Dimension-variable ring-shaped working flume structure for ultrasonic scanning of large-scale rings

An ultrasonic and ring technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve problems such as limited adaptability, reduce container space, and improve water injection efficiency. , The effect of saving water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

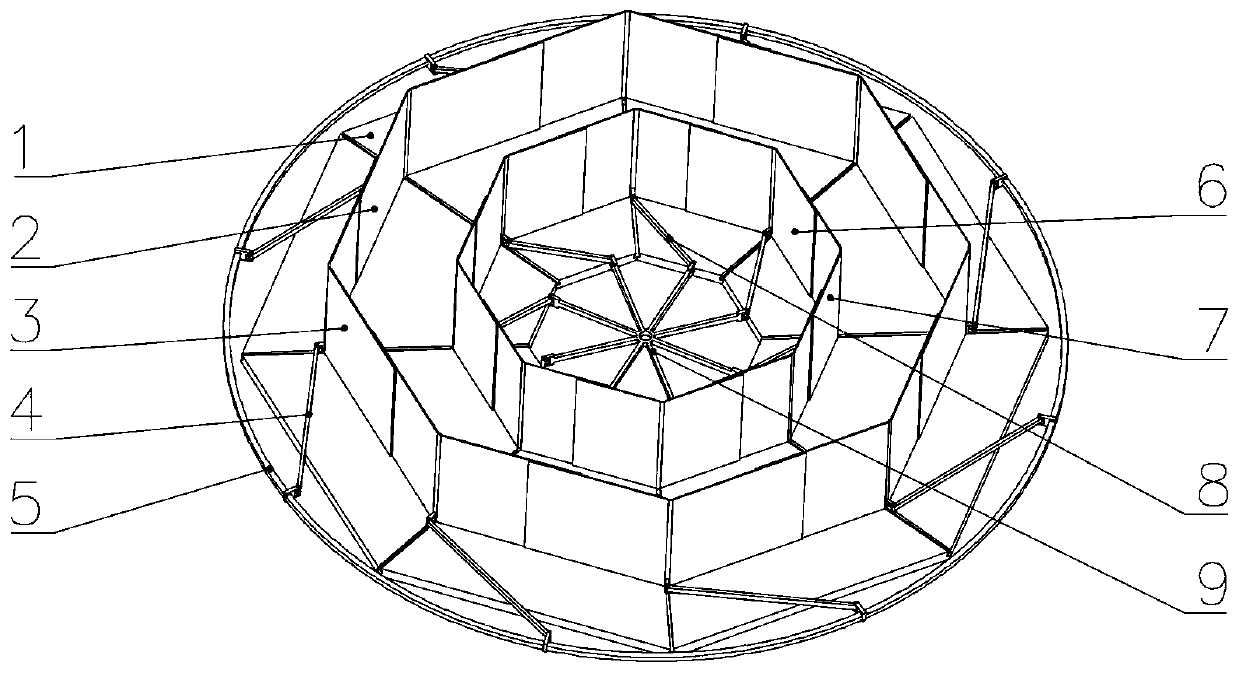

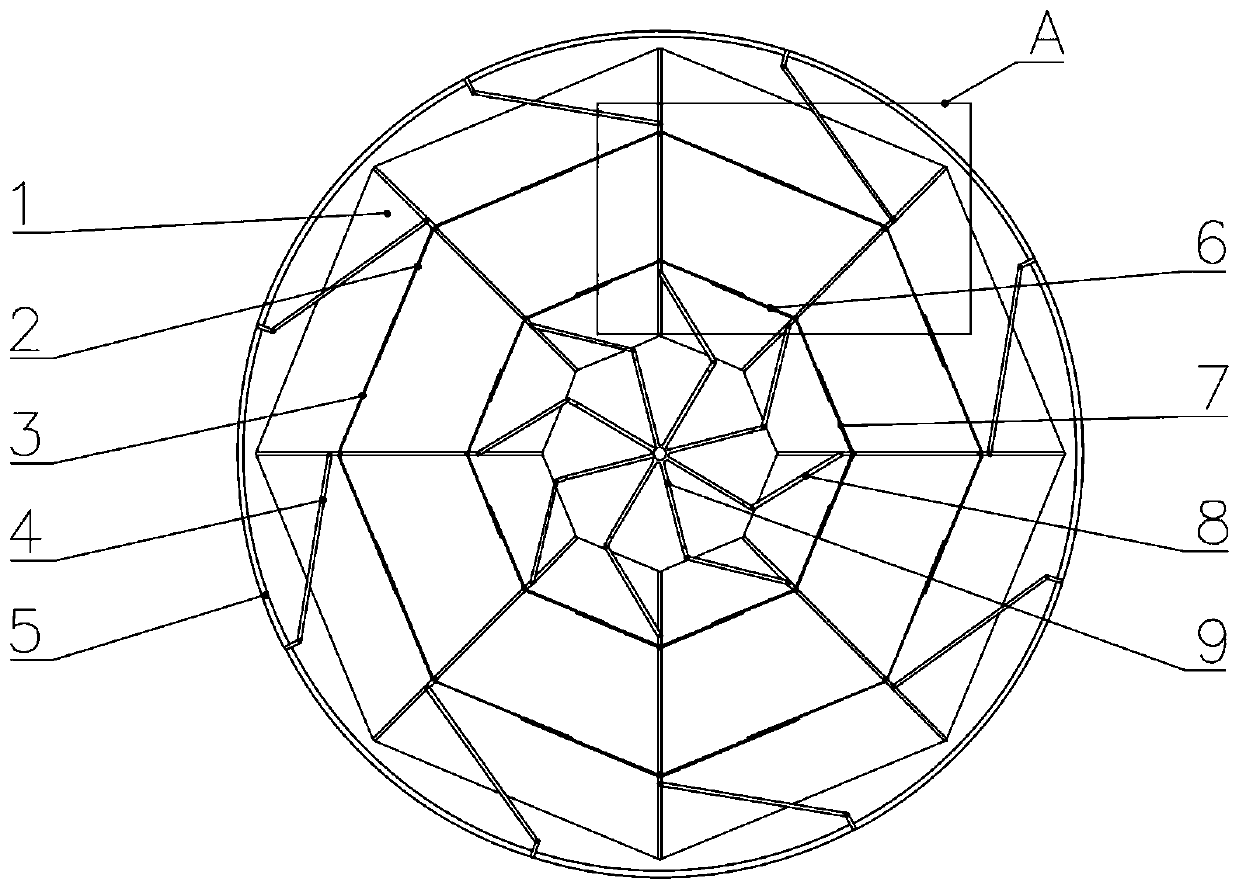

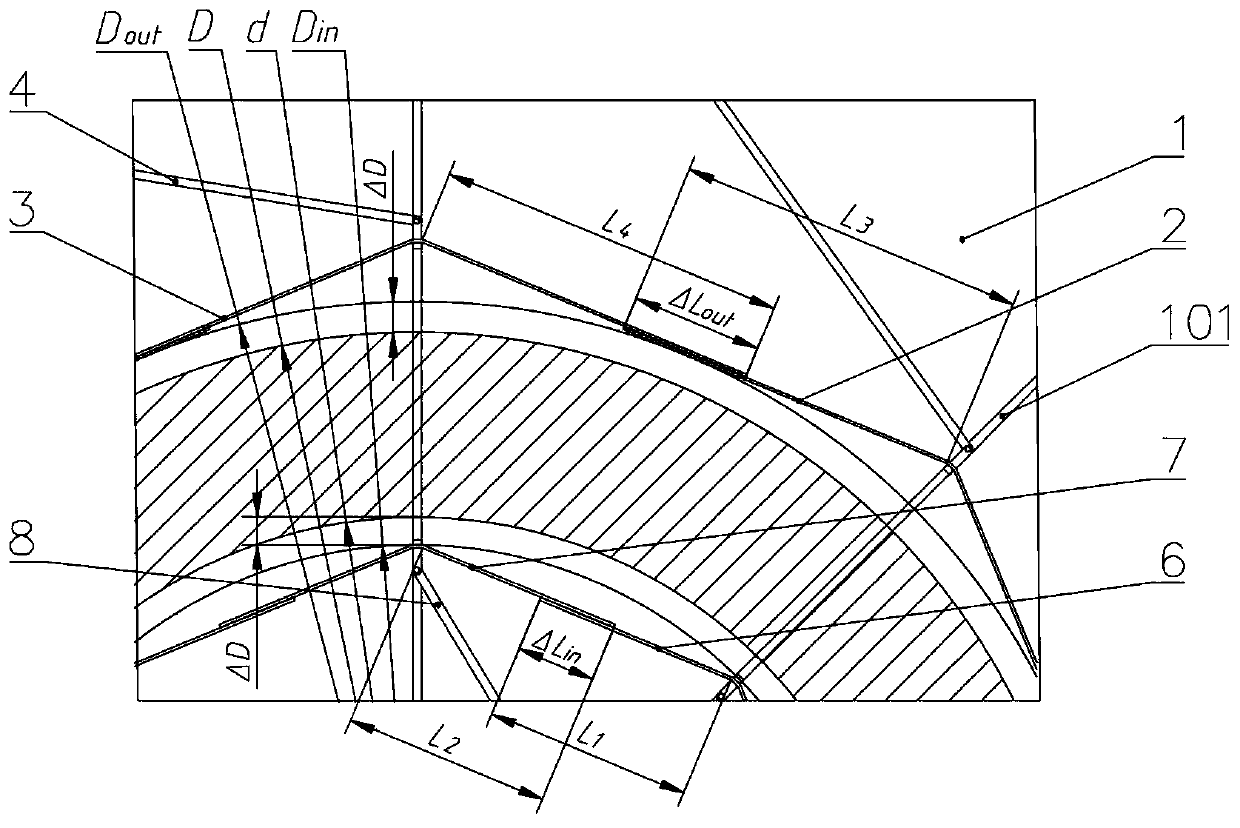

[0032] refer to figure 1 , figure 2 , a size-variable ring-shaped working water tank structure for ultrasonic scanning of large-scale ring parts, including a bottom plate 1, an inner wall plate and its synchronous structure, an outer wall plate and its synchronous structure, and the inner wall plate and the outer wall plate are vertically installed on the bottom plate On 1, two polygonal tubes, inner and outer, are formed. The geometric centers of the two polygons coincide. The number of sides of the polygonal tube is N, and N is an even number and not less than 4. In the present embodiment, N=8; the outer side of the polygonal tube surrounded by the inner wall plate, the inner side of the polygonal tube surrounded by the outer wall plate and the upper side of the bottom plate form an annular container space with an upper opening, and the large ring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com