Method for calculating torque capacity of light hybrid power system

A technology of power system and calculation method, applied in hybrid vehicles, motor vehicles, transportation and packaging, etc., can solve the problem of lack of accurate and reliable sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

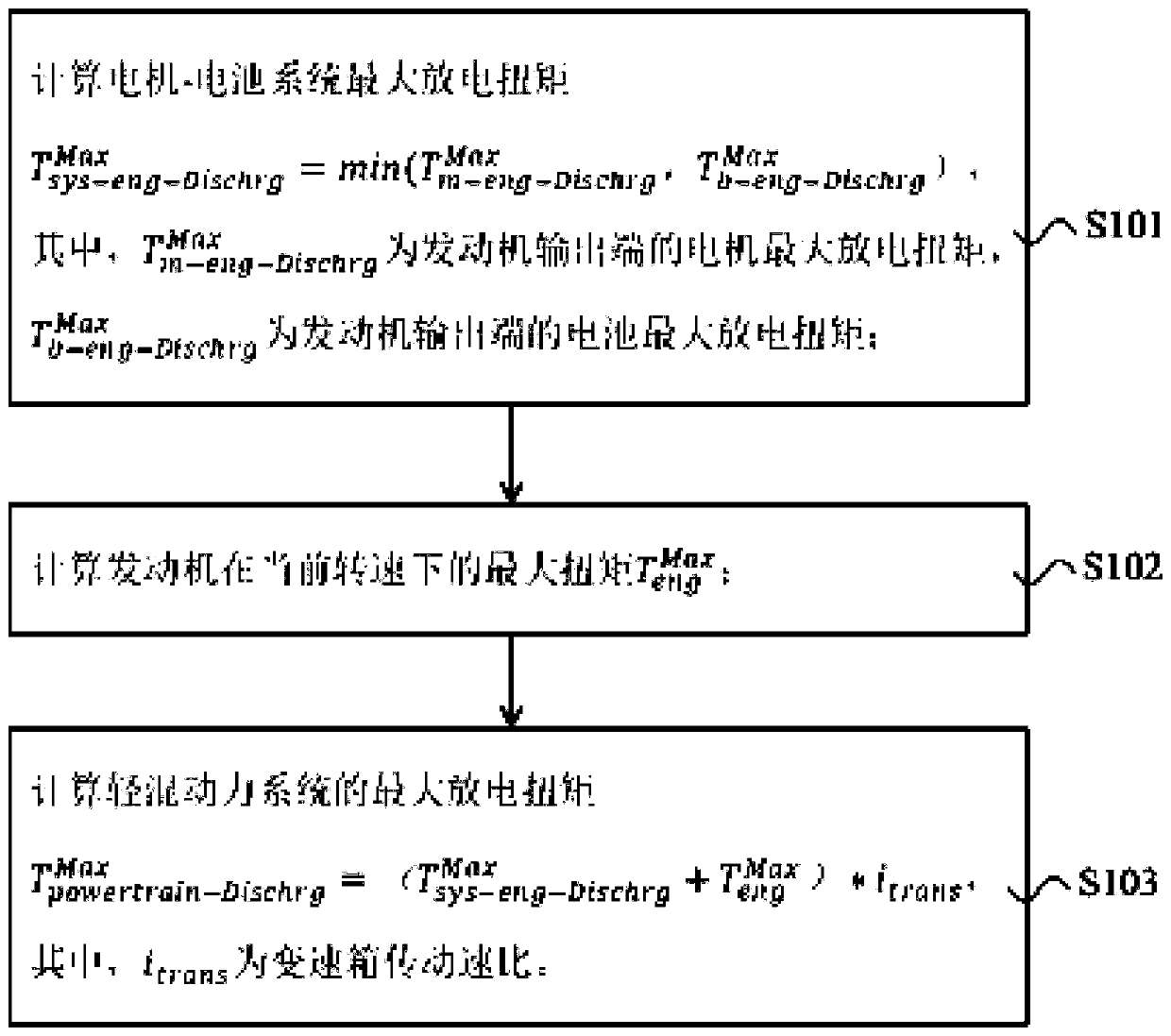

[0050] This embodiment provides a method for calculating the torque capability of a mild hybrid system. The mild hybrid system includes a connected motor-battery system, an engine, and a gearbox. The motor-battery system includes a motor and a battery. like figure 1 As shown, the method for calculating the maximum discharge torque capacity of the light hybrid system includes the following steps:

[0051] S101. Calculate the maximum discharge torque of the motor-battery system in, is the maximum discharge torque of the motor at the output end of the engine, is the maximum discharge torque of the battery at the output end of the engine;

[0052] S102. Calculate the maximum torque of the engine at the current speed

[0053] S103. Calculating the maximum discharge torque of the mild hybrid power system Among them, i trans is the transmission speed ratio of the gearbox.

