Clamping mechanism and electroplating device

A clamping mechanism and clamping frame technology, applied in the electrolysis process, electrolysis components, etc., can solve problems such as difficulty in meeting, and achieve the effect of ensuring accuracy and facilitating processing and preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

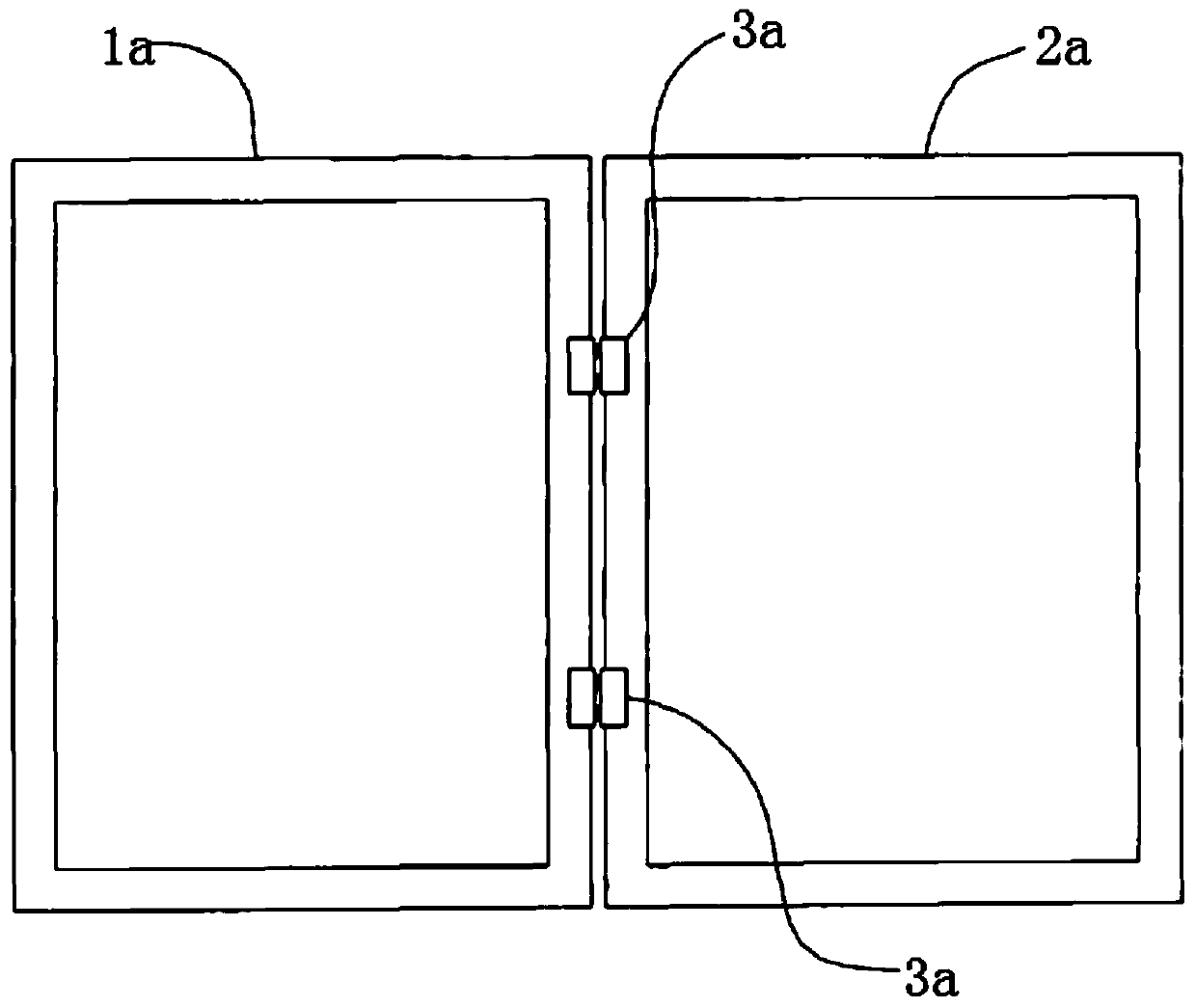

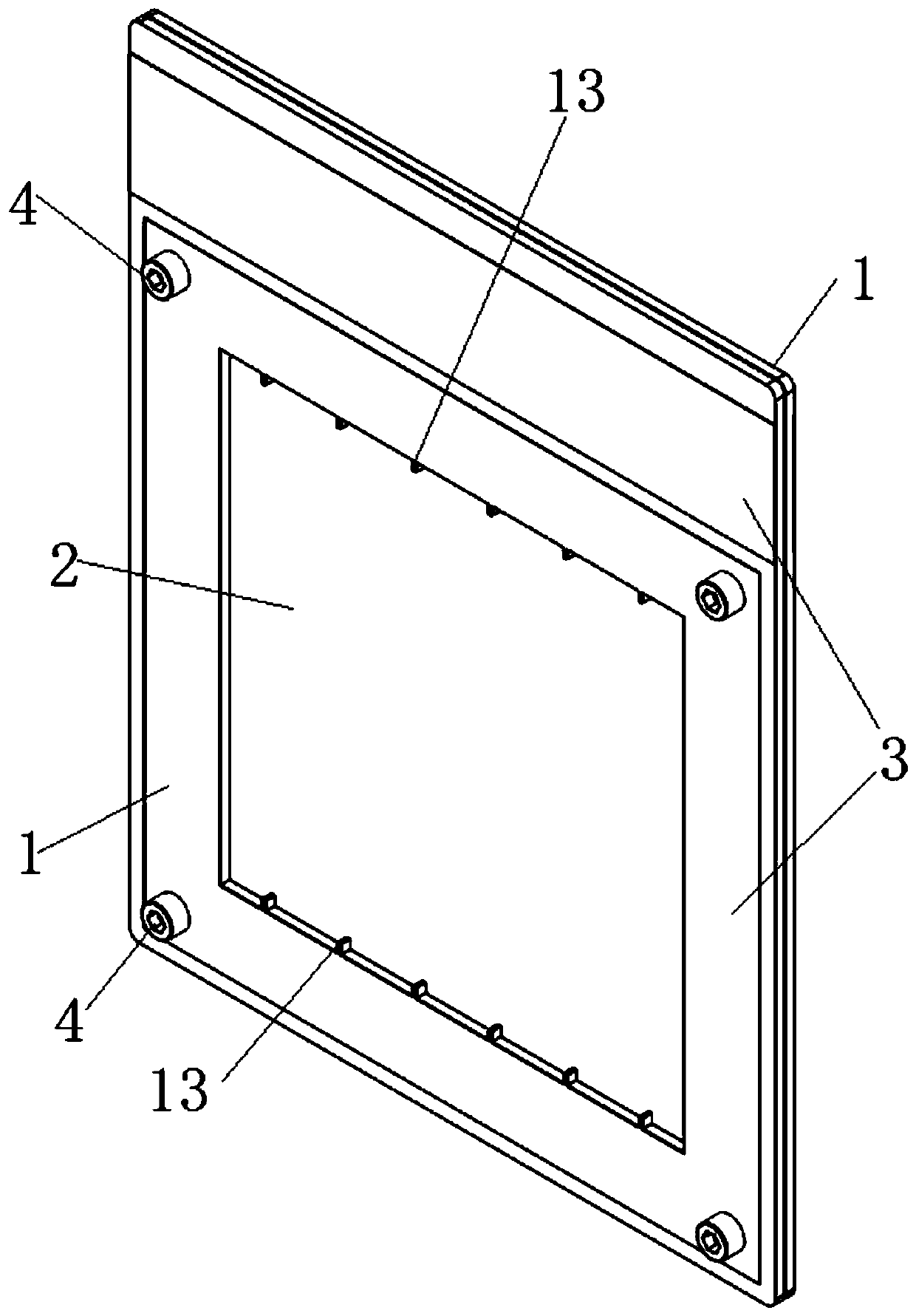

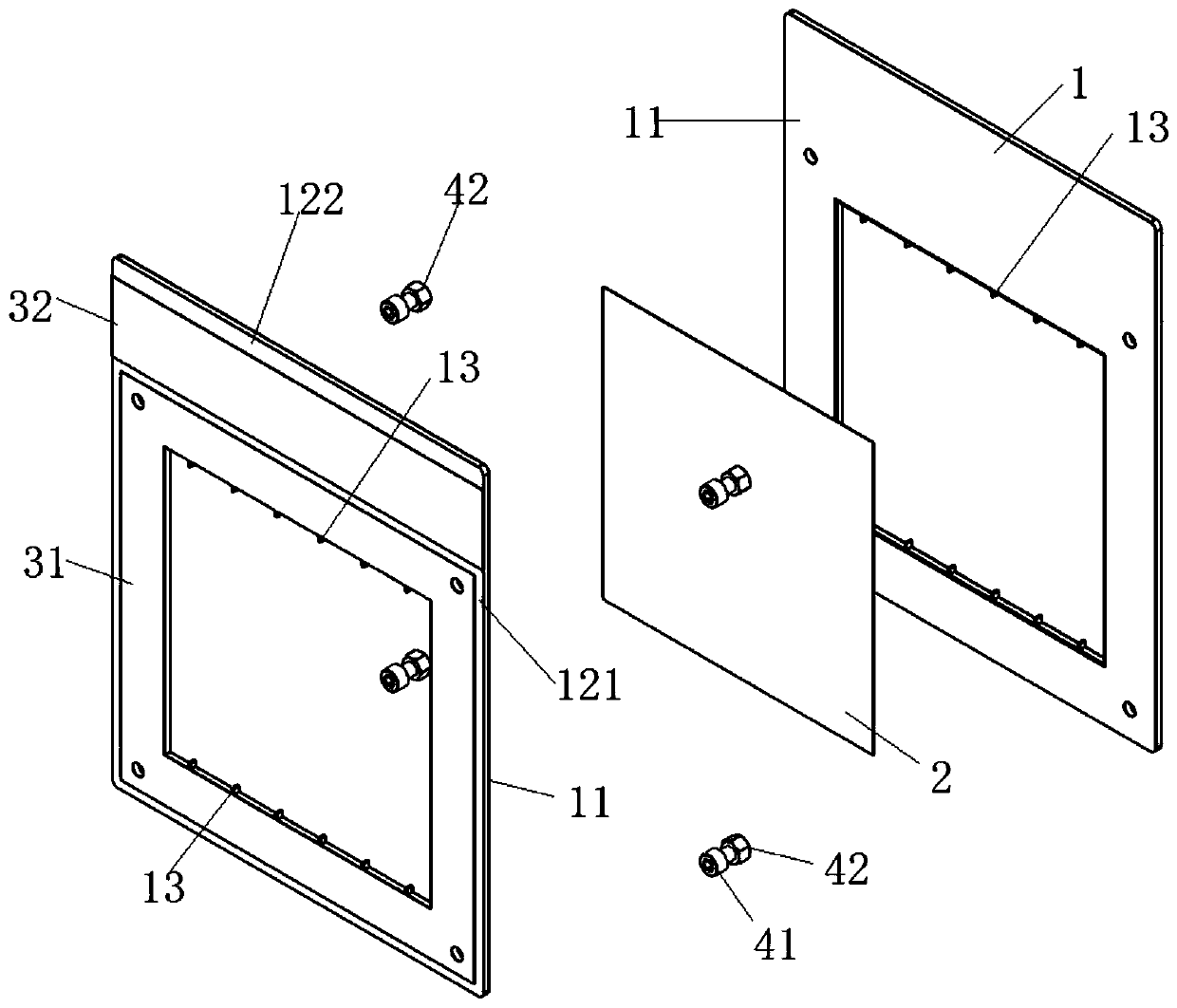

[0057] This embodiment provides a clamping mechanism, such as Figure 2 to Figure 6 As shown, two clip frames 1 that are relatively movable and detachably fixed are included. For the convenience of expression, the two clip frames 1 are respectively expressed as the first clip frame (such as figure 2 The left clip frame in ) and the second clip frame (such as figure 2 in the right clip box).

