Novel automobile sealing strip extrusion machine head

A technology of automobile sealing strip and extruder head, applied in the field of automobile, can solve the problems of reducing production efficiency, existence of dead angle, waste of rubber material, etc., and achieve the effect of improving production quality and production efficiency, avoiding dead angle and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

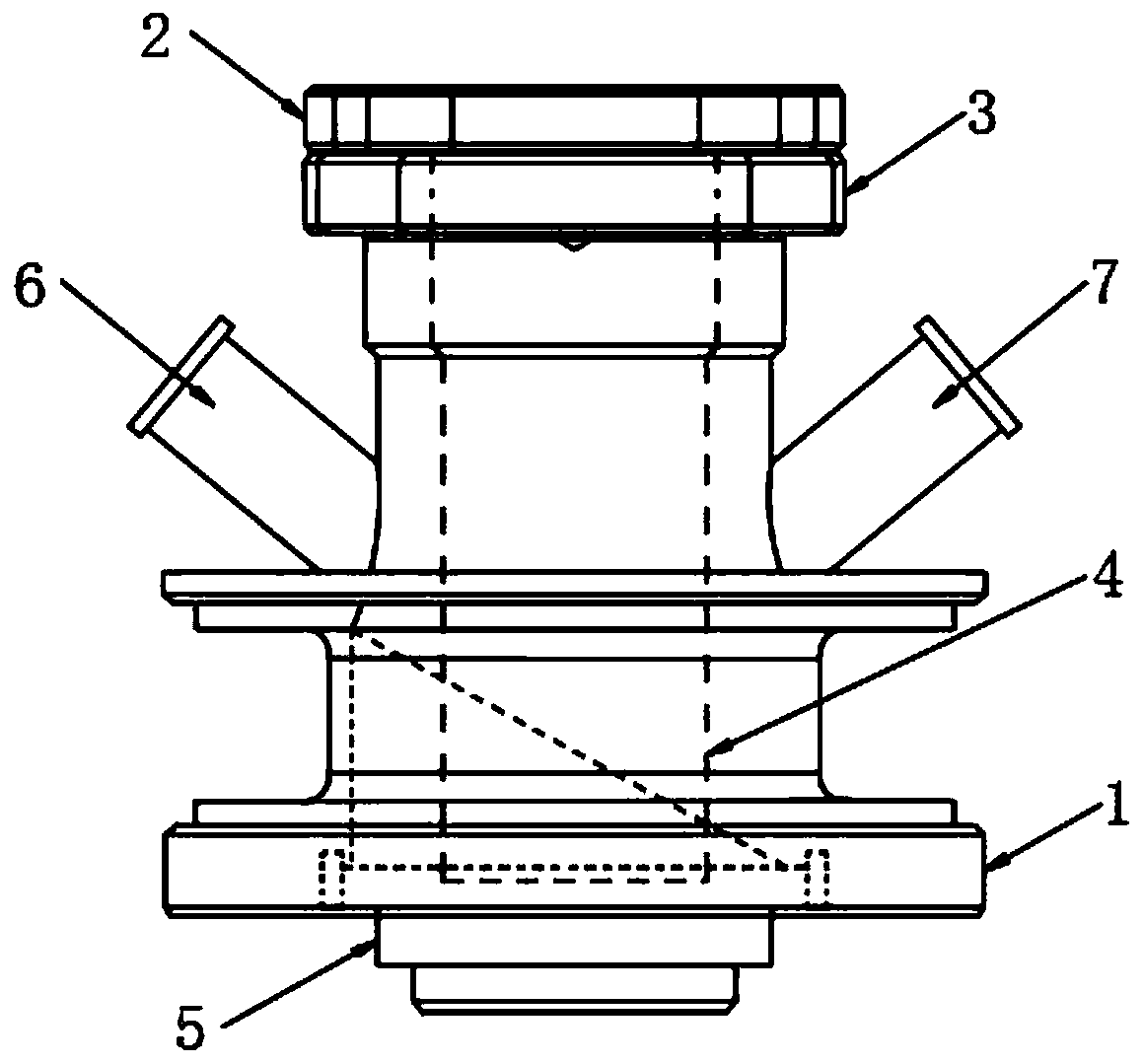

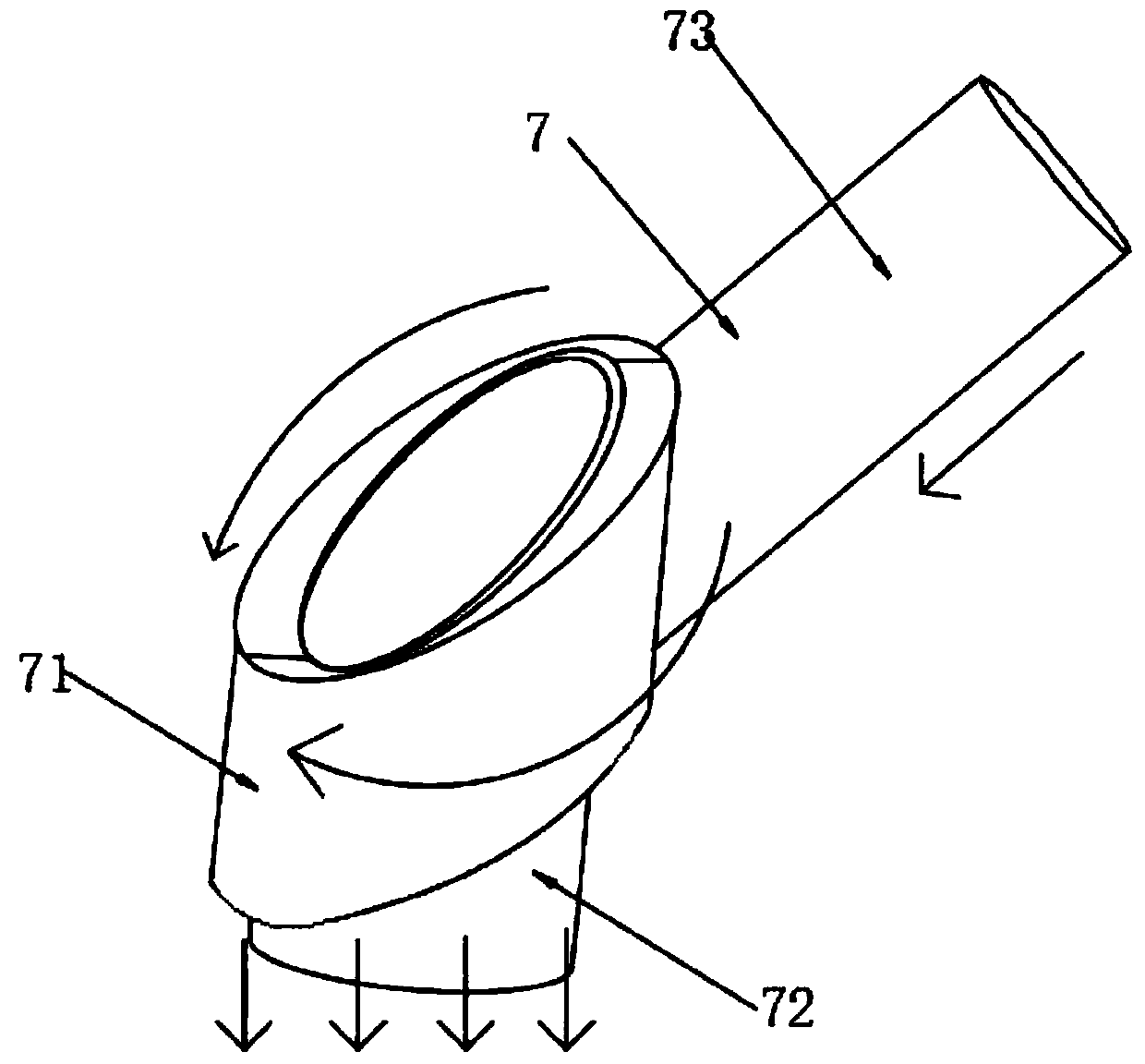

[0033] see Figure 1-7 , the present invention provides the following technical solutions: a novel automobile sealing strip extrusion head, including a head body 1, a B mandrel 3 is arranged on the machine head body 1, and a D mandrel 4 is fixedly connected to the inner side of the B mandrel 3 , the inner side of the D mandrel 4 is provided with the A mandrel 2, the A mandrel 2 is fixedly connected with the D mandrel 4, the C mandrel 5 is fixed inside the bottom end of the machine head body 1, and the top of the machine head body 1 is close to the B core The left side of the rod 3 is provided with a sponge rubber flow channel 6, and the top of the machine head body 1 is provided with a dense rubber flow channel 7 on the right side close to the B mandrel 3. Body 1 is fixedly connected;