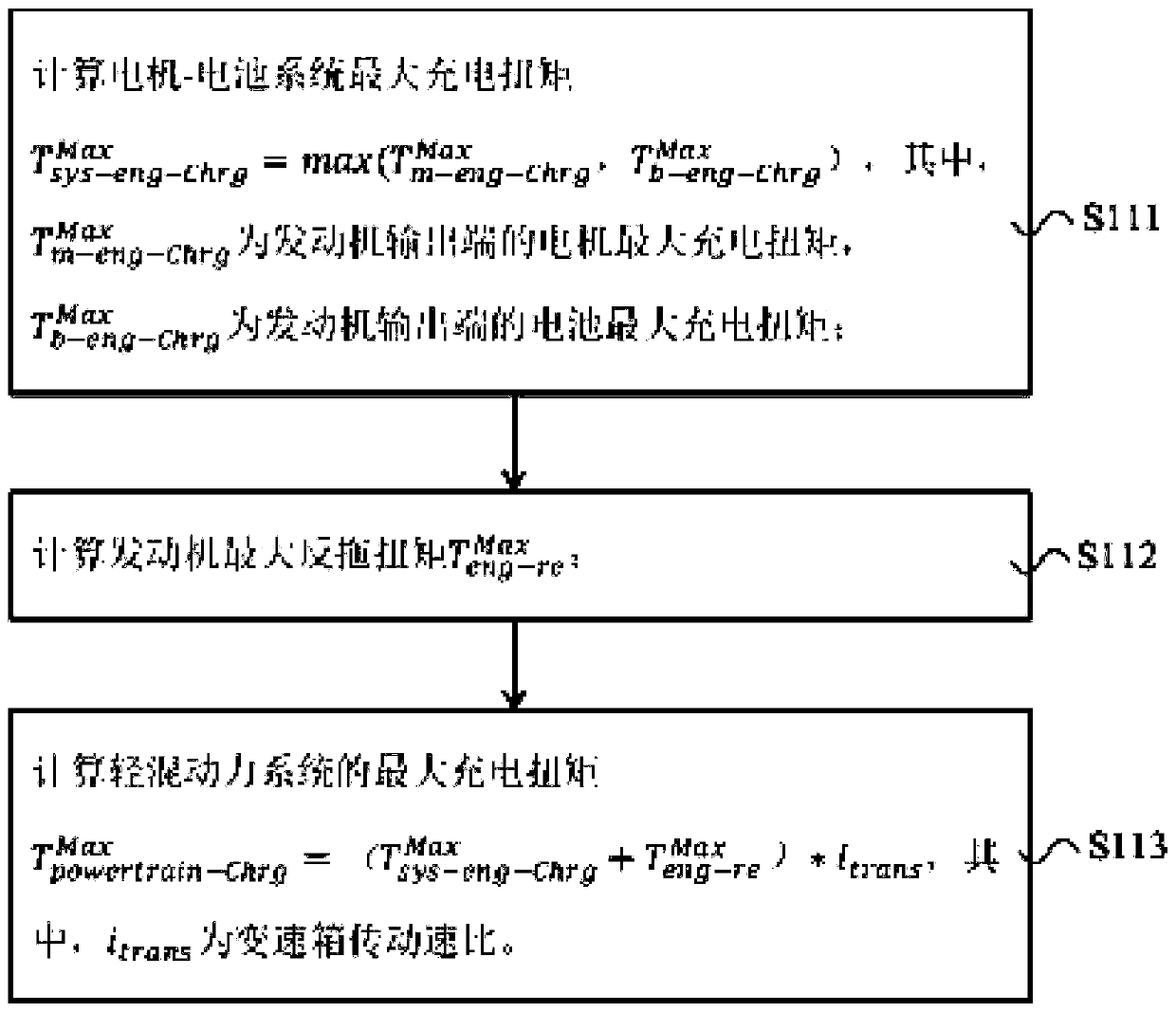

[0054] like figure 2 As shown, the method for calculating the maximum discharge torque capacity ...

