rubber flow channel 6 is composed of a sponge rubber extrusion A section 61, a sponge rubber extrusion B section 62 and a sponge rubber input section 63. The sponge rubber input section 63 is located at the top left outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com