[0058] The two clip frames 1 can be switched between the limit state and the open state, wherein, in the limit state, the first clip frame and the second clip frame are stacked and fixedly connected, and the hollow inner cavity of the two clip frames 1 overlap; as Figure 4 , Figure 5 and Figure 6 As shown, the first clamping frame and the second clamping frame are adjacent to the inner wall of the inner cavity of the hollow cavity to form a notch at the abutting position to communicate with the limiting groove 14 of the hollow inner cavity, and the limiting groove 14 is suitable...

Embodiment 2

[0091] This embodiment provides an electroplating device, including any one of the clamping mechanisms provided in Embodiment 1, a plurality of electroplating tanks, and a plurality of electroplating fixtures. Wherein, a plurality of electroplating tanks are arranged in sequence, and the tank walls of two adjacent electroplating tanks are connected, and the electroplating tanks are used to place electroplating chemicals.

[0092] A plurality of electroplating fixtures are fixed on the delivery mechanism, and a plurality of electroplating fixtures will be clamped on one end of the clamping mechanism provided in Embodiment 1 (such as, preferably, clamped on the second conductive part of clamp frame 1 in Embodiment 1). area 122), so that the clamping mechanism extends vertically in the air; the peripheral edges of the plate 2 are embedded in the limiting groove 14 of the clamping mechanism, and the rest of the plate 2 is exposed in the hollow cavity of the clamping frame 1. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com