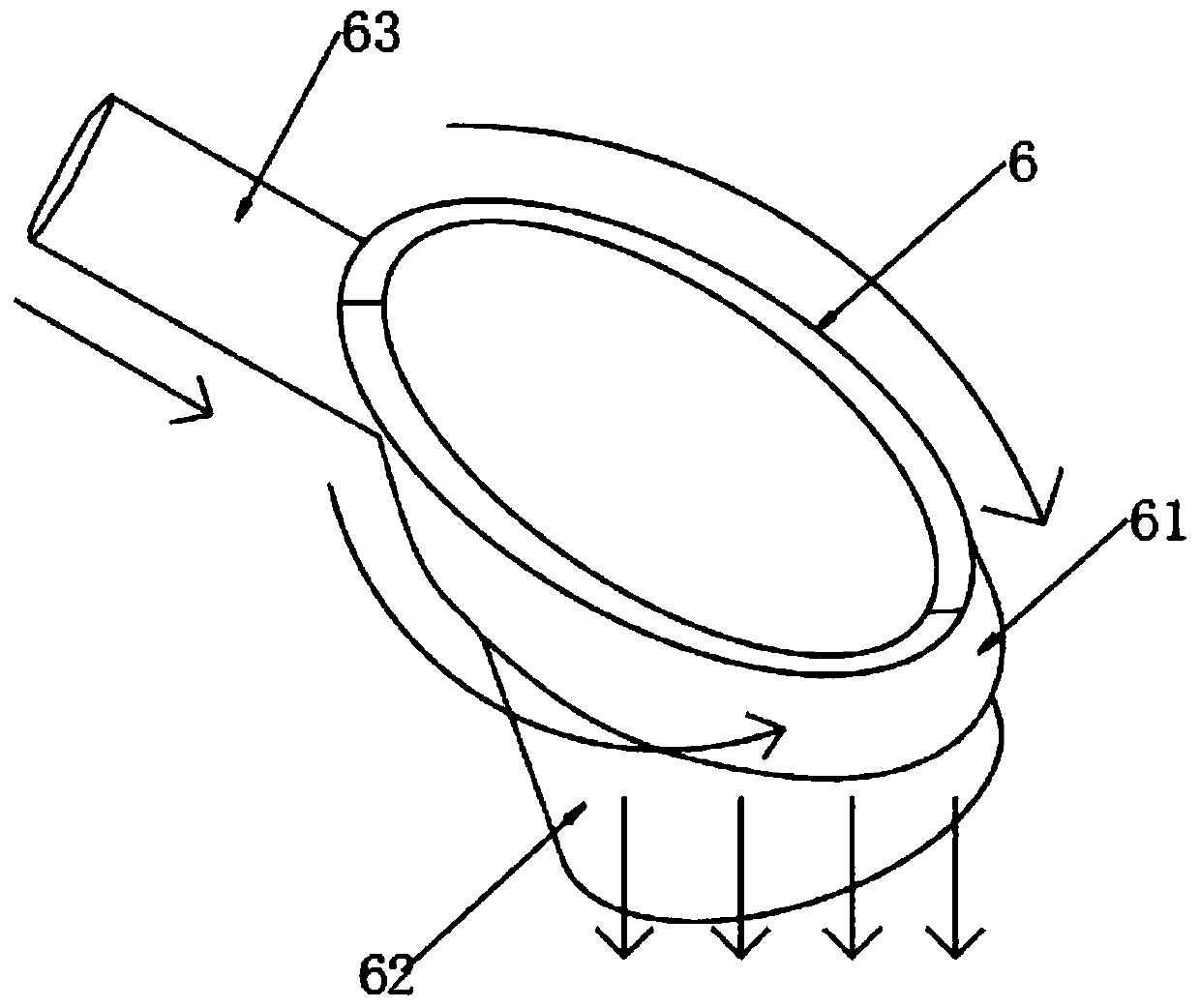

[0034] The sponge rubber flow channel 6 is composed of a sponge rubber extrusion A section 61, a sponge rubber extrusion B section 62 and a sponge rubber input section 63. The sponge rubber in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com