Embodiment 2

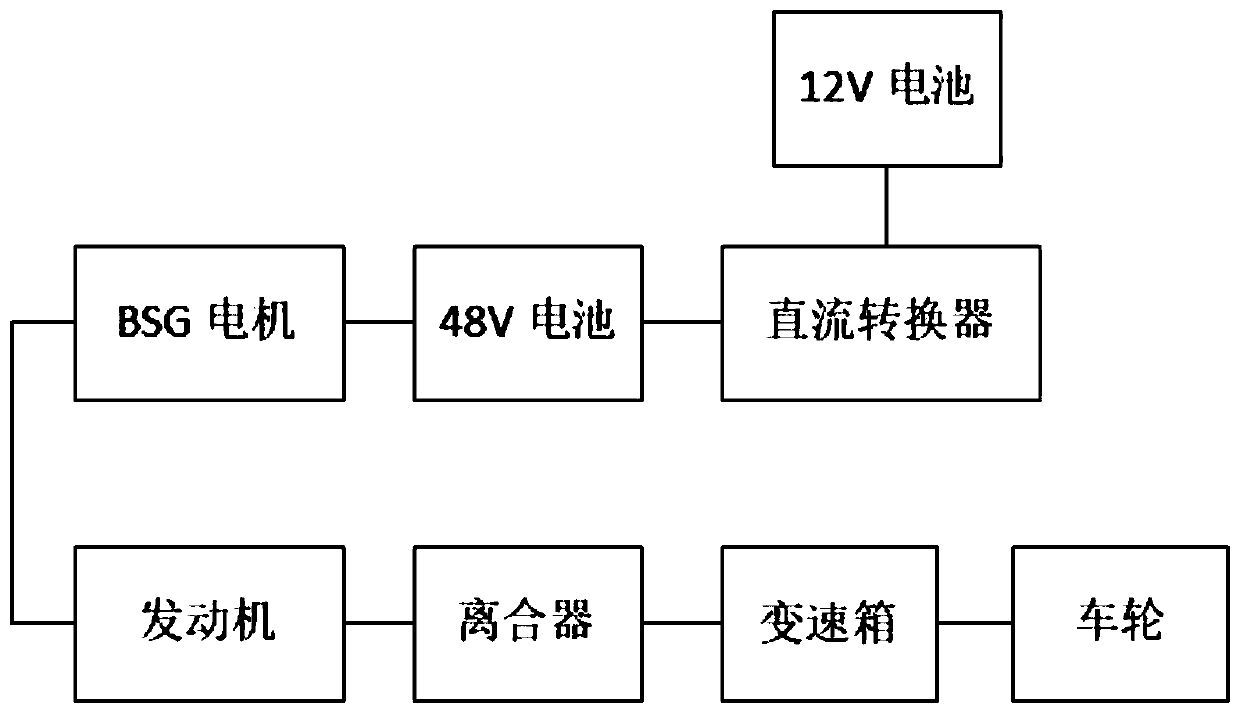

[0084] like image 3 As shown, this embodiment provides a method for calculating the torque capacity of a mild hybrid power system. The light hybrid power system includes a connected motor-battery system, engine, gearbox, DC converter, clutch, HCU and MCU, and the motor-battery The system includes a belt-driven starter generator (Belt-driven Starter Generator, BSG motor for short), a 48V battery and a 12V battery. The output end of the gearbox is connected to the wheels, and the maximum discharge torque of the mild hybrid system and the maximum charge torque of the mild hybrid system both refer to the maximum torque output to the wheels by the mild hybrid system.

[0085] The mild hybrid system is a 48V mild hybrid system, such as Figure 4 As shown, the calculation method of the maximum discharge torque capacity of the mild hybrid system includes the following steps:

[0086] S201. According to the motor torque characteristics, temperature characteristics, and MCU network s...

Embodiment 3

[0100] This embodiment provides a method for calculating the torque capacity of a mild hybrid system. The mild hybrid system includes a connected motor-battery system, engine, gearbox, DC converter, clutch, HCU and MCU. The motor-battery system includes a motor and battery. Among them, the motor is a belt-driven starter generator (Belt-driven Starter Generator, BSG motor for short), the battery is a 48V power battery pack, and the DC converter is a DCDC converter.

[0101] The light hybrid power system is a 48V light hybrid power system, and the calculation method for the maximum discharge torque capacity of the light hybrid power system includes the following steps:

[0102] S301. According to the motor speed-torque external characteristic curve, use the look-up table method to obtain the maximum discharge torque T of the motor at the current speed mDischrg ;

[0103] S302. According to the motor temperature-torque limit characteristic curve, use the look-up table method